Documente Academic

Documente Profesional

Documente Cultură

Crane Terminology

Încărcat de

Prem KumarDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Crane Terminology

Încărcat de

Prem KumarDrepturi de autor:

Formate disponibile

Crane Terminology

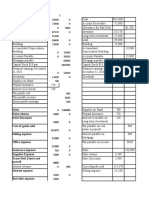

ADJUSTABLE FREQUENCY DRIVE A motor control- Trolley Frame

ler designed to convert fixed frequency AC power Hoist motor

to available frequency power for AC motor speed

control. The system is used in conjunction with a

squirrel cage motor to control speed over a

relatively wide, constant torque range, by

maintaining a constant voltage / frequency ratio.

This type of control leashes the in-rush current to

deliver startup power to the motor as efficiently

as possible providing a soft-start feature thereby

minimizing load swing.

Hoist Gearbox

ANTI-COLLISION An Electrical means of keeping

trolley wheels Trolley Drive

two (2) or more cranes from contacting each other.

drum

ANTI-SKEWING Capability of the crane design to

maintain squareness in relation to the runway structure.

Lower

AUXILIARY HOIST A supplemental hoisting unit, usually block

designed to handle lighter loads at a higher speed than

the main host.

CLEARANCE Minimum distance from the extremity of a

BOGIE A type of short end truck, used to allow greater crane to the nearest obstruction.

distribution of crane wheel loads, by placing multiple

wheels at each corner of the crane. C.M.A.A. Crane Manufacturers Association of America,

Inc. (formerly EOCIElectric Overhead Crane Institute).

BOX SECTION The rectangular cross section of girders,

trucks or other members, comprised of two (2) rolled steel COLLECTORS Contacting devices for collecting current

side plates, a top plate, and a bottom plate. from the runway or bridge conductors. The main line collec-

tors are mounted on the bridge to transmit current from the

BRIDGE That part of an overhead crane consisting of runway conductors, and the trolley collectors are mounted

girders, trucks, end ties, walkway and drive mechanism on the trolley to transmit current from the bridge conductors.

which carries the trolley and travels in a direction parallel

to the runway. COVER PLATE The top or bottom plate of a box girder.

BRIDGE GIRDER The main horizontal structural member(s) CRITICAL LOAD Any lifted load whose uncontrolled

of the crane bridge supported by the end trucks. movement or release could adversely affect any

safety-related system when such a system is required for

CAMBER The slight upward vertical curve given to girders unit safety. A crane used for lifting a critical load shall be

to compensate partially for deflection due to hook load designed with single failure proof features so that any

and weight of the Crane. credible failure of a single component will not result in the

loss of capability to stop or hold the load.

CAPACITY The maximum rated load for which a crane is

designed to handle. Measured in tons. DOUBLE GIRDER CRANE A crane which runs on two (2)

bridge girders mounted between and supported by end

CASK HANDLING CRANE A crane specifically designed to trucks at each runway.

handle a cask loaded with spent nuclear fuel. A crane of this

type is typically provided with single failure proof features. DRIVE GIRDER The girder on which the bridge drive

machinery is mounted.

531 Old Swede Road, Douglassville, PA 19518 877.877.6778 610.385.6061

AmericanCrane.com

110

END APPROACH The minimum horizontal distance, OVERHEAD CRANE A crane with a moveable bridge

parallel to the runway, between the outermost extremities carrying a moveable or fixed hoisting mechanism and

of the crane and the centerline of the hook. traveling on an overhead fixed runway structure.

END TIE A structural member other than the end truck RATED LOAD The maximum load which the crane is

which connects the ends of the girders to maintain the designed to handle safely

squareness of the bridge.

REEVING Terminology used to describe the path of the

END TRUCK The unit consisting of truck frame, wheels, hoist wire rope as it pays off the hoist drum and wraps

bearings, axles, etc., which supports the bridge girders. around the various upper and lower sheaves.

EXPLOSION PROOF CRANE A crane designed using REGENERATIVE BRAKING A method of controlling speed

specially constructed electrical components to prevent in which electrical energy generated by the motor is

the ignition of hazardous materials in the surrounding feedback into the power system.

atmosphere, by containing any explosions that may

occur within the components. RUNWAY The rails, beams, brackets and framework on

which the crane operates.

FESTOONING A method for providing power to a hoist

traveling along a beam. SHEAVE A grooved wheel or pulley used with a rope or

chain to change direction and point of application of a

FLUX VECTOR DRIVE A special type of adjustable frequency pulling force.

motor control, utilizing an incremental encoder to

constantly monitor the speed and direction of the motor SINGLE GIRDER CRANE A crane which runs on a single

shaft. This closed-loop system allows the control to know bridge girder.

what the motor is doing at all times. Flux vector control

provides a wide range of speed and reliability in hoisting SINGLE FAILURE PROOF Those features that are included in

applications where no mechanical load brake is utilized. the crane design such that any credible failure of a single

component will not result in the loss of capability to stop

GAGE- Horizontal distance between the centerlines of the and hold the critical load within facility acceptable

rails that support the trolley on a double girder bridge. excursion limits.

GANTRY CRANE A crane similar to an overhead crane SPAN The horizontal distance center-to-center of runway

except that the bridge for carrying the trolley or trolleys is rails.

rigidly supported on two or more legs running on fixed rails

or other runway. TOP RUNNING CRANE An overhead traveling crane

having the end trucks supported on rails attached to the

GEAR REDUCER Device to convert high speed motor shaft top of the runway support beams.

rotation to usable output shaft speed for hoist, trolley or

bridge motion. TROLLEY The unit carrying the hoisting mechanism which

travels on the bridge rails.

GRAPPLE A job specific load handling device, designed

to pick up bulk material, containers, barrels or drums. TROLLEY FRAME The basic structure of the trolley on which

Actuation can be mechanical, electrical or hydraulic. are mounted the hoisting and traversing mechanisms.

HOIST A mechanism used for lifting and lowering a load. TWO BLOCKING Condition under which the load block or

load suspended from the hook becomes jammed against

HOLDING BRAKE A brake that automatically prevents the crane structure preventing further winding up of the

motion when power is off. hoist drum.

HOOK APPROACH The minimum horizontal distance UNDER RUNNING CRANE A crane that has a movable

between the center of the runway rail and the hook. bridge running on the lower flanges of a fixed overhead

runway structure which has a movable or fixed hoisting

JIB CRANE A crane design whereby the bridge girder system.

(commonly called the boom) is fixed at one end, allowing

the opposite end to cantilever. The fixed end generally is WEB PLATE The vertical plate connecting the upper and

hinged to allow rotation. lower flanges or cover plates of a girder.

LIFT Maximum safe vertical distance through which the WHEEL LOAD The load without vertical inertia force on any

hook, magnet, or bucket can move. wheel with the trolley and lifted load (rated capacity)

positioned on the bridge to give maximum loading.

LOAD BLOCK The assembly of hook, swivel, bearing,

sheaves, pins and frame suspended by the hoisting ropes. WHEELBASE Distance from center-to-center of wheels,

as measured in the direction running parallel with the

LOAD CYCLE One (1) lift cycle with load plus one lift cycle support rail.

without load.

531 Old Swede Road, Douglassville, PA 19518 877.877.6778 610.385.6061

AmericanCrane.com

110

S-ar putea să vă placă și

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocument40 paginiMachining Processes Used To Produce Round Shapes: Turning and Hole MakingSaurabh ChoudhariÎncă nu există evaluări

- Technical Specifications: Zoomlion Ztc800V Truck CraneDocument27 paginiTechnical Specifications: Zoomlion Ztc800V Truck CraneRajÎncă nu există evaluări

- 9.optimisation in Design of Mechanical Scissor LiftDocument5 pagini9.optimisation in Design of Mechanical Scissor LiftAmit GhadeÎncă nu există evaluări

- 009-2021 - R1 - Techno-Commercial Proposal-MAKDocument28 pagini009-2021 - R1 - Techno-Commercial Proposal-MAKpavanÎncă nu există evaluări

- MS Erection of PH Activities 63mtr 25.12.21Document8 paginiMS Erection of PH Activities 63mtr 25.12.21AltafÎncă nu există evaluări

- ZCJK Brick Machine Price List - LilyDocument4 paginiZCJK Brick Machine Price List - LilyTimothy Ndeleva100% (1)

- Rate Analysis For Basic Work Items: Price Code Labour Component Unit Quantity Rate AmountDocument2 paginiRate Analysis For Basic Work Items: Price Code Labour Component Unit Quantity Rate AmountKrishan RodrigoÎncă nu există evaluări

- Cranes Used in Shipping Industry (Ports & Shipyards)Document11 paginiCranes Used in Shipping Industry (Ports & Shipyards)Nishant GauravÎncă nu există evaluări

- Rack and Binion Using LiftDocument29 paginiRack and Binion Using LiftRamachantran RamachantranÎncă nu există evaluări

- PDFDocument4 paginiPDFAliRouyouÎncă nu există evaluări

- Introduction To Lifting PlanDocument44 paginiIntroduction To Lifting PlanÐôùxBébê Ðê MãmäñÎncă nu există evaluări

- Crane Components: Technical CatalogueDocument30 paginiCrane Components: Technical CatalogueWissam JarmakÎncă nu există evaluări

- Zamil-Sicc Daily Erection Report 2015-11-09 PDFDocument1 paginăZamil-Sicc Daily Erection Report 2015-11-09 PDFrazi khanÎncă nu există evaluări

- Modern Machine India Bombay Modern Machine India Bombay Essar Sales & Services Essar Sales & ServicesDocument2 paginiModern Machine India Bombay Modern Machine India Bombay Essar Sales & Services Essar Sales & ServicesasifmullaÎncă nu există evaluări

- Crane Guide 2 E5 PDocument6 paginiCrane Guide 2 E5 PsergiooiÎncă nu există evaluări

- PODEM ANUPAM Brochure CraneComponentDocument28 paginiPODEM ANUPAM Brochure CraneComponentJnanamÎncă nu există evaluări

- Elevator Safety EquipmentDocument3 paginiElevator Safety Equipmentjack.simpson.changÎncă nu există evaluări

- BWSR Safety Features PDFDocument3 paginiBWSR Safety Features PDFVijayakumarVageesanÎncă nu există evaluări

- Pedal Operated ForkliftDocument56 paginiPedal Operated Forkliftfahamith ahamed100% (1)

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 paginiValvula Reductora de Presion Bermad Area 675 720-ULChristian FherÎncă nu există evaluări

- Wire Rope Slings PDFDocument9 paginiWire Rope Slings PDFmpcd07Încă nu există evaluări

- MECH3110 Final Design Report Group22Document101 paginiMECH3110 Final Design Report Group22Kevin Huynh100% (2)

- 1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceDocument11 pagini1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceIstiQamahh MuhamadÎncă nu există evaluări

- CraneDocument80 paginiCranehoseinÎncă nu există evaluări

- Scissor LiftDocument8 paginiScissor LiftSiew Hiong JongÎncă nu există evaluări

- Adhikary Plant CycleDocument19 paginiAdhikary Plant CyclerpshvjuÎncă nu există evaluări

- Cost EstimationDocument16 paginiCost EstimationAnkit ShrivastavaÎncă nu există evaluări

- Fenner GearsDocument28 paginiFenner Gearsmanoj983@gmail.comÎncă nu există evaluări

- Passenger and Material Hoist According To TRA 1100 / EN 12159Document2 paginiPassenger and Material Hoist According To TRA 1100 / EN 12159PhanHathamÎncă nu există evaluări

- Combi-SC: The Cost Effective Solution For Handling Containers & Oversized LoadsDocument8 paginiCombi-SC: The Cost Effective Solution For Handling Containers & Oversized LoadsShahril SabarÎncă nu există evaluări

- Partlist - Paddy Seperator 400D-TDocument14 paginiPartlist - Paddy Seperator 400D-TGENIUS1507100% (1)

- Direct Manpower Manhour - RevDocument1 paginăDirect Manpower Manhour - RevAbuAhmedQuaziÎncă nu există evaluări

- Lifting Device Used in ConstructionDocument18 paginiLifting Device Used in ConstructionAr Deyvanai Kannan100% (1)

- Scaffolding-Medical Cert.Document13 paginiScaffolding-Medical Cert.qoolshabiÎncă nu există evaluări

- Residential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationDocument7 paginiResidential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationPedro JonesÎncă nu există evaluări

- Crane Solutions and ModelsDocument24 paginiCrane Solutions and ModelsAmandeep NandaÎncă nu există evaluări

- 8 Rope Reeving 3 PDFDocument4 pagini8 Rope Reeving 3 PDFsanjay aÎncă nu există evaluări

- Boiler Water TDSDocument5 paginiBoiler Water TDSDurjoy ChakrabortyÎncă nu există evaluări

- Components in LiftDocument2 paginiComponents in LiftDausCR7Încă nu există evaluări

- 3220-CRN-001 - 5t X 8.5m Arm X 30m HOL Pillar Jib Crane - GA Drawing PDFDocument1 pagină3220-CRN-001 - 5t X 8.5m Arm X 30m HOL Pillar Jib Crane - GA Drawing PDFpawan100% (1)

- Heavy Equipment Checklist: Project Contract No. Location Equipment Model Equipment No. Date TimeDocument1 paginăHeavy Equipment Checklist: Project Contract No. Location Equipment Model Equipment No. Date Timesawkariqbal100% (1)

- ROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFDocument24 paginiROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFFayaz MohammedÎncă nu există evaluări

- 1000kv Gene - Installation Lifting PlanDocument10 pagini1000kv Gene - Installation Lifting Plansaud salemÎncă nu există evaluări

- How To Estimate The Cost of Mechanical DredgingDocument21 paginiHow To Estimate The Cost of Mechanical DredgingKaren LimÎncă nu există evaluări

- Wire Rope SlingsDocument27 paginiWire Rope Slingsnasirfahim100% (1)

- Spek Lift 320kgDocument1 paginăSpek Lift 320kgVictoria Anna100% (1)

- Abacus HoistDocument22 paginiAbacus Hoistomiti Engineering systemsÎncă nu există evaluări

- Erection Methodology PresentationDocument34 paginiErection Methodology PresentationCyril BayugaÎncă nu există evaluări

- Operation Manual: Temporarily Installed Suspended Access EquipmentDocument35 paginiOperation Manual: Temporarily Installed Suspended Access EquipmentfuadkhoirulÎncă nu există evaluări

- Description:: Fig.1. DJ BMUDocument6 paginiDescription:: Fig.1. DJ BMUHarith ObeidÎncă nu există evaluări

- Container Gantry Crane StructureDocument40 paginiContainer Gantry Crane StructureMogan RajÎncă nu există evaluări

- 261 Many Tower Cranes, Self Erecting Cranes and Accessories CatalogueDocument20 pagini261 Many Tower Cranes, Self Erecting Cranes and Accessories CatalogueBoruida MachineryÎncă nu există evaluări

- Crane Operator Hoist 2 PK Crane Operator Hoist 2 PK: Sydney Hoist Rentals Pty LTDDocument2 paginiCrane Operator Hoist 2 PK Crane Operator Hoist 2 PK: Sydney Hoist Rentals Pty LTDBoruida MachineryÎncă nu există evaluări

- Enchlor Catalog 2013Document8 paginiEnchlor Catalog 2013Pablo NavasÎncă nu există evaluări

- Branchtein LifelineDesign Presentation PDFDocument12 paginiBranchtein LifelineDesign Presentation PDFmbranchteinÎncă nu există evaluări

- Crane TermsDocument2 paginiCrane TermsErnane MagalhãesÎncă nu există evaluări

- Crane Terminology PDFDocument2 paginiCrane Terminology PDFandredurvalandradeÎncă nu există evaluări

- PSME CODE (Ethics)Document7 paginiPSME CODE (Ethics)John Francis Pirote FriasÎncă nu există evaluări

- Procedure of Crane Girder Design: Presentation OnDocument65 paginiProcedure of Crane Girder Design: Presentation OnShamik Ghosh100% (1)

- Glossary of Crane TerminologyDocument11 paginiGlossary of Crane TerminologyvizonspiderÎncă nu există evaluări

- 50243-16-2p-Commented FileDocument2 pagini50243-16-2p-Commented FilePrem KumarÎncă nu există evaluări

- A Hazard Assessment Matrix Was Developed To Determine A Hazard Risk Index Using Frequency of Occurrence and Hazard CategoryDocument1 paginăA Hazard Assessment Matrix Was Developed To Determine A Hazard Risk Index Using Frequency of Occurrence and Hazard CategoryPrem KumarÎncă nu există evaluări

- L G PI E PC E: 2 - Station VPI Station VPCDocument2 paginiL G PI E PC E: 2 - Station VPI Station VPCPrem KumarÎncă nu există evaluări

- 520367-9-6P Aid: 30951 - 03/03/2019Document1 pagină520367-9-6P Aid: 30951 - 03/03/2019Prem KumarÎncă nu există evaluări

- 12 9PDocument1 pagină12 9PPrem KumarÎncă nu există evaluări

- Fender PerDocument1 paginăFender PerPrem KumarÎncă nu există evaluări

- 100 Speed Wind Total Speed Wind of Duration Wind %Document2 pagini100 Speed Wind Total Speed Wind of Duration Wind %Prem KumarÎncă nu există evaluări

- ITC Driver's RoomDocument9 paginiITC Driver's RoomPrem KumarÎncă nu există evaluări

- Itc PPT 2Document12 paginiItc PPT 2Prem KumarÎncă nu există evaluări

- KSS Check ListDocument4 paginiKSS Check ListPrem KumarÎncă nu există evaluări

- Comparison of Design Procedures For Pre Engineering Buildings PEB A Case StudyDocument6 paginiComparison of Design Procedures For Pre Engineering Buildings PEB A Case StudyPrem KumarÎncă nu există evaluări

- Weld Joint Rust. Aluminum Paint To ApplyDocument10 paginiWeld Joint Rust. Aluminum Paint To ApplyPrem KumarÎncă nu există evaluări

- It 1Document5 paginiIt 1Prem KumarÎncă nu există evaluări

- Weld Joint Rust. Aluminum Paint To ApplyDocument10 paginiWeld Joint Rust. Aluminum Paint To ApplyPrem KumarÎncă nu există evaluări

- Newton First Law of MotionDocument6 paginiNewton First Law of MotionKin ChristineÎncă nu există evaluări

- Tachi e 2004Document12 paginiTachi e 2004Ahsan Habib TanimÎncă nu există evaluări

- Brochure Cementindustrie PfeifferDocument24 paginiBrochure Cementindustrie Pfeifferdoxa maria0% (1)

- Is The Financial Performance of Insurance Companies Listed in Idx Able To Make Profitability After The Existence of BPJS?Document10 paginiIs The Financial Performance of Insurance Companies Listed in Idx Able To Make Profitability After The Existence of BPJS?Bunga LophitaÎncă nu există evaluări

- CADCAM PortfolioDocument5 paginiCADCAM PortfolioGuhan MÎncă nu există evaluări

- ECG553 Week 10-11 Deep Foundation PileDocument132 paginiECG553 Week 10-11 Deep Foundation PileNUR FATIN SYAHIRAH MOHD AZLIÎncă nu există evaluări

- Technical Drafting I: (Manual Drafting) 2Nd SemesterDocument18 paginiTechnical Drafting I: (Manual Drafting) 2Nd SemesterhakkensÎncă nu există evaluări

- Statistics & Probability: Q4 - Learning Activity Sheet #1 Testing HypothesisDocument2 paginiStatistics & Probability: Q4 - Learning Activity Sheet #1 Testing HypothesisEeNihc DPÎncă nu există evaluări

- 5 - WQU - 622 CTSP - M5 - CompiledContentDocument34 pagini5 - WQU - 622 CTSP - M5 - CompiledContentJoe NgÎncă nu există evaluări

- ASHRAE Table9 Hot Water Demand PDFDocument1 paginăASHRAE Table9 Hot Water Demand PDFsenthilkumar_5425717Încă nu există evaluări

- Strength of Materials Unit 3 Question Bank: Jansons Institute of TechnologyDocument3 paginiStrength of Materials Unit 3 Question Bank: Jansons Institute of TechnologyVasanth KumarÎncă nu există evaluări

- C Programming Board Solve PDFDocument12 paginiC Programming Board Solve PDFEstiak Hossain ShaikatÎncă nu există evaluări

- WS-Problems Solved by Quadratic EquationsDocument1 paginăWS-Problems Solved by Quadratic EquationsNorul AzimÎncă nu există evaluări

- Tafl KCS 402 Cia-I 2019-20Document2 paginiTafl KCS 402 Cia-I 2019-20vikÎncă nu există evaluări

- Ak98 Preset ListDocument21 paginiAk98 Preset ListHichem NaghmouchiÎncă nu există evaluări

- Bio Sem2 EssayDocument2 paginiBio Sem2 EssayEileen WongÎncă nu există evaluări

- Unit 9: Areas and PerimetersDocument22 paginiUnit 9: Areas and PerimetersSanchit GargÎncă nu există evaluări

- Actor-Network Theory and After - Jonh Law and John HassardDocument14 paginiActor-Network Theory and After - Jonh Law and John HassardGabriel RomanÎncă nu există evaluări

- On Predicting Roller Milling Performance Part II. The Breakage FunctionDocument13 paginiOn Predicting Roller Milling Performance Part II. The Breakage FunctionKenneth AdamsÎncă nu există evaluări

- En 2014 New Brochure WebDocument20 paginiEn 2014 New Brochure WebSasa NackovicÎncă nu există evaluări

- Dke672 ch2Document44 paginiDke672 ch2Siraj MohammedÎncă nu există evaluări

- Life Sciences Grade 10 ATP 2024Document19 paginiLife Sciences Grade 10 ATP 2024olwe149Încă nu există evaluări

- Civl432 Bridge Design SummaryDocument5 paginiCivl432 Bridge Design SummarySheikh Mizanur RahmanÎncă nu există evaluări

- Sequential Reliability TestsDocument2 paginiSequential Reliability Teststanpreet_makkadÎncă nu există evaluări

- A Presentation OF Vocational Training On Combined Cycle Power PlantDocument20 paginiA Presentation OF Vocational Training On Combined Cycle Power PlantramezhosnyÎncă nu există evaluări

- Viscosity MeasurementDocument8 paginiViscosity MeasurementRian SteveÎncă nu există evaluări

- Process Control Plan Excel TemplateDocument13 paginiProcess Control Plan Excel TemplateTalal NajeebÎncă nu există evaluări

- Zanussi Zou 342 User ManualDocument12 paginiZanussi Zou 342 User Manualadatok2Încă nu există evaluări

- MPM2D CPT: Knights of The Night Station: Include All Your Work For Each Part On Their Own .PDF File orDocument5 paginiMPM2D CPT: Knights of The Night Station: Include All Your Work For Each Part On Their Own .PDF File orKavya Pandya100% (2)

- Fastener NoteDocument8 paginiFastener NoteAmit PrajapatiÎncă nu există evaluări