Documente Academic

Documente Profesional

Documente Cultură

Cec2 Operation

Încărcat de

Wilson CendalesDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cec2 Operation

Încărcat de

Wilson CendalesDrepturi de autor:

Formate disponibile

SECTION D: SYSTEM OPERATION

CEC2 CONTROLS

Items discussed in the SYSTEM OPERATION section are:

1.0 PURPOSE

2.0 STARTING THE VEHICLE

3.0 OPERATION OF THE SHIFT SELECTOR

3.1 Range Selection - "Keypad" Pushbutton Shifter

3.2 Range Selection - Lever Selector

3.3 Function of the Mode Button

3.4 Shift Schedules

- Primary Mode

- Secondary Mode

- Hold Upshift

- Preselect Downshift

4.0 DIAGNOSTIC TELLTALES

4.1 "Check Trans" Light

4.2 Diagnostic Data Reader

4.3 Diagnostic Codes

4.4 Special Uses, i.e. Cooling Tests

5.0 OPERATION OF OPTIONAL TRANSMISSION FEATURES

5.1 Retarder

OCC2D August 23, 2005

NOTE:

The latest automatic electronic CEC2 controls are available on all off-

highway transmission model families. Manual electric and manual hydraulic

models also continue to be available in the 5000 and 6000 model families.

Similarly, manual electric models continue to be available for the models in

the 8000 and 9000 series families. Generally the model designations

models used in hauling applications are H5610, H9610, etc. while other

mobile versions of these models are M5610, M9610, etc. For stationary

versions these model designations are S5610, S9610, etc. The "xx10"

designates that these transmissions share some parts required for CEC2

controls, such as housings and speed sensors.

In the case of the 5000 and 6000 transmission families, Allison Transmission

continues to produce direct replacement models for CEC1 controlled

transmissions. These are available as a customer convenience as

replacements for CEC1 models used in existing installations due to the

large volume of 5000 and 6000 CEC1 models in the field. CEC1 models are

no longer available in the 8000 and 9000 model families. However, CEC2

models in any family can be used as replacements for CEC1 models by

utilizing jumper harnesses as described in Section G: CEC2 Support

Equipment and Controls Definition Worksheets of the CEC2 Electronic

Controls manual. This document, along with other technical reference

information, may be found in the Tech Data section of the Extranet channel

of the Allison Transmission website www.allisontransmission.com. Contact

your Allison representative if you do not have access to the Allison

Transmission Extranet.

CEC2 Controls Installation Manual - August 23, 2005 Page D-2

SECTION D. SYSTEM OPERATION

1.0 GENERAL

The purpose of this section is to describe the function and operation of the transmission control

system and components. Included in this section are discussions of: starting the vehicle; operation

of the shift selector(s), including usage of the MODE button and availability of multiple shift sched-

ules; understanding and using the diagnostic telltales; and operation of certain optional transmission

features.

Unless otherwise noted, all documents referenced in this section may be found in the Tech Data

section of the Extranet channel of the Allison Transmission website www.allisontransmission.com.

To locate these documents, which are identified by italic font, look for Tech Data under the Engineer-

ing heading on the Extranet home page. Contact your Allison representative if you do not have

access to the Allison Transmission Extranet.

2.0 STARTING THE VEHICLE

No special procedure is required. The driver must simply verify that the brakes are applied and

NEUTRAL has been selected (if the vehicle is equipped with a lever shifter. The "keypad" pushbutton

shifter will automatically initialize in NEUTRAL.) When this condition is present and the ignition is

turned on, the digital display will indicate "N" for NEUTRAL and the vehicle may be started.

3.0 OPERATION OF THE SHIFT SELECTOR

The vehicle may be equipped with one or two shift selectors, depending upon the number of operator

stations for driving the vehicle and/or operating chassis-mounted equipment. The shift selector(s)

may be either pushbutton or lever type. When using two shift selectors, the active shifter's display

will be lit.

With an Allison automatic transmission, the shift selector is used by the operator to select Neutral

(N), Reverse gear (R), or a range of forward gears. When a forward gear range has been selected,

the transmission starts in the lowest gear of the range and, as conditions permit, automatically

upshifts until the highest gear in the selected range is in use.

When appropriate, the control system will invoke built-in logic to protect the transmission from some

types of abusive operation. For example:

except in some types of specialized equipment, neutral-to-reverse shifts are normally inhibited

above specified throttle positions (typically, above 20% throttle)

forward/reverse directional changes are typically not permitted if appreciable output shaft speed or

throttle position is detected. The ECU will indicate that the shift is inhibited by flashing the "range

select" digit on the selector. Engine speed, including

a high idle condition, is not accounted for in D-R or

R-D shifts.

3.1 RANGE SELECTION -

"KEYPAD" PUSHBUTTON SHIFTER

The function of each position of the keypad pushbutton

shifter is as follows (Refer to Figure D-1):

Select REVERSE gear by pressing "R".

Two reverse ranges are available with some transmis-

sion models. In these circumstances, pressing "R" SE059

selects either low-speed reverse ("R1") or high-speed

reverse ("R2"), depending on the position of a dash- Figure D-1: "Keypad" Pushbutton

mounted "R1/R2" selection switch. Shift Selector

CEC2 Controls Installation Manual - August 23, 2005 Page D-3

Select NEUTRAL by pressing "N". The area around the "N" button is a raised ridge so the driver can

orient his hand to the pushbuttons by touch, without looking at the display. It is not necessary to

press this button prior to starting the vehicle.

Select DRIVE range by pressing "D". The highest forward gear will appear on the SELECT display

and the transmission will shift to the starting gear.

The UPSHIFT (!) and DOWNSHIFT (") arrow buttons are used to select a higher (if not in "D") or

lower (if not in "1") forward range. These buttons are not functional in NEUTRAL or REVERSE. One

press changes the range selected by one range. If the button is held continuously, the selected

range will continue to change up or down until the button is released or until the highest or lowest

possible range of gears is selected.

3.2 RANGE SELECTION - LEVER SHIFTER

Refer to Figure D-2.

R REVERSE.

Some transmission models are equipped with

two reverse ranges. In these circumstances,

the shiftselector will show two reverse selections:

"R1" for low-speed reverse, and "R2" for high-

speed reverse.

N NEUTRAL; must be selected prior to starting

vehicle

D DRIVE; selects the highest forward range

1-6 FORWARD RANGE selection; operation for

SE060 all the ranges is the same as described for the

Figure D-2: Lever Shift Selector pushbutton range selected

The lever shifter features a detent to prevent inadvertent shifting between "R" (or "R1" and "R2", if

applicable), "N", and "D". To release the lever from any of these positions, the detent must first be

unlocked by depressing the thumb release button on the shifter handle. All other forward ranges can

be selected by simply moving the lever.

3.3 FUNCTION OF THE MODE BUTTON

Both lever and keypad pushbutton shift selectors feature a MODE button on the face of

the shifter bezel. This button is used to invoke a special function that has been pro-

grammed into the ECU. A small red light near the MODE button is illuminated when the MODE

function is activated. A label should be placed near the mode button to identify the function

associated with a mode change. (A variety of labels are supplied with each shifter for this

purpose).

3.4 SHIFT SCHEDULES

The points at which shifting occurs is dependent upon predetermined speeds and other operating

conditions, as determined by the calibration. A transmission "shift calibration" includes several sets

of shift points which may be requested by the operator according to current or anticipated operating

conditions.

CEC2 Controls Installation Manual - August 23, 2005 Page D-4

Two separate and distinct shift calibrations ("primary" and "secondary") may be used for operating

the vehicle. Several combinations of Primary/Secondary shift schedules, which are customer-

specified when ordering an ECU, are readily available. For more details on this subject, contact your

Allison Sales representative.

Appropriate Hold Upshift and Preselect Downshift schedules are established for each transmission

on the basis of engine characteristics, vehicle gearing, etc. Customer input is not necessary to

define these shift schedules for a transmission application.

PRIMARY This shift schedule is used each time the vehicle is started. Typically, this is used for

normal vehicle operation.

SECONDARY This is an alternate shift schedule that the ECU uses upon request. The request

can be interlocked with a vehicle component, or be operator-

controlled via the MODE button or a dash mounted switch.

HOLD UPSHIFT This shift schedule permits upshifts to occur if an overspeed condition could

result by the transmission remaining (by operator selection) in a lower range. These shifts occur at

engine speeds which are higher than normal upshifts.

PRESELECT DOWNSHIFT This shift schedule is used when the driver preselects a lower range.

The transmission will downshift when an overspeed condition will not result after the shift. These

downshifts occur at engine speeds which are higher than normal downshifts.

RETARDER The retarder shift schedule incorporates elevated closed-throttle downshifts to opti-

mize retarder capacity during retarder operation. Retarder closed throttle downshifts are similar to

preselect downshifts. This shift schedule is activated when the retarder is switched on and all

programmed requirements for retarder operation are met (See Section E: Customizing the Controls

Configuration to Your Vehicle of this manual).

OVERTEMP The transmission is restricted to operation in the lower gear ranges during oil

overtemp conditions. If the transmission is above the maximum available range when overtemp

occurs, preselect downshifts are used until that range is reached.

4.0 DIAGNOSTICS

Diagnostic features are provided with the transmission control system to assist in troubleshooting of

malfunctions and/or the monitoring of specific operating parameters. These features include a

CHECK TRANS light at the operators station, and the diagnostic program which is used primarily as

a service tool. When a malfunction is detected in the control system, a series of "diagnostic codes"

are used to identify and clarify the nature of the malfunction.

4.1 "CHECK TRANS" LIGHT

This indicator is usually located on the instrument panel.

Illumination of this light indicates that a problem has been detected and shifts may be CHECK

TRANS

restricted. Depending upon the severity of the problem, the readout digit on the shifter

display may be blank. Operation may continue in order to reach service assistance.

The ECU may not respond to shift selector requests, since operating limitations are being placed on

the transmission, i.e. upshifts and downshifts may be restricted. Direction changes will not occur.

Any time this light has been illuminated, the ECU will register a diagnostic code. It may be identified

on the display and/or the diagnostic program

CEC2 Controls Installation Manual - August 23, 2005 Page D-5

4.2 ALLISON DOC FOR PC DIAGNOSTICS PROGRAM

Control system diagnostics are provided with this PC (Windows)-based interface/software program

which is available through Allison service tool sources. The purpose of the program is to assist in

the installation checkout and the troubleshooting of malfunctions as detected by the ECU. It may

also be used to modify certain customer-modifiable parameters, including Input/Output Function

packages. For more information, refer to Section E: Input / Output Functions of this manual and to

the operators literature which is provided with the PC program.

The diagnostics program uses the PC as a receiver/transmitter/display unit. The program transmits

and receives data to/from the ECU, processes the data and displays appropriate information to the

service technician. Operating instructions are supplied with the software.

For source information, refer to Section K: Support Equipment of the Off-HighwayTransmission

Installation Manual.

4.3 DIAGNOSTIC CODES

The CHECK TRANS light is illuminated briefly during vehicle start-up as a bulb check. Illumination of the

CHECK TRANS light at any time after start-up indicates that the ECU has registered a diagnostic code.

To further assist when troubleshooting, a cross-reference of diagnostic codes with the associated

transmission or controls incident is shown in Tables D-3a and D-3b at the end of this section. In

addition, a wiring harness summary of function by wire number is provided in Table D-4.

Diagnostic codes can be displayed either by the diagnostic tool or on the display portion of the shift

selector. The following information describes use of the diagnostic capabilities of the system without

a diagnostic tool. For a more complete description of the diagnostics tool and a step-by-step proce-

dure for its use, consult the operating instructions which are supplied with the software and/or the

Troubleshooting Manual (available from Allison Parts Distribution Center).

Up to 5 diagnostic codes can be registered in the ECU at one time. In addition to the display of the

codes themselves, any inhibits which result from active codes are also identified.

TO ENTER DIAGNOSTIC MODE: The general procedure to display the codes is to first enter the

diagnostic mode by pressing the upshift and downshift arrow buttons simultaneously on the

keypad pushbutton selector, or pressing the diagnostic mode button on the lever shift selector once.

Diagnostic mode will be entered only with the vehicle stopped. (The transmission should be shifted

to NEUTRAL and the vehicle parking brake applied.) For each code stored in memory, beginning with

any code that is presently inhibiting the transmission, the 4 digits of the code and the pertinent pa-

rameters are continuously flashed on the display. Pressing the mode button once will cause the next

code with its pertinent information to be displayed. Dashes indicate all stored codes have been

displayed.

To clear any active inhibits, depress the mode button and hold for 3 - 5 seconds. Depressing and

holding the mode button for 8 - 10 seconds will clear inactive codes from memory. All active inhibits

will also be cleared during a normal powerdown (ignition switched off followed by zero output and

zero engine speeds).

After a fixed number of ignition cycles, any code will automatically disappear from memory if it has

not reoccurred. "Ignition cycle counts", which indicate the age of a stored code, and "event counts",

which indicate the frequency of code occurrence, are available for reference but accessible only

with the diagnostic tool.

CEC2 Controls Installation Manual - August 23, 2005 Page D-6

TO EXIT DIAGNOSTIC MODE: Exit the diagnostic mode using one or the following procedures:

Press any range button (D, N, R) on the pushbutton shift selector. If the selector is the lever-type,

select any other transmission gear range.

Pushbutton shift selector only: simultaneously press the upshift (!) and downshift (") arrow

buttons.

Lever shift selector only: momentarily depress the "Diagnostic Mode" button.

Turn off power to the ECU (turn off the vehicle engine at the ignition switch)

Wait for the system to automatically reset

(approximately ten minutes after last operator input)

Press and hold the "Mode" button for approximately 5 seconds after all codes have been cleared.

5.0 OPERATION OF OPTIONAL TRANSMISSION FEATURES

5.1 RETARDER

The purpose of the retarder is to assist in stopping the vehicle during stop-and-go driving and to

control the downhill speed of the vehicle on a grade. For both of these uses, the retarder serves to

extend the life of the service brakes and to enhance vehicle control.

For details relating to the retarder control, refer to discussions regarding "Retarder Enable" input

function and "Retarder Indicator" output function in Section E: Customizing the Controls Configuration

to Your Vehicle of this manual.

CEC2 Controls Installation Manual - August 23, 2005 Page D-7

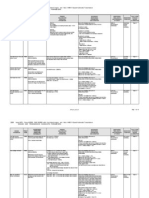

CEC2 DIAGNOSTIC INCIDENT CODE LIST

(5000-Series, 6000-Series, and 9600-Series Transmission Models)

NOTE: For 8000-Series Models, refer to Figure D-3(b)

CODES INCIDENT CLEARING PROCEDURES* CODES INCIDENT CLEARING PROCEDURES*

12 12 INACTIVE. RESERVED FOR FUTURE USE. 44 12 INACTIVE. RESERVED FOR FUTURE USE.

12 23 INACTIVE. RESERVED FOR FUTURE USE. 44 13 INACTIVE. RESERVED FOR FUTURE USE.

44 14 INACTIVE. RESERVED FOR FUTURE USE.

13 12 ECU INPUT VOLTAGE LOW PMS 44 15 INACTIVE. RESERVED FOR FUTURE USE.

13 23 ECU INPUT VOLTAGE HIGH PMS 44 16 INACTIVE. RESERVED FOR FUTURE USE.

44 21 INACTIVE. RESERVED FOR FUTURE USE.

14 12 INACTIVE. RESERVED FOR FUTURE USE. 44 22 INACTIVE. RESERVED FOR FUTURE USE.

14 23 INACTIVE. RESERVED FOR FUTURE USE. 44 23 INACTIVE. RESERVED FOR FUTURE USE.

44 26 INACTIVE. RESERVED FOR FUTURE USE.

21 12 THROTTLE SENSOR FAILED LOW PMS

21 23 THROTTLE SENSOR FAILED HIGH PMS 45 12 LOW-SIDE FAILURE: F SOLENOID PM

45 13 LOW-SIDE FAILURE: K SOLENOID PM

22 14 ENGINE SPEED SENSOR PMS 45 14 LOW-SIDE FAILURE: B SOLENOID PM

22 15 TURBINE SPEED SENSOR PMS 45 15 LOW-SIDE FAILURE: G SOLENOID PM

22 16 OUTPUT SPEED SENSOR PMS 45 16 LOW-SIDE FAILURE: E SOLENOID PM

45 21 LOW-SIDE FAILURE: J SOLENOID PM

23 12 PRIMARY SHIFT SELECTOR PMS 45 22 LOW-SIDE FAILURE: A SOLENOID PM

23 13 PRIMARY SHIFT SELECTOR MODE FUNCTION FAULT PMS 45 23 LOW-SIDE FAILURE: D SOLENOID PM

23 14 SECONDARY SHIFT SELECTOR PMS 45 26 LOW-SIDE FAILURE: C SOLENOID PM

23 15 SECONDARY SHIFT SELECTOR MODE FUNCTION FAULT PMS

23 16 SHIFT SELECTOR DISPLAY LINE FAULT PMS 46 21 HIGH-SIDE OVERCURRENT: J SOLENOID CIRCUIT PM

46 26 HIGH-SIDE OVERCURRENT: E,C,& D SOLENOID CIRCUIT PM

24 12 SUMP OIL TEMPERATURE COLD PMS 46 27 HIGH-SIDE OVERCURRENT: A,B,F,G,& K SOL. CIRCUIT PM

24 23 SUMP OIL TEMPERATURE HOT PMS

56 00 LOCKUP RATIO VERIFICATION TEST P-M

25 11 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 1ST PMS 56 11 RATIO RANGE VERIFICATION TEST, 1ST PM

25 22 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 2ND PMS 56 22 RATIO RANGE VERIFICATION TEST, 2ND PM

25 33 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 3RD PMS 56 33 RATIO RANGE VERIFICATION TEST, 3RD PM

25 44 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 4TH PMS 56 44 RATIO RANGE VERIFICATION TEST, 4TH PM

25 55 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 5TH PMS 56 55 RATIO RANGE VERIFICATION TEST, 5TH PM

25 66 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 6TH PMS 56 66 RATIO RANGE VERIFICATION TEST, 6TH PM

25 77 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 7TH PMS 56 77 RATIO RANGE VERIFICATION TEST, R1 OR 7TH PM

25 88 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 8TH PMS 56 88 RATIO RANGE VERIFICATION TEST, R2 OR 8TH PM

56 99 HYDRAULIC LOCK IN RANGE P-M-S

26 00 THROTTLE SOURCE NOT DETECTED PMS

63 00 INACTIVE. RESERVED FOR FUTURE USE.

33 12 SUMP OIL TEMPERATURE SENSOR FAILED LOW PMS 63 26 INACTIVE. RESERVED FOR FUTURE USE.

33 23 SUMP OIL TEMPERATURE SENSOR FAILED HIGH PMS

65 00 ENGINE RATING TOO HIGH P

34 12 FACTORY CALIB. COMPATABILITY NO. WRONG OR INVALID

TRANS. MODEL CODE IN CALIB. PARA. TRANSMOD PS 66 00 SCI (SERIAL COMMUN. INTERFACE) THROTTLE FAULT PMS

34 13 FACTORY CALIBRATION BLOCK CHECKSUM PS 66 11 INACTIVE. RESERVED FOR FUTURE USE.

34 14 POWER OFF BLOCK CHECKSUM P

34 15 DIAGNOSTIC QUEUE BLOCK CHECKSUM P 69 27 ECU: INOPERATIVE F_HI SWITCH PM

34 16 REAL TIME BLOCK CHECKSUM P 69 28 ECU: INOPERATIVE J_HI SWITCH PM

34 17 CUSTOMER MODIFIABLE CONSTANTS CHECKSUM P 69 29 ECU: INOPERATIVE C & D_HI SWITCH PM

69 33 ECU: COP (COMPUTER OPER. PROPERLY) TIMEOUT P

35 00 POWER INTERRUPTION PM 69 34 ECU: EEPROM WRITE TIMEOUT CC

35 16 REAL TIME EEPROM WRITE INTERRUPTION P 69 35 ECU: EPROM CHECKSUM TEST P

69 36 ECU: RAM SELF TEST P

36 00 HARDWARE/SOFTWARE NOT COMPATIBLE PS 69 39 CAN CHIP TO CPU CONNECTION ERROR P

36 01 TRANS ID NOT COMPATIBLE WITH ECU SOFTWARE P 69 41 ECU: I/O ASIC ADDRESSING TEST P

36 02 TRANS ID COULD NOT COMPLETE P 69 42 SPI OUTPUT FAILURE PS

69 43 SPI INPUT FAILURE P

42 12 INACTIVE. RESERVED FOR FUTURE USE.

42 13 INACTIVE. RESERVED FOR FUTURE USE. 70 12 ECU: SOFTWARE, MINOR LOOP OVERRUN PM

42 14 INACTIVE. RESERVED FOR FUTURE USE. 70 13 ECU: SOFTWARE, ILLEGAL WRITE TO ADDRESS $0000 PM

42 15 INACTIVE. RESERVED FOR FUTURE USE. 70 14 ECU: SOFTWARE, MAJOR LOOP OVERRUN PM

42 16 INACTIVE. RESERVED FOR FUTURE USE.

42 21 INACTIVE. RESERVED FOR FUTURE USE.

42 22 INACTIVE. RESERVED FOR FUTURE USE. * CLEARING PROCEDURES

42 23 INACTIVE. RESERVED FOR FUTURE USE. P = NORMAL ECU POWERDOWN REQUIRED

42 26 INACTIVE. RESERVED FOR FUTURE USE. M = MANUAL CLEARING AVAILABLE

S = ECU SELF-CLEARING AVAILABLE

CC = CODE CANNOT BE CLEARED

Figure D-3(a): CEC2 Diagnostic Codes 5000-Series, 6000-Series, and 9600-Series

Transmission Models

CEC2 Controls Installation Manual - August 23, 2005 Page D-8

CEC2 DIAGNOSTIC INCIDENT CODE LIST

(8000-Series Transmission Models)

NOTE: For 5000-Series, 6000-Series, and 9600-Series Models, refer to Figure D-3(a)

CODES INCIDENT CLEARING PROCEDURES* CODES INCIDENT CLEARING PROCEDURES*

12 12 INACTIVE. RESERVED FOR FUTURE USE. 44 14 INACTIVE. RESERVED FOR FUTURE USE.

12 23 INACTIVE. RESERVED FOR FUTURE USE. 44 15 INACTIVE. RESERVED FOR FUTURE USE.

44 16 INACTIVE. RESERVED FOR FUTURE USE.

13 12 ECU INPUT VOLTAGE LOW PMS 44 21 INACTIVE. RESERVED FOR FUTURE USE.

13 23 ECU INPUT VOLTAGE HIGH PMS 44 22 INACTIVE. RESERVED FOR FUTURE USE.

44 23 INACTIVE. RESERVED FOR FUTURE USE.

14 12 INACTIVE. RESERVED FOR FUTURE USE. 44 26 INACTIVE. RESERVED FOR FUTURE USE.

14 23 INACTIVE. RESERVED FOR FUTURE USE.

45 12 LOW-SIDE FAILURE: F SOLENOID PM

21 12 THROTTLE SENSOR FAILED LOW PMS 45 13 LOW-SIDE FAILURE: K SOLENOID PM

21 23 THROTTLE SENSOR FAILED HIGH PMS 45 14 LOW-SIDE FAILURE: B SOLENOID PM

45 15 LOW-SIDE FAILURE: G SOLENOID PM

22 14 ENGINE SPEED SENSOR PMS 45 16 LOW-SIDE FAILURE: E SOLENOID PM

22 15 TURBINE SPEED SENSOR PMS 45 21 LOW-SIDE FAILURE: H SOLENOID PM

22 16 OUTPUT SPEED SENSOR PMS 45 22 LOW-SIDE FAILURE: A SOLENOID PM

45 23 LOW-SIDE FAILURE: D SOLENOID PM

23 12 PRIMARY SHIFT SELECTOR PMS 45 24 LOW-SIDE FAILURE: I SOLENOID PM

23 13 PRIMARY SHIFT SELECTOR MODE FUNCTION FAULT PMS 45 26 LOW-SIDE FAILURE: C SOLENOID PM

23 14 SECONDARY SHIFT SELECTOR PMS

23 15 SECONDARY SHIFT SELECTOR MODE FUNCTION FAULT PMS 46 21 HIGH-SIDE OVERCURRENT: H SOLENOID CIRCUIT PM

23 16 SHIFT SELECTOR DISPLAY LINE FAULT PMS 46 26 HIGH-SIDE OVERCURRENT: E,C,& D SOLENOID CIRCUIT PM

46 27 HIGH-SIDE OVERCURRENT: A,B,F,G,I, & K SOL. CIRCUIT PM

24 12 SUMP OIL TEMPERATURE COLD PMS

24 23 SUMP OIL TEMPERATURE HOT PMS 56 00 LOCKUP RATIO VERIFICATION TEST P-M

56 11 RATIO RANGE VERIFICATION TEST, 1ST PM

25 11 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 1ST PMS 56 22 RATIO RANGE VERIFICATION TEST, 2ND PM

25 22 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 2ND PMS 56 33 RATIO RANGE VERIFICATION TEST, 3RD PM

25 33 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 3RD PMS 56 44 RATIO RANGE VERIFICATION TEST, 4TH PM

25 44 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 4TH PMS 56 55 RATIO RANGE VERIFICATION TEST, 5TH PM

25 55 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 5TH PMS 56 66 RATIO RANGE VERIFICATION TEST, 6TH PM

25 66 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 6TH PMS 56 77 RATIO RANGE VERIFICATION TEST, R1 OR 7TH PM

25 77 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 7TH PMS 56 88 RATIO RANGE VERIFICATION TEST, R2 OR 8TH PM

25 88 OUTPUT SPEED SENSOR, DETECTED AT 0 SPD., 8TH PMS 56 99 HYDRAULIC LOCK IN RANGE P-M-S

26 00 THROTTLE SOURCE NOT DETECTED PMS 63 00 INACTIVE. RESERVED FOR FUTURE USE.

63 26 INACTIVE. RESERVED FOR FUTURE USE.

33 12 SUMP OIL TEMPERATURE SENSOR FAILED LOW PMS

33 23 SUMP OIL TEMPERATURE SENSOR FAILED HIGH PMS 65 00 ENGINE RATING TOO HIGH P

34 12 FACTORY CALIB. COMPATABILITY NO. WRONG OR INVALID 66 00 SCI (SERIAL COMMUN. INTERFACE) THROTTLE FAULT PMS

TRANS. MODEL CODE IN CALIB. PARA. TRANSMOD PS 66 11 INACTIVE. RESERVED FOR FUTURE USE.

34 13 FACTORY CALIBRATION BLOCK CHECKSUM PS

34 14 POWER OFF BLOCK CHECKSUM P 69 27 ECU: INOPERATIVE F_HI SWITCH PM

34 15 DIAGNOSTIC QUEUE BLOCK CHECKSUM P 69 28 ECU: INOPERATIVE H_HI SWITCH PM

34 16 REAL TIME BLOCK CHECKSUM P 69 29 ECU: INOPERATIVE C & D_HI SWITCH PM

34 17 CUSTOMER MODIFIABLE CONSTANTS CHECKSUM P 69 29 ECU: CLOSED SWITCH: H & K SOLENOID CIRCUIT PM

69 33 ECU: COP (COMPUTER OPER. PROPERLY) TIMEOUT P

35 00 POWER INTERRUPTION PM 69 34 ECU: EEPROM WRITE TIMEOUT CC

35 16 REAL TIME EEPROM WRITE INTERRUPTION P 69 35 ECU: EPROM CHECKSUM TEST P

69 36 ECU: RAM SELF TEST P

36 00 HARDWARE/SOFTWARE NOT COMPATIBLE PS 69 39 CAN CHIP TO CPU CONNECTION ERROR P

36 01 TRANS ID NOT COMPATIBLE WITH ECU SOFTWARE P 69 41 ECU: I/O ASIC ADDRESSING TEST P

36 02 TRANS ID COULD NOT COMPLETE P 69 42 SPI OUTPUT FAILURE PS

69 43 SPI INPUT FAILURE P

42 12 INACTIVE. RESERVED FOR FUTURE USE.

42 13 INACTIVE. RESERVED FOR FUTURE USE. 70 12 ECU: SOFTWARE, MINOR LOOP OVERRUN PM

42 14 INACTIVE. RESERVED FOR FUTURE USE. 70 13 ECU: SOFTWARE, ILLEGAL WRITE TO ADDRESS $0000 PM

42 15 INACTIVE. RESERVED FOR FUTURE USE. 70 14 ECU: SOFTWARE, MAJOR LOOP OVERRUN PM

42 16 INACTIVE. RESERVED FOR FUTURE USE.

42 21 INACTIVE. RESERVED FOR FUTURE USE.

42 22 INACTIVE. RESERVED FOR FUTURE USE.

42 23 INACTIVE. RESERVED FOR FUTURE USE. * CLEARING PROCEDURES

42 26 INACTIVE. RESERVED FOR FUTURE USE. P = NORMAL ECU POWERDOWN REQUIRED

M = MANUAL CLEARING AVAILABLE

44 12 INACTIVE. RESERVED FOR FUTURE USE. S = ECU SELF-CLEARING AVAILABLE

44 13 INACTIVE. RESERVED FOR FUTURE USE. CC = CODE CANNOT BE CLEARED

Figure D-3(b): CEC2 Diagnostic Codes 8000-Series Transmissions

CEC2 Controls Installation Manual - August 23, 2005 Page D-9

WIRE NUMBER / FUNCTION CROSS REFERENCE

Wire # Function Wire # Function

101 C Solenoid, Low 156 Throttle Position Sensor

102 Solenoid Supply (F,G,I) 157 Vehicle Speed

103 B Solenoid, Low 159 Diagnostic Com. Link (ISO9141)

104 A Solenoid, Low 161 Digital Ground (GPI)

105 General Purpose Output 162

107 Solenoid Supply (J for 5/6000; H for 8/9000) 163 General Purpose Input

110 Solenoid, Low (J for 5/6000; H for 8/9000) 164

111 I Solenoid, Low (for 8/9000 models only) 165

112 General Purpose Output 166 General Purpose Output

113 Reverse Warning 167 General Purpose Output

114 General Purpose Output 169 General Purpose Input

115 Check Transmission 170 Primary Shift Selector,Data Bit 1

116 Solenoid Supply (E) 171 Primary Shift Selector,Data Bit 2

117 General Purpose Input 172 Primary Shift Selector,Data Bit 4

118 General Purpose Input 173 Primary Shift Selector,Data Bit 8

119 General Purpose Input 174 Primary Shift Selector, Parity

120 F Solenoid, Low 175 Shift Selector Mode Input

121 Solenoid Supply (K) 176 General Purpose Output

123 Neutral Start 177 General Purpose Input

124 Throttle Sensor Power 178 General Purpose Input

125 General Purpose Output 179 (for future use)

126 General Purpose Input 180 Shift Selector Display

127 D Solenoid, Low 182 Can Controller Shield (J1939)

128 K Solenoid, Low 183 Can Controller, Hi (J1939)

129 E Solenoid, Low 184 Can Controller, Lo (J1939)

130 Solenoid Supply (A,B) 186 Dimmer Input A

131 G Solenoid, Low 187 Dimmer Input B

132 General Purpose Output 188 Dimmer Ground

135 Throttle Sensor Low / Sump Temp. Sensor Low 190 Secondary Shift Selector,Data Bit 1

136 Battery Power 191 Secondary Shift Selector,Data Bit 2

137 General Purpose Input 192 Secondary Shift Selector,Data Bit 4

138 193 Secondary Shift Selector,Data Bit 8

139 Output Speed Hi 194 Secondary Shift Selector, Parity

140 Turbine Speed Lo 195 (for future use)

141 Engine Speed Hi

142 Serial Commun. Interface, Hi

143 Battery Ground

146 Ignition Sense NOTE: For pin assignments and routing

147 Sump Temp Sensor Input of wires see System Schematic Drawing

148 Output Speed Lo AS00-166.

149 Turbine Speed Hi

150 Engine Speed Lo

151 Serial Commun. Interface, Lo

153 General Purpose Input

154 General Purpose Input

155 General Purpose Input

Figure D-4: Wire Number / Function Cross Reference

CEC2 Controls Installation Manual - August 23, 2005 Page D-10

REVISION HISTORY

AUGUST 23, 2005:

Updated format and added revision history. Updated references to diagnostics tools.

CEC2 Controls Installation Manual - August 23, 2005 Page D-11

S-ar putea să vă placă și

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDe la EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusÎncă nu există evaluări

- Allison Gen4 Diag CodesDocument21 paginiAllison Gen4 Diag CodesJeremiahÎncă nu există evaluări

- Transmission - C.E.C. 2: DescriptionDocument22 paginiTransmission - C.E.C. 2: DescriptionFaraz Electronic100% (2)

- Vehicle InterfaceDocument20 paginiVehicle InterfaceNgoc NguyenÎncă nu există evaluări

- Electronic ControlsDocument16 paginiElectronic ControlseefariasÎncă nu există evaluări

- Allison Trans PDFDocument748 paginiAllison Trans PDFoundilahmed100% (5)

- Allison Transmission 30004000 Series Fault Code List - Download PDF ManualDocument10 paginiAllison Transmission 30004000 Series Fault Code List - Download PDF ManualVladimirÎncă nu există evaluări

- D 350 eDocument2 paginiD 350 eMahmoud ElbakryÎncă nu există evaluări

- Body Builder Transmission InterfacesDocument5 paginiBody Builder Transmission InterfacesHamilton MirandaÎncă nu există evaluări

- Intelligent Plus: Installation ManualDocument54 paginiIntelligent Plus: Installation ManualAle LatroÎncă nu există evaluări

- Allison 1,000 & 2,000 Group 21Document4 paginiAllison 1,000 & 2,000 Group 21Robert WhooleyÎncă nu există evaluări

- Yamaha RX v459, DSP Ax459, HTR 5935, HTR 5940Document49 paginiYamaha RX v459, DSP Ax459, HTR 5935, HTR 5940Жанна Григорьева100% (2)

- AllisonDocument11 paginiAllisonpfe20100% (1)

- Electronic Control Module (ECM) : Shutdown SIS Previous ScreenDocument5 paginiElectronic Control Module (ECM) : Shutdown SIS Previous ScreenWladimir AmaguañaÎncă nu există evaluări

- Identification of SAE J1939 DatalinksDocument3 paginiIdentification of SAE J1939 DatalinksMuhammad SohailÎncă nu există evaluări

- Spectrum 375 MillerDocument36 paginiSpectrum 375 Millerluiz-simoesÎncă nu există evaluări

- Allison - Technical Documents 157 - Cooling Test - UpdateDocument29 paginiAllison - Technical Documents 157 - Cooling Test - Updateangie michell paccini rodriguezÎncă nu există evaluări

- 2014 Truck Products Catalogue (Usa)Document28 pagini2014 Truck Products Catalogue (Usa)Adolfo CisnerosÎncă nu există evaluări

- D-Series ADT (B35D-B50D) Mark 7.4 StageII-English (Broch15790614) WebDocument24 paginiD-Series ADT (B35D-B50D) Mark 7.4 StageII-English (Broch15790614) WebAlejandro Quiñonez100% (2)

- 735 Articulated Truck Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pagini735 Articulated Truck Electrical System: Electrical Schematic Symbols and DefinitionsNorman CoetzeeÎncă nu există evaluări

- Level 2 - TR100 SA Allison CEC2 020710Document83 paginiLevel 2 - TR100 SA Allison CEC2 020710Anonymous 340A7vnwV1100% (5)

- S2000 Ddec Iv 170708Document95 paginiS2000 Ddec Iv 170708Anonymous 340A7vnwV1100% (4)

- Ptos Allison PDFDocument65 paginiPtos Allison PDFnolascoÎncă nu există evaluări

- At22 MaintenanceDocument37 paginiAt22 MaintenancefabuleukalengaÎncă nu există evaluări

- ECM - No CommunicationDocument22 paginiECM - No CommunicationMohamed ZakiÎncă nu există evaluări

- 2-Operator Manual 293850858-CLT-700 PDFDocument35 pagini2-Operator Manual 293850858-CLT-700 PDFadvantage025Încă nu există evaluări

- Electric Protective System Wiring Diagrams: Component Abbreviations (REF 5N360)Document11 paginiElectric Protective System Wiring Diagrams: Component Abbreviations (REF 5N360)ali0% (1)

- Allison Transmission ECUDocument1 paginăAllison Transmission ECULouis Hardy50% (2)

- DrewLinQ User ManualDocument30 paginiDrewLinQ User Manualjose alvarezÎncă nu există evaluări

- Allison Transmission Oil Change IntervalDocument28 paginiAllison Transmission Oil Change IntervalJeremy Martin0% (1)

- Trouble Code List PDFDocument21 paginiTrouble Code List PDFTun Nay AungÎncă nu există evaluări

- TM 5 4210 227 24 and P 4 PDFDocument612 paginiTM 5 4210 227 24 and P 4 PDFLaura HawkinsÎncă nu există evaluări

- Deutsche GROVE Kessler Power Train: General Description: Transfer CaseDocument7 paginiDeutsche GROVE Kessler Power Train: General Description: Transfer CaseВиталий РогожинскийÎncă nu există evaluări

- 2011 Mad PogDocument81 pagini2011 Mad PogBruno Pilieci100% (1)

- 3000 and 4000 Product Familiy Transmission Mechanic's Tips - 4th Gen ControlsDocument128 pagini3000 and 4000 Product Familiy Transmission Mechanic's Tips - 4th Gen ControlsgaryvarnerÎncă nu există evaluări

- MX447 Parts Manual 2011 Update 1Document317 paginiMX447 Parts Manual 2011 Update 1Victor PinedoÎncă nu există evaluări

- L30030W Trailer Service Manual PLC, PLC-Plus, PLC-Select 6-03 Web-OnlyDocument99 paginiL30030W Trailer Service Manual PLC, PLC-Plus, PLC-Select 6-03 Web-Onlyenzo7259Încă nu există evaluări

- 2006 Trans Eng12Document19 pagini2006 Trans Eng12eurospeed2Încă nu există evaluări

- 5 Volt Boot Block Flash Memory: PreliminaryDocument44 pagini5 Volt Boot Block Flash Memory: PreliminaryMuhammedHanifÎncă nu există evaluări

- Sis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page PDFDocument46 paginiSis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page PDFMiguel GutierrezÎncă nu există evaluări

- Mechanic TipsDocument76 paginiMechanic TipsDaniel FordÎncă nu există evaluări

- Allison Presentation For Bus SeriesDocument22 paginiAllison Presentation For Bus SeriesnikodjoleÎncă nu există evaluări

- 180 Ton LTM 1160-1 LiebherrDocument13 pagini180 Ton LTM 1160-1 Liebherrcornel_lupuÎncă nu există evaluări

- 3566 HorDocument16 pagini3566 HorSaid TouhamiÎncă nu există evaluări

- 2005 22-TR-05 Rev A TCM TRBSHTNG 4 Gen PDFDocument4 pagini2005 22-TR-05 Rev A TCM TRBSHTNG 4 Gen PDFJuan Carlos Gaytan LopezÎncă nu există evaluări

- Allison Tran ManualDocument94 paginiAllison Tran Manualalex3158100% (1)

- Freightliner - S2 Chassis Maintenance ManualDocument91 paginiFreightliner - S2 Chassis Maintenance ManualEdwin Alfonso Hernandez MontesÎncă nu există evaluări

- SingleLine General Manual GRASERADocument40 paginiSingleLine General Manual GRASERAYoseth Jose Vasquez Parra67% (3)

- Allison WTEC III OM2995EN PDFDocument68 paginiAllison WTEC III OM2995EN PDFHarrier Technologies100% (2)

- Manual Transimision Automatica FerraraDocument296 paginiManual Transimision Automatica Ferraramark_59Încă nu există evaluări

- Manual CR0403Document306 paginiManual CR0403giusssy100% (1)

- ServiceInfo15-WT-05 Rev ADocument38 paginiServiceInfo15-WT-05 Rev AhoiÎncă nu există evaluări

- Webasto Evo Troubleshooting GuideDocument69 paginiWebasto Evo Troubleshooting GuideMišo Vučko50% (2)

- Allison Prognostics BodygearsDocument4 paginiAllison Prognostics Bodygearsrbrto100% (1)

- Allison 6600 PDFDocument2 paginiAllison 6600 PDFJulian Felipe Noguera CruzÎncă nu există evaluări

- OC442012e FN72-00 (F2000) SPECIFICATIONS 11-00Document7 paginiOC442012e FN72-00 (F2000) SPECIFICATIONS 11-00profistarÎncă nu există evaluări

- Product Families: Mechanic'S TipsDocument77 paginiProduct Families: Mechanic'S TipsJuan VelizÎncă nu există evaluări

- Illustration 1 Schematic of The Circuit For The Shift LeverDocument8 paginiIllustration 1 Schematic of The Circuit For The Shift Leverlahcen boudaoudÎncă nu există evaluări

- Section I: Shift Controls: Allison Off-Highway Transmission ModelsDocument8 paginiSection I: Shift Controls: Allison Off-Highway Transmission Modelsamin chaabenÎncă nu există evaluări

- 3.TGS LeverDocument18 pagini3.TGS Leveralex generalÎncă nu există evaluări

- RexrothDocument14 paginiRexrothWilson CendalesÎncă nu există evaluări

- Rexroth Pilot Air Valves PDFDocument33 paginiRexroth Pilot Air Valves PDFWilson Cendales100% (1)

- Installation and Maintenance Instructions Standard Ventilated Clutch Model SVDocument4 paginiInstallation and Maintenance Instructions Standard Ventilated Clutch Model SVWilson CendalesÎncă nu există evaluări

- Chain SpecsDocument12 paginiChain SpecsWilson CendalesÎncă nu există evaluări

- SV - Standard Ventilated Clutch: Description Air SetsDocument2 paginiSV - Standard Ventilated Clutch: Description Air SetsWilson CendalesÎncă nu există evaluări

- MODEL 2542 Pressure Control Head - Single Output: Ordering Information Model DesignationsDocument2 paginiMODEL 2542 Pressure Control Head - Single Output: Ordering Information Model DesignationsWilson CendalesÎncă nu există evaluări

- A 10 VoDocument44 paginiA 10 VoEliasd100% (7)

- 0710170Document4 pagini0710170Amanda FitzgeraldÎncă nu există evaluări

- CR191135 - E - Spare PartsDocument109 paginiCR191135 - E - Spare PartsWilson Cendales100% (2)

- Especificaciones Tecnicas Um189030 - e PDFDocument136 paginiEspecificaciones Tecnicas Um189030 - e PDFWilson CendalesÎncă nu există evaluări

- V80838 Murphy PowerView Wiring DiagramsDocument2 paginiV80838 Murphy PowerView Wiring DiagramsPaulPaucarCampos100% (1)

- Calibration & Functional Test - HH102-PTWDocument10 paginiCalibration & Functional Test - HH102-PTWWilson CendalesÎncă nu există evaluări

- Barco BJ PDFDocument9 paginiBarco BJ PDFJose CamachoÎncă nu există evaluări

- 9fa2b PDFDocument73 pagini9fa2b PDFWilson CendalesÎncă nu există evaluări

- RexrothDocument14 paginiRexrothWilson CendalesÎncă nu există evaluări

- 9fa2b PDFDocument73 pagini9fa2b PDFWilson CendalesÎncă nu există evaluări

- C300torque Convert PDFDocument11 paginiC300torque Convert PDFWilson Cendales0% (1)

- NSK CAT Design (Rolling Bearing)Document279 paginiNSK CAT Design (Rolling Bearing)gainÎncă nu există evaluări

- Bendix Brake Handbook 2009Document70 paginiBendix Brake Handbook 2009tornoman100% (1)

- Drilling Mud D-GasserDocument12 paginiDrilling Mud D-GasserWilson CendalesÎncă nu există evaluări

- Catalogo Timken PDFDocument148 paginiCatalogo Timken PDFWilson CendalesÎncă nu există evaluări

- Bendix® AD-IS® Air Dryer and Reservoir SystemDocument16 paginiBendix® AD-IS® Air Dryer and Reservoir Systemjgomez30100% (2)

- William Controls PDFDocument252 paginiWilliam Controls PDFWilson CendalesÎncă nu există evaluări

- Chelsea 852 Lista de PartesDocument12 paginiChelsea 852 Lista de PartesImpulsando Consultorio PsicopedagogicoÎncă nu există evaluări

- 5020 A - Product Spec Sheet (2013) PDFDocument2 pagini5020 A - Product Spec Sheet (2013) PDFWilson CendalesÎncă nu există evaluări

- Kobelt Tabla de EspecificacionesDocument43 paginiKobelt Tabla de EspecificacionesWilson CendalesÎncă nu există evaluări

- Chain SpecsDocument12 paginiChain SpecsWilson CendalesÎncă nu există evaluări

- SV - Standard Ventilated Clutch: Description Air SetsDocument2 paginiSV - Standard Ventilated Clutch: Description Air SetsWilson CendalesÎncă nu există evaluări

- 5020 A - Product Spec Sheet (2013)Document2 pagini5020 A - Product Spec Sheet (2013)Wilson CendalesÎncă nu există evaluări

- Catalogo Llave de VarillaDocument38 paginiCatalogo Llave de VarillaWilson Cendales100% (1)

- Detection of Mastitis and Lameness in Dairy Cows UsingDocument10 paginiDetection of Mastitis and Lameness in Dairy Cows UsingKalpak ShahaneÎncă nu există evaluări

- C++ - Difference Between A Virtual Function and A Pure Virtual Function - Stack OverflowDocument2 paginiC++ - Difference Between A Virtual Function and A Pure Virtual Function - Stack OverflowNeli MkhatshwaÎncă nu există evaluări

- Preliminary Wing Design Parameter Selection Rev 3 PDFDocument8 paginiPreliminary Wing Design Parameter Selection Rev 3 PDFvirgilioÎncă nu există evaluări

- Hach 8021 Cloro Residual Ed 09Document8 paginiHach 8021 Cloro Residual Ed 09Beth AlvaradoÎncă nu există evaluări

- Final PPT of Carbon NanotubesDocument29 paginiFinal PPT of Carbon Nanotubesmkumar_5481450% (2)

- Sudhanshu Kumar: ResumeDocument3 paginiSudhanshu Kumar: ResumePradeepÎncă nu există evaluări

- Nitrosyl Complexes of RutheniumDocument26 paginiNitrosyl Complexes of RutheniumBenjamín Marc Ridgway de SassouÎncă nu există evaluări

- Lasal: Laser Cutting SolutionsDocument4 paginiLasal: Laser Cutting SolutionsGeorge ZiovasÎncă nu există evaluări

- 1520 0477 Bams D 22 0164.1Document22 pagini1520 0477 Bams D 22 0164.1Slobodna DalmacijaÎncă nu există evaluări

- Audi A6 2.7t Component LocationDocument3 paginiAudi A6 2.7t Component LocationLucian MicurescuÎncă nu există evaluări

- AndroidDocument61 paginiAndroidNamithaÎncă nu există evaluări

- RBH AxiomV Catalog v2011Document16 paginiRBH AxiomV Catalog v2011Sundar RamasamyÎncă nu există evaluări

- GOC & EAS CPP-II - PMDDocument14 paginiGOC & EAS CPP-II - PMDVansh sareenÎncă nu există evaluări

- ASC - Chap 1-3 - v2013Document13 paginiASC - Chap 1-3 - v2013Tu vu vanÎncă nu există evaluări

- First Quarter Summative Test in Math 7Document2 paginiFirst Quarter Summative Test in Math 7Lemanuel097 FloresÎncă nu există evaluări

- Economics 101: Interactive BrokersDocument11 paginiEconomics 101: Interactive BrokersDennys FreireÎncă nu există evaluări

- GCSE Higher Student Book Unit Test AnswersDocument26 paginiGCSE Higher Student Book Unit Test Answersswiftmessi100% (5)

- Cooling Water Sump Model Studies Through CFD AnalysisDocument6 paginiCooling Water Sump Model Studies Through CFD AnalysisvijayasarathiÎncă nu există evaluări

- 9.coordination CompoundsDocument46 pagini9.coordination CompoundsSeenu MÎncă nu există evaluări

- Operational AmplifiersDocument35 paginiOperational AmplifierskunwarÎncă nu există evaluări

- Mongo DB Basic CommandsDocument15 paginiMongo DB Basic CommandsgauriÎncă nu există evaluări

- Shell & DecksDocument63 paginiShell & DecksParth GoswamiÎncă nu există evaluări

- Heat Treatment: Unit - IiDocument8 paginiHeat Treatment: Unit - IiParameswara RajaÎncă nu există evaluări

- Chem 105 Lab Manual 08 EKIM 1Document42 paginiChem 105 Lab Manual 08 EKIM 1hooraÎncă nu există evaluări

- ASAM XIL Release-Presentation V2-2-0Document34 paginiASAM XIL Release-Presentation V2-2-0Arsalan KhanÎncă nu există evaluări

- REVIEW TASK 1 - Capitalization, Punctuation, Fragments, Run-On Sentences and Subject & Verb Agreement Review (-1Document2 paginiREVIEW TASK 1 - Capitalization, Punctuation, Fragments, Run-On Sentences and Subject & Verb Agreement Review (-1Johao DoradoÎncă nu există evaluări

- Modeling COVID-19 Epidemics in An Excel SpreadsheeDocument15 paginiModeling COVID-19 Epidemics in An Excel SpreadsheeMagesha kumarÎncă nu există evaluări

- Maths - 2B Imp QuestionsDocument93 paginiMaths - 2B Imp QuestionsBandaru Chiranjeevi100% (1)

- Software Engineering 2Document9 paginiSoftware Engineering 2ch muneeb0% (1)

- ISCSI OptimizationDocument28 paginiISCSI OptimizationrahulhclÎncă nu există evaluări