Documente Academic

Documente Profesional

Documente Cultură

Design of Ipe360

Încărcat de

HaymanAHMEDDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design of Ipe360

Încărcat de

HaymanAHMEDDrepturi de autor:

Formate disponibile

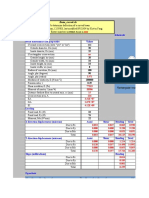

E. B. NALDOZA Engineering Design Project Irish Cement Ltd. - Kiln 3 Ref. No.

Registered in Dublin, Ireland (with Branch Office in Cement Mill-Silos Structure PB9729

Cavite, Philippines) Subject Design of Steel Beam at EL 56.40

Eddie Naldoza, BSc MIES MPICE Beam No. 192-195, 47

E: eddienaldoza@engineer.com Calculated Checked Date Page

W: www.eddienaldoza.com E. Naldoza E. Naldoza 26/09/07 of 3

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216 Gridlines : 6 / C-E Limited to Plastic Section & Major Axis Bending only)

(Developed by: Eddie Naldoza, BSc MIES MPICE www.eddienaldoza.com)

Code / 1. Loadings : (Ultimate Loads)

Clause Maximum Moment, Mx = kN-m Point Load, P = 0 kN

BS5950 Maximum Shear at Support,Fv = kN Distance of point load from nearer support, ae = 2 mm

Part 1 : Total Span, L = 6100 mm Maximum Shear at Point Load

2000 / Load factor for Imposed Loads, fi = 1.5 or at Point of Maximum Moment, Fvc = 89 kN

2. Member Checks :

2.1 Trial Section : 356x171x67 UB Steel Grade = S 355

From Member Capacity Tables (Blue Book)

Moment Capacity, Mc = 300.00 kN-m

2.2 Section Properties :

D = 363.4 mm b = 86.6 mm r = 10.20 mm Local Buckling Ratios :

B = 173.20 mm d = 311.60 mm E = 2.05E+05 N/mm 2

b/T = 5.52

t = 9.10 mm Sx = 1211 cm3 Ix = 19460 cm4 d/t = 34.20

T = 15.70 mm Zx = 1071 cm3 ry = 39.9 mm

x = 24.4

2.3 Section Classification :

3.1.1 T < 16 mm 275 275

= = = 0.88 (3.5.2-Table 11 b )

Table 9 Therefore; py = 355 N/mm2 py 355

3.5.2 For Rolled Section; Outstand Element of Compression Flange -

Table 11 For Flange : = x 0.9 = 7.9 ; Actual b/T = 5.52 < 7.9

= ###

b/T ### Flange is Class 1 Plastic

Web of an I-, H- or Box Section; Neutral Axis at Mid-depth -

For Web : d/t = 80 = 80 x 0.9 = 70.4 ; Actual d/t = 34.20 < 70.4 Web is Class 1 Plastic

Therefore : Section is Class 1 Plastic

4.2.3 2.4 Check For Shear Buckling if : d/t > 70

70 = 70 x 0.88 = 61.6 ; Actual d/t = 34.20 < 61.6

No need to check for Shear Buckling

4.2.3 2.5 Check For Shear Capacity : Fv or Fvc Pv

py = 355 N/mm2 ; Av = t D = 9.1 x 363.4 = 3306.94 mm2

Pv = 0.6 py Av ; Pv = 0.6 x 355 N/mm2 x 3306.9 mm2 = 704378 N 704 kN > 88.8 kN

; Adequate for Shear

4.2.5 2.6 Check For Moment Capacity : Mx Mcx

4.2.5.2/

4.2.5.3

Check for High/Low Shear (at point of Maximum Moment, Fvm)

Shear at point of Maximum Moment ; Fvc = 89 kN

Limiting Shear, Fve = 0.60 x Pv = 0.60 x 704 kN = 423 kN > 88.8 kN

Low Shear

For Low Shear (for Class 1 Plastic or Class 2 Compact cross-sections)

Mcx = py Sx = 355 N/mm x 1211 cm = 429.9 kN-m > 0.0 kN-m ; Adequate for Flexure

4.2.5.1 2.7 Check Limit To Avoid Irreversible Deformation Under Serviceability Loads :

For simply supported beam : Mcx 1.2 py Zx

Mcx = 1.2 x 355 N/mm x 1071 cm3

2

429.9 < 456.25 kN-m ; Adequate for Flexure

E. B. NALDOZA Engineering Design Project Irish Cement Ltd. - Kiln 3 Ref. No.

Registered in Dublin, Ireland (with Branch Office in Cement Mill-Silos Structure PB9729

Cavite, Philippines) Subject Design of Steel Beam at EL 56.40

Eddie Naldoza, BSc MIES MPICE Beam No. 192-195, 47

E: eddienaldoza@engineer.com Calculated Checked Date Page

W: www.eddienaldoza.com E. Naldoza E. Naldoza 26/09/07 of 3

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216 Gridlines : 6 / C-E Limited to Plastic Section & Major Axis Bending only)

(Developed by: Eddie Naldoza, BSc MIES MPICE www.eddienaldoza.com)

E. B. NALDOZA Engineering Design Project Irish Cement Ltd. - Kiln 3 Ref. No.

Registered in Dublin, Ireland (with Branch Office in Cement Mill-Silos Structure PB9729

Cavite, Philippines) Subject Design of Steel Beam at EL 56.40

Eddie Naldoza, BSc MIES MPICE Beam No. 192-195, 47

E: eddienaldoza@engineer.com Calculated Checked Date Page

W: www.eddienaldoza.com E. Naldoza E. Naldoza 26/09/07 of 3

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216 Gridlines : 6 / C-E Limited to Plastic Section & Major Axis Bending only)

(Developed by: Eddie Naldoza, BSc MIES MPICE www.eddienaldoza.com)

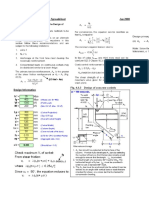

Part 1 : 2.8 Web Bearing and Buckling Under the Point Load :

2000 / 2.8.1 Bearing capacity of the unstiffened web : P Pbw ; Pbw = (b1 + nk) t pyw ; pyw = 355 N/mm2

4.5.2.1 b1 = t + 1.6r + 2T

= 56.8 mm ; n ###

= (not at the end of the member) ; k = T+r = 25.9 mm

Pbw = [ 56.8 + ###

( x 25.9 ) ] 9.1 x 355 = 601.91 kN > 0 kN

; Therefore Bearing Capacity of the unstiffened web under the point load is adequate

4.5.3.1 2.8.2 Buckling resistance of the unstiffened web : P Px ;

Check if ; ae 0.7d ; ae is the distance from the load to the nearer end of the member = 2 mm

1.53 0.7 x 311.60 ; 2 < 218.1 mm ; Therefore

ae + 0.7d 25 T 25 x 0.9 x 15.7 x 601.9 1.53 + 218.1

Px= x Pbw ; Px= x

1.4 d 1 + nk) d

(b ( 57 ###+ x 25.9 ) x 311.60 1.40 x 311.60

Px = 862.96 kN x 0.50 x 434.5 kN

> 0 kN

; Therefore Buckling Resistance of the unstiffened web under the point load is adequate

2.9 Web Bearing and Buckling at the Support :

4.5.2.1 2.9.1 Bearing capacity of the unstiffened web : Fv Pbw ; Pbw = (b1 + nk) t pyw ; pyw = 355 N/mm2

b1 = t + T + 0.8r - g

= 9.1 + 15.7 + 0.8 x 10.2 - 10 = 22.96 mm (properties of the supporting element )

n = 2 + 0.6be/k###

; be is the distance to the nearer end of the member from the end of the stiff bearing = 0 mm

n ###

= + 0.6 x 0 / 25.9 = 2.0 ### < ; Therefore use n = 2.0 ; k = T+r = 54.1 + 30.0 = 84.1 mm

Pbw = [ 23.0 + ( 2.0 x 25.9 ) ] 9.1 x 355 = 241.5 kN > 0.0 kN

; Therefore Bearing Capacity of the unstiffened web at the support is adequate

4.5.3.1 2.9.2 Buckling resistance of the unstiffened web : Fv Px ;

Check if ; ae 0.7d ; ae is the distance from the reaction to the nearer end of the member = 25 mm

25 0.7 x 311.60 ; 25 < 218.1 mm ; Therefore

ae + 0.7d 25 T 25 x 0.9 x 15.7 x 241.5 25 + 218.1

Px= x Pbw ; Px= x

1.4 d (b1 + nk) d ( 23.0 ### + x 84.1 ) x 311.60 1.40 x 311.60

Px = 341.85 kN x 0.56 = 190.5 kN

> 0.0 kN

; Therefore Buckling Resistance of the unstiffened web at the support is adequate

2.5.2 2.10 Serviceabilty Limit States : Deflection Check

The serviceability Loads are taken as unfactored imposed loads. In this case, as only ultimate loads are the available data,

the unfactored imposed loads will be taken as Mc or P / f i conservatively, for simplicity; fi to be the load factor = 1.5

From Maximum Moment, Mc; wi = Unfactored Distributed Load

wi Le2 8 Mc ### x 0 kN-m

Mc = 1.5 ; wi = = = 0.0 kN/m

8 1.5 Le2

1.5 x 6.1 ###

m

From Point Load P; W i = Unfactored Point Load Limits for calculated deflection (2.5.2 Table 8)

P = 1.5 W i ; P 0.0 for : Other Beams (except purlins and sheeting

Wi = = = 0 kN

1.5 1.5 rails)

The total deflection is given by: Allowable deflection, a

### wi Le4 Le 6100

= a = = = 30.50 mm

384 E I 200 200

### x 0.0 x 6.1

### Therefore : 356x171x67 UB

=

384 x 2.E+05 x 19460 is Adequate, Adopt Section

; Adequate for deflection

= 0.000 mm < 30.50 mm

E. B. NALDOZA Engineering Design Project Irish Cement Ltd. - Kiln 3 Ref. No.

Registered in Dublin, Ireland (with Branch Office in Cement Mill-Silos Structure PB9729

Cavite, Philippines) Subject Design of Steel Beam at EL 56.40

Eddie Naldoza, BSc MIES MPICE Beam No. 192-195, 47

E: eddienaldoza@engineer.com Calculated Checked Date Page

W: www.eddienaldoza.com E. Naldoza E. Naldoza 26/09/07 of 3

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216 Gridlines : 6 / C-E Limited to Plastic Section & Major Axis Bending only)

; Adequate

(Developed by: Eddie Naldoza, BSc MIES MPICE for deflection

www.eddienaldoza.com)

= 0.000 mm < 30.50 mm

E. B. NALDOZA Engineering Design Project Irish Cement Ltd. - Kiln 3 Ref. No.

Registered in Dublin, Ireland (with Branch Office in Cement Mill-Silos Structure PB9729

Cavite, Philippines) Subject Design of Steel Beam at EL 56.40

Eddie Naldoza, BSc MIES MPICE Beam No. 192-195, 47

E: eddienaldoza@engineer.com Calculated Checked Date Page

W: www.eddienaldoza.com E. Naldoza E. Naldoza 26/09/07 of 3

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216 Gridlines : 6 / C-E Limited to Plastic Section & Major Axis Bending only)

(Developed by: Eddie Naldoza, BSc MIES MPICE www.eddienaldoza.com)

4.3.0 2.11 Lateral Torsional Buckling : Mx Mb/mLT ;

Maximum Major axis Moment Effective Length of the segment, LE = 700 mm

in the segment, Mx = 2 kN-m

4.3.6.7 =LE/ry = 700 / 39.9 = 17.5 ; /x = 17.5 / 24.4 = 0.7 ; = 0.5 (Equal flange) ; v = 0.99 (Table 19)

4.3.6.8 u = 0.9 (for Rolled I of Equal flange-4.3.6.8) ; W = 1.0 (for Class 1 Plastic or Class 2 Compact Sections-4.3.6.9)

Equivalent Slenderness ; LT = uvw ; Limiting equivalent slenderness ; LO = 0.4(E/py)0.5

LT = 0.9 x 0.99 x 17.5 x 1.0 = 16 LO = 0.4 x ( x 2.05E+05 / 355 )0.5 = 30.20

B.2.2 Perry factor & Robertson constant ; LT = aLT(LT-LO)/1000 ; aLT = 7.0

LT = 7.0 x ( 16 - 30.20 )/ 1000 = -0.1

B.2.1 pE = E/LT2 py+(LT+1)pE 355 + ( -0.1 ###

+ ) 8236

; LT = = = 3877

= x 2.05E+05 / 16 2

= 8236 ### ###

pE py 8236 x 355

Bending Strength, pb = = = 397 N/mm2

LT+(LT2-pE py) 0.5

3877 + ( 3877 2

- 8236 x 355 ) 0.5

4.3.6.4 Buckling Resistance Moment; Mb = pb Sx = 397 x 1211000 = 481.32 kN-m

Uniform Moment Factor for Lateral Torsional Buckling (General case); mLT

Moments at quarter points Moments at mid point

M2 = 2 kN-m M3 = 2 kN-m

M4 = 2 kN-m

Table 18 0.15M2+0.5M3+0.15M4 0.15 x 2 + 0.50 x 2 + 0.15 x 2

mLT = 0.2 + = 0.2 + = 1.00

Mx 2

4.3.6.2 Mb 481.32 ; Therefore Buckling Resistance

= = 481 kN-m > 2 kN-m

mLT 1.00 Moment is Adequate

E. B. NALDOZA Engineering Design Project Irish Cement Ltd. - Kiln 3 Ref. No.

Registered in Dublin, Ireland (with Branch Office in Cement Mill-Silos Structure PB9729

Cavite, Philippines) Subject Design of Steel Beam at EL 56.40

Eddie Naldoza, BSc MIES MPICE Beam No. 192-195, 47

E: eddienaldoza@engineer.com Calculated Checked Date Page

W: www.eddienaldoza.com E. Naldoza E. Naldoza 26/09/07 of 3

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216 Gridlines : 6 / C-E Limited to Plastic Section & Major Axis Bending only)

(Developed by: Eddie Naldoza, BSc MIES MPICE www.eddienaldoza.com)

S-ar putea să vă placă și

- RAFTER-COLUMN CONNECTION DESIGNDocument6 paginiRAFTER-COLUMN CONNECTION DESIGNpriantomoÎncă nu există evaluări

- Base PlateDocument13 paginiBase PlateNaga Manikanta TatikondaÎncă nu există evaluări

- Seated ConnectionDocument5 paginiSeated ConnectionMcsSelvaÎncă nu există evaluări

- Sample DBR With MonoslopeDocument27 paginiSample DBR With MonoslopeNitish TakalkarÎncă nu există evaluări

- SL - No Description Reference 1 Load Input For Silo (7M X 7M) 1.1 Basic InputDocument8 paginiSL - No Description Reference 1 Load Input For Silo (7M X 7M) 1.1 Basic Inputkushaljp8989Încă nu există evaluări

- IS800_2007_Tube Design CalculationDocument4 paginiIS800_2007_Tube Design CalculationLandon MitchellÎncă nu există evaluări

- Base Plate Dan Anchor Bolt Calculation: Connection DesignDocument21 paginiBase Plate Dan Anchor Bolt Calculation: Connection DesignSurya FahmiÎncă nu există evaluări

- 4 stiffened-WH500X400X12X25-WH500X400X12X25Document7 pagini4 stiffened-WH500X400X12X25-WH500X400X12X25phanikrishnabÎncă nu există evaluări

- BASE EN GaDocument95 paginiBASE EN Ganitin400100% (2)

- DESIGN OF BASE PLATE AND ANCHOR BOLTSDocument5 paginiDESIGN OF BASE PLATE AND ANCHOR BOLTSRajasekar MeghanadhÎncă nu există evaluări

- Bolt Design (Blodget)Document4 paginiBolt Design (Blodget)mayureshÎncă nu există evaluări

- Design of Moment and Shear ConnectionDocument4 paginiDesign of Moment and Shear ConnectionAndro RebuyasÎncă nu există evaluări

- Pedestal DesignDocument2 paginiPedestal DesignRamadanÎncă nu există evaluări

- STRENGTH CALCULATION: Decking Profile 51mm/961mm: Safe Safe SafeDocument5 paginiSTRENGTH CALCULATION: Decking Profile 51mm/961mm: Safe Safe SafePratyayaParija100% (2)

- Chequred PlateDocument2 paginiChequred PlateKumar Prasanna HNÎncă nu există evaluări

- Structural Steelwork ConnectionsDocument4 paginiStructural Steelwork Connectionstheunknown076Încă nu există evaluări

- For Battened Columns For Strength Cal 10% Increase in The KL/RDocument4 paginiFor Battened Columns For Strength Cal 10% Increase in The KL/RvineetukÎncă nu există evaluări

- Steel Connection Design Workbook DisclaimerDocument49 paginiSteel Connection Design Workbook Disclaimergissel vicencioÎncă nu există evaluări

- Entrance B: 1008 72 CHS 559x25 (S355) 80.64 1314 72 CHS 610x28 (S355) 105.12Document2 paginiEntrance B: 1008 72 CHS 559x25 (S355) 80.64 1314 72 CHS 610x28 (S355) 105.12suman_civilÎncă nu există evaluări

- "Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesDocument16 pagini"Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesArdXkillerÎncă nu există evaluări

- Wind PDFDocument24 paginiWind PDFnagarajhebbarÎncă nu există evaluări

- Bolt Group DesignDocument4 paginiBolt Group Designezarul fitriÎncă nu există evaluări

- AISC Connection 2nd Edition (4+2) Bolts Knee No UseDocument6 paginiAISC Connection 2nd Edition (4+2) Bolts Knee No UseTuấnThanhÎncă nu există evaluări

- Schematic Beam Dimensions and Properties ValuesDocument4 paginiSchematic Beam Dimensions and Properties ValuesFredy Campos FloresÎncă nu există evaluări

- Moment ConnectionDocument7 paginiMoment Connectionkashyap_structuralÎncă nu există evaluări

- Building - B: Vertical Haunch Conn Along Line-A & B: Mark:-NONEDocument18 paginiBuilding - B: Vertical Haunch Conn Along Line-A & B: Mark:-NONEmaheshbandhamÎncă nu există evaluări

- Design of doubly reinforced beam LRFDDocument6 paginiDesign of doubly reinforced beam LRFDUsman AfzalÎncă nu există evaluări

- RC Beam - CantileverDocument2 paginiRC Beam - CantilevermayphyoÎncă nu există evaluări

- BeamDocument42 paginiBeamlavyÎncă nu există evaluări

- Seismic AnalysisDocument34 paginiSeismic AnalysisCarla OrbetaÎncă nu există evaluări

- Short Term Deflection: CK y ST SC C SDocument6 paginiShort Term Deflection: CK y ST SC C SAnkit SuriÎncă nu există evaluări

- Design of rigid connection detail 85Document215 paginiDesign of rigid connection detail 85Umer AziqÎncă nu există evaluări

- Base Plate Connection DesignDocument4 paginiBase Plate Connection DesignAnonymous 1HFV185Sl4Încă nu există evaluări

- Beam To Column End Plate ConnectionDocument10 paginiBeam To Column End Plate ConnectionParchuri PraveenÎncă nu există evaluări

- Moment ConnectionsDocument16 paginiMoment Connectionsankit kadam0% (1)

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 paginiR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkÎncă nu există evaluări

- Splice Design - LRFDDocument22 paginiSplice Design - LRFDkalpanaadhiÎncă nu există evaluări

- Stiffner Design For Beam Column ConnectionsDocument84 paginiStiffner Design For Beam Column ConnectionsfabnameÎncă nu există evaluări

- Anchor Bolt Design Per IS LSMDocument6 paginiAnchor Bolt Design Per IS LSMdebjyoti_das_6Încă nu există evaluări

- Connection Design-VijayDocument278 paginiConnection Design-VijayPrabhumk07Încă nu există evaluări

- Vulnerability Factors Checklist for Building TypesDocument8 paginiVulnerability Factors Checklist for Building TypesPrakash SIngh RawalÎncă nu există evaluări

- Star Column Coordinates For StaadDocument5 paginiStar Column Coordinates For StaadShriniwas NaikÎncă nu există evaluări

- Bolted Moment Connection 2x2Document22 paginiBolted Moment Connection 2x2Немања КараклајићÎncă nu există evaluări

- Fin Plate To Column Flange - LRFDDocument23 paginiFin Plate To Column Flange - LRFDkalpanaadhiÎncă nu există evaluări

- CRACK WIDTH CHECKDocument9 paginiCRACK WIDTH CHECKSaugat ThapaÎncă nu există evaluări

- Steel Cap Plate Connections DesignDocument18 paginiSteel Cap Plate Connections DesignVinoth KumarÎncă nu există evaluări

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDocument4 paginiShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalÎncă nu există evaluări

- Circular WeldDocument12 paginiCircular WeldJohn Paul UmaliÎncă nu există evaluări

- Est SHTDocument26 paginiEst SHTselvakumarÎncă nu există evaluări

- 2 ConnectionDocument18 pagini2 Connectionssikha100% (1)

- Design Criteria/Design Check For Star Deck Sheet (44/130)Document2 paginiDesign Criteria/Design Check For Star Deck Sheet (44/130)Advanced Structural EngineeringÎncă nu există evaluări

- Baseplate MonorailDocument31 paginiBaseplate Monorailmohamad chandraÎncă nu există evaluări

- Design Data: Design For Base Plate (Fixed)Document4 paginiDesign Data: Design For Base Plate (Fixed)Wibawa WorksÎncă nu există evaluări

- Cantilever Slab Design: (Based On BS8110:2000-Part1)Document2 paginiCantilever Slab Design: (Based On BS8110:2000-Part1)mayphyoÎncă nu există evaluări

- Welded Splice Connection-R2Document33 paginiWelded Splice Connection-R2Anonymous cG5MyHM100% (1)

- Beam Design With Crackwidth CalculationDocument16 paginiBeam Design With Crackwidth CalculationFazilat Mohammad ZaidiÎncă nu există evaluări

- Beam Sample DESIGNDocument11 paginiBeam Sample DESIGNPampha MoktanÎncă nu există evaluări

- Design of Steel I-Section (BS5950)Document6 paginiDesign of Steel I-Section (BS5950)Rachelle C. Abanes50% (4)

- Design of Steel I Section BS5950Document6 paginiDesign of Steel I Section BS5950amachmouchi100% (1)

- Design of Steel I-Section (BS5950)Document3 paginiDesign of Steel I-Section (BS5950)gertjaniÎncă nu există evaluări

- Pile Driving Set Calculator R 20130Document1 paginăPile Driving Set Calculator R 20130Haffizul SaidÎncă nu există evaluări

- Two Pile GroupDocument12 paginiTwo Pile GroupJammy KingÎncă nu există evaluări

- Sheet Pile Anchor Rod Case1 - Edit2Document1 paginăSheet Pile Anchor Rod Case1 - Edit2Haffizul SaidÎncă nu există evaluări

- Load Test On SoilDocument52 paginiLoad Test On SoilHaffizul Said100% (1)

- Moment and Shear FormulaDocument2 paginiMoment and Shear FormulaHaffizul SaidÎncă nu există evaluări

- Drainage Technician's Handbook Provides Guidance on Road Drainage DesignDocument51 paginiDrainage Technician's Handbook Provides Guidance on Road Drainage DesignRusdee KamisÎncă nu există evaluări

- Standard Form of Contract NoteDocument24 paginiStandard Form of Contract NoteHaffizul SaidÎncă nu există evaluări

- Design of A Shallow FoundationDocument9 paginiDesign of A Shallow FoundationHaffizul SaidÎncă nu există evaluări

- Non-Destructive Testing Methods Determine Concrete StrengthDocument9 paginiNon-Destructive Testing Methods Determine Concrete StrengthHaffizul SaidÎncă nu există evaluări

- Moment and Shear FormulaDocument2 paginiMoment and Shear FormulaHaffizul SaidÎncă nu există evaluări

- Circular Piles Load AnalysisDocument1 paginăCircular Piles Load AnalysisHaffizul SaidÎncă nu există evaluări

- Moment and Shear FormulaDocument2 paginiMoment and Shear FormulaHaffizul SaidÎncă nu există evaluări

- Pile Ecc CheckDocument1 paginăPile Ecc CheckHaffizul SaidÎncă nu există evaluări

- Pile Ecc Check PDFDocument1 paginăPile Ecc Check PDFHaffizul SaidÎncă nu există evaluări

- Beam Deflection CheckDocument1 paginăBeam Deflection CheckHaffizul SaidÎncă nu există evaluări

- Precast Corbel Design SpreadsheetDocument6 paginiPrecast Corbel Design SpreadsheetHaffizul SaidÎncă nu există evaluări

- SYABAS Pressure Test and Leakage Test PDFDocument1 paginăSYABAS Pressure Test and Leakage Test PDFHaffizul SaidÎncă nu există evaluări

- SYABAS Pressure Test and Leakage TestDocument1 paginăSYABAS Pressure Test and Leakage TestHaffizul SaidÎncă nu există evaluări

- Pile Ecc CheckDocument1 paginăPile Ecc CheckHaffizul SaidÎncă nu există evaluări

- Beam Deflection CheckDocument1 paginăBeam Deflection CheckHaffizul SaidÎncă nu există evaluări

- Pile Ecc CheckDocument1 paginăPile Ecc CheckHaffizul SaidÎncă nu există evaluări

- Finding My Voice in ChinatownDocument5 paginiFinding My Voice in ChinatownMagalí MainumbyÎncă nu există evaluări

- 341SAM Ethical Leadership - Alibaba FinalDocument16 pagini341SAM Ethical Leadership - Alibaba FinalPhoebe CaoÎncă nu există evaluări

- Financial Reporting Statement Analysis Project Report: Name of The Company: Tata SteelDocument35 paginiFinancial Reporting Statement Analysis Project Report: Name of The Company: Tata SteelRagava KarthiÎncă nu există evaluări

- Semi Detailed Lesson Plan ElementaryDocument3 paginiSemi Detailed Lesson Plan ElementaryJinky JunioÎncă nu există evaluări

- Hmdu - EnglishDocument20 paginiHmdu - EnglishAbdulaziz SeikoÎncă nu există evaluări

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocument4 paginiPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideÎncă nu există evaluări

- The Golden HarvestDocument3 paginiThe Golden HarvestMark Angelo DiazÎncă nu există evaluări

- Polymer Science: Thermal Transitions in PolymersDocument20 paginiPolymer Science: Thermal Transitions in Polymerstanveer054Încă nu există evaluări

- V60 Ventilator Specifications PDFDocument4 paginiV60 Ventilator Specifications PDFJonathan Issac Dominguez RamirezÎncă nu există evaluări

- A Laboratory Experiment in Crystals and Crystal Model Building ObjectivesDocument7 paginiA Laboratory Experiment in Crystals and Crystal Model Building ObjectivesrajaaÎncă nu există evaluări

- TiONA 592 PDS - ENDocument1 paginăTiONA 592 PDS - ENQuang VAÎncă nu există evaluări

- LaQshya Labour Room Quality Improvement InitiativeDocument2 paginiLaQshya Labour Room Quality Improvement InitiativeHimanshu SharmaÎncă nu există evaluări

- DionWIred Black FridayDocument13 paginiDionWIred Black FridayAmon SimelaneÎncă nu există evaluări

- Basic Concepts of Citrix XenAppDocument13 paginiBasic Concepts of Citrix XenAppAvinash KumarÎncă nu există evaluări

- Footprints 080311 For All Basic IcsDocument18 paginiFootprints 080311 For All Basic IcsAmit PujarÎncă nu există evaluări

- 4WE10 New Series Directional Valves NG10Document9 pagini4WE10 New Series Directional Valves NG10Paulo ArrudaÎncă nu există evaluări

- Balzac and the Little Chinese Seamstress: A Journey During the Cultural RevolutionDocument4 paginiBalzac and the Little Chinese Seamstress: A Journey During the Cultural RevolutionRogona 123Încă nu există evaluări

- Types of Ego?Document2 paginiTypes of Ego?S.UdhayakumarÎncă nu există evaluări

- Perbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACDocument15 paginiPerbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACYuli RahmawatiÎncă nu există evaluări

- Introduction To The Philosophy of The Human Person Quarter I - Module 2Document26 paginiIntroduction To The Philosophy of The Human Person Quarter I - Module 2Katrina TulaliÎncă nu există evaluări

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDocument2 paginiKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyÎncă nu există evaluări

- Optitex Com Products 2d and 3d Cad SoftwareDocument12 paginiOptitex Com Products 2d and 3d Cad SoftwareFaathir Reza AvicenaÎncă nu există evaluări

- July 4th G11 AssignmentDocument5 paginiJuly 4th G11 Assignmentmargo.nicole.schwartzÎncă nu există evaluări

- Clinnic Panel Penag 2014Document8 paginiClinnic Panel Penag 2014Cikgu Mohd NoorÎncă nu există evaluări

- PMMC ExperimentDocument2 paginiPMMC ExperimentShyam ShankarÎncă nu există evaluări

- Topographic Map of Blooming GroveDocument1 paginăTopographic Map of Blooming GroveHistoricalMapsÎncă nu există evaluări

- Cost and Benefit Analysis of Outsourcing From The Perspective of Datapath LTDDocument59 paginiCost and Benefit Analysis of Outsourcing From The Perspective of Datapath LTDranzlorenzoo100% (1)

- Literature Revisited: Understanding Key Concepts and Applying Analytical SkillsDocument31 paginiLiterature Revisited: Understanding Key Concepts and Applying Analytical SkillsMuhammad Furqan Aslam Awan100% (2)

- WP1019 CharterDocument5 paginiWP1019 CharternocnexÎncă nu există evaluări

- Interview Question SalesforceDocument10 paginiInterview Question SalesforcesomÎncă nu există evaluări