Documente Academic

Documente Profesional

Documente Cultură

Production Planning Setup in Datatex - NOW

Încărcat de

shoaib_textechDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Production Planning Setup in Datatex - NOW

Încărcat de

shoaib_textechDrepturi de autor:

Formate disponibile

User Manual Datatex

x

Production Planning Set up

Production Planning Set up Phases (Make to Order Scenario) for Knitted Garment Unit

Logic (Planning by Order)

When the system works by order the planning function selects all the record of VIEWProductionPlanning according to the selection

parameters input by the user in the initial parameter. This VIEW is built on customer order delivery with different join in order to

give as result:

(Customer order delivery quantity – Replenishment requisition quantity – Production Demand quantity – Allocation quantity)

The result is the not covered order quantity that can be planned. All the exploded levels by the planning are linked with the customer

order delivery using the links on the demand header. In Delivery selection is used the requested date. When planning finished the

explosion of a Delivery and the date has been shifted, set on it the Planned date with the lower date obtained by the explosion.

Process Flow

Rule Planning Production Planning

Rule

Template Template Planning Trace

Document Designed by Muhammad Shoaib Asad Page 1

User Manual Datatex

x

Production Planning Set up

Rule Template

Go to Menu of “Rule Template” by any means, go directly that menu titles or type initial in Search bar press enter. Rule Template Collection

screen appear then press “New” following screen will show,

1. Give Code and Description in required fields

2. Used for = Planning (by drop down)

3. Select input entities = Product.

4. Press Detail Manager button

Document Designed by Muhammad Shoaib Asad Page 2

User Manual Datatex

x

Production Planning Set up

Following screen will appears

Document Designed by Muhammad Shoaib Asad Page 3

User Manual Datatex

x

Production Planning Set up

1. following will perform here,

i. Check “Item type code” line of “Product” entity label (Red highlighted)

a. Enter its sequence = “10”

b. Attribute Type = “Input”

c. Out value = “No Value”

d. Oper. (operation) = “equals”

ii. On entity label = Planning Rule Output set each line as (Yellow highlighted)

a. Enter its sequence = “0”

b. Attribute Type = “Output”

c. Out value = “Constant”

d. Oper. (operation) = “No oper.”

2. Press Submit, system will show the collection of Details setup.

Document Designed by Muhammad Shoaib Asad Page 4

User Manual Datatex

x

Production Planning Set up

Rule

Now create Rule against that “Rule Template” created as follows

Go to Menu of “Rule” by any means, go directly that menu titles or type initial in Search bar press enter. The “ Rule” collection screen

appear then press “New” following screen will show,

1. Give Code and Description in required fields

2. Enter Rule template =PG1 that’s was created before

3. Press Data button for the rule definition entries, Rule Choose Keys screen will appears as;

Document Designed by Muhammad Shoaib Asad Page 5

User Manual Datatex

x

Production Planning Set up

4. Enter the sequence number = 10 and check the box of Item type

5. Press the + of same line. screen will as

Document Designed by Muhammad Shoaib Asad Page 6

User Manual Datatex

x

Production Planning Set up

6. Press Rule definition

Document Designed by Muhammad Shoaib Asad Page 7

User Manual Datatex

x

Production Planning Set up

7. Enter data as;

Contd . . . more left > > > > >

Document Designed by Muhammad Shoaib Asad Page 8

User Manual Datatex

x

Production Planning Set up

Each field has it own importance which will discuss later in this document.

8. Press Validate button, and then Submitt.

9. Planning Rule create, now to create “Planning Template”

Document Designed by Muhammad Shoaib Asad Page 9

User Manual Datatex

x

Production Planning Set up

Planning Template

Now create Planning Template against that defined Rule for Planning created as follows

Go to Menu of “Planning Template” by any means, go directly that menu titles or type initial in Search bar press enter. The “Planning

Template” collection screen appear then press “New” following screen will show,

1. Enter Code

2. Enter Rule (Planning) =PG1 that’s was created before (by lookup)

3. Enter Rule Policy (by lookup; only one)

4. Planning by = “Order” (drop down)

a. In case of Re-order / safety stocks planning always choose “Availability” will discuss in discuss later in this document.

5. Press Submit button. Created.

Document Designed by Muhammad Shoaib Asad Page 10

User Manual Datatex

x

Production Planning Set up

Production Planning

Now create Production Planning (Planning Explosion) against that defined Planning Templates created and other parameter as follows

Go to Menu of “Production Planning” by any means, go directly that menu titles or type initial in Search bar following screen will show,

1. Enter Planning Template = (specification)

2. Limited Date = (of sales order delivery date till which planning to be required)

3. Periodized Calendar = “M01”

a. Limit date is used as final date during the order selection. (Will be taken in consideration only the delivery lines with

requested date <= limit date).

4. Run description = simple text input.

5. Press Next; screen follows

6. Delivery date values (this appear after press Next button in Base01

a. 1 = No shift - Block: if during the planning one lower demand is earlier than today the order will not be planned.

Document Designed by Muhammad Shoaib Asad Page 11

User Manual Datatex

x

Production Planning Set up

b. 2 = No shift – Force : if during the planning one lower demand is earlier than today the order will be planned.

c. 3 = Shift : if during the planning one lower demand is earlier than today the order date will be shifted until all the lower

levels will obtain a date greater than or equal to today.

Document Designed by Muhammad Shoaib Asad Page 12

User Manual Datatex

x

Production Planning Set up

7. Sales Order Template = for which Sales order template planning to be run

8. Sales Order Line Template = no specific use

9. Customer = for which customer (order partner) planning to be run

10. Projects, Logical Warehouse, Availability warehouse group no specific use.

11. Item Type = Item type for which planning to be run

a. If user enters the item type system will shows the Sub-codes details. Where user can enter full or selective sub-codes (pls

check the box of sub-codes with out check in this case), and also can give range of product by check the Display final item

code.

12. Delivery; enter the sales order delivery line number; as detail shows in above screen shot.

13. Press Submit; system will assign the number to this planning job.

14. To see the job status user can view it from menu called “ABS Submitted Job” collection as

Document Designed by Muhammad Shoaib Asad Page 13

User Manual Datatex

x

Production Planning Set up

15. The important attribute here is Status in which the specific status are,

a. On Queue; in Queue

b. Executing, in process (working)

Document Designed by Muhammad Shoaib Asad Page 14

User Manual Datatex

x

Production Planning Set up

c. Ended (finished / completed)

d. Ended with info (finished / with error or info)

e. In case if “Ended with info” status one can easily check the info / error by clicking the specific Job and press the “Info”

button.

Document Designed by Muhammad Shoaib Asad Page 15

User Manual Datatex

x

Production Planning Set up

Production Planning Trace

To the Executed (Planning Exploded) against that defined Production Planning created as follows

Go to Menu of “Production Planning Trace” by any means, go directly that menu titles or type initial in Search bar following Collection

screen of all Planning exploded will show,

Document Designed by Muhammad Shoaib Asad Page 16

User Manual Datatex

x

Production Planning Set up

Here user can identify its Job / Planning by different attribute like

User

Description

Submitted Job and Creation date and Time

So after select the specific Planning Job,

Go Line for details of exploded line of each level from Sales order delivery to Requisition of Yarn, that’s how picture looks like;

Document Designed by Muhammad Shoaib Asad Page 17

User Manual Datatex

x

Production Planning Set up

Contd.. > > > >

Document Designed by Muhammad Shoaib Asad Page 18

User Manual Datatex

x

Production Planning Set up

Document Designed by Muhammad Shoaib Asad Page 19

User Manual Datatex

x

Production Planning Set up

Now to confirm the level (or / and) sequence by click the of Confirm / Delete button

As click on that button same screen (of line will have bit change like)

Document Designed by Muhammad Shoaib Asad Page 20

User Manual Datatex

x

Production Planning Set up

(The detail functionality is discussed later in this document.), Press Submit to proceed the status and then go back and press Submit on

Header Page. Planning is done

Document Designed by Muhammad Shoaib Asad Page 21

User Manual Datatex

x

Production Planning Set up

Important Points and Description specific Attribute

1. There major changing in new Planning Module, no Additional data on Product to enter. No need to enter Production demand

template code (now enter in Planning Rule) and replenishment requisition template code plus usual supplier enters in

“Replenishment” table in Product (only for the purchase product. Procedure as follows

a. Enter in to specific purchased product, go “Function” (drop down) select “Replenishment”

Document Designed by Muhammad Shoaib Asad Page 22

User Manual Datatex

x

Production Planning Set up

b. System will the collection of Item Replenishment press New button to create, and enter data in specific Tab like, Screen

shot as shown

i. Base2 (Usual Supplier ; Requisition Template) by lookup.

ii. Lead times (Purchase Lead Time) in days for that specific product against supplier.

iii. Press Submit. Item Replenishment generated.

Document Designed by Muhammad Shoaib Asad Page 23

User Manual Datatex

x

Production Planning Set up

2. Attribute in Planning Rule

a. Item Type: item type of Product, enter Item type BOM Level wise for each of Rule definition

b. Commercial Lot: Minimum Order Qty to Plan

c. Commercial Lot Policy: Commercial Lot Qty based on which UoM Primary ; Secondary ; Packing

d. Min Prod Lot: Minimum Production Lot Size

e. Optimal Prod Lot: Optimum Production Lot Size

f. Max Prod Lot: Maximum Production Lot Size

g. Netting Policy: To check available and adjust Qty from Stock of assign whs or Available whs grp in to Production Demand

or Requisition. Netting by Qty ; No Netting ; Netting by Period (no use)

h. Periodized Calendar: which calendar to for period actions;

i. Demand Policy: Production Demand Qty based on which UoM Primary ; Secondary ; Packing

j. Availability Whs Group: set of Logical Warehouse in one.

k. Operation: what operation required on Item Type option are No Explosion (no explosion required for further level);

Explosion (explosion required for further level) ; Purchase (Item type to be purchased)

l. Warehouse: (Planning Warehouse no not required if Availability Whs Grp entered

m. Internal Template: internal Document setting, not required

n. Code: Production Demand Template Code.

Document Designed by Muhammad Shoaib Asad Page 24

User Manual Datatex

x

Production Planning Set up

3. Status of Planning Trace

All the options are applicable within a single customer order delivery line.

It’s not possible apply an action to a single reservation.

If a Demand is selected, the same action will be applied to its reservations.

a. None = no action (record not selected)

b. Confirm/Delete = conf/del only the selected row

Document Designed by Muhammad Shoaib Asad Page 25

User Manual Datatex

x

Production Planning Set up

c. Confirm/Delete sequence = conf/del the selected record and all the lower levels

Document Designed by Muhammad Shoaib Asad Page 26

User Manual Datatex

x

Production Planning Set up

d. Confirm/Delete level = conf/del all the records at the same level of the selected one.

Document Designed by Muhammad Shoaib Asad Page 27

User Manual Datatex

x

Production Planning Set up

e. Confirm/Delete level sequence = conf/del all the records at the same level of the selected one and all the lower levels.

Document Designed by Muhammad Shoaib Asad Page 28

S-ar putea să vă placă și

- UML Class DiagramDocument47 paginiUML Class Diagramthanhluantink30c100% (1)

- T-CodeDocument196 paginiT-Codeshoaib_textechÎncă nu există evaluări

- Oracle SQL PL SQL A Brief IntroductionDocument112 paginiOracle SQL PL SQL A Brief IntroductionSadat Mohammad Akash100% (2)

- SAP Batch Management OverviewDocument70 paginiSAP Batch Management Overviewlibran_15Încă nu există evaluări

- Sap MM Master DataDocument19 paginiSap MM Master DataImran PatelÎncă nu există evaluări

- Integrate It! - SAP and MES Integration. Step-By-Step Guide: QuoteDocument18 paginiIntegrate It! - SAP and MES Integration. Step-By-Step Guide: QuoteSANDEEP KKPÎncă nu există evaluări

- Fifo in Batch ManagementDocument3 paginiFifo in Batch ManagementsuritataÎncă nu există evaluări

- KANBAN PROCESS IN SAP for TOYOTADocument20 paginiKANBAN PROCESS IN SAP for TOYOTAShweta SinhaÎncă nu există evaluări

- MM IV Validation and Substitution in Invoice VerificationDocument7 paginiMM IV Validation and Substitution in Invoice VerificationSilva SilvaÎncă nu există evaluări

- SAP Overview: ACC LimitedDocument37 paginiSAP Overview: ACC LimitedSrinivasa ReddyÎncă nu există evaluări

- PP-Interview Questions: Skip To End of MetadataDocument3 paginiPP-Interview Questions: Skip To End of MetadataShiva KumarÎncă nu există evaluări

- Sap PP SyllabusDocument4 paginiSap PP SyllabusZaheer AhamedÎncă nu există evaluări

- Rework in ManufacturingDocument4 paginiRework in ManufacturingSameenaNaseemÎncă nu există evaluări

- Add New or Custom Fields To COOIS Output - SAP BlogsDocument25 paginiAdd New or Custom Fields To COOIS Output - SAP BlogsNEHAÎncă nu există evaluări

- Steps To Create A Simple LSMW Using Batch Input RecordingDocument18 paginiSteps To Create A Simple LSMW Using Batch Input RecordingSharad TiwariÎncă nu există evaluări

- Datatex NOW Training GuideDocument308 paginiDatatex NOW Training Guidesagar67% (3)

- Batch Unique at Plant LevelDocument11 paginiBatch Unique at Plant LevelNagarjuna ReddyÎncă nu există evaluări

- MES Discrete MFG v2Document50 paginiMES Discrete MFG v2san_bit2002Încă nu există evaluări

- Accessing The TransactionDocument6 paginiAccessing The Transactiondoubledeed150% (2)

- Data Migration and Consolidation A Complete GuideDe la EverandData Migration and Consolidation A Complete GuideÎncă nu există evaluări

- Standard SOP Process FlowDocument10 paginiStandard SOP Process Flowsrinivasa varmaÎncă nu există evaluări

- Define SAP Product Hierarchies in 5 StepsDocument6 paginiDefine SAP Product Hierarchies in 5 StepsJames Yung100% (1)

- SAP Manual for UD Reversal Requirements and Inspection Lot CreationDocument8 paginiSAP Manual for UD Reversal Requirements and Inspection Lot Creationpawandubey9Încă nu există evaluări

- Muhammad Shoaib Asad Khalid SAP PPDocument2 paginiMuhammad Shoaib Asad Khalid SAP PPshoaib_textechÎncă nu există evaluări

- Muhammad Shoaib Asad Khalid SAP PPDocument2 paginiMuhammad Shoaib Asad Khalid SAP PPshoaib_textechÎncă nu există evaluări

- Advance Excel VBA ProgrammingDocument5 paginiAdvance Excel VBA Programmingali_zulfikarÎncă nu există evaluări

- 2023 Top 10 Erp Systems Report Panorama ConsultingDocument19 pagini2023 Top 10 Erp Systems Report Panorama ConsultingMeriemÎncă nu există evaluări

- TERP10 - Study Guide With AnswersDocument48 paginiTERP10 - Study Guide With AnswersFatsieSA0% (1)

- Work Center in SAP PP: Create, Change, DisplayDocument10 paginiWork Center in SAP PP: Create, Change, DisplaysowjanyaÎncă nu există evaluări

- WMS Guide to Mobile Data Entry FeaturesDocument116 paginiWMS Guide to Mobile Data Entry FeaturesLoveÎncă nu există evaluări

- SAP Manufacturing ExecutionDocument14 paginiSAP Manufacturing Executionrizqi_83100% (2)

- Placement Office Automation: Bachelor of TechnologyDocument57 paginiPlacement Office Automation: Bachelor of TechnologySrimanik KamarapuÎncă nu există evaluări

- Automatic Batch Determination Shelf LifeDocument18 paginiAutomatic Batch Determination Shelf LifeKhalil EL KARAMAÎncă nu există evaluări

- Getting Started with Dynamics NAV 2013 Application DevelopmentDe la EverandGetting Started with Dynamics NAV 2013 Application DevelopmentÎncă nu există evaluări

- User Manual for Datatex Purchase Master Data and Order FulfillmentDocument11 paginiUser Manual for Datatex Purchase Master Data and Order Fulfillmentshoaib_textechÎncă nu există evaluări

- Lorhan-Texpro Solution - V3.0Document41 paginiLorhan-Texpro Solution - V3.0sihalim17100% (1)

- Combined Production Order Processing (DIMP) - SCNDocument9 paginiCombined Production Order Processing (DIMP) - SCNmohameds1988100% (1)

- Tips To Be Remember in SapDocument7 paginiTips To Be Remember in SapSahil MalhotraÎncă nu există evaluări

- Combined Production Order ProcessingDocument12 paginiCombined Production Order Processingsaps4hana ppÎncă nu există evaluări

- BaanERP Enterprise PlanningDocument43 paginiBaanERP Enterprise Planningrashidkamal994386Încă nu există evaluări

- Calibration CertificateDocument29 paginiCalibration CertificateSrinivasa Rao MullapudiÎncă nu există evaluări

- MRP Reorder Point PlanningDocument6 paginiMRP Reorder Point PlanningAni MeniniÎncă nu există evaluări

- MRP Stabilization in 4 StepsDocument13 paginiMRP Stabilization in 4 StepsPoonam BhallaÎncă nu există evaluări

- (TEST CASE) Creating Formulas For Work Centers - ERP Manufacturing (PP) - Community WikiDocument5 pagini(TEST CASE) Creating Formulas For Work Centers - ERP Manufacturing (PP) - Community WikiVigneshÎncă nu există evaluări

- Test Case of Salary or Pay SlipDocument2 paginiTest Case of Salary or Pay SlipAnonymous uSOuOYV0% (1)

- Supplier Integration - Siemens PLM SoftwareDocument3 paginiSupplier Integration - Siemens PLM Softwareamrin jannatÎncă nu există evaluări

- MP220 - Kanban Production Classroom LogisticsDocument64 paginiMP220 - Kanban Production Classroom Logisticskannanraj666Încă nu există evaluări

- SAP APO Interview Questions & AnswersDocument7 paginiSAP APO Interview Questions & AnswersnileshÎncă nu există evaluări

- Global inventory visibility with cloud networksDocument17 paginiGlobal inventory visibility with cloud networksArvin PagarÎncă nu există evaluări

- Batch DeterminationDocument21 paginiBatch Determinationmintu12353Încă nu există evaluări

- B1 90 MRP ProcessDocument54 paginiB1 90 MRP ProcessCristhian MercadoÎncă nu există evaluări

- Define Product Hierarchies (SAP Library - Material Master)Document4 paginiDefine Product Hierarchies (SAP Library - Material Master)varunnuraÎncă nu există evaluări

- SAP PP Production Execution End User DocumentsDocument3 paginiSAP PP Production Execution End User Documentsshiv_patel14Încă nu există evaluări

- Integrated business planning Standard RequirementsDe la EverandIntegrated business planning Standard RequirementsEvaluare: 1 din 5 stele1/5 (1)

- SAP MII and PCo Drive Real-Time Manufacturing VisibilityDocument5 paginiSAP MII and PCo Drive Real-Time Manufacturing VisibilitydvdmxÎncă nu există evaluări

- 2015 LSMW TutorialDocument34 pagini2015 LSMW TutorialVarun Bisht100% (1)

- Sap Mmphysical InventoryDocument9 paginiSap Mmphysical Inventorykumarranjit228Încă nu există evaluări

- Material Master SAPDocument1 paginăMaterial Master SAPAna Maria KapnobataiÎncă nu există evaluări

- Get serial numbers and equipment for GI deliveries in SAP SDDocument2 paginiGet serial numbers and equipment for GI deliveries in SAP SDPrashant SharmaÎncă nu există evaluări

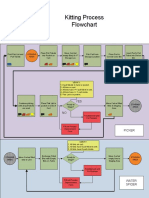

- Kitting Process Flowchart PDFDocument1 paginăKitting Process Flowchart PDFNaveen KumarÎncă nu există evaluări

- Create and transfer production plan in SAPDocument39 paginiCreate and transfer production plan in SAPVenkat VaranasiÎncă nu există evaluări

- Nautilus Table DB Rel02Document10 paginiNautilus Table DB Rel02api-3758975Încă nu există evaluări

- Hydra Mes Within Sap Environment Eng 276148Document4 paginiHydra Mes Within Sap Environment Eng 276148Pro5perÎncă nu există evaluări

- User Manual Developer Portal Manual Version 3Document96 paginiUser Manual Developer Portal Manual Version 3Janagar SundaramoorthyÎncă nu există evaluări

- ALE Step by Step Configuration For Message Type MATMASDocument23 paginiALE Step by Step Configuration For Message Type MATMASsukumarreddykÎncă nu există evaluări

- MRP ExerciseDocument3 paginiMRP ExerciseAbdelrahman El-OrbanyÎncă nu există evaluări

- Sample Drawing ProcedureDocument6 paginiSample Drawing ProceduremansurskÎncă nu există evaluări

- Two-Tier ERP Strategy A Clear and Concise ReferenceDe la EverandTwo-Tier ERP Strategy A Clear and Concise ReferenceÎncă nu există evaluări

- SAP System Tables OverviewDocument4 paginiSAP System Tables OverviewArun KumarÎncă nu există evaluări

- Discrete Vs REM Manufacturing in SAPDocument3 paginiDiscrete Vs REM Manufacturing in SAPshoaib_textechÎncă nu există evaluări

- Basic Tex InfoDocument2 paginiBasic Tex Infoshoaib_textechÎncă nu există evaluări

- SAP Freguently Used ButtonsDocument2 paginiSAP Freguently Used ButtonsPriyesh ETÎncă nu există evaluări

- SAP SummaryDocument2 paginiSAP Summaryshoaib_textechÎncă nu există evaluări

- Muhammad Shoaib Asad KhalidDocument2 paginiMuhammad Shoaib Asad Khalidshoaib_textechÎncă nu există evaluări

- Product Definition ManualDocument9 paginiProduct Definition Manualshoaib_textechÎncă nu există evaluări

- CHP 11Document30 paginiCHP 11shoaib_textechÎncă nu există evaluări

- Java R19 - Unit-1Document45 paginiJava R19 - Unit-1Lalit GautamÎncă nu există evaluări

- Data Compression KCS064Document2 paginiData Compression KCS064Shoaib SalmaniÎncă nu există evaluări

- TCP Concurrent Echo Program Using Fork and Thread: Ms - Rupilaa V.M., Ms - Sangeetha M., MR - Sathya Seelan K., MR - Vadivel RDocument5 paginiTCP Concurrent Echo Program Using Fork and Thread: Ms - Rupilaa V.M., Ms - Sangeetha M., MR - Sathya Seelan K., MR - Vadivel Rsankalp nayakÎncă nu există evaluări

- Mysql v5 - Mysql v1 Simatic 30Document14 paginiMysql v5 - Mysql v1 Simatic 30sybaritzÎncă nu există evaluări

- ENGG1811 Assignment 1 (Semester 1, 2017)Document6 paginiENGG1811 Assignment 1 (Semester 1, 2017)SasukeÎncă nu există evaluări

- Revised Chap06 EX SolutionsDocument4 paginiRevised Chap06 EX SolutionsSamantha' Dextre EspinozaÎncă nu există evaluări

- Project Report - SteganographyDocument72 paginiProject Report - SteganographyDeFreeMe33% (3)

- Algorithms and ProgrammingDocument17 paginiAlgorithms and ProgrammingperakoyotÎncă nu există evaluări

- Create API To Crud Videos Using HTTP Methods and Javascript and Entity FramworkDocument7 paginiCreate API To Crud Videos Using HTTP Methods and Javascript and Entity Framworktomeh100Încă nu există evaluări

- Radio Button: Latihan Konversi Suhu: Celsius Fahrenheit Fahrenheit CelsiusDocument5 paginiRadio Button: Latihan Konversi Suhu: Celsius Fahrenheit Fahrenheit CelsiusagustavÎncă nu există evaluări

- DBMS Lab Manual 2020 - 21 Student Copy UpdatedDocument59 paginiDBMS Lab Manual 2020 - 21 Student Copy Updatedgautham100% (1)

- Gym Management System 24 26 36Document23 paginiGym Management System 24 26 36noemailokisaidnoÎncă nu există evaluări

- Error LogDocument59 paginiError LogHusni MohdÎncă nu există evaluări

- Brief History and Introduction to C ProgrammingDocument26 paginiBrief History and Introduction to C ProgrammingbhdbkhqÎncă nu există evaluări

- ReportDocument3 paginiReportmau vatsÎncă nu există evaluări

- B.SC Computer Applications PDFDocument25 paginiB.SC Computer Applications PDFManoj KumarÎncă nu există evaluări

- Two Marks Questions with Answers on Computer ArchitectureDocument19 paginiTwo Marks Questions with Answers on Computer ArchitectureAKASH KSÎncă nu există evaluări

- Object Oriented Analysis and Design - SyllabusDocument1 paginăObject Oriented Analysis and Design - SyllabusDeepa LakshmiÎncă nu există evaluări

- UntitledDocument2 paginiUntitledgilangellyÎncă nu există evaluări

- Network ProgrammingDocument351 paginiNetwork ProgrammingBnod MsraÎncă nu există evaluări

- CP All ProgramsDocument17 paginiCP All Programs1SiDE PYROÎncă nu există evaluări

- XML Technologies and Applications: Rajshekhar SunderramanDocument24 paginiXML Technologies and Applications: Rajshekhar SunderramanAshok Kumar JangamÎncă nu există evaluări

- Indexing and SlicingDocument13 paginiIndexing and Slicingnaveen kumarÎncă nu există evaluări

- PRM Electric Mountain Railway Ticket Booking SolutionDocument5 paginiPRM Electric Mountain Railway Ticket Booking SolutionNouman Fida - 63451/TCHR/PCKÎncă nu există evaluări

- 1.3 Lexical Analysis of PythonDocument8 pagini1.3 Lexical Analysis of PythonkalyanÎncă nu există evaluări