Documente Academic

Documente Profesional

Documente Cultură

Finalised PFD

Încărcat de

ShahrizatSmailKassimTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Finalised PFD

Încărcat de

ShahrizatSmailKassimDrepturi de autor:

Formate disponibile

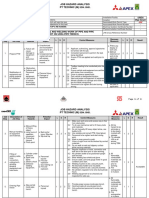

AIR RECYCLE N2, H2

STEAM

N2, H2

N2, H2O, CO CO2, H2, CO CO, CO2 N2, H2

Steam-methane SYNTHESIS GAS Ammonia

sulphurization Shift conversion Co2 removal methanation AND COMPRESSION synthesis

catalytic refome H2 N2,H20

RECYCLE OF CO2 N2,H2,NH3

NATURAL GAS Ammonia

separator

NH3 (LIQUID)

LIQUID NH3

CO2 storage tank Urea plant

CO2 FROM RECYCLE

GRANULATED SOLID UREA

FIGURE : BLOCK DIAGRAM OF UREA PRODUCTION

DESCRIPTION OF THE BLOCK DIAGRAM

1. Desulphurization

Removes of sulphur by using catalytic hydrogenation

Equation : H2+ RSH RH+H2S(gas)

In the reactor using AL2O3 as catalyst

H2S +ZNO ZNS +H20

2. STEAM METHANE CATLYTIC REFORMER

CH4(g)+H2O(g) CO(g)+3H2(g)

In this system will involve of 2 types of reformer

1. Primary reformer

2. Secondary reformer

AIR +H2(g) N2(g) +H20

Air being introduce in the 2nd reformer as the air will react with hydrogen that being

produced by the 1st reformer

3. SHIFT CONVERSION

CO(g)+ H20(g) CO2(g)+H20(g)

4. CO2 REMOVAL

Catalyst of mono-ethanolamine (MEA) OR MDEA as the CO2 remove by the absorption of

catalyst

5. METHANATION

COG)+3H2(g) CH4(g)+H20(g)

CO2(g)+4H2(g) CH4(g)+2H20(g)

6. AMMONIA REACTOR

in this reactor we will used iron oxide as the catalyst.

N2(g)+H3(g) 3NH2(g)

7. UREA PLANT

Happen in the reactor at high temperature and pressure

Involve in 2 steps for the formation of urea

2NH3(g) + CO2(g) NH2COONH4(g)

NH2COONH4 H20+NH2CONH2(urea)

PFD WE USE IN THIS PROJECT DESIGN

ALL OF THE EQUIPMENT INVOLVED IN THIS PROJECT DESIGN

1. Compressor

2. Preheater

3. Hydrogenation reactor

4. Adsorb to remove H2S

5. Tube furnace

6. Converter

7. Steam boiler

8. Converter of CO

9. Absorber of CO2

10. Reboiler

11. Regenerator of monoethanolamine solution

12. Pump

13. Hydrogenation vessel of residual CO and CO2

14. Air cooled heat echanger

15. Condensation column

16. Evaporator of liquid NH3

17. Ammonia converter

18. Water heater

19. Heat exchanger

20. Separator

1

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- How To Post Bail For Your Temporary Liberty?Document5 paginiHow To Post Bail For Your Temporary Liberty?Ruel Benjamin Bernaldez100% (1)

- Refill Brand Guidelines 2Document23 paginiRefill Brand Guidelines 2Catalin MihailescuÎncă nu există evaluări

- Aspen Simulation WorkbookDocument24 paginiAspen Simulation Workbookwalisyh100% (2)

- Hospital DocumentsDocument17 paginiHospital DocumentsRaviraj PisheÎncă nu există evaluări

- Hot Work: Job Hazard Analysis PT Technic (M)Document4 paginiHot Work: Job Hazard Analysis PT Technic (M)ShahrizatSmailKassim100% (1)

- Writing NuocRut Ver02Document118 paginiWriting NuocRut Ver02thuy linhÎncă nu există evaluări

- Aspen-HYSYS Simulation of Natural Gas Processing PlantDocument4 paginiAspen-HYSYS Simulation of Natural Gas Processing Plantsorincarmen88Încă nu există evaluări

- Nagpur Company List 2Document10 paginiNagpur Company List 2Kaushik BachanÎncă nu există evaluări

- Chemical Injection: Offshore Coshh EssentialsDocument3 paginiChemical Injection: Offshore Coshh EssentialsShahrizatSmailKassimÎncă nu există evaluări

- Cis WSH Cetsp32 137664 7Document31 paginiCis WSH Cetsp32 137664 7Ashok SureshÎncă nu există evaluări

- Bem Form PDFDocument4 paginiBem Form PDFShahrizatSmailKassimÎncă nu există evaluări

- Bem Form PDFDocument4 paginiBem Form PDFShahrizatSmailKassimÎncă nu există evaluări

- JHA Lifting-Moving Heavy Objects - ROMODocument5 paginiJHA Lifting-Moving Heavy Objects - ROMOsyafiqhashim1703Încă nu există evaluări

- 77 Chemical Mixing and Handling - JOB PROCEDUREDocument2 pagini77 Chemical Mixing and Handling - JOB PROCEDUREShahrizatSmailKassim100% (1)

- Folding Mobile Floor Crane-JOB PROCEDUREDocument4 paginiFolding Mobile Floor Crane-JOB PROCEDUREBayu Biroe100% (1)

- Law 299, Q2B.BDocument1 paginăLaw 299, Q2B.BShahrizatSmailKassimÎncă nu există evaluări

- Take Home TestDocument3 paginiTake Home TestShahrizatSmailKassimÎncă nu există evaluări

- Request Confirmation Letter Template 2 - Amended 02.04.2018Document1 paginăRequest Confirmation Letter Template 2 - Amended 02.04.2018ShahrizatSmailKassimÎncă nu există evaluări

- TheBalance - Cover Letter 2062548Document1 paginăTheBalance - Cover Letter 2062548Rush YuviencoÎncă nu există evaluări

- TOPIC 2 - Classification of CompanyDocument24 paginiTOPIC 2 - Classification of CompanyShahrizatSmailKassimÎncă nu există evaluări

- Law 299, Q2B.BDocument1 paginăLaw 299, Q2B.BShahrizatSmailKassimÎncă nu există evaluări

- 116 126 PMR Jul07 PDFDocument11 pagini116 126 PMR Jul07 PDFShahrizatSmailKassimÎncă nu există evaluări

- CO Abatement Through A Methanol Production Process: C H E M I C A L E N G I N E E R I N G T R A N S A C T I O N SDocument6 paginiCO Abatement Through A Methanol Production Process: C H E M I C A L E N G I N E E R I N G T R A N S A C T I O N SShahrizatSmailKassimÎncă nu există evaluări

- Market 2Document32 paginiMarket 2ShahrizatSmailKassimÎncă nu există evaluări

- Soga AaDocument43 paginiSoga AaShahrizatSmailKassimÎncă nu există evaluări

- 299 CertaintyDocument29 pagini299 CertaintyShahrizatSmailKassimÎncă nu există evaluări

- Report LiDocument12 paginiReport LiShahrizatSmailKassimÎncă nu există evaluări

- ReferencesDocument1 paginăReferencesShahrizatSmailKassimÎncă nu există evaluări

- Correction of PFD Dp1Document3 paginiCorrection of PFD Dp1ShahrizatSmailKassimÎncă nu există evaluări

- Chapter 2Document24 paginiChapter 2ShahrizatSmailKassimÎncă nu există evaluări

- Solid AssigmentDocument4 paginiSolid AssigmentShahrizatSmailKassimÎncă nu există evaluări

- Solid Calculation PDFDocument17 paginiSolid Calculation PDFShahrizatSmailKassimÎncă nu există evaluări

- Chapter 2Document14 paginiChapter 2ShahrizatSmailKassimÎncă nu există evaluări

- Briefing For Students 2017 - 1st BriefingDocument24 paginiBriefing For Students 2017 - 1st BriefingShahrizatSmailKassimÎncă nu există evaluări

- Ariando Purba: Nov 2017-: CV. Mulia Abadi (Knitto Textiles) - Present System Development and ImplementationDocument3 paginiAriando Purba: Nov 2017-: CV. Mulia Abadi (Knitto Textiles) - Present System Development and ImplementationariandoÎncă nu există evaluări

- EE/CS-320 - Computer Organization & Assembly Language (Fall Semester 2013-14) Assignment 2Document11 paginiEE/CS-320 - Computer Organization & Assembly Language (Fall Semester 2013-14) Assignment 2Haris AliÎncă nu există evaluări

- Đo Nhiệt Độ LI-24ALW-SelectDocument4 paginiĐo Nhiệt Độ LI-24ALW-SelectThang NguyenÎncă nu există evaluări

- Google Translate - Google SearchDocument1 paginăGoogle Translate - Google SearchNicole Alex Bustamante CamposÎncă nu există evaluări

- Estrada, Roubenj S. Quiz 1Document13 paginiEstrada, Roubenj S. Quiz 1Roubenj EstradaÎncă nu există evaluări

- FPO Policy-1Document96 paginiFPO Policy-1shashanksaranÎncă nu există evaluări

- A Comprehensive Review On Evaluation of Environmental Friendly Machinability, Cutting Fluids and Techniques in Metal Cutting OperationDocument13 paginiA Comprehensive Review On Evaluation of Environmental Friendly Machinability, Cutting Fluids and Techniques in Metal Cutting OperationIJAR JOURNALÎncă nu există evaluări

- Types of Annuity & Intra Year Compounding: Dr. Anubha GuptaDocument15 paginiTypes of Annuity & Intra Year Compounding: Dr. Anubha GuptarashmipoojaÎncă nu există evaluări

- DocumentDocument2 paginiDocumentAddieÎncă nu există evaluări

- 213-Article Text-620-1-10-20201118Document6 pagini213-Article Text-620-1-10-20201118Arlin FebriantiÎncă nu există evaluări

- QuickTransit SSLI Release Notes 1.1Document12 paginiQuickTransit SSLI Release Notes 1.1subhrajitm47Încă nu există evaluări

- Helicoil Plus en 0100Document56 paginiHelicoil Plus en 0100Khổng MạnhÎncă nu există evaluări

- Labour Bureau: Ministry of Labour and Employment, Government of IndiaDocument1 paginăLabour Bureau: Ministry of Labour and Employment, Government of IndiavinodÎncă nu există evaluări

- Dorp Handbook and Plan EBCESDocument30 paginiDorp Handbook and Plan EBCESJenelou delapenaÎncă nu există evaluări

- 2019 FTX2000S Course OutlineDocument11 pagini2019 FTX2000S Course OutlineAhmed PatelÎncă nu există evaluări

- Thermister O Levels Typical QuestionDocument4 paginiThermister O Levels Typical QuestionMohammad Irfan YousufÎncă nu există evaluări

- Full Download Test Bank For Managerial Decision Modeling With Spreadsheets 3rd Edition by Balakrishnan PDF Full ChapterDocument36 paginiFull Download Test Bank For Managerial Decision Modeling With Spreadsheets 3rd Edition by Balakrishnan PDF Full Chapterhospital.epical.x6uu100% (20)

- CBL 2022 2023Document41 paginiCBL 2022 2023Roy SaberdoÎncă nu există evaluări

- Map of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectDocument10 paginiMap of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectAltanochir AagiiÎncă nu există evaluări

- Installation Instructions: LRM1070, LRM1080Document2 paginiInstallation Instructions: LRM1070, LRM1080Stefan JovanovicÎncă nu există evaluări

- 14.symmetrix Toolings LLPDocument1 pagină14.symmetrix Toolings LLPAditiÎncă nu există evaluări

- Recovering From Intrusions in Distributed Systems With D: Taesoo Kim, Ramesh Chandra, and Nickolai Zeldovich Mit CsailDocument7 paginiRecovering From Intrusions in Distributed Systems With D: Taesoo Kim, Ramesh Chandra, and Nickolai Zeldovich Mit CsailRoshan PiyushÎncă nu există evaluări

- Batch 2 SEC Online Test AnswersDocument5 paginiBatch 2 SEC Online Test AnswersBhairav YouthsÎncă nu există evaluări

- Incorporation of Industrial Wastes As Raw Materials in Brick's Formulation (Wiemes-Brasil-2016)Document9 paginiIncorporation of Industrial Wastes As Raw Materials in Brick's Formulation (Wiemes-Brasil-2016)juan diazÎncă nu există evaluări

- Labor Case Digest MidtermsDocument219 paginiLabor Case Digest MidtermsMvapsÎncă nu există evaluări