Documente Academic

Documente Profesional

Documente Cultură

QC Manual ISO 3834 - 2 QM-02 Final

Încărcat de

avinash1987Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QC Manual ISO 3834 - 2 QM-02 Final

Încărcat de

avinash1987Drepturi de autor:

Formate disponibile

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 0.1 Revision - 00 TITLE -COVER SHEET Effective Date 01.06.2016 Page no.-1

Quality Manual

Fusion Welding of Metallic

Material

Conformance Standard :

ISO 3834-2:2006 (E) (QM-2)

Comprehensive quality requirements

ISO 9001-2008 (QM-1)

DOCUMENT NO. - QM: 02

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 1 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 0.2 Revision - 00 TITLE TABLE OF CONTENT Effective Date 01.06.2016 Page no.-1

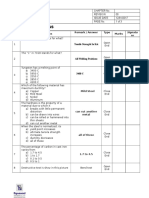

Sr. TITLE Section Rev. Total

No. no. no. Pages

1 COVER SHEET 0.1 00 1

2 TABLE OF CONTENTS 0.2 00 1

3 DISTRIBUTION OF MANUAL 0.3 00 1

4 AMENDMENT HISTORY 0.4 00 1

5 ABBREVIATION 0.5 00 1

6 INTRODUCTION OF ORGANISATION & EXCLUSIONS CLAIMED 0.6 00 3

7 INTRODUCTION OF ISO 3834-2 0.7 00 1

8 SCOPE 1 00 2

9 NORMATIVE REFERENCE 2 00 1

10 TERMS & DEFINITION 3 00 1

11 GENERAL OUT LINE OF ISO 3834 4 00 1

12 REVIEW OF REQUIREMENT AND TECHNICAL REVIEW 5 00 1

13 SUB-CONTRACTING 6 00 2

14 WELDING & RELATED ACTIVITIES 7 00 4

15 INSPECTION AND TESTING PERSONNEL 8 00 1

16 EQUIPMENT 9 00 2

17 WELDING CONSUMABLE 10 00 1

18 STORAGE AND PERENT MATERIAL 11 00 2

19 POST WELD HEAT TREATMENT 12 00 1

20 INSPECTION AND TESTING 13 00 2

21 NON-CONFIRMANCE& CORRECTIVE ACTION 14 00 1

22 CALIBRATION AND VALIDATION OF MEASURING 15 00 1

INSTRUMENTS

23 IDENTIFICATION AND TRECEBILITY 16 00 1

24 CONTROL OF DOCUMENTS & QUALITY RECORD 17 00 1

For Reference and application for ISO 3834-2

Follow the ISO 9001-2008 Established Quality Manual / Work Instruction / Mandatory Procedure.

Documentation requirement / control of document / Record / Formats / Infrastructure List / Mandatory

procedure / work Instruction / statuary requirement / regularly requirement

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 2 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 0.3 Revision - 00 TITLE DISTRIBUTION OF QUALITY MANUAL 3834-2 Effective Date Page no.-1

01.06.2016

DISTRIBUTION OF QUALITY MANUAL ISO 3834-2

SR.NO. TYPE OF COPY DISTRIBUTE TO DISTRIBUTE COPY

1 MASTER COPY QC MANAGER. 1 NO.

2 CONTROLLED COPY WELDING CO-ORDINATOR 1 NO.

3 CONTROLLED COPY MANAGER (PLANNING) 1 NO.

4 CONTROLLED COPY MANAGER (PRODUCTION) 1 NO.

5 CONTROLLED COPY GENERAL MANAGER 1 NO.

6 CONTROLLED COPY DIRECTOR 1 NO

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 3 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 0.4 Revision - 00 TITLE AMENDMENT HISTORY Effective Date 01.06.2016 Page no.-1

AMENDMENT HISTORY SHEET

Effective

Sr. Page Approved

Section No. Existing Detail Revised to Amendment

No No. By

Date

1

2

3

4

5

6

7

8

9

10

11

12

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 4 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 0.5 Revision - 00 TITLE ABBREVIATION Effective Date 01.06.2016 Page no.-1

0.5 ABBREVIATION

SR.NO. ABBREVIATION FULL FORM

1 AI AUTHORISED INSPECTOR

2 AWS AMERICAN WELDING SOCIETY

3 ASME AMERICAN SOCIETY OF MECHANICAL ENGINEERS

4 ASTM AMERICAN SOCIETY OF TESTING MATERIAL

5 AC ALTERNATE CURRENT

6 AMP AMPEREAGE

7 DC DIRECT CURRENT

8 FCAW FLUX CORE ARC WELDING

9 GM GENERAL MANAGER

10 GTAW GAS TUNGSTEN ARC WELDING

11 GMAW GAS METAL ARC WELDING

12 ISO INTERNATIONAL ORGANIZATION FOR STANDARDIZATION

13 ITP INSPECTION AND TEST PLAN

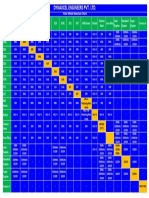

14 DEPL DYNAXCEL ENGINEERS PVT. LTD.

15 LPT LIQUID PENETRENT TEST

16 MRM MANAGEMENT REVIEW MEETING

17 MR MANAGEMENT REPRESENTATIVE

18 MPT MAGNETIC PARTICAL TEST

19 NDT NON DISTRICTIVE TESTING

20 PCN PERSONNEL CERTIFICATION IN NON-DESTRUCTIVE TESTING

21 PROD PRODUCTION

22 PLG. PLANNING

23 PE PRODUCTION ENGINEER

24 PPM PRODUCTION PLANNING MANAGER

25 PQR PROCEDURE QUALIFICATION RECORD

26 QMS QUALITY MANAGEMENT SYSTEM

27 QAP QUALITY ASSURANCE PLAN

28 QCE QUALITY CONTROL ENGINEER

29 QCM QUALITY CONTROL MANAGER

30 RT RADIOGRAPHY TEST

31 SMAW SHIELDED METAL ARC WELDING

32 SK STORE KEEPER

32 SM STORE MANAGER

33 TIG TUNGSTEN INERT GAS WELDING

34 UT ULTRASONIC TEST

35 VOLT VOLTAGE

36 WPQR WELDER PROCEDURE QUALIFICATION RECORD

37 WPS WELDING PROCEDURE SPECIFICATION

38 IWE/IWT/IWS/WE INTERNATIONAL WELDING ENGINEER/TECHNOLOGIST/ SPECIALIST/ ENGR

39 WQT WELDER QUALIFICATION RECORD

40 EN EUROPIAN STANDARD

41 MDR MANUFACTURING DOSSIER RECORD

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 5 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 0.6 Revision - 00 TITLE INTORDUCTION OF ORGANISATION Effective Date 01.06.2016 Page no.-1

0.6 INTRODUCTION OF ORGANISATION

Dynaxcel Engineers Pvt. Limited are ISO 9001:2008, ISO14001:2004, OHSAS 18001:1999 certified

manufacturers of engineering equipment in various materials like Stainless Steel, Carbon steel, Nickel

& its alloys, Copper, Titanium & its alloys etc. We have proficiency in manufacture & supply of

fabricated metal equipments and engineering job works.

Heat exchangers,

Pressure Vessels, Reactors

Distillation columns, Condensers

Bleaching towers, tubes, pulpers, de-aerators, UTMs, SILOs, Screen Vessels, and Drum

washers, Disc Filters, Approach flow piping for paper industry.

Textile dyeing machines, jiggers, dryers.

Acoustic enclosures, silencers / baffles for power generation equipment.

Fabrication of Heavy equipments up to 35 tons for power generation eqpt manufacturers.

We have the experience of doing jobs under the third party inspection agencies viz.

Bureau Veritas,

TUV India,

ABS,

Tata Projects Ltd.,

Lloyds Register etc.

DEPL maintains strict manufacturing & documents control of equipments. DEPL also specializes in

executing projects at site along with mechanical design, fabrication & erection of equipments at site.

We undertake projects consisting of stainless steel fabrication at our factory, delivered at site,

part/full fabrication at site and erection & commissioning. We have a team of 80 skilled, semiskilled

workers & experienced supervisors for execution of this activity.

In addition to this, we are working with OEMs in Paper Machinery Suppliers for manufacture of paper

pulp equipment in India. We also supply fabricated assemblies with critical machining to global

market. We have exported process equipment like sludge mixers, agitators for flotation cell in effluent

treatment plants, Pressure screen Housings , Bearing Columns, Refiners Housings to American &

European OEMs.

DEPL is more concern for manufacturing Equipment related to Mining, Power sector, Paper Industry,

Food Industry, filtration unit, process and chemical plants, structural work etc.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 6 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 7 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

ORGANIZATION CHART FOR QC DEPARTMENT

MANAGING DIRECTOR

MANAGER (Q.A./ Q.C.) WELDING ENGINEER+ WELDING COORDINATOR

Sr. Q. C. ENGINEER Q.C. ENGINEER WELDING INSPECTOR

+DEPUTY WELDING +DEPUTY WELDING +DEPUTY WELDING

CO-ORDINATOR CO-ORDINATOR CO-ORDINATOR

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 8 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 0.7 Revision - 00 TITLE INTRODUCTION OF ISO 3834-2 Effective Date 01.06.2016 Page no.-1

0.7 INTRODUCTION OF ISO 3834-2

Dynaxcel Engineers Pvt. limited has implemented ISO 3834-2 welding Quality management System for

fusion welding which are widely used to Steel Structures as per the standard of EN ISO standards/

PED /ASME / API-2H / AWS D1.1.

This will be particularly applicable for Structural Steel components designed as per Eurocode 3 (EN-

1993), IS-800 & BS 5950 the standard ISO 3834-2 is applying only welding containing part.

Products may range from simple to complex. These welding management processes exert a profound

influence on the cost of manufacture and quality of the product. It is important, therefore, to ensure

that these welding management processes are carried out in the most effective way and that

appropriate control is exercised over all aspects of the operation. ISO 3834-2 is use full tool for

welding & allied processes in ISO 9001-2008 QMS. Fusion Welding process is considered as special

processes in ISO 9001:2008.

Dynaxcel Engineers Pvt. Ltd. will follow the clients specification / Approved drawings / weld map and

other special instruction for control the welding process. If nothing is specified in drawings, then

Dynaxcel will work as per applicable minimum levels of applicable EN ISO standards. Refer standard

welding quality plan no (QC/15 rev 01 Dt. 01/01/2015)

Dynaxcel Engineers Pvt. Ltd. will follow the self-design of equipment drawing / weld map etc. to

control the welding process.

EXCLUSIONS CLAIMED

No exclusions to EN ISO 3834-2 & ISO 9001: 2008 are claimed by the Organization. Similarly, for ISO

3834-2, Dynaxcel has included all processes in control of the organization for implementation.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 9 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 1 Revision - 00 TITLE SCOPE OF ISO 3834-2 Effective Date 01.06.2016 Page no.-1

1 SCOPE OF ISO 3834-2 Clause No : 01

This part of ISO 3834 defines comprehensive quality requirements for fusion welding of metallic

materials in workshops.

This part of ISO 3834 specifies the documents with which it is necessary to conform to claim

conformity to the quality requirements of ISO 3834-2, ISO 3834-3 or ISO 3834-4. It can only be used in

conjunction with

ISO 3834-2, ISO 3834-3 or ISO 3834-4.

This part of ISO 3834 does not specify requirements for a total quality management system. However,

Clause 6 identifies quality management system elements where their inclusion will complement ISO

3834.

Industry Thickness

Scope Equipment Covered Covered Material Range

Welding and Heat exchangers, Railway, Ferrous e.g. 1.5 mm to

manufacturing Pressure Vessels, Reactors Mining, Power Carbon Steel, 112 mm

& supply of Distillation columns, Condensers sector, Paper Mild Steel and

fabricated Bleaching towers, tubes, pulpers, Industry, Food more as per

metal de-aerators, UTMs, Silos, Screen Industry, approved WPS

equipment Vessels, and Drum washers, Disc filtration unit,

and Filters, Approach flow piping for process and

engineering paper industry. chemical

job works Textile dyeing machines, jiggers, plants,

dryers. structural work

Non Ferrous 1.15 mm

Acoustic enclosures, silencers / etc.

e.g. Stainless to 100 mm

baffles for power generation

Steel, Nickel &

equipment.

its alloys more

Fabrication of Heavy

as per

equipments up to 35 tons for

approved WPS

power generation eqpt

manufacturers.

Customer orientated equipment

for list of Industry given in right

side column.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 10 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Clause 6 - Elements to be considered for a quality management system to complement ISO

3834

ISO 3834 contains many attributes that contribute to a quality management system (QMS). This clause

Identifies those QMS elements that the DEPL has consider implementing to support the ISO 3834

quality requirements

A) Control of documents and records (see ISO 9001:2008, 4.2.3, 4.2.4);

B) Management responsibilities (see ISO 9001:2008, Clause 5);

C) Provision of resources (see ISO 9001:2008, 6.1);

D) Competence, awareness and training of operational personnel [see ISO 9001:2008, 6.2.2, 7.5.2 b)];

E) Planning of product realization (see ISO 9001:2008, 7.1);

F) Determination of requirements related to the product (see ISO 9001:2008, 7.2.1);

G) Review of requirements related to the product (see ISO 9001:2008, 7.2.2);

H) Purchasing (see ISO 9001:2008, 7.4);

I) Validation of processes (see ISO 9001:2008, 7.5.2);

J) Customer property (see ISO 9001:2008, 7.5.4);

K) Internal audit (see ISO 9001:2008, 8.2.2);

L) Monitoring and measurement of product (see ISO 9001:2008, 8.2.4).

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 11 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 2 Revision - 00 TITLE NORMATIVE REFERANCE Effective Date 01.06.2016 Page no.-1

2. NORMATIVE REFERENCE Clause No : 02

The following referenced documents are indispensable for the application of this document. For dated

References, only the edition cited applies. For undated references, the latest edition of the referenced

Document (including any amendments) applies.

ISO 9001:2008, Quality management systems Fundamentals and vocabulary

The following referenced documents are indispensable for the application of this document. For dated

References, only the edition cited applies. For undated references, the latest edition of the referenced

Document (including any amendments) applies.

ISO 3834-1, Quality requirements for fusion welding of metallic materials Part 1: Criteria for the

selection of the appropriate level of quality requirements

ISO 3834-5:2005, Quality requirements for fusion welding of metallic materials Part 5: Documents

with which it is necessary to conform to claim conformity to the quality requirements of ISO 3834-2,

ISO 3834-3 or ISO 3834-4

ASME - AWS AMERICAN WELDING SOCIETY

ISO 9606-1, Qualification test of welders Fusion welding Part 1: Steels

ISO 9712, Non-destructive testing Qualification and certification of personnel

ISO 14731, Welding coordination Tasks and responsibilities

ISO 14732, Welding personnel - Approval testing of welding operators for fusion welding and of resistance

Weld setters for fully mechanized and automatic welding of metallic materials

ISO 15607, Specification and qualification of welding procedures for metallic materials General rules

ISO 15609-1, Specification and qualification of welding procedures for metallic materials welding

Procedure specification Part 1: Arc welding

ISO 15610, Specification and qualification of welding procedures for metallic materials Qualification based

on tested welding consumables

ISO 15611, Specification and qualification of welding procedures for metallic materials Qualification based

on previous welding experience

ISO 15612, Specification and qualification of welding procedures for metallic materials Qualification by

Adoption of a standard welding procedure

ISO 15613, Specification and qualification of welding procedures for metallic materials Qualification based

on pre-production welding test

ISO 15614-1, Specification and qualification of welding procedures for metallic materials welding

Procedure test Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

ISO 17635, Non-destructive testing of welds General rules for fusion welds in metallic materials

ISO 17637, Non-destructive testing of welds Visual testing of fusion-welded joints

ISO 17638, Non-destructive testing of welds Magnetic particle testing

ISO 17639, Destructive tests on welds in metallic materials Macroscopic and microscopic examination of

Welds

Quality manual # (DEPL/QM Rev-01 DT. 01/01/2009)

OHS Manual # (DEPL/EHS Rev.00 DT. 01/01/2015)

ENV Manual # (DEPL/EHS Rev.00 DT. 01/01/2015)

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 12 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 3 Revision - 00 TITLE TERMS AND DEFINITIONS Effective Date 01.06.2016 Page no.-1

3 Terms and definitions Clause No : 03

For the purposes of this document, the terms and definitions given in ISO 9000:2000 and the

following apply.

3.1 Company/DEPL

DYNAXCEL ENGINEERS PVT LIMITED

3.2 Design specification

Requirements for products specified by customers or by the organization in anticipation of customer

requirements, or by regulation

NOTE:-the requirements for products and in some cases associated processes can be contained in, for

example, technical specifications, product standards, process standards, contractual agreements and

regulatory requirements.

3.3 Qualified person

Person whose competence and knowledge have been obtained by education, training and/or relevant

practical experience

NOTE:-In order to demonstrate the level of competence and knowledge, a qualification test may be

required.

3.4 Construction

Product, structure or any other welded item.

3.5 Manufacturer/fabricator

Person or organization responsible for the welding production.

3.6 Sub-contractor

Supplier of products, services and/or activities to the DEPL in a contractual situation

3.7 welding operator

Person who performs fully mechanised or automatic fusion welding processes

3.8 Document

This is information and its supporting medium.

3.9 Non Conformity

Non-fulfilment of a requirement

3.10 Procedure

Specified way to carry out an activity or a process.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 13 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 4 Revision 00 TITLE GENERAL OUT LINE OF ISO 3834 Effective Date 01.06.2016 Page no.-1

4 GENERAL OUTLINE OF ISO 3834 Clause No : 04

The requirements contained within ISO 3834-2 are adopted in full.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 14 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 5 Revision - 00 TITLE REVIEW OF REQUIREMENTS & TECHNICAL Effective Date Page no.-1

REVIEW 01.06.2016

5 Review of requirements and technical review Clause No:-05

5.1 General

Dynaxcel Engineers Pvt. Ltd. (DEPL) review the contractual requirements and any other requirements, together

with any technical data provided by the purchaser or in-house data when the construction is designed by the

DEPL. Dynaxcel Engineers Pvt. Ltd. shall establish that all information necessary to carry out the manufacturing

operations is complete and available prior to the commencement of the work. DEPL affirm capability to meet all

requirements and shall ensure adequate planning of all quality-related activities. The review of requirements is

carried out by the DEPL to verify that the work content is within its capability to perform, that sufficient

resources are available to achieve delivery schedules and that documentation is clear and unambiguous. The

DEPL shall ensure that any variations between the contract and any previous quotation are identified and the

purchaser notified of any programme, cost or engineering changes that may result. Items in 5.2 are typically

considered at or before the time of the review of requirements review. Items in 5.3 usually form part of the

technical review and are considered during the initial planning stage. When a contract does not exist, e.g. items

made for stock; DEPL is required to take into consideration the requirements of 5.2 while carrying out the

technical review (see 5.3).

The Responsible Planning Engineer shall review the contract requirements as per Document No:-PLAN/03

Rev.00 dt.01/06/2016.

5.2 Review of requirements

Aspects to be considered shall include the following:

a) The product standard to be used, together with any supplementary requirements;

b) Statutory and regulatory requirements;

c) Any additional requirement determined by the DEPL;

d)The capability of the DEPL to meet the prescribed requirements.

5.3 Technical review

Technical requirements to be considered shall include the following:

a)Parent material(s) specification and welded joint properties;

b)Quality and acceptance requirements for welds;

c)Location, accessibility and sequence of welds, including accessibility for inspection and for non-destructive

testing;

d)The specification of welding procedures, non-destructive testing procedures and heat-treatment procedures;

e)The approach to be used for the qualification of welding procedures;

f) The qualification of personnel;

g)Selection, identification and/or traceability (e.g. for materials, welds);

h) quality-control arrangements, including any involvement of an independent inspection body;

i)Inspection and testing;

j)Sub-contracting;

l)Other welding requirements, e.g. batch testing of consumables, ferrite content of weld metal, ageing,

Hydrogen content, permanent backing, use of penning, surface finish, weld profile;

m)Use of special methods (e.g. to achieve full penetration without backing when welded from one side only);

n)Dimensions and details of joint preparation and completed weld;

o)Welds which are to be made in the workshop, or elsewh0ere;

p)Environmental conditions relevant to the application of the process (e.g. very low-temperature ambient

Conditions or any necessity to provide protection against adverse weather conditions);

q)Handling of non-conformances.

The Technical Review of Requirements shall be carried out by Designated Planning Engineer as perPLAN/02

Rev.00 dt.01/06/2016.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 15 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 6 Revision - 00 TITLE SUB CONTRACTING Effective Date 01.06.2016 Page no.-1

6. Sub-Contracting Clause No :6

As a policy decision, Dynaxcel Engineers Pvt. Ltd. has decided not to outsource welding

activities related to fabricated Structures and components. However following activities shall

be hired for meeting the product requirement

1. Calibration of the measuring instruments

1.1 Scope This Section describes all scope of work is in QMS Section No.: QM7.6 Rev 00 dt.

01/01/2009 (Doc No: Pur/02 Rev 01 Dt. 01/01/2013)

2 Non Destructive testing Material

2.1 Scope This section describes requirements for NDE during Fabrication of Steel

Structures.

All NDE shall be performed in accordance with applicable NDE procedures duly reviewed &

approved by qualified personnel with level III in accordance to ISO 9712/ ASNT. Evaluation

of applicable NDE shall be done by qualified personnel with level II or III in accordance to

ISO 9712/ ASNT.

2.2 Qualification of NDE Personnel NDE Level III shall be appointed by Dynaxcel Engineers

Pvt. Ltd.depending on the project specific requirements by Sub-contracting. Accordingly

PCN / ASNT Level III personnel shall be appointed. The appointment of NDE Level III is

based on his Education, Training and Qualification, Experience and ASNT / PCN Level III

certification.

NDE Level III shall be responsible for:

Training of NDE Level I/II personnel.

Examination and Qualification of NDE Personnel.

Certification of NDE Personnel is done by NDE level III and QCM.

Maintaining Qualification and Certification records of NDE Personnel.

Preparation and Approval of NDE Procedures.

Guidance in Calibration of NDE equipment at shop and field sites.

To assist in review and analysis of NDE documents with respect to applicable Code

Edition.

2.3 NDE Procedures All NDE shall be performed according to following procedures approved

by ISO 9712/EN473/ASNT Level III.

a. Liquid Penetrant Examination : DEPL/NDE/PT/01

b. Radiographic Examination : DEPL/NDE/RT/01

c. Ultrasonic Examination : DEPL/NDE/EN/UT/01

d. Magnetic particle testing : DEPL/NDE/EN/MPT/01

All NDE reports shall be reviewed and evaluated for acceptance by EN 473/ISO 9712 or

Level II.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 16 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Note NDE: At present RT method are not used at DYNAXCEL ENGG. PVT. LTD. However, when

RT method is required to be used, the procedure for RT shall be developed and approved by EN

ISO 9712/EN473/PCN Level III / Level II or ASNTs SNT-TC-1A/ ISNT Level III / Level II prior

to their use on job. Also the NDE personnel shall be trained, qualified and certified for these

methods.

2.4 Performance of NDE EN ISO 9712/EN473/PCN Level III / Level II or ASNTs SNT-TC-1A/

ISNTLevel III / Level II shall review all applicable job documents and identify the required

NDE procedures & Techniques. The NDE Level III/Level II shall select the applicable NDE

procedures from the existing approved procedures provided they comply with the job

requirements and the Code. On completion of the welding, Production Engineer shall offer

the weld joint to QCE for visual examination. Extent of NDE shall be as per Controlled

Copy drawing(s) and approved Weld Map. Based on ITP after ensuring that the previous

examination stages are cleared and visually examining the weld joint, QCE shall fill the

Request for MPT (Doc no:- QC/37 Rev.-00, Dt. 01/01/2016), Request of UT (Doc no:-

QC/37 Rev.-00, Dt. 01/01/2016Request for PT (Doc No:- QC/37 Rev.-00, Dt. 01/01/2016)

and hand over to NDE Level II.

2.5 Subcontracting NDE may be subcontracted to an organization whose written practice &

personnel qualification comply with ISO 9712. All Subcontractors NDE personnel

documentation shall be reviewed and approved by Dynaxcel ENGG. PVT. LTDs QCM.

All NDE Records shall be maintained by QCE / QCM.

2.6 Re-Qualification The NDE Level III may ask for re-qualification of NDE procedures & NDE

personnel at any time and for any changes to essential variables in NDE Procedures.

2.7 Calibration of NDE Equipment The QCE shall monitor NDE Equipment for calibration and

maintain its records.

2.8 NDE Reports The results of NDE shall be recorded on Liquid Penetrant test report,

Magnetic Particle Test report, Radiography Inspection Test Report& Ultrasonic Inspection

Test Report. All NDE reports shall be filled by QCE in the job inspection File & shall be made

available to the Inspector (as applicable) for Review.

(Doc No: pur/02 Rev 01 Dt. 01/01/2013)

3 Destructive testing Material Destructive Testing of material is carried out at

NABL accredited Laboratory only on Raw materials & Test Pieces.

(Doc No: pur/02 Rev 01 Dt. 01/01/2013)

4 Heat Treatment: Heat treatment of the material / PWHT carried out at Supplier

place from approved supplier list (Doc No: - Pur/02 Rev.00 Dt. 01.10.2005) of Dynaxcel

Engineers Pvt. Ltd as per procedure (Doc No:- DEPL/HT-01, Rev. 00 Dt. 01.06.2016)

given by DEPL to the supplier.

(Doc No: pur/02 Rev 01 Dt. 01/01/2013)

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 17 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 7 Revision - 00 TITLE WELDING PERSONNEL Effective Date 01.06.2016 Page no.-1

7 Welding & Related Activities

7.1 General

The DEPL has at his disposal sufficient and competent personnel for the planning, performing and

supervising of the welding production according to specified requirements.

All Welding Shall be performed by qualified welders, using qualified WPS in accordance with EN ISO

15609-1 and/or applicable requirements of Code of Construction (e.g. ASME/ AWS/ PED).

7.2 Welding Procedure Specifications (WPS)/pWPS Clause No : 10.2& 10.3

The QC personnel are responsible for the preparation and qualification of pWPS. The Welding

Inspector personnel shall approve WPS by signing after its successful qualification.

The QC personnel shall arrange for the qualification of each WPS, witness the welding of the test

coupon and record the variables used for each qualification test in the PQR.

Test coupons are welded under supervision of the internal welding inspector/ QC engineer or TPI

arrange by DEPL. Preparation and testing of the test specimens are performed in accordance with EN

ISO 15614-1/ applicable standards by testing laboratory. The test results report of the testing lab is

reviewed by the QCE / QCM, and if test results are acceptable, he prepares and certifies the PQR by

signature and date, recording actual variables used while making the weld coupon and test results of

the weld coupon.

Using certified PQR QCE/QCM prepares WPS. Completed WPS shall describe all the essential,

nonessential, and when required supplementary essential variables for each welding process used in

the WPS. The WPS shall have reference of the supporting PQR and is approved by QCE / QCM.

The QCE files the PQR, All changes to nonessential variables of a WPS require a revision of the WPS

which is signed, dated and controlled in the same way as the original without re-qualification.

When there is a change to an essential variables, and in-case of impact testing requirements a change

in supplementary essential variables, the WPS shall be revised and re-qualified.

When defect in a weld is repaired prior to final acceptance, the repair will be considered part of the

welding process as long as the same WPS is used. No NCR will be issued. A separate repair report shall

be generated as per Doc. No: DEPL/REPAIR PROCEDURE/1 REV.00 Dt. 01/03/2013 & for Dish End

DEPL/REPAIR PROCEDURE/2 REV.00 Dt. 01/08/2015 in-case any repair is to be carried out.

The QCE is responsible to make qualified WPS available to the PPM/PE and welders in the shop.

Using Controlled Copy drawing(s), QCE prepares Weld Map (QC/20 Rev.0 Dt. 01/02/2013) and

same is approved by QCM. The assignment of WPS to the respective weld joints shall be indicated on

the Weld Map by QCE and shall be forwarded to PPM/PE for implementation.

When fabrication drawing(s) are revised, the Weld Map shall be reviewed for changes by QCE. If Weld

Map is required to be revised due to revision in drawing, same shall be carried out by QCE

appropriately.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 18 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

7.3 Welders Qualification Clause No : 7.2

The WE/QCM is responsible for training, qualification and certification of the welders.

All welders performing welds on Steel Structures are to be qualified according to the requirements of

EN ISO 9606-1/other applicable standards & Codes & any additional requirement of the Code under

the supervision of the QCE. Preparation and testing of the required specimens, or NDE test of welds,

are conducted by a testing laboratory. The test report is reviewed by the QCE and if acceptable, he

certifies the WPQ. The WPQ documents include the essential variables for performance qualification

used for the test welds, and the ranges qualified for welding during fabrication.

A WPQ is not required for welders who are performing test welds to qualify a WPS or re-qualify it.

7.4 Re-Qualification of Welders Clause No : 7.2

Welders qualification shall be affected if one of the following conditions occurs:

A) If a welder has not welded with the specific process for six months or more, as identified in

the Welder Continuity Log/Record (Doc no:-QC/40 Rev.0 Dt. 01/06/2016) and the Qualified

Welder List (Doc No:-QC/39 Rev.0 Dt. 01/06/2016)then his qualification for that process

shall expire unless:

- A welder has welded prior to expiration of his qualification using a manual or

semiautomatic welding process which will maintain his qualification for manual and

semiautomatic welding with that process for further six months.

- The welding operator has welded prior to expiration of his qualification with that process

using machine or automatic welding, under the supervision and control of the qualifying

DEPL.

B) If there is a specific reason to question his ability to make welds that meet The Code

requirements, then his qualifications which support the welding work in question shall only

be re qualified. The successful test of a test coupon covering the planned fabrication, welding

and testing as required by EN ISO 9606-1, renews his qualification.

C) If anyone has reason to question a welders ability to make welds that meet the Code

requirements, he may ask for re-qualification at any time.

D) If there is a change in variable of his qualification.

7.5 Qualified Welders List (QWL) Clause No : 7.2

The QCE / WE is responsible for preparing and updating the Qualified Welders List (QWL) (Doc No:-

QC/39 Rev.0 Dt. 01/06/2016) at least every 3 Months or earlier in case of a new qualification or

expiry of qualification and shall be approved by QCM. QCE / WE determines when welders

qualification will expire. Copy of Qualified Welder List (QWL) is provided by QCE to PPM/PE and

QCM.

7.6 Welders Identification Clause No : 7.2

The QCE / WE shall assign to each qualified welder a unique identification number. If welder leaves

the company, his unique identification number shall not be re-assigned.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 19 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

7.7 Welding Coordination Personnel Clause No : 7.3

NDT & Welding Coordinator Personnel Details

Sr Name Designation NDT Experience Details

No Qualification

1 Rahul Quality Control ASNT Level II 10 years hand on experience in

Chaukhande Manager (PT,RT) overall quality management in

fabrication & team handling.

2 Vikas Dighe Welding ASNT NDT Level 28 years experience in metallurgy,

Engineer+ III UT, RT, MT, PT Quality management, assurance &

Welding & VT. Control in manufacturing

Coordinator International Engineering industries like

Welding Engineer. Automobiles, heavy engineering,

Certified Welding renewable energy, & Professional

Inspector. services.

Certified Quality

Manager

3 Utereshwar Sr. QC Engineer + ASNT Level II Five years experience in

Miskin Deputy Welding (UT) production & quality of fabrication

Coordinator of heat exchanger, pressure

vessels, boilers, storage tanks,

piping & structures

4 Avinash QC Engineer + ASNT Level II (UT, Five years experience in

Silimkar Deputy Welding RT, MT, PT,VT) Constructional & Fabrication field

Coordinator CSWIP 3.1 involves Weldings and NDT of heat

Welding Inspector exchanger, pressure vessels,

boilers, storage tanks, piping &

structures

5 Navid Omne QC Engineer + ASNT Level II 4 year experience in NDT &

Deputy Welding (VT,UT, RT,MT) welding of Casting, heat exchanger,

Coordinator pressure vessels, boilers, storage

tanks, piping & structures.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 20 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

7.8 Production Planning Clause No : 10.1

a) The QCE / WE is responsible for making qualified WPS available to the PPM/PE and welders

in the shop.

b) Weld Map is prepared by QCE and approved by QCM for each item.

c) Weld Map shall be forwarded to PPM/PE by QCE for implementation on each item.

d) The QCE shall prepare and update the QWL at least every 3 months and obtain approval from

QCM. QWL shall be provided to PPM/PE and QCM by Quality Engineer.

e) PPM/PE assigns qualified welders on job using QWL and Weld Map for Code work.

The Production Planning Items to be considered shall include at least:

1- Specification of the sequence by which the construction shall be manufactured (e.g. as single parts

or sub-assemblies, and the order of subsequent final assembly);(As per attached Document no-

PLAN/01Rev.00Dt.01/01/2012)

2-identification of the individual processes required to manufacture the construction; (As per

attached Document no - PLAN/01 Rev.00 Dt.01/01/2012)

3- Reference to the appropriate procedure specifications for welding and allied processes;(As per Doc

no:- QC/20 Rev.0 Dt. 01/02/2013)

4- Sequence in which the welds are to be made; (As per Doc no:- QC/20 Rev.0 Dt. 01/02/2013)

5- Order and timing in which the individual processes are to be performed;

6- Specification for inspection and testing, including the involvement of any independent inspection

body; (As per Client Approved ITP)

7- Environmental conditions (e.g. protection from wind and rain);

8- Identification by batches, components or parts, as appropriate;

9- Allocation of qualified personnel; (As per Section 0.6 of manual QM-02)

10- Arrangement for any production test.

7.9 Work instructions Clause No : 10.4

The DEPL use the welding-procedure specification directly for instruction purposes. Alternatively,

Dedicated work instructions may be used. Such dedicated work instructions shall be prepared from a

qualified Welding-procedure specification and do not require separate qualification.

If any additional instructions are to be issued, the same shall only be issued by QCE / QCM to WE. The

necessary instructions shall only be prepared in accordance to Approved WPS-PQR, Relevant codes &

Standards & Specification.

This Work instruction is made in local languages for better understandings.

7.10 Procedures for preparation and control of documents Clause No : 10.5

DEPL establish and maintain procedures for the preparation and control of relevant quality

Documents as per Master List of WPS (Doc No.: QC/45 Rev.00 Dt. 01/06/2016) as per relevant

standards.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 21 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 8 Revision - 00 TITLE INSPECTION AND TESTING PERSONNEL Effective Date 01.06.2016 Page no.-1

8 Inspection and testing personnel Clause No : 08

8.1 General

The manufacturer shall have at his disposal sufficient and competent personnel for planning,

performing, and supervising the inspection and testing of the welding production according to

specified requirements.

8.2 Non-destructive testing personnel

The non-destructive testing personnel shall be qualified in accordance to EN ISO 9712/EN473/

ASNTs SNT-TC-1A/ ISNT. For visual testing, a qualification test may not be required. When a

qualification test is not required, competence shall be verified by the DEPL.

The ISO documents to which it is required to conform to fulfil the quality requirements are specified

in

ISO 3834-5:2005, Table 3, for arc welding, electron beam welding, laser beam welding and gas

welding, and in ISO 3834-5:2005, Table 10, for other fusion welding processes.

DEPL has decided to outsource this activities from approved NDT supplier from approved supplier

List(Doc No.: Pur/02 Rev.01 Dt. 01/01/2013)& Non-destructive testing personnel qualification List

(Doc No.: QC/46 Rev.00 Dt. 01/07/2016).

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 22 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 9 Revision - 00 TITLE EQUIPMENTS Effective Date 01.06.2016 Page no.-1

9 Equipment Clause No : 09

9.1 Production and testing equipment

The following equipment shall be available, when necessary:

1 - Power sources and other machines (as per Doc. No. MM-01 Rev.00 Dt.01/06/2016);

2 - Equipment for joint and surface preparation and for cutting, including thermal cutting (as per Doc.

No. - MM-01 Rev.00 Dt.01/06/2016);

3 - Equipment for preheating and post-heat treatment including temperature indicator;

4 - Jigs and fixtures;

5 - Cranes and handling equipment used for the production (as per Doc. No. - MM-01 Rev.00

Dt.01/06/2016);

6 - Personal protective equipment and other safety equipment, directly associated with the applicable

Manufacturing process (as per Doc. No. - MM-01 Rev.00 Dt.01/06/2016):-

1-Ovens, quivers, etc. used for treatment of welding consumables (as per Doc. No. - MM-01

Rev.00 Dt.01/06/2016);

2-Facilities for surface cleaning (as per Doc. No. - MM-01 Rev.00 Dt.01/06/2016);

3-Destructive and non-destructive testing facilities.

9.2 Description of equipment

DEPL maintain a list of essential equipment, used for the production. This list shall identify items of

major equipment, essential for an evaluation of workshop capacity and capability. This includes, for

Example:

1-Maximum capacity of crane(s) (as per Doc. No. - MM-01 Rev.00 Dt.01/06/2016);

2-Size of components that the workshop is able to handle (As per MCC Certificate);

3-Capability of mechanised or automatic welding equipment (as per Doc. No.-MM-01Rev.00

Dt.01/06/2016);

4-Dimensions and maximum temperature of furnaces for post-weld heat treatment;

5-Capacities of rolling, bending and cutting equipment (as per Doc. No. - MM-01 Rev.00

Dt.01/06/2016).

Other equipment only needs to be specified by approximate total numbers which cover each general

type

(E.g. total number of power sources for the different processes).

9.3 Suitability of equipment

The equipment has been checked & found adequate for the application concerned.

9.4 New equipment

After installation of new (or refurbished) equipment appropriate tests of the equipment shall be

performed by supplier services engineer.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 23 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

9.5 Equipment maintenance

DEPL has documented plans for the maintenance of equipment. The plan shall ensure Maintenance

checks of those items in the equipment which control variables listed in the relevant procedure

specifications. The maintenance plan is shown in #MAIN/01 Rev. 00 Dt. 01/01/2014.

Defective equipment shall not be used& shall be tagged SCRAP / UNDER MAINTENANCE.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 24 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 10 Revision - 00 TITLE WELDING CONSUMABLE Effective Date 01.06.2016 Page no.-1

10 Welding consumables (ML: Pur/05 Dt. 01/08/2016) Clause No : 11

10.1 General

Responsibilities and procedures for control of welding consumables are specified.

Following Documents shall be maintained:-

1. Welding Consumable Inspection Report QC/41 Rev 00 Dt. 01/06/2016

2. Material Issue Slip Doc No. PROD/12 REV. 00 Dt. 01/05/2016

3. Welding Consumable Requision Slip Store/06 Rev 00 Dt.01/07/2016

4. Welding Consumable Issue File DEPL/STORE/05-F Rev.00 Dt. 01/06/2016

5. Welding Electrode Baking File Doc No DEPL/STORE/07-F Rev.00 Dt. 01/06/2016

10.2 Batch testing

Batch testing of welding consumables shall be required only if specified in Contract.

10.3 Storage and handling

1.1 Scope This procedure describes the minimum requirements to be complied with for

receipt, storage, issue, handling, and treatment of welding consumables prior to use in

order to ensure acceptable weld quality during fabrication & erection is as per procedure

no DEPL/WCP-01 Rev.00 Dt.01/06/2016.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 25 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 11 Revision - 00 TITLE STORAGE OF PERENT MATERIAL Effective Date 01.00.2016 Page no.-1

11Storage of parent materials Clause No : 12

Storage shall be such that the material, including material supplied by the client (if any), will not be

adversely affected. Identification shall be maintained during storage& manufacturing.

SK is responsible to check the material and the delivery challan for compliance with the PI / P.O. as

follows but not limited to

A) Quantity and transit damage if any.

B) Packaging (Defects)

C) General Condition

D) MTR/MTC Status

Store Keeper (SK) prepares Goods Receipt Note (GRN) (Doc No - STORE/03 REV.00 Dt.01/05/2016)

upon receipt of the material and forwards GRN with necessary attachments to QCE/WE for receiving

inspection.

The QCE/WE upon notification from SK shall verify that material is correctly marked in accordance

with the Material Purchase Specification (MPS) and material specification as per the Code and Issue

CT number (Doc No: QC/30 Rev. 00 Dt.01/10/2013) to material. QCE/WE shall verify the markings as

per the Code requirements and shall record their observation on the Incoming Material Inspection

Report (IMIR) (Doc No - QC/42 Rev. 00 Dt. 01/06/2016).

After Identified & clearance from QCE by verification of Physical copy of MTC & Visual then CT

Number will be given to them to as identity for production and it shall be marked by preferably

permanent paint marker.

11.1 Material Release:-

The QCE checks the MTR/MTC against the Material Purchase Specification (MPA). The MTR/MTC is

checked for compliance with the requirements of Code.

Acceptable Material is released by QCE / QCM by Signing the IMIR.

When the material is found to be acceptable, approval for usage shall be given by signature and date of

the QCM/QCE on the IMIR

Acceptable material shall be attached with a tag/sticker ACCEPTED (Exhibit No. 6.08) and shall be

allowed to be kept in stores.

If the material does not conform to the requirements of the Code, specification & P.O. then QCE will

put the remarks on the IMIR & it shall be considered as Non Conformity and to be handled as per

Section 12 (Correction of Nonconformities) of the QC Manual QM-02.

All materials which do not conform to the Code, specification/P.O. or specified requirements shall be

attached with a tag/sticker HOLD(Exhibit No. 6.08) until NCR is resolved.

Rejected material shall be attached with a tag/sticker REJECTED (Exhibit No. 6.08) and shall not be

allowed to enter in store & shall be kept outside of stores at separate identified area.

Hard stamping shall not be applied to ferrous material less than (6 mm) and nonferrous material

less than (13 mm) thickness. In this case marking shall be done preferably by etching or engraving

or by permanent paint marker.

Available stock materials shall be inspected by QCE. He will review available marking to verify

compliance with applicable Code requirements. Where necessary MTR / MTC and any additional

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 26 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

material or inspection requirement shall be validated to ensure conformance to the requirements of

Code. If current Edition of the Specification calls for additional tests, the same shall be undertaken as

necessary.

11.2 Material Issuance:-

The SK/QCE shall be responsible for controlled issuance of material. Production Engineer (PE) shall

arrange to mark accepted material with proper stamping (E.g. Job No., Part No., Material Spec. & Grade

& Heat No. etc.).

The PE shall raise the Material Issue Slip (Doc No:-Prod/12 Rev.00 Dt. 01/05/2016) in order to issue the

material from the stores

11.3 Marking Transfer:-

Before material is cut into two or more pieces, or the original marking is cut out or obliterated, either

the complete Code required markings or a minimum of following marks shall be transferred by hard

punching for proper Traceability of materials on each piece.

PLATE: Material Specification, Grade/Type/Class as applicable, CT No., Project Name (If required)

PIPE: Material Specification, Grade/Type/Class as applicable, CT No., Project Name (If required).

FORGING: Material Specification, Grade/Type/Class as applicable, Size, Rating, Heat/Lot No.

Note:

If the Size of the part does not permit complete marking as above, part shall be identified with the

relevant Part No., material P No. or Material grade. Other details of such parts i.e. Heat No,

Plate No. etc. shall be documented on Material Heat Chart (Doc No:-QC/10 Rev 00 Dt.

01/10/2005) for the job.

If the hard stamping is not permitted or not possible, the marking shall be done by Permanent

Marker or any other suitable method.

The QCE shall confirm the proper transfer of marking as per above.

11.4 Non-Conforming Material:-

Nonconforming material shall be handled as described in Section 14 (Correction of

Nonconformities).

11.5 Material Testing:-

When supplementary material testing is required (e.g. impact testing) the QCM shall be responsible

for subcontracting to laboratory complying with the Code requirements for calibration and

certification.

11.6 Incoming Material Inspection Report (IMIR):-

All IMIR mentioned in this Section are made available by the QCM with all accepted test results for

review to the AI (if applicable) and are filed in the job file.

11.7 Rejection of Materials:-

Materials which do not conform to Code requirements shall be rejected by QCE in concurrence with

the QCM with the appropriate comments on the corresponding NCR (QC/16 Rev. 01 dt.

01/01/2016).

Rejected materials shall be identified with REJECTED (Exhibit No. 6.08) tag and will be stored at

separate identified location.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 27 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 12 Revision - 00 TITLE POST WELD HEAT TREATMENT Effective Date 01.06.2016 Page no.-1

12Post-weld heat treatment (ML# Pur/02 Rev01 Dt.01/01/2013) Clause No:13

Heat treatment of the material / PWHT carried out at Supplier place from approved supplier list

(Doc No: - Pur/02 Rev.00 Dt. 01.10.2005) of Dynaxcel Engineers Pvt. Ltd as per procedure (Doc

No:- DEPL/HT-01, Rev. 00 Dt. 01.06.2016) given by DEPL to the supplier.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 28 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 13 Revision - 00 TITLE INSPECTION AND TESTING Effective Date 01.06.2016 Page no.-1

13Inspection and testing Clause No : 14

13.1 General

Applicable inspections and tests shall be implemented at appropriate points in the manufacturing

process to assure conformity with contract requirements. Location and frequency of such inspections

and/or tests will depend on the Standard Quality Plan (QC/15 Rev01 Dt. 01/01/2012)

NOTE DEPL may carry out additional tests without restriction. Reporting of such tests is not required.

13.2 Inspection and testing before welding

Before the start of welding, the following shall be checked:

1-Suitability and validity of welders and welding operators qualification certificates (As per Doc No -

QC/39 Rev.0 Dt. 01/06/2016);

2-Suitability of welding-procedure specification (As per Doc No - QC/20 Rev.0 Dt. 01/02/2013);

3-Identity of parent material (As per Approved Drawings);

4-Identity of welding consumables (As per batch no.);

5-Joint preparation (e.g. shape and dimensions) As per Doc No - QC/43 Rev.00 Dt. 19/07/2016;

6-fit-up, jigging and tacking

7-Any special requirements in the welding-procedure specification (e.g. prevention of distortion);

8-Suitability of working conditions for welding, including environment (As per Doc No - QC/43 Rev.00

Dt. 19/07/2016).

13.3 Inspection and testing during welding

During welding, the following shall be checked at suitable intervals or by continuous monitoring:

1-Essential welding parameters (e.g. welding current, arc voltage and travel speed);

2-preheating/interposes temperature;

3-Cleaning and shape of runs and layers of weld metal;

4-Back gouging;

5-Welding sequence;

6-Correct use and handling of welding consumables;

7-Control of distortion;

8- And intermediate examination (e.g. checking of dimensions).

All the above parameters shall be recorded in Document No - As per Doc no:- Form no: QC/43 Rev.00

Dt. 19/07/2016.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 29 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

13.4 Inspection and testing after welding

After welding, the compliance with relevant acceptance criteria shall be checked:

1-by visual inspection (As per Doc no - QC/11 REV.00. DT. 01/10/05);

2-by non-destructive testing (As per approved NDT report formats in NDT Procedure No -

DEPL/NDE/PT/01; DEPL/NDE/RT/01; DEPL/NDE/UT/01; DEPL/NDE/MPT/01

3-by destructive testing (Lab Test Reports If Applicable);

4-Form, shape and dimensions of the construction (As per Doc no - QC/9 REV.01 REV. DT.

01/07/2012);

5-Results and records of post-weld operations (e.g. post-weld heat treatment, ageing).

13.5 Inspection and test status

Measures shall be taken, as appropriate, to indicate, e.g. by marking of the item, the status of

inspection and test of the welded construction, Welding History Chart.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 30 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 14 Revision - 00 TITLE NON CONFIRMANCE AND CORRECTIVE Effective Date Page no.-1

ACTION 01.06.2016

14Non-conformance and corrective actions Clause No : 15

14.1 Definition:-

Nonconformity is any condition which does not comply with the applicable rules of the Code, the QC

Manual, or other specified requirements. Non conformities must be corrected before the completed

component can be considered to comply with the Code.

All NCRs shall be closed out before the QCM certifies the MDR.

14.2 Nonconformity Identification:-

Scope This Section describes all scope of work is in QMS Section No.: QM8.3 Rev.00 Dt. 01/01/2009,

as per procedure no P/05/MR rev.00 Dt. 01/01/2009

14.3 Corrective Action:-

1.1 Scope This Section describes all scope of work is in procedure no. P/04/MR Rev.00, Dt.

01/01/2009

14.4 Preventive Action:-

When the proposed corrective action has been completed and verified by the QCM, the NCR shall be

signed by the QCM for acceptance of NCR Closure. The QCE then shall remove the Hold tag from the

item.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 31 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 15 Revision - TITLE CALIBRATION AND VALIDATION OF Effective Date Page no.-1

01 MEASURING / INSPECTION / TESTING EQUIPMENT 01.06.2016

Clause No : 16

15Calibration and validation of measuring, inspection and testing equipment

15.1 Scope:-

1.1 This Section describes the calibration of examination, measurement and test equipment

used in fulfillment of applicable Code requirements& all scope of work describe in QMS

Section No.: QM7.6 Rev.00, dated 01/01/2009

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 32 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 16 Revision - 00 TITLE IDENTIFICATION AND TRECEBILITY Effective Date 01.06.2016 Page no.-1

16Identification and traceability Clause No : 17

Identification and traceability shall be maintained throughout the manufacturing process, if required.

Documented systems to ensure identification and traceability of the welding operations shall include,

if Required:

1-Identification of production plans

2-Identification of routing cards

3-Identification of weld locations in construction

4-Identification of non-destructive testing procedures and personnel (As per Clause 6 sub clause 2 of

manual QM-02);

5-Identification of welding consumable

(E.g. designation, trade name, manufacturer of consumables and Batch or cast numbers)(As per Doc

No:- QC/41 Rev.00 Dt. 01/06/2016);

6-Identification and/or traceability of parent material (e.g. type, cast number)(As per Doc No:- QC/30

Rev.00 Dt.01/10/2013);

7-Identification of location of repairs

8-Traceability for fully mechanised and automatic welding units to specific welds

9-Traceability of welder and welding operators to specific welds (As per Doc No:- QC/20 Rev.00 Dt.

01/02/2013));

10-Traceability of welding-procedure specifications to specific welds(As per Doc No:- QC/20 Rev.00 Dt.

01/02/2013).

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 33 of 34

QUALITY MANUAL FOR

FUSION WELDING OF METALLIC MATERIAL

QM-02 ISO 3834 2 : 2006 (E)

Section 17 Revision - 00 TITLE QUALITY RECORD Effective Date 01.06.2016 Page no.-1

17Quality records Clause No : 18

Quality records shall include, when applicable:

1-Record of requirement/technical review(As per Doc No:- PLAN/03 Rev.00 dt.01/06/2016&(As per Doc

No:- PLAN/02 Rev.00 dt.01/06/2016)

2-Material inspection documents(As per Doc No:- QC/42 Rev. 00 Dt. 01/06/2016)

3-Welding consumable inspection documents(As per Doc No:- QC/41 Rev 00 Dt. 01/06/2016)

4-Welding-procedure specifications (As per Clause 7.2 of manual QM-02)

5-Equipment maintenance records

6-Welding-procedure qualification records (WPQR)

7-Welder or welding-operator qualification certificates (As per Clause 7.3 & 7.4 of manual QM-02)

8-Production plan(As per Doc No:-Prod/03 Rev.00, Dt. 01/10/2005)

9-Non-destructive testing personnel certificates (As per Clause 6 sub clause 2 of manual QM-02)

10-heat-treatment procedure specification and records

11-non-destructive testing and destructive testing procedures and reports (As per Clause 6 sub

clause 2 of manual QM-02)

12-Dimensional reports(As per Doc No:-QC/09 Rev 01 Dt. 01/07/2012)

13-Records of repairs and non-conformance reports(As per Doc No:- QC/06 Rev 01 Dt. 01/01/2008)

14-Other documents, if required.

Quality records shall be retained for a minimum period of five years in the absence of any other

specified Requirements.

Mr. Avinash Silimkar Mr. Vikas Dighe Mr. Rahul Chaukhande

PREPARED BY REVIEWED BY APPROVED BY

Page No. 34 of 34

S-ar putea să vă placă și

- Filler Metal Selection ChartDocument1 paginăFiller Metal Selection Chartavinash19870% (1)

- Sae J20-2-2018Document4 paginiSae J20-2-2018Vedpal Singh ChoudharyÎncă nu există evaluări

- Sample - Welding ManualDocument42 paginiSample - Welding ManualAmit shah100% (3)

- ISO 3834 - Checklist-2Document6 paginiISO 3834 - Checklist-2Abhishek Anand80% (5)

- Welding procedure specification guideDocument3 paginiWelding procedure specification guideAnilÎncă nu există evaluări

- ISO 9606 Revised 4 SeptDocument34 paginiISO 9606 Revised 4 Septaravindan100% (5)

- ISO 3834 - ChecklistDocument26 paginiISO 3834 - ChecklistAbhishek Anand83% (6)

- Requirements ISO 3834Document76 paginiRequirements ISO 3834mdasifkhan2013100% (7)

- Welding Manual for Boiler ComponentsDocument19 paginiWelding Manual for Boiler ComponentsRajesh ThakurÎncă nu există evaluări

- SMETA Best Practice GuidanceDocument47 paginiSMETA Best Practice GuidancePinaki Das100% (1)

- Screw Conveyor Design Analysis MatlabDocument21 paginiScrew Conveyor Design Analysis Matlabavinash1987Încă nu există evaluări

- ISO 3834 by SelvaDocument83 paginiISO 3834 by Selvaaravindan100% (11)

- Welding CoordinationDocument3 paginiWelding CoordinationIon PlesaÎncă nu există evaluări

- CE Mark en 1090 Iso 3834 Manual DocumentsDocument10 paginiCE Mark en 1090 Iso 3834 Manual DocumentsDan DumbravescuÎncă nu există evaluări

- WPS Format For ISO 9606-1 WelderDocument2 paginiWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- ISO 3834 Quality Docs Plans Procedures Maintenance WeldingDocument1 paginăISO 3834 Quality Docs Plans Procedures Maintenance WeldingSatish KeskarÎncă nu există evaluări

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 paginiWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- WPS Format For ISO 15614-1 PQRDocument3 paginiWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- Welding Coordination Activities and ResponsibilitiesDocument7 paginiWelding Coordination Activities and ResponsibilitieseliiiiiiÎncă nu există evaluări

- Welding Coordinator Tasks and ResponsibilitiesDocument3 paginiWelding Coordinator Tasks and ResponsibilitiesShaun Holder100% (4)

- Koc Standard For Low Voltage Switchgear DOC. NO. KOC-E-009: Standards PublicationDocument45 paginiKoc Standard For Low Voltage Switchgear DOC. NO. KOC-E-009: Standards Publicationinb100% (1)

- Sample of Welding Quality ManualDocument5 paginiSample of Welding Quality ManualwentropremÎncă nu există evaluări

- ISO 3834-2 Compliance Check ListDocument1 paginăISO 3834-2 Compliance Check ListMichael Tayactac100% (1)

- Tecnical Review ChecklistDocument6 paginiTecnical Review ChecklistShaun Holder100% (1)

- Iws Fabrication Application PDFDocument245 paginiIws Fabrication Application PDFScott Trainor100% (1)

- Introduction to ISO 3834Document54 paginiIntroduction to ISO 3834amit50% (2)

- Supplier/subcontractor Quality RequirementsDocument68 paginiSupplier/subcontractor Quality RequirementsSagar ShahÎncă nu există evaluări

- ISO 3834-5 Ver EDocument10 paginiISO 3834-5 Ver ETrung Nguyễn100% (4)

- Technical Review For ISO 3834Document1 paginăTechnical Review For ISO 3834Satish Keskar100% (3)

- BSI Standards Publication: BS EN ISO 15609 1:2019Document34 paginiBSI Standards Publication: BS EN ISO 15609 1:2019Ирина Михайлова67% (6)

- BS en 13263 - 2 - 2009Document24 paginiBS en 13263 - 2 - 2009Gianni TogniÎncă nu există evaluări

- QMS Manual PDFDocument112 paginiQMS Manual PDFSwat Guratai by javed Javed iqbalÎncă nu există evaluări

- ISO 3834 Welding Certification GuideDocument11 paginiISO 3834 Welding Certification GuideWeld Bro Sandeep100% (1)

- ISO 9606-1 Interpretations 2019-04-10Document5 paginiISO 9606-1 Interpretations 2019-04-10alevent100% (1)

- Welders Certification Designation Acc. To EN ISO 9606-1Document1 paginăWelders Certification Designation Acc. To EN ISO 9606-1vonipko100% (9)

- Iso 3834-5 - 2015Document14 paginiIso 3834-5 - 2015raghulramasamy100% (1)

- Retail Sector in India A Case of Big BazaarDocument44 paginiRetail Sector in India A Case of Big Bazaaravinash1987100% (7)

- ISO 3834 & EN 15085 Welding Standards GuideDocument10 paginiISO 3834 & EN 15085 Welding Standards Guide0502raviÎncă nu există evaluări

- Interview QuestionsDocument5 paginiInterview Questionsavinash1987100% (1)

- Review of RequirementsDocument1 paginăReview of RequirementsSatish KeskarÎncă nu există evaluări

- Specific Size Agitator Selection Process & Specification PDFDocument28 paginiSpecific Size Agitator Selection Process & Specification PDFParth ThakarÎncă nu există evaluări

- Quest Audit 3834Document38 paginiQuest Audit 3834g33k59100% (2)

- Need of ISO 3834 To Welding Fabrication IndustryDocument4 paginiNeed of ISO 3834 To Welding Fabrication IndustrySatish Keskar100% (1)

- TQMDocument177 paginiTQMWillyanto LeeÎncă nu există evaluări

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 paginiWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEÎncă nu există evaluări

- Method Statement For Civil Foundations & GroutingDocument18 paginiMethod Statement For Civil Foundations & GroutingAbdullah Abdullah100% (1)

- Quality CultureDocument2 paginiQuality CultureFahrul RoyÎncă nu există evaluări

- Guideline Welding Coordination For ISO 1090-2Document33 paginiGuideline Welding Coordination For ISO 1090-2apostolidis83100% (1)

- Project Quality Plan (PQP) (Project Construction and Management)Document23 paginiProject Quality Plan (PQP) (Project Construction and Management)Imran ZamanÎncă nu există evaluări

- Aqap 2110 eDocument19 paginiAqap 2110 eAlemirPLÎncă nu există evaluări

- Irca 106 Audit Log SheetDocument18 paginiIrca 106 Audit Log Sheetpkkohli123100% (1)

- ISO 3834 welding certification levelsDocument9 paginiISO 3834 welding certification levelsvilukÎncă nu există evaluări

- Shop Construction and Field Assembly: Asme Code Section Viii Division 1Document8 paginiShop Construction and Field Assembly: Asme Code Section Viii Division 1Mohd AshrafÎncă nu există evaluări

- Implement ISO 3834 welding standardsDocument34 paginiImplement ISO 3834 welding standardschowhkÎncă nu există evaluări

- Handbook of Quality Integrated Circuit ManufacturingDe la EverandHandbook of Quality Integrated Circuit ManufacturingEvaluare: 5 din 5 stele5/5 (1)

- Iso 3834Document52 paginiIso 3834Akshay Kumar100% (1)

- BS en Iso 3834-5 2015Document18 paginiBS en Iso 3834-5 2015dan100% (2)

- IIW Guidance For 3834Document20 paginiIIW Guidance For 3834Necati Dayı80% (5)

- ISO 3834 Evaluation TestDocument2 paginiISO 3834 Evaluation TestSatish KeskarÎncă nu există evaluări

- Method Statement For External Joint CoatingDocument15 paginiMethod Statement For External Joint CoatingAbdullah AbdullahÎncă nu există evaluări

- Welding Coordination Tasks ISO 14731Document1 paginăWelding Coordination Tasks ISO 14731Ion Plesa100% (1)

- Vda 6.3Document207 paginiVda 6.3MANUELÎncă nu există evaluări

- BS en Iso 3834-3 - 2021Document16 paginiBS en Iso 3834-3 - 2021jesonelite100% (2)

- Buma 30033 - Funds of Bpo 102Document69 paginiBuma 30033 - Funds of Bpo 102Hilary OdinadaÎncă nu există evaluări

- Overzicht en Iso 3834 Editie 2017 - Engels PDFDocument1 paginăOverzicht en Iso 3834 Editie 2017 - Engels PDFrohit mathankerÎncă nu există evaluări

- Iso 3834 GuidelinesDocument3 paginiIso 3834 Guidelinesshabashakkim0% (1)

- OGGB-Material and Equipment Standard For Cathodic ProtectionDocument182 paginiOGGB-Material and Equipment Standard For Cathodic ProtectionBahmanTamaddonÎncă nu există evaluări

- VR Aslow 81tab Validation ReportDocument31 paginiVR Aslow 81tab Validation Reportziauddin bukhariÎncă nu există evaluări

- SOP Name SOP For Led Driver Quality Test (Refrigerator) DATE ISSUED 07.07.2020Document7 paginiSOP Name SOP For Led Driver Quality Test (Refrigerator) DATE ISSUED 07.07.2020swapon kumar shill0% (1)

- MS - DraftDocument12 paginiMS - Draftmuthu219ableÎncă nu există evaluări

- Quality Manual As Per Iso 9001:2015: Doc No.: Sipl/Qms Rev. No: 03 Effective Date: 01.03.2022Document26 paginiQuality Manual As Per Iso 9001:2015: Doc No.: Sipl/Qms Rev. No: 03 Effective Date: 01.03.2022production steelinnovationsÎncă nu există evaluări

- Calibration of Liquid ThermometersDocument12 paginiCalibration of Liquid ThermometerstungluongÎncă nu există evaluări

- A Qac Pro 000 38951Document30 paginiA Qac Pro 000 38951Amin GÎncă nu există evaluări

- Quality Manual - Simba Fashions Ltd.Document143 paginiQuality Manual - Simba Fashions Ltd.ABDULÎncă nu există evaluări

- Apollo Heat Exchangers PVT LTD: SR - No. EN Ref - No. List of Standard For en 15085-2 Existing Version New VersionDocument1 paginăApollo Heat Exchangers PVT LTD: SR - No. EN Ref - No. List of Standard For en 15085-2 Existing Version New VersionQC apollohxÎncă nu există evaluări

- Atal Pension Yojana MatrixDocument2 paginiAtal Pension Yojana Matrixavinash1987Încă nu există evaluări

- Apy Chart PDFDocument1 paginăApy Chart PDFavinash1987100% (1)

- Award Certificate TemplatesDocument1 paginăAward Certificate Templatesavinash1987Încă nu există evaluări

- Hi-Alloy Care of ElectrodesDocument1 paginăHi-Alloy Care of Electrodesmohdrafeek83Încă nu există evaluări

- Management Training - Team NewtonDocument16 paginiManagement Training - Team Newtonavinash1987Încă nu există evaluări

- I9000 1 94Document28 paginiI9000 1 94shganesh81Încă nu există evaluări

- CV of Rifat 26 Nov 2014Document9 paginiCV of Rifat 26 Nov 2014sjkdaÎncă nu există evaluări

- MA - 406 MA - 505 MA - 506: MHZ Range Crystal UnitDocument2 paginiMA - 406 MA - 505 MA - 506: MHZ Range Crystal UnitCharles Albert Esquivel EspinozaÎncă nu există evaluări

- QMDocument29 paginiQMNathan Montgomery100% (1)

- MTR Document Package January 21, 2014 Trevor Wynnychuk Celtic Pride Manufacturing LTDDocument8 paginiMTR Document Package January 21, 2014 Trevor Wynnychuk Celtic Pride Manufacturing LTDCristian BarbuceanuÎncă nu există evaluări

- DCP1001ADocument7 paginiDCP1001Aacrisiu2005Încă nu există evaluări

- Global Brand Local ServiceDocument192 paginiGlobal Brand Local ServiceHynetecSacÎncă nu există evaluări

- GM Customer Specifics - Rev 05-07-15Document34 paginiGM Customer Specifics - Rev 05-07-15hugocronyÎncă nu există evaluări

- IRIS TrianingDocument66 paginiIRIS TrianingSANKUSIÎncă nu există evaluări

- CASESTUDYMERCZIDocument8 paginiCASESTUDYMERCZISheila Mae RiveraÎncă nu există evaluări

- The Contemporary Landscape of Asset Mana PDFDocument8 paginiThe Contemporary Landscape of Asset Mana PDFBogasi Q.Încă nu există evaluări

- ASME Boiler and Pressure Vessel Code SynopsisDocument7 paginiASME Boiler and Pressure Vessel Code SynopsisarissaÎncă nu există evaluări

- IPMA OCB v1Document67 paginiIPMA OCB v1coyote41Încă nu există evaluări

- ISO 9000 Quality Systems Standards GuideDocument11 paginiISO 9000 Quality Systems Standards GuideSukanth KannanÎncă nu există evaluări

- IMS-F MR MASTER LIST OF DOCUMENTS & RECORDS Revised 07-11-2023Document9 paginiIMS-F MR MASTER LIST OF DOCUMENTS & RECORDS Revised 07-11-2023Sandeep Mazumdar100% (1)

- Marketing Plan AssignmentDocument12 paginiMarketing Plan AssignmentUsman50% (2)

- CV Radivoj Jovanov FM LASTDocument5 paginiCV Radivoj Jovanov FM LASTRadivojJovanovÎncă nu există evaluări