Documente Academic

Documente Profesional

Documente Cultură

Gap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)

Încărcat de

Javier GutierrezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Gap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)

Încărcat de

Javier GutierrezDrepturi de autor:

Formate disponibile

16/06/2017

OPERATIONS / MAINTENANCE

KILNS MECHANICAL MAINTENANCE

Code..

Chapter 1

GAP MEASUREMENT (Clearance) AND DISPLACEMENT (Control of Clearance) BETWEEN

THE KILN SHELL AND TIRE (Kiln Tires).

1.1 OBJECTIVE AND SCOPE

The objective of this measurement is to count with the necessary information to control displacement

and clearance between the kiln tube and tires due that it is fundamental for the refractory life as well

as for mechanical conditions.

This is a control requiring a lot of caution, and the recommendation is to check at least once per shift.

1.2 METHOD BASIS OR FOUNDATION

There are kilns with tires that due to their design are fixed; i.e., they do not have sliding between the

kiln tube and tire, but in the FLS kilns (F. L. Smidth) rolling rings of "floating" single type or "migrating"

type are used, with certain diameter difference between the kiln tire and the kiln shell (support

blocks).

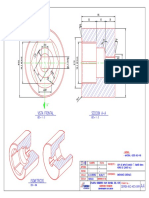

The kiln tube and the rolling rings are dimensioned so that D internal diameter, of kiln tire, is a little bit

bigger than the d kiln tube external diameter, measured in support blocks (or in the kiln tube). The

diameter difference is necessary considering that the thermal expansion is a little bit bigger than the

kiln tube.

The absolute diameter difference, i.e., the diameter difference between a circular kiln tire and a

circular kiln shell, is named 2s. See Figure number 1.1.

The diameter difference provokes, during the kiln rotation, a relative movement between the kiln tire

and the kiln shell due to the different expanded lengths of both supporting faces.

The kiln tire movement, regarding the kiln shell, is named kiln tire displacement.

Figure 1.1.

The displacement of the kiln tire in a kiln rotation is classified with the letter V.

CHAPTER 1 Kilns Maintenance Manual Page 1 of 8

16/06/2017

OPERATIONS / MAINTENANCE

KILNS MECHANICAL MAINTENANCE

Code..

1.2.1 Importance of Clearance

It is important that the clearance between the kiln tube and the kiln tire is maintained within certain values

obtained by experimentation.

If the kiln tube temperature is suddenly increased, so that the temperature difference between the kiln

tube and the kiln tire is substantial, perhaps the clearance between these becomes null or negative. This

way represents a possible choking between the kiln and the kiln tire. In case the choking is very

pronounced, a permanent deformation called "constriction" (or trumpet) will be produced in the reinforced

kiln shell of the kiln tube.

The risk of this situation is higher in the kiln tires, above and below the calcinations zone. Consequently,

it is important that the relative displacement between the kiln and the kiln tires is controlled.

In case of producing permanent deformations on the kiln tube, this can result in, that a diameter extended

difference involves difficulties in coating, with the consequent need to reduce the clearance between the

kiln tires and the support blocks for the ring due to supplements placed below the blocks.

In order to protect the rotary kiln against deformations and / or damages in coating, produced by

overheating during service, it is necessary to control strictly and perform, if possible, service corrections to

maintain the diameter difference, between the kiln and the kiln tire, within an acceptable level, so that the

ovality can be maintained within the admissible maximum and minimum limits.

A control of the current diameter difference, during the kiln service, is made in the simplest and most

accurate mode in order to measure the kiln tire displacement, the kiln tube relative movement regarding

the kiln tires.

1.2.2 Kiln tire displacement Measurement.

As previously mentioned, the supports are built so that there will be in the hot kiln a diameter difference

from 0 to 3 mm between the kiln tube and the kiln tire.

The diameter difference, the clearance between the kiln shell and the kiln tire, provokes, as indicated, a

relative movement between these two components.

The theoretical diameter difference, 2s, produces a relative movement as follows:

Vt = .( 2RL - 2 RO ) RL = Internal radius

RO = External radius

Vt = . 2s

The relative movement or displacement V, between the deformed kiln shell and the kiln tire, according to

acquired experiences will be, 1 1/2 - 2 times the upper clearance d (gap). When dealing with small holes,

it will be 1 1/2 times and 2 times in big size kilns.

The theoretical and real displacement of kiln tire, are in reality the same, whatever the deformation is.

It is not possible measuring the diameter difference in a hot kiln, but, considering that the kiln tire

displacement is a function of the diameter difference, this can be indirectly controlled by the kiln tire

displacement confirmation.

CHAPTER 1 Kilns Maintenance Manual Page 2 of 8

16/06/2017

OPERATIONS / MAINTENANCE

KILNS MECHANICAL MAINTENANCE

Code..

1.2.3 Causes of kiln tire clearance reduction

A kiln tire in cold status is never fixed seated over the kiln. The technical reasons related to mounting

explain the need to have certain clearance, so that the kiln tire can move along the kiln.

With the purpose to consider the variable thermal expansions of the kiln shell and kiln tire during the

heating period; the kilns suppliers calculate both diameters so that the clearance between the kiln tire and

kiln, at service temperature, adopts a minimum value. It would be ideal that the kiln, in hot status, would

exert certain pressure over the kiln tire, without being subject to a contraction. This would naturally

demand that the temperatures used for calculation would be really reached during the service. It is

confirmed, based on experience, that it is practically impossible to anticipate the calculation of the

temperatures profile related to a rotary kiln shell.

There is always a danger for the kiln when the kiln shell expands with a higher speed than that of the kiln

tire.

It is easy to understand that this happens when a coating damage occurs under the kiln tire. But it is not

clear, on the other hand, a too quick heating condition, i.e. a start within a record time, can also have

serious consequences. In this case, the kiln tire is relatively cold and the kiln shell is quickly heated, so

that permanent deformations can occur due to the kiln shell contraction. In such cases, the kiln tire

internal heating can lead to an inadmissible increase in the kiln tire clearance.

Figure 1.2 shows the temperature development of the kiln tire and kiln shell during a kiln facility-heating

period.

t mx. is the maximum temperature difference, which can occur between the kiln tire and the kiln shell.

CHAPTER 1 Kilns Maintenance Manual Page 3 of 8

16/06/2017

OPERATIONS / MAINTENANCE

KILNS MECHANICAL MAINTENANCE

Code..

752

[0F]

572

Fur nace

Cuirass

392

Rolling Ring

212

Hours

Figure 1.2

T = Thermal stress with obstructed expansion

t max = Maximum temperature difference between the kiln tire and

cover

t s = Operation temperature difference

t = Expansion Coefficient

Temperature curve of kiln tire and kiln shell during a kiln-heating phase

A kiln shell permanent contraction will be produced below the kiln tire when the thermal stress T for a kiln

shell impaired expansion exceeds the elasticity limit F.

sT = E . t . t max < F

This can be the case when the required clearance in cold status sth is little or zero.

In the same way, whenever the maximum temperature difference t max is too high due to an

excessively fast heating situation.

1.3 METHOD DEVELOPMENT

1.3.1 Equipment and tools to be used

F.L. Smidth supplies automatic equipment for kiln tire displacement surveillance and control. In case that

such equipment is not available, it is possible to measure the kiln tire displacement manually.

One of the most utilized methods in Cemex is the use of Displacement and Gap Meter (Figure 1.3). This

measurement appliance is composed by a bracket (02) that, through a magnetic base, is placed on one

of the support blocks. The bracket supports a recording needle (03), under a spring and in horizontal

CHAPTER 1 Kilns Maintenance Manual Page 4 of 8

16/06/2017

OPERATIONS / MAINTENANCE

KILNS MECHANICAL MAINTENANCE

Code..

position, pressed against a piece of paper that is, through the usage of adhesive tape, fixed to a plate

(04), that in turn, is fastened to the kiln tire by magnetic blocks.

Additionally the measuring can be made by a manual method, which is described in the procedures

section.

1.3.2 Periodicity

The measuring operation of the kiln tire (tire) displacement and gap is a control requiring the most

caution, and the recommendation is to check it at least once by shift.

When dealing with kiln starts, the measuring operation must be more intensive, i.e. measuring two or

more times per shift.

1.3.3 Procedure, calculation methods and results

1.3.3.1 By the displacement and gap-measuring appliance.

Placing coupled marks in the kiln tire and in the kiln tube can perform, in a very easy way, the simplest

kiln tire displacement measuring method. Whenever the kiln has been spinning, for example, 10 rotations,

the displacement between marks is measured, in this way, the average displacement calculation is

possible.

The clearance can consecutively be found when dividing V by 1.5 - 2, i.e.:

V

= -------------

1.5 a 2

If the displacement average V is divided by , the result is :

V/ = 2s, it means

The theoretical clearance in the circular kiln tube / kiln tire.

1.3.3.2 Using the displacement and gap meter.

A method even more practical for measuring V and , utilized by CEMEX, is performed with a single

appliance named: displacement and gap meter, shown in Figure 1.3, described as follows:

The appliance is placed as illustrated in Figure 1.3 and during the kiln rotation; the recording needle will

draw a curve, as illustrated in Figure 1.4, corresponding to the kiln base where the kiln is to be measured.

The curves shown are equivalent to 5 kiln turns or rotations illustrated in Figure 1.4, the values V and S

can be directly measured in the curve.

CHAPTER 1 Kilns Maintenance Manual Page 5 of 8

16/06/2017

OPERATIONS / MAINTENANCE

KILNS MECHANICAL MAINTENANCE

Code..

As previously mentioned, it is important that the clearance between the kiln shell and the kiln tire is

maintained within determined values.

Figure 1.3

Figure 1.4

If the recording needle, during the kiln starting process, begins to draw smaller and smaller curves, means

that V and S tend to null value, and it can be necessary to participate in order to prevent "constriction".

1.3.4 Interpretation of results.

Gap Adjustment

CHAPTER 1 Kilns Maintenance Manual Page 6 of 8

16/06/2017

OPERATIONS / MAINTENANCE

KILNS MECHANICAL MAINTENANCE

Code..

As previously mentioned, the big deformations are observed in the zone of the kiln tires having an

important clearance.

In order to reduce deformations, it is necessary to reduce the kiln tire clearance by lower shimming of kiln

tires wear pads, provided that it is constructively possible (kiln tire wear pads are screwed).

In such case, the thickness of plates to be placed must be determined.

The safest method for this purpose is the following:

- Daily determination of a relative movement U and / or during a period sufficiently long (3 months).

- The minimum value U and / or V occurring within this period must serve to determine the mean

clearance of the kiln tire.

- The supplementary plates thickness is obtained from the mean clearance of the kiln tire s th and / or .

U

sth = --------

- As a safety factor regarding the big thermal expansions, the supplementary plates thickness will be

dimensioned so that the clearance in service status is within the order of 3 mm.

Therefore, the thickness for the supplementary plates is the following:

sth - 3

tB = ------------- mm

2

1.3.5 Safety aspects

In order to measure the kiln tire gap and the displacement, the activity must be executed with the kiln

running and in hot condition, as previously mentioned, thereby special caution and attention must be paid

to prevent damage by burning or by touching the equipment in motion.

1.3.6 Condemning or permissible limits

The relative movement or displacement V, between the deformed kiln shell and the kiln tire, must be

according to the acquired experiences, 1 1/2 - 2 times the upper clearance d (gap). When dealing with

little kilns, it will be 1 1/2 times and 2 times for big size kilns.

1.4 COMMENTS AND OBSERVATIONS

As previously mentioned, it is very important to have kiln tire gap and displacement control, this procedure

is therefore classified as general observance and mandatory.

CHAPTER 1 Kilns Maintenance Manual Page 7 of 8

16/06/2017

OPERATIONS / MAINTENANCE

KILNS MECHANICAL MAINTENANCE

Code..

1.5 ATTACHMENTS AND USED FORMS

The form used to record information is free, it means the wanted information can be utilized according to

each plant needs.

1.6 REFERENCES

- Control of clearance between the kiln tube and the kiln tires,

Manual F.L. Smidth 19124-01.

- Recommended Procedures for Mechanical Analysis of rotary kilns,

Book of Robert P. Chapman (Fuller Company).

CHAPTER 1 Kilns Maintenance Manual Page 8 of 8

S-ar putea să vă placă și

- Kiln Migration and Its Effect On Brick LiningDocument3 paginiKiln Migration and Its Effect On Brick LiningJunaid Mazhar100% (2)

- Kiln MigrationDocument3 paginiKiln MigrationfaheemqcÎncă nu există evaluări

- Heat correction of kiln cranks is cost effectiveDocument4 paginiHeat correction of kiln cranks is cost effectiveMohamed Shehata100% (2)

- Kiln Shell and TyresDocument37 paginiKiln Shell and TyresMudassir Rafiq100% (1)

- Atox Vertical Roller Mill, Maintenance and RepairDocument77 paginiAtox Vertical Roller Mill, Maintenance and RepairKhalil AhmedÎncă nu există evaluări

- Rotary Kiln Reconditioning Tyre and Roller GrindingDocument8 paginiRotary Kiln Reconditioning Tyre and Roller GrindingTiago CamposÎncă nu există evaluări

- 17.kiln Air GapDocument7 pagini17.kiln Air GapSUNIL TVÎncă nu există evaluări

- 1 Exemplary Technical Report 2012Document99 pagini1 Exemplary Technical Report 2012MKPashaPashaÎncă nu există evaluări

- 2020 - 07 - SZS WPU 274Document12 pagini2020 - 07 - SZS WPU 274pinion gearÎncă nu există evaluări

- Comprehensive Alignment of Kiln PDFDocument95 paginiComprehensive Alignment of Kiln PDFAamirKhanÎncă nu există evaluări

- Hot Kiln SurveyDocument2 paginiHot Kiln SurveyHenok Moges KassahunÎncă nu există evaluări

- Philips Kiln ServicesDocument20 paginiPhilips Kiln ServicesAbul Qasim QasimÎncă nu există evaluări

- Girth Gear Alignment ProcedureDocument14 paginiGirth Gear Alignment Procedurepinion gear100% (1)

- What To Do When A Kiln Tire Stops MigratingDocument16 paginiWhat To Do When A Kiln Tire Stops MigratingVisnu Sankar100% (3)

- Vertical Mill PresesntationDocument54 paginiVertical Mill PresesntationrecaiÎncă nu există evaluări

- VRM (Vertical Roller Uninstallation) PDFDocument23 paginiVRM (Vertical Roller Uninstallation) PDFShariq KhanÎncă nu există evaluări

- Main Bearing Mounting and Maintenance GuideDocument16 paginiMain Bearing Mounting and Maintenance Guidezementhead100% (1)

- Ball Mill InspectionDocument4 paginiBall Mill Inspectionlovepink_17Încă nu există evaluări

- Two-Pier Drum AlignmentDocument27 paginiTwo-Pier Drum AlignmentemadsabriÎncă nu există evaluări

- Thrust Roller Manual Operation and MaintenanceDocument48 paginiThrust Roller Manual Operation and Maintenancesreeganeshr100% (2)

- Raw Mill Vertical Roller Mill PDFDocument58 paginiRaw Mill Vertical Roller Mill PDFganong itbÎncă nu există evaluări

- 011-Repl of Kiln Shell Under TyreDocument32 pagini011-Repl of Kiln Shell Under Tyremkpq100% (3)

- Tire CreepDocument3 paginiTire Creepnazmul hasan0% (1)

- FK PumpDocument29 paginiFK PumpPP2 Common ID/OperationÎncă nu există evaluări

- 2016 - 06 - PeG (Overhauling Report of MAAG Gear by Peter Gunsch)Document10 pagini2016 - 06 - PeG (Overhauling Report of MAAG Gear by Peter Gunsch)AamirKhanÎncă nu există evaluări

- Kiln Alignment AnalysisDocument32 paginiKiln Alignment Analysiszementhead100% (6)

- Rotary Inclinometer Product DescriptionDocument8 paginiRotary Inclinometer Product DescriptionfetniÎncă nu există evaluări

- Kiln Mechanics - (1.3) - ''Design''.ppsDocument110 paginiKiln Mechanics - (1.3) - ''Design''.ppsDiego AlejandroÎncă nu există evaluări

- Hydraulic Thrust DeviceDocument2 paginiHydraulic Thrust DeviceAlbar Budiman100% (6)

- Kiln Producers: UkashmDocument2 paginiKiln Producers: UkashmDurga PrasadÎncă nu există evaluări

- Rotary Kiln AlignmentDocument1 paginăRotary Kiln AlignmentAnonymous YY2JbqyjMtÎncă nu există evaluări

- AUMUND Pan Conveyors Fd0a10Document24 paginiAUMUND Pan Conveyors Fd0a10Bruno100% (1)

- Kiln Trouble ShootingDocument3 paginiKiln Trouble Shootingemad sabriÎncă nu există evaluări

- KILN TechnicalDocument37 paginiKILN TechnicalVisnu SankarÎncă nu există evaluări

- Kiln MiscellaneousDocument69 paginiKiln MiscellaneousKayıhan Çağlar88% (8)

- Multi-Movable Cross-Bar CoolerDocument8 paginiMulti-Movable Cross-Bar Coolergsreddy42100% (1)

- Hot Alignment 2009Document97 paginiHot Alignment 2009Anonymous V210wtJiZÎncă nu există evaluări

- Exemplary Hot Kiln Alignment ReportDocument82 paginiExemplary Hot Kiln Alignment ReportsamihakhanÎncă nu există evaluări

- How to repair cement kiln tire and roller wearDocument8 paginiHow to repair cement kiln tire and roller wearmahreza18950% (2)

- Vertical Roller MillsDocument52 paginiVertical Roller MillsThibaut Leconte50% (2)

- Mpam-Kiln 2Document7 paginiMpam-Kiln 2sreeganeshrÎncă nu există evaluări

- OK MillDocument52 paginiOK MillHazem Hasan100% (2)

- Mech Kiln InspectionDocument2 paginiMech Kiln InspectionMohamed ShehataÎncă nu există evaluări

- Kiln Mechanics 222222Document59 paginiKiln Mechanics 222222Said EL FakkoussiÎncă nu există evaluări

- Grease Girth GearDocument32 paginiGrease Girth Gearsatfas100% (1)

- Cooler ETA Vs Grate JG (Document39 paginiCooler ETA Vs Grate JG (NaelÎncă nu există evaluări

- Kiln Alignment AnalysisDocument36 paginiKiln Alignment AnalysisIIÎncă nu există evaluări

- Kiln DriveDocument83 paginiKiln DriveMohammed BÎncă nu există evaluări

- 5.kiln BearingsDocument60 pagini5.kiln BearingsKayıhan Çağlar96% (23)

- Girth Gear InspectionDocument2 paginiGirth Gear Inspectionn_ashok6890390% (2)

- Tires and Tire ElementsDocument20 paginiTires and Tire ElementsRamsai ChigurupatiÎncă nu există evaluări

- HTDDocument18 paginiHTDSami YouseefÎncă nu există evaluări

- Central or Girth Gear Drive For Ball Mills - 1Document26 paginiCentral or Girth Gear Drive For Ball Mills - 1Vishnu Vardhan . C100% (3)

- Kiln Maintenance ManualDocument111 paginiKiln Maintenance ManualJavier Gutierrez100% (5)

- Control of Gearing Between Gear Ring and Pinion in Kiln - Through Leaden HeelsDocument3 paginiControl of Gearing Between Gear Ring and Pinion in Kiln - Through Leaden HeelsJavier GutierrezÎncă nu există evaluări

- Thermal Expansion Effects and Mechanical Issues for Kiln PatrollersDocument30 paginiThermal Expansion Effects and Mechanical Issues for Kiln Patrollersbulentbulut100% (3)

- Kiln Erection ProblemsDocument10 paginiKiln Erection Problemsmuhammad mujahidÎncă nu există evaluări

- Calendering Gauge ControlDocument9 paginiCalendering Gauge ControlChinmay HegdeÎncă nu există evaluări

- Tyre Creep: Refractory Engineering and Kiln Maintenance in Cement PlantsDocument4 paginiTyre Creep: Refractory Engineering and Kiln Maintenance in Cement PlantsMedical LafargeÎncă nu există evaluări

- Understanding Process Sensitivities in Press Quenching An IntegratedDocument19 paginiUnderstanding Process Sensitivities in Press Quenching An Integratedmanashree02Încă nu există evaluări

- ISO 10816 - Severidad en Vibracion PDFDocument2 paginiISO 10816 - Severidad en Vibracion PDFJuan Carlos Bonifacio BricenoÎncă nu există evaluări

- Gap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Document8 paginiGap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Javier Gutierrez100% (1)

- Lube Oil Pump B Vibration 270219Document7 paginiLube Oil Pump B Vibration 270219Javier GutierrezÎncă nu există evaluări

- Approximate Vibration Levels enDocument2 paginiApproximate Vibration Levels enJavier GutierrezÎncă nu există evaluări

- Copa 90mm Horno #5 Cemex-Nic-Hc5-089Document1 paginăCopa 90mm Horno #5 Cemex-Nic-Hc5-089Javier GutierrezÎncă nu există evaluări

- SeasonalDocument20 paginiSeasonalJavier GutierrezÎncă nu există evaluări

- Soft FootDocument1 paginăSoft FootJavier GutierrezÎncă nu există evaluări

- Peak VueDocument1 paginăPeak VueJavier GutierrezÎncă nu există evaluări

- Motor Bars All1Document158 paginiMotor Bars All1Javier GutierrezÎncă nu există evaluări

- SeasonalDocument20 paginiSeasonalJavier GutierrezÎncă nu există evaluări

- GM Motors &DELPHI Vibration STD PDFDocument66 paginiGM Motors &DELPHI Vibration STD PDFMachineryeng0% (1)

- RCM II Decision Diagram - v2Document2 paginiRCM II Decision Diagram - v2Javier Gutierrez100% (1)

- Motor DatabaseDocument55 paginiMotor DatabaseJavier GutierrezÎncă nu există evaluări

- The HFD Value Can Be Obtained As FollowsDocument2 paginiThe HFD Value Can Be Obtained As FollowsJavier GutierrezÎncă nu există evaluări

- Vibration Diagnostic ChartDocument49 paginiVibration Diagnostic ChartAlex George100% (4)

- Parameter ProfileDocument1 paginăParameter ProfileJavier GutierrezÎncă nu există evaluări

- Vertical alignment maintenanceDocument6 paginiVertical alignment maintenanceJavier GutierrezÎncă nu există evaluări

- Control of Gearing Between Gear Ring and Pinion in Kiln - Through Leaden HeelsDocument3 paginiControl of Gearing Between Gear Ring and Pinion in Kiln - Through Leaden HeelsJavier GutierrezÎncă nu există evaluări

- Gear Ring Radial AlignmentDocument2 paginiGear Ring Radial AlignmentJavier GutierrezÎncă nu există evaluări

- Kiln Maintenance ManualDocument111 paginiKiln Maintenance ManualJavier Gutierrez100% (5)

- Chaveta Piñon Transmision Principal - Horno #5 - CEMEX-NIC-HC5-090Document1 paginăChaveta Piñon Transmision Principal - Horno #5 - CEMEX-NIC-HC5-090Javier GutierrezÎncă nu există evaluări

- Alignement of The Main Transmission, Gear Ring and PinionDocument5 paginiAlignement of The Main Transmission, Gear Ring and PinionJavier GutierrezÎncă nu există evaluări

- 5S Team Lead & Area ListDocument33 pagini5S Team Lead & Area ListJavier GutierrezÎncă nu există evaluări

- 5S Audit FormDocument12 pagini5S Audit FormJavier GutierrezÎncă nu există evaluări

- 5S Audit Checklist - Supply StorageDocument16 pagini5S Audit Checklist - Supply StorageJavier GutierrezÎncă nu există evaluări

- 5S Implementation Audit: 5S To-Do Items Observed Condition Improvement ActionDocument2 pagini5S Implementation Audit: 5S To-Do Items Observed Condition Improvement ActionJavier GutierrezÎncă nu există evaluări

- Steel Beam BS 5950Document17 paginiSteel Beam BS 5950Javier GutierrezÎncă nu există evaluări

- MC1087 Welding BoothDocument2 paginiMC1087 Welding BoothJavier GutierrezÎncă nu există evaluări

- Mangueras Succion de GasesDocument12 paginiMangueras Succion de GasesJavier GutierrezÎncă nu există evaluări

- SAP HANA Analytics Training at MAJUDocument1 paginăSAP HANA Analytics Training at MAJUXIÎncă nu există evaluări

- Shore Activities and Detachments Under The Command of Secretary of Navy and Chief of Naval OperationsDocument53 paginiShore Activities and Detachments Under The Command of Secretary of Navy and Chief of Naval OperationskarakogluÎncă nu există evaluări

- Nicolas-Lewis vs. ComelecDocument3 paginiNicolas-Lewis vs. ComelecJessamine OrioqueÎncă nu există evaluări

- Social Marketing PlanDocument25 paginiSocial Marketing PlanChristophorus HariyadiÎncă nu există evaluări

- CV Jan 2015 SDocument4 paginiCV Jan 2015 Sapi-276142935Încă nu există evaluări

- Letter of Reccommendation For LuisaDocument3 paginiLetter of Reccommendation For Luisaapi-243184335Încă nu există evaluări

- 1000 Electronic Devices & Circuits MCQsDocument467 pagini1000 Electronic Devices & Circuits MCQskibrom atsbha67% (3)

- Converting Units of Measure PDFDocument23 paginiConverting Units of Measure PDFM Faisal ChÎncă nu există evaluări

- International Journal of Current Advanced Research International Journal of Current Advanced ResearchDocument4 paginiInternational Journal of Current Advanced Research International Journal of Current Advanced Researchsoumya mahantiÎncă nu există evaluări

- Class 11 English Snapshots Chapter 1Document2 paginiClass 11 English Snapshots Chapter 1Harsh彡Eagle彡Încă nu există evaluări

- Digoxin FABDocument6 paginiDigoxin FABqwer22Încă nu există evaluări

- United States v. Christopher King, 724 F.2d 253, 1st Cir. (1984)Document9 paginiUnited States v. Christopher King, 724 F.2d 253, 1st Cir. (1984)Scribd Government DocsÎncă nu există evaluări

- Wave Optics Part-1Document14 paginiWave Optics Part-1Acoustic GuyÎncă nu există evaluări

- Tangina Tapos NadenDocument7 paginiTangina Tapos NadenJamesCubeÎncă nu există evaluări

- Business Policy FormulationDocument21 paginiBusiness Policy FormulationWachee Mbugua50% (2)

- Photojournale - Connections Across A Human PlanetDocument75 paginiPhotojournale - Connections Across A Human PlanetjohnhorniblowÎncă nu există evaluări

- Notes On Statement AssumptionDocument5 paginiNotes On Statement Assumptionsangamesh mbÎncă nu există evaluări

- Med 07Document5 paginiMed 07ainee dazaÎncă nu există evaluări

- Edu 510 Final ProjectDocument13 paginiEdu 510 Final Projectapi-324235159Încă nu există evaluări

- Veerabhadra Swamy MantrasDocument6 paginiVeerabhadra Swamy Mantrasगणेश पराजुलीÎncă nu există evaluări

- Cambridge Intl. Sr. Sec. School Class: X, Preboard Examination-1 Subject: Mathematics Time Allowed: 3Hrs. M.M: 80Document5 paginiCambridge Intl. Sr. Sec. School Class: X, Preboard Examination-1 Subject: Mathematics Time Allowed: 3Hrs. M.M: 80Suyash PandeyÎncă nu există evaluări

- Productivity in Indian Sugar IndustryDocument17 paginiProductivity in Indian Sugar Industryshahil_4uÎncă nu există evaluări

- 317 Midterm QuizDocument5 pagini317 Midterm QuizNikoruÎncă nu există evaluări

- Introduction To Tensors: Contravariant and Covariant VectorsDocument18 paginiIntroduction To Tensors: Contravariant and Covariant VectorslilaÎncă nu există evaluări

- Experiment 5 ADHAVANDocument29 paginiExperiment 5 ADHAVANManoj Raj RajÎncă nu există evaluări

- Larry Dossey - HealingBeyondtheBodyDocument2 paginiLarry Dossey - HealingBeyondtheBodypaulxeÎncă nu există evaluări

- TRU BRO 4pg-S120675R0 PDFDocument2 paginiTRU BRO 4pg-S120675R0 PDFtomÎncă nu există evaluări

- Newton-Raphson MethodDocument32 paginiNewton-Raphson MethodnafisbadranÎncă nu există evaluări

- Module 3 in Oral Com 1Document20 paginiModule 3 in Oral Com 1Trisha DiohenÎncă nu există evaluări

- Enterprise Information Management (EIM) : by Katlego LeballoDocument9 paginiEnterprise Information Management (EIM) : by Katlego LeballoKatlego LeballoÎncă nu există evaluări