Documente Academic

Documente Profesional

Documente Cultură

Experimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse Aggregate

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Experimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse Aggregate

Drepturi de autor:

Formate disponibile

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

Experimental Investigation Of Waste Plastic

Fiber In Reinforced Cement Concrete Using

Recycled Coarse Aggregate

T.Subramani1, T.Anandavel2, S.Priyanka3

1

Professor & Dean, Department of Civil Engineering, VMKV Engineering College,

Vinayaka Missions University, Salem, India

2

PG Student of Structural Engineering, Department of Civil Engineering, VMKV Engg. College,

Vinayaka Missions University, Salem, India

3

UG Student, , Department of Civil Engineering, VMKV Engineering College,

Vinayaka Missions University, Salem, India

ABSTRACT

This study is aimed at investigating the shear strength and work ability characteristics of Fiber Reinforced High

Strength Concrete (FRHSC) which use recycled coarse aggregates that have originated from demolished

construction wastes. Different mixes were taken with 20%, 40% replacement of natural coarse aggregate with

recycled coarse aggregate. To improve the ductility and performance, 1% steel fiber is also added to the concrete.

The concrete has main advantage that it has a better compressive strength. The compressive strength of concrete

can be represented as cube or cylinder compressive strength. The compressive strength of concrete is depending on

size and shape of the test specimens. In this study, the conventional concrete was reinforced by the plastic fibers

obtained from waste plastic bottles. The cube and cylinder compressive strength of conventional concrete and

plastic fibers reinforced concrete were determined in the laboratory. The M30 grades of concrete and two fiber

geometry at volume fractions 0.0 % to 3.0 % were used in the experimentations. All specimens were tested after

curing age 28 days. In this paper the relationship between cube and cylinder compressive strength for conventional

and plastic fibers reinforced concrete were established and compared with standards.

Keywords: Experimental, Investigation, Waste Plastic Fiber, Reinforced Cement Concrete, Recycled Coarse

Aggregate

1.INTRODUCTION

Since the large demand has been placed on building material industry especially in the last decade owing to the

increasing population which causes a chronic shortage of building materials, the civil engineers have been challenged

to convert the industrial wastes to useful building and construction materials. This experimental study which

investigates the potential use of waste plastic fibre for producing a low-cost and light weight composite as a building

material. These alternatives were made with plastic fibre. Any construction activity requires several materials such as

concrete, steel, brick, stone, glass, clay, mud, wood, and so on. However, the cement concrete remains the main

construction material used in construction industries. For its suitability and adaptability with respect to the changing

environment, the concrete must be such that it can conserve resources, protect the environment, economize and lead to

proper utilization of energy. To achieve this, major emphasis must be laid on the use of wastes and byproducts in

cement and concrete used for new constructions. The utilization of recycled aggregate is particularly very promising as

75 per cent of concrete is made of aggregates. The use of recycled aggregates from construction and demolition wastes

is showing prospective application in construction as alternative to primary (natural) aggregates. Research on the usage

of waste construction materials is very important since the materials waste is gradually increasing with the increase of

population and increasing of urban development. The reasons that many investigations and analysis had been made on

recycled aggregate are because recycled aggregate is easy to obtain and the cost is cheaper than virgin aggregate.

Volume 6, Issue 5, May 2017 Page 239

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

2.METHODOLOGY

The methodology for the research is explain in pictorial representation in the flow chart.

Figure1 Methodology chart

3. MATERIAL COLLECTION

3.1 Introduction

The material collection is following cement, fine aggregate, recycled aggregate & paper.

3.1.1 Cement

Cement is one of the binding materials in this project. Cement is the important building material in todays

construction world 53 grade Ordinary Portland Cement (OPC) conforming to IS: 8112-1989.

3.1.2 Fine Aggregate

Concrete produced from a mixture of fine aggregate (sand), a binder (cement), and water. Fine-aggregate concrete is

similar to building mortars in its composition and certain properties. It is used mainly for making thin-walled and

conventional rein-forced-concrete structural components and products.Fine-aggregate concrete is used in highway and

airfield construction because of the high tensile strength that results from its fine-grained structure. The absence of

coarse aggregate (crushed stone or gravel) substantially facilitates the preparation, transport, and placing of the

concrete, particularly when concrete pumps are used. A disadvantage of fine-aggregate concrete is the increased

consumption of binder compared to other types of concrete and the associated greater shrinkage and creep. The

quantity of binder in the concrete can be reduced by pulverizing some of the sand, by the use of plasticizers, or by

autoclaving of products.The sand which was locally available and passing through 4.75mm IS sieve is used. The

specific gravity of fine aggregate was 2.60.

3.1.3 Coarse Aggregate

Locally available crushed blue granite stones conforming to graded aggregate of nominal size 12.5 mm as per IS: 383

1970. Crushed granite aggregate with specific gravity of 2.77 and passing through 4.75 mm sieve and will be used for

casting all specimens. Several investigations concluded that maximum size of coarse aggregate should be restricted in

strength of the composite. In addition to cement paste aggregate ratio, aggregate type has a great influence on

concrete dimensional stability.

Volume 6, Issue 5, May 2017 Page 240

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

3.1.4 Recycled Aggregate

Recycling is the act of processing the used material for use in creating new product. The usage of natural aggregate is

getting more and more intense with the advanced development in infrastructure area. In order to reduce the usage of

natural aggregate, recycled aggregate can be used as the replacement materials. Recycled aggregate are comprised of

crushed, graded inorganic particles processed from the materials that have been used in the constructions and

demolition debris. To achieve this, major emphasis must be laid on the use of wastes and byproducts in cement and

concrete used for new constructions. The utilization of recycled aggregate is particularly very promising as 75 per cent

of concrete is made of aggregates. In that case, the aggregates considered are slag, power plant wastes, recycled

concrete, mining and quarrying wastes, waste glass, incinerator residue, red mud, burnt clay, sawdust, combustor ash

and foundry sand. The enormous quantities of demolished concrete are available at various construction sites, which

are now posing a serious problem of disposal in urban areas. This can easily be recycled as aggregate and used in

concrete. Research & Development activities have been taken up all over the world for proving its feasibility, economic

viability and cost effectiveness. Buildings, roads, bridges, and sometimes even from catastrophes, such as wars and

earthquakes.(Figure.2). There are many advantages through using the recycled aggregate. The advantages that occur

through usage of recycled aggregate are listed below.

a) Environmental Gain

b) Cost

c) Job Opportunities

d) Sustainability

3.2 Plastic Fibre

Plastic is also is a waste and this waste is using for many works as recycle products. Among the plastics family

Polyethylene Terephthalate (PET) is one of the major products using by the society in the form of various articles. In

this connection a review is presenting below related to PET fibres and RAC. Conducted the experimentation on

concrete with plastic waste. The plastic material was used as sand substitution in the concrete. The results showed that

the use of plastic bottle waste was effective and it attracts as low cost material.(Figure.3)

Figure 2 Recycled Aggregate Figure 3 Waste Domestic Plastics Are Made In To Fibre

4.MATERIALS PROPERTIES

4.1 Introduction

Materials properties like Properties of cement, Setting time, Consistency, Soundness and properties of fine & recycled

aggregate

4.2 Properties Of Cement

4.2.1 Physical Properties Of Cement

Table 1 shows the Physical Properties Of Cement

Volume 6, Issue 5, May 2017 Page 241

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

Table 1 Physical Properties Of Cement

4.2.2 Setting Time

Cement paste setting time is affected by a number of items including: cement fineness, water-cement ratio,

chemical content (especially gypsum content) and admixtures. Setting tests are used to characterize how a

particular cement paste sets.

For construction purposes, the initial set must not be too soon and the final set must not be too late. Normally, two

setting times are defined:

Initial set. Occurs when the paste begins to stiffen considerably.

Final set. Occurs when the cement has hardened to the point at which it can sustain some load.

Setting is mainly caused by C3A and C3S and results in temperature rise in the cement paste.

False set :No heat is evolved in a false set and the concrete can be re-mixed without adding water

Occures due to the conversion of unhydreous/semi hydrous gypsum to hydrous gypsum (CaSO4.2H2O)

Flash Set: is due to absence of Gypsum. Specifically used for under water repair.

4.2.3 Consistency

The consistency is measured by the Vicat apparatus using a 10mm diameter plunger.

A trial paste of cement and water is mixed and placed in the mold having an inside diameter of 70mm at the base

and 60mm at the top, and a height of 40mm.

The plunger is then brought into contact with the top surface of the paste and released. Under the action of its

weight the plunger will penetrate the paste. The depth depending on the consistency.

4.2.4 Soundness

When referring to Portland cement, "soundness" refers to the ability of a hardened cement paste to retain its

volume after setting without delayed expansion. This expansion is caused by excessive amounts of free lime (CaO)

or magnesia (MgO). Most Portland cement specifications limit magnesia content and expansion.

The cement paste should not undergo large changes in volume after it has set. However, when excessive amounts

of free CaO or MgO are present in the cement, these oxides can slowly hydrate and cause expansion of the

hardened cement paste.

Soundness is defined as the volume stability of the cement paste.

4.3 Properties Of Fine Aggregate

4.3.1 Absorption, Porosity, And Permeability

The internal pore characteristics are very important properties of aggregates. The size, the number, and the continuity

of the pores through an aggregate particle may affect the strength of the aggregate, abrasion resistance, surface texture,

specific gravity, bonding capabilities, and resistance to freezing and thawing action. Absorption relates to the particle's

Volume 6, Issue 5, May 2017 Page 242

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

ability to take in a liquid. Porosity is a ratio of the volume of the pores to the total volume of the particle. Permeability

refers to the particle's ability to allow liquids to pass through. If the rock pores are not connected, a rock may have high

porosity and low permeability.

4.3.2 Surface Texture

Surface texture is the pattern and the relative roughness or smoothness of the aggregate particle. Surface texture plays a

big role in developing the bond between an aggregate particle and a cementing material. A rough surface texture gives

the cementing material something to grip, producing a stronger bond, and thus creating a stronger hot mix asphalt or

portland cement concrete. Surface texture also affects the workability of hot mix asphalt, the asphalt requirements of

hot mix asphalt, and the water requirements of portland cement concrete. Some aggregates may initially have good

surface texture, but may polish smooth later under traffic. These aggregates are unacceptable for final wearing surfaces.

Limestone usually falls into this category.

4.3.3 Strength And Elasticity

Strength is a measure of the ability of an aggregate particle to stand up to pulling or crushing forces. Elasticity

measures the "stretch" in a particle. High strength and elasticity are desirable in aggregate base and surface courses.

These qualities minimize the rate of disintegration and maximize the stability of the compacted material. The best

results for portland cement concrete may be obtained by compromising between high and low strength, and elasticity.

This permits volumetric changes to take place more uniformly throughout the concrete.

4.3.4 Hardness

The hardness of the minerals that make up the aggregate particles and the firmness with which the individual grains

are cemented or interlocked control the resistance of the aggregate to abrasion and degradation. Soft aggregate particles

are composed of minerals with a low degree of hardness. Weak particles have poor cementation. Neither type is

acceptable. The Mohs Hardness Scale is frequently used for determination of mineral hardness.

4.4 Properties Of Coarse Aggregate

The shape and texture of aggregate affects the properties of fresh concrete more than hardened concrete. Concrete is

more workable when smooth and rounded aggregate is used instead of rough angular or elongated aggregate. Most

natural sands and gravel from riverbeds or seashores are smooth and rounded and are excellent aggregates. Crushed

stone produces much more angular and elongated aggregates, which have a higher surface-to-volume ratio, better bond

characteristics but require more cement paste to produce a workable mixture. The surface texture of aggregate can be

either smooth or rough. A smooth surface can improve workability, yet a rougher surface generates a stronger bond

between the paste and the aggregate creating a higher strength. The grading or size distribution of aggregate is an

important characteristic because it determines the paste requirement for workable concrete. This paste requirement is

the factor controlling the cost, since cement is the most expensive component.

It is therefore desirable to minimize the amount of paste consistent with the production of concrete that can be

handled, compacted, and finished while providing the necessary strength and durability. The required amount of

cement paste is dependent upon the amount of void space that must be filled and the total surface area that must be

covered. The moisture content of an aggregate is an important factor when developing the proper water/cementitious

material ratio. All aggregates contain some moisture based on the porosity of the particles and the moisture condition of

the storage area. The moisture content can range from less than one percent in gravel to up to 40 percent in very porous

sandstone and expanded shale. Aggregate can be found in four different moisture states that include oven-dry (OD),

air-dry (AD), saturated-surface dry (SSD) and wet. Of these four states, only OD and SSD correspond to a specific

moisture state and can be used as reference states for calculating moisture content. In order to calculate the quantity of

water that aggregate will either add or subtract to the paste, the following three quantities must be calculated:

absorption capacity, effective absorption, and surface moisture.

The density of the aggregates is required in mixture proportioning to establish weight-volume relationships. Specific

gravity is easily calculated by determining the densities by the displacement of water. All aggregates contain some

porosity, and the specific gravity value depends on whether these pores are included in the measurement. There are two

terms that are used to distinguish this measurement; absolute specific gravity and bulk specific gravity. Absolute

Specific Gravity (ASG) refers to the solid material excluding the pores, and Bulk Specific Gravity (BSG), sometimes

called apparent specific gravity, includes the volume of the pores.

Volume 6, Issue 5, May 2017 Page 243

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

4.5 Properties Of Recycled Aggregate

The crushing characteristics of hardened concrete are similar to those of natural rock and are not significantly affected

by the grade or quality of the original concrete. Recycled concrete aggregates produced from all but the poorest quality

original concrete Recycled concrete aggregates contain not only the original aggregates, but also hydrated cement paste.

This paste reduces the specific gravity and increases the porosity compared to similar virgin aggregates. Higher

porosity of RCA leads to a higher absorption.In terms of composition, recycled aggregates, obtained from crushed waste

concrete, consist of original aggregates and adhered mortar. Two factors which need to be taken into consideration in

the use of these recycled materials in the production of new concrete is their structural behavior and durability. It is the

percentage of recycled aggregate used, which influences the structural behavior of the new concrete. Also, durability of

the recycled aggregate concrete depends on the heterogeneity of the recycled particles. Hence it is important to identify

the mechanical, physical and chemical properties of the original coarse aggregates, as well as the original fine

aggregates present in adhered mortar, to understand their suitability in the production of recycled concrete. The

research involved experiments to analyze the structural behavior of recycled aggregate concrete, using different

percentages of recycled aggregates.Construction and demolition waste control becomes indispensable from the moment

that statistics refer to the wastes volume approaching an unsustainable level. The utilization of waste material as

secondary raw material is the solution to the problem of an excess of waste material, not forgetting the parallel trend of

improvement of final product quality. A systematic use of waste materials involves the classification of the mentioned

waste materials according to their strength capacity, durability and utility. The basic components obtained from

construction and demolition waste in concrete, masonry and mortar. Secondary raw aggregates are obtained from the

waste crushed concretes. From a quality point of view, the original aggregates are heterogeneous in composition being

derived from different minerals and adhered mortar. Primary raw coarse aggregate (granite) and sand (crushed

limestone) were used indifferent concrete mixes.

4.6 Properties Of Water

Water used for mixing and curing shall be clean and free from injurious amounts of Oils, Acids, Alkalis, Salts, Sugar,

Organic materials Potable water is generally considered satisfactory for mixing concrete Mixing and curing with sea

water shall not be permitted. The pH value shall not be less than 6

4.7 Properties Of Plastic Fiber

Usually replacement of only 10% to 30% virgin sand is used for new concrete. Is approved using 100% recycled coarse

aggregate produces acceptable quality concrete. Use of recycled fines, however, in a new mix requires close

examination. Recycled fine aggregate is angular, with a high porosity and low specific gravity. The particles of crushed

brick are generally more porous and have a lower density when compared to natural and recycled concrete aggregates.

It is found that concrete made with crushed brick generally has comparable compressive and tensile strengths compared

to those of conventional concrete. However, the modulus of elasticity, shrinkage, creep, initial surface absorption and

chloride diffusion are inferior compared to those of natural concrete. Though, successful applications of crushed brick

as the aggregates in the production of concretes are possible.

4.8 Fresh Concrete Properties

4.8.1 Workability

With the addition of furnace slag, the slump loss with time is directly proportional to increase in the slag content due to

the introduction of large surface area in the concrete mix by its addition. Although the slump decreases, the mix

remains highly cohesive.

4.8.2 Segregation And Bleeding

Furnace slag reduces bleeding significantly because the free water is consumed in wetting of the large surface area of

the furnace slag and hence the free water left in the mix for bleeding also decreases. Furnace slag also blocks the pores

in the fresh concrete so water within the concrete is not allowed to come to the surface.

4.9 Hardened Concrete Properties

4.9.1 Compression Test On Concrete Cubes

The determination of the compressive strength of concrete is very important because the compressive strength is the

criterion of its quality. Other strength is generally prescribed in terms of compressive strength. The strength is

expressed in N/mm2. This method is applicable to the making of preliminary compression tests to ascertain the

suitability of the available materials or to determine suitable mix proportions. The concrete to be tested should not have

the nominal maximum size of aggregate more than 20mm test specimens are either 15cm cubes or 15cm diameter used.

Volume 6, Issue 5, May 2017 Page 244

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

At least three specimens should be made available for testing. Where every cylinder is used for compressive strength

results the cube strength can be calculated as under.

Minimum cylinder compressive strength = 0.8 x compressive strength cube (10 cm x 10 cm) The concrete specimens

are generally tested at ages 7 days and 28 days.

4.9.2 Split Tensile Test On Cylinder

Concrete is strong in compression but weak in tension. Tension stresses are likely to develop in concrete due to drying

shrinkage, rusting of reinforcement, temperature gradient etc.

In concrete road slab this tensile stresses are developed due to wheel loaded and volume changes in concrete are

available to determine this. Split test is one of the indirect methods available to find out the tensile strength.

4.9.3 Flexural Test On Beams

It is the ability of a beam or slab to resist failure in bending. It is measured by loading un-reinforced 6x6 inch concrete

beams with a span three times the depth (usually 18 in.). The flexural strength is expressed as Modulus of Rupture

(MR) in psi. Flexural MR is about 12 to 20 percent of compressive strength.

5. TESTING PROCEDURE

5.1 Introduction

The following test done by the concrete compressive strength of cube, flexural strength of beam & split tensile strength

for cylinder

5.2 Compressive Strength Test

When a specimen of material is loaded in such a way that it extends it is said to be in tension. On the other hand if the

material compresses and shortens it is said to be in compression. On an atomic level, the molecules or atoms are forced

apart when in tension whereas in compression they are forced together. Since atoms in solids always try to find an

equilibrium position, and distance between other atoms, forces arise throughout the entire material which oppose both

tension and compression. The phenomena prevailing on an atomic level are therefore similar.The "strain" is the

relative change in length under applied stress; positive strain characterises an object under tension load which tends to

lengthen it, and a compressive stress that shortens an object gives negative strain. Tension tends to pull small sideways

deflections back into alignment, while compression tends to amplify such deflection into buckling. Compressive

strength is measured on materials, components, and structures. By definition, the ultimate compressive strength of a

material is that value of uniaxial compressive stress reached when the material fails completely. The compressive

strength is usually obtained experimentally by means of a compressive test. The apparatus used for this experiment is

the same as that used in a tensile test. However, rather than applying a uniaxial tensile load, a uniaxial compressive

load is applied. As can be imagined, the specimen (usually cylindrical) is shortened as well as spread laterally. At the

time of testing, each specimen must keep in compressive testing machine. The maximum load at the breakage of

concrete block will be noted. From the noted values, the compressive strength may calculated by using below formula.

Figure. 4 shows Compression Test.

Compressive Strength = Load / Area

Size of the test specimen=150mm x 150mm x 150mm

5.3 Split Tensile Test

The size of cylinders 300 mm length and 150 mm diameter are placed in the machine such that load is applied on the

opposite side of the cubes are casted. Align carefully and load is applied, till the specimen breaks. Figure.5 shows Split

Tensile Test The formula used for calculation.

Split tensile strength = 2P/ dl

5.4 Flexural Strength Test

During the testing, the beam specimens of size 7000mmx150mmx150mm were used. Specimens were dried in open air

after 7 days of curing and subjected to flexural strength test under flexural testing assembly. Apply the load at a rate

that constantly increases the maximum stress until rupture occurs. Figure 6 shows Flexural Strength Test The fracture

indicates in the tension surface within the middle third of span length. The flexural strength was obtained using the

formula (R)

R = Pl/bd2

Where,

R = Modulus of rupture (N/mm2)

P = Maximum applied load (N/mm2)

Volume 6, Issue 5, May 2017 Page 245

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

l = Length of specimen (mm)

b = Width of specimen (mm)

d = depth of specimen (mm)

Figure. 4 Compression Test Figure.5 Split Tensile Test Figure 6 Flexural Strength Test

6.TEST RESULTS

6.1 Introduction

The test result taking for mix design by M30 for as conventional as well as recycled concrete & plastic fibre concrete.

6.1.1 For M30 Grade Concrete

RATIO I

Recycled Aggregate 100 % by replacement of Coarse Aggregate

RATIO - II

Plastic Fibre 20 % by replacement of Recycled Aggregate

RATIO III

Plastic Fibre 40 % by replacement of Recycled Aggregate

6.2. Compressive Strength

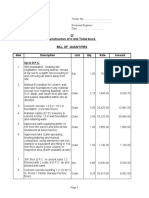

Table 2 shows Compressive Test results. Figure 7 shows Graph of Compressive Test

Table 2 Compressive Test

Volume 6, Issue 5, May 2017 Page 246

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

Figure 7 Compressive Test

8.3. Split Tensile Strength Of Concrete

Table 3 Split Tensile Strength Figure. 10 Graph Shown Split Tensile Strength

Table 3 Split Tensile Strength

Figure 8 Split Tensile Strength

Volume 6, Issue 5, May 2017 Page 247

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

8.4. Flexural Strength On Beam

Table 6 shows Flexural Strength. Figure.9 shows Graph of Flexural Strength

Table 6 Flexural Strength

Figure 9 Flexural Strength

CONCLUSION

The behavior of green concrete under slump and compaction factor tests shows that workability is reduced in

PFRC. It was due to resistance offered by the fibers to the movement of aggregates. The dry density is also reduced

in PFRC but it is beneficial to reduce dead weight of concrete.

Utilisation of fibres in plastic concrete in various proportions to improve the strength.

Plastic fibres along with steel fibres can be used to improve the strength of concrete.

This preliminary study has thus shown that the relationships between compressive strength, as used in European

standard for plain concrete, can be applied to concrete containing PET-fibers.

The relationship between cube and cylinder compressive strength is linear.

In Our Project We Discuss 100% Of Recycled Aggregate With Various Percentage Of plastic fibre as 20%, 40%.

Replacement Level Of 40% Recycled Aggrgate in concrete mixes was found to be the optimum level to obtain

higher value of the strength at the age of 28 days.

The Optimum Level Of Compressive Strength Is 49.6 N/mm2 With The Replacement Of 40% plastic fibre.

This preliminary study has thus shown that the relationships between compressive strength, as used in European

standard for plain concrete, can be applied to concrete containing PET-fibers.

Volume 6, Issue 5, May 2017 Page 248

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

REFERENCES

[1] T.Subramani, S.Krishnan, S.K.Ganesan, G.Nagarajan. Investigation of Mechanical Properties in Polyester and

Phenyl-ester Composites Reinforced With Chicken Feather Fiber International Journal of Engineering Research

and Applications Vol. 4, Issue 12(Version 4), pp.93-104, 2014.

[2] T.Subramani, J.Jayalakshmi , " Analytical Investigation Of Bonded Glass Fibre Reinforced Polymer Sheets With

Reinforced Concrete Beam Using Ansys" , International Journal of Application or Innovation in Engineering &

Management (IJAIEM) , Volume 4, Issue 5, pp. 105-112 , 2015

[3] T.Subramani, D.Latha , " Experimental Study On Recycled Industrial Waste Used In Concrete" , International

Journal of Application or Innovation in Engineering & Management (IJAIEM) , Volume 4, Issue 5, pp. 113-122 ,

2015

[4] T.Subramani, V.Angappan , " Experimental Investigation Of Papercrete Concrete" , International Journal of

Application or Innovation in Engineering & Management (IJAIEM) , Volume 4, Issue 5, pp. 134-143 , 2015

[5] T.Subramani, V.K.Pugal , " Experimental Study On Plastic Waste As A Coarse Aggregate For Structural

Concrete" , International Journal of Application or Innovation in Engineering & Management (IJAIEM) , Volume

4, Issue 5, pp.144-152 2015

[6] T.Subramani, B.Suresh , " Experimental Investigation Of Using Ceramic Waste As A Coarse Aggregate Making A

Light Weight Concrete " , International Journal of Application or Innovation in Engineering & Management

(IJAIEM) , Volume 4, Issue 5, pp. 153-162 , 2015

[7] T.Subramani, M.Prabhakaran , " Experimental Study On Bagasse Ash In Concrete" , International Journal of

Application or Innovation in Engineering & Management (IJAIEM) , Volume 4, Issue 5, pp. 163-172 , 2015

[8] T.Subramani, A.Mumtaj , " Experimental Investigation Of Partial Replacement Of Sand With Glass Fibre" ,

International Journal of Application or Innovation in Engineering & Management (IJAIEM) , Volume 4, Issue 5,

pp. 254-263 , 2015

[9] T.Subramani, S.B.Sankar Ram Experimental Study on Concrete Using Cement With Glass Powder, IOSR Journal

of Engineering,Volume 5 , Issue 5, Version 3, pp43-53, 2015

[10] T.Subramani, S.Kumaran , " Experimental Investigation Of Using Concrete Waste And Brick Waste As A Coarse

Aggregate " , International Journal of Application or Innovation in Engineering & Management (IJAIEM) ,

Volume 4, Issue 5, pp. 294-303 , 2015

[11] T.Subramani, G.Ravi, Experimental Investigation Of Coarse Aggregate With Steel Slag In Concrete, IOSR

Journal of Engineering, Volume 5,Issue 5, Version 3, pp64-73, 2015

[12] T.Subramani, K.S.Ramesh , " Experimental Study On Partial Replacement Of Cement With Fly Ash And

Complete Replacement Of Sand With M sand" , International Journal of Application or Innovation in Engineering

& Management (IJAIEM) , Volume 4, Issue 5 , pp. 313-322 , 2015

[13] T.Subramani, G.Shanmugam , " Experimental Investigation Of Using Papercrete And Recycled Aggregate As A

Coarse Aggregate " , International Journal of Application or Innovation in Engineering & Management (IJAIEM)

, Volume 4, Issue 5, pp. 323-332 , May 2015

[14] T.Subramani, P.Sakthivel , " Experimental Investigation On Flyash Based Geopolymer Bricks" , International

Journal of Application or Innovation in Engineering & Management (IJAIEM) , Volume 5, Issue 5, pp. 216-227 ,

2016 .

[15] T.Subramani, R.Siva, Experimental Study On Flexural And Impact Behavior Of Ferrocement Slabs

International Journal of Application or Innovation in Engineering & Management (IJAIEM), Volume 5, Issue 5,

pp. 228-238 , 2016 .

[16] T.Subramani, A.Anbuchezian , " Experimental Study Of Palm Oil Fuel Ash As Cement Replacement Of Concrete

" , International Journal of Application or Innovation in Engineering & Management (IJAIEM), Volume 6, Issue

3, March 2017 , pp. 001-005 , ISSN 2319 - 4847.

[17] T.Subramani, A.Anbuchezian , " Experimental Study Of Mineral Admixture Of Self Compacting Concrete " ,

International Journal of Application or Innovation in Engineering & Management (IJAIEM), Volume 6, Issue 3,

March 2017 , pp. 006-010 , ISSN 2319 - 4847.

[18] T.Subramani, A.Anbuchezian , " Experimental Test On Bitumen With Addition Of 35% Of Plastic Fibre " ,

International Journal of Application or Innovation in Engineering & Management (IJAIEM), Volume 6, Issue 3,

March 2017 , pp. 017-022 , ISSN 2319 - 4847.

[19] T.Subramani, A.Anbuchezian , " Stabilization Of M30 Concrete Pavement By Partially Replacing Cement By 20%

Of Flyash And Sodium Silicate " , International Journal of Application or Innovation in Engineering &

Management (IJAIEM), Volume 6, Issue 3, March 2017 , pp. 023-031 , ISSN 2319 - 4847.

[20] T.Subramani, A.Anbuchezian , " Experimental Investigation On Flexural Behavior Of Folded Ferro Cement

Panels " , International Journal of Application or Innovation in Engineering & Management (IJAIEM), Volume 6,

Issue 3, March 2017 , pp. 045-049 , ISSN 2319 - 4847.

Volume 6, Issue 5, May 2017 Page 249

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

[21] T.Subramani, A.Anbuchezian , " Experimental Study On Replacement Of Concrete Material By Water Treatment

Plant Waste Sewage " , International Journal of Application or Innovation in Engineering & Management

(IJAIEM), Volume 6, Issue 3, March 2017 , pp. 050-057 , ISSN 2319 - 4847.

[22] T.Subramani, A. Fizoor Rahman , " An Experimental Study On The Properties Of Pet Fibre Reinforced Concrete "

, International Journal of Application or Innovation in Engineering & Management (IJAIEM), Volume 6, Issue 3,

March 2017 , pp. 058-066 , ISSN 2319 - 4847.

AUTHOR

Prof. Dr.T.Subramani Working as a Professor and Dean of Civil Engineering in VMKV

Engineering College, Vinayaka Missions University, Salem, TamilNadu, India. Having more than

27 years of Teaching experience in Various Engineering Colleges. He is a Chartered Civil

Engineer and Approved Valuer for many banks. Chairman and Member in Board of Studies of

Civil Engineering branch. Question paper setter and Valuer for UG and PG Courses of Civil

Engineering in number of Universities. Life Fellow in Institution of Engineers (India) and

Institution of Valuers. Life member in number of Technical Societies and Educational bodies.

Guided more than 400 students in UG projects and 300 students in PG projects. He is a reviewer

for number of International Journals and published 174 International Journal Publications and presented more than 25

papers in International Conferences.

T. Anandavel completed his Bachelor of Engineering in the branch of Civil Engineering in

Government College of Engineering Salem . He is working as lecturer in Jeyam Polytechnic

College, Dharmapuri. Currently he is doing M.E( Structural Engineering ) in VMKV

Engineering College of Vinayaka Missions University, Salem, Tamilnadu , Indian.

S.Priyanka is persuing B.E. Degree in the branch of Civil Engineering in

V.M.K.V.Engineering College, Vinayaka Missions University, Salem. She has illustrious career

in her intermediate and matriculation exams, her hobby is cooking and surfing internet.

Volume 6, Issue 5, May 2017 Page 250

S-ar putea să vă placă și

- Colibri - DEMSU P01 PDFDocument15 paginiColibri - DEMSU P01 PDFRahul Solanki100% (4)

- Implementing Strategies: Management & Operations Issues: Strategic Management: Concepts & Cases 13 Edition Fred DavidDocument23 paginiImplementing Strategies: Management & Operations Issues: Strategic Management: Concepts & Cases 13 Edition Fred Davidmwm_koolguyÎncă nu există evaluări

- Geologic ProcessesDocument37 paginiGeologic ProcessesMaricar Vecinal Magnaye100% (1)

- Ss1169 - Telecom Frameworx l1TMFDocument65 paginiSs1169 - Telecom Frameworx l1TMFPrince SinghÎncă nu există evaluări

- Worship LyricsDocument3 paginiWorship LyricsCharisma MeromiÎncă nu există evaluări

- Sika Saudi Arabia: Safety Data SheetDocument4 paginiSika Saudi Arabia: Safety Data Sheetusman khalid100% (1)

- Fire and Life Safety Assessment ReportDocument5 paginiFire and Life Safety Assessment ReportJune CostalesÎncă nu există evaluări

- Midterm Exam StatconDocument4 paginiMidterm Exam Statconlhemnaval100% (4)

- Risk and Uncertainty in Estimating and TenderingDocument16 paginiRisk and Uncertainty in Estimating and TenderingHaneefa ChÎncă nu există evaluări

- SPIE Oil & Gas Services: Pressure VesselsDocument56 paginiSPIE Oil & Gas Services: Pressure VesselsSadashiw PatilÎncă nu există evaluări

- Ainable Architecture: Submitted By: Akshita Saklani 03 /16 Chahat Bassi 47 /16Document73 paginiAinable Architecture: Submitted By: Akshita Saklani 03 /16 Chahat Bassi 47 /16Akshita SaklaniÎncă nu există evaluări

- 4th Periodical Test Chemistry 1 2017 2018 (Mid Term)Document15 pagini4th Periodical Test Chemistry 1 2017 2018 (Mid Term)Marjorie BrondoÎncă nu există evaluări

- PricingDocument26 paginiPricingDr. Smita ChoudharyÎncă nu există evaluări

- Two 2 Page Quality ManualDocument2 paginiTwo 2 Page Quality Manualtony sÎncă nu există evaluări

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 paginiDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- On Applied EthicsDocument34 paginiOn Applied Ethicsamanpatel78667% (3)

- Unit 1 The Capitalist Revolution 1.0Document33 paginiUnit 1 The Capitalist Revolution 1.0knowme73Încă nu există evaluări

- Computer Vision and Action Recognition A Guide For Image Processing and Computer Vision Community For Action UnderstandingDocument228 paginiComputer Vision and Action Recognition A Guide For Image Processing and Computer Vision Community For Action UnderstandingWilfredo MolinaÎncă nu există evaluări

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 paginiImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- STS Course OutlineDocument1 paginăSTS Course OutlineCarol Neng CalupitanÎncă nu există evaluări

- SyllabusDocument6 paginiSyllabusannelle0219Încă nu există evaluări

- Replacement of Waste Material in Concrete Using Recycled PlasticDocument6 paginiReplacement of Waste Material in Concrete Using Recycled Plasticsinghal siddhant100% (1)

- Profit Planning and Activity Based BudgetingDocument50 paginiProfit Planning and Activity Based BudgetingShaiannah Veylaine Recinto ApostolÎncă nu există evaluări

- 2015 Utilization of Waste Plastic Water Bottle As A Modifier For Asphalt Mixture PropertiesDocument20 pagini2015 Utilization of Waste Plastic Water Bottle As A Modifier For Asphalt Mixture PropertiesKhalil ZaaimiaÎncă nu există evaluări

- Topic 2 Lecture 3 Discounted Cash Flow ValuationDocument44 paginiTopic 2 Lecture 3 Discounted Cash Flow ValuationSyaimma Syed AliÎncă nu există evaluări

- Capital BudgetingDocument9 paginiCapital BudgetingHamoudy DianalanÎncă nu există evaluări

- Syllabi Art AppreciationDocument12 paginiSyllabi Art Appreciationjessemar waoÎncă nu există evaluări

- Edited - 10 23 2019Document40 paginiEdited - 10 23 2019Karyl Sepulveda De VeraÎncă nu există evaluări

- Introduction To Investing Powerpoint Presentation 1 12 1 g1Document40 paginiIntroduction To Investing Powerpoint Presentation 1 12 1 g1api-344976556Încă nu există evaluări

- Recycled Decorative Pots: Effects On SBCA's Bottle Wastes ManagementDocument44 paginiRecycled Decorative Pots: Effects On SBCA's Bottle Wastes ManagementLloyd DechavezÎncă nu există evaluări

- Plastic Pollution Policy Country Profile PhilippinesDocument9 paginiPlastic Pollution Policy Country Profile PhilippinesVisaya L. ClaudineÎncă nu există evaluări

- Talahib NFPC Comparative StudyDocument6 paginiTalahib NFPC Comparative StudykirstennoelleignacioÎncă nu există evaluări

- Price Spread, Marketing Channel of Banana in Southern Tamil NaduDocument5 paginiPrice Spread, Marketing Channel of Banana in Southern Tamil NaduEditor IJTSRDÎncă nu există evaluări

- Chapter 17 - Force, Energy and Power in ActionDocument15 paginiChapter 17 - Force, Energy and Power in ActionSuresh SenanayakeÎncă nu există evaluări

- SMATH311LC Laboratory Exercise2 PDFDocument1 paginăSMATH311LC Laboratory Exercise2 PDFambiÎncă nu există evaluări

- MomentumDocument17 paginiMomentumJohnwell balbagÎncă nu există evaluări

- Syllabus 2019-2020 (Retorika)Document11 paginiSyllabus 2019-2020 (Retorika)Michael MosendeÎncă nu există evaluări

- Payback Period AnalysisDocument16 paginiPayback Period AnalysisashishkapoorsrmÎncă nu există evaluări

- Analysis of Climate ChangeDocument16 paginiAnalysis of Climate Changerenan georgeÎncă nu există evaluări

- Icc ProposalDocument7 paginiIcc ProposalKerwin ZamoraÎncă nu există evaluări

- Establishing Company Direction - Lecture 2Document6 paginiEstablishing Company Direction - Lecture 2api-3710170100% (1)

- Mmiers 1Document55 paginiMmiers 1michael17ph2003Încă nu există evaluări

- MODULE 1: COMMUNICATION: An Introduction: UNIT 1: Communication Concepts and PrinciplesDocument6 paginiMODULE 1: COMMUNICATION: An Introduction: UNIT 1: Communication Concepts and PrinciplesGab IgnacioÎncă nu există evaluări

- Handout - Educ90 - 1. Understanding Curriculum pt.1Document16 paginiHandout - Educ90 - 1. Understanding Curriculum pt.1RUTHY ANN BALBIN BEEd 2-1Încă nu există evaluări

- Carlos Sierra - Mine Ventilation - A Concise Guide For Students-Springer International Publishing - Springer (2020)Document372 paginiCarlos Sierra - Mine Ventilation - A Concise Guide For Students-Springer International Publishing - Springer (2020)George GomezÎncă nu există evaluări

- Research MethodsDocument73 paginiResearch MethodsDONALD INONDAÎncă nu există evaluări

- Plastic Waste Concrete-Litrature ReviewDocument10 paginiPlastic Waste Concrete-Litrature ReviewYara MounaÎncă nu există evaluări

- ScienceDocument3 paginiScienceNuha ScssrÎncă nu există evaluări

- 20171204131250C2 Gravimetric AnalysisDocument79 pagini20171204131250C2 Gravimetric Analysismuhd abbasÎncă nu există evaluări

- F.M Chapter 1 PDFDocument10 paginiF.M Chapter 1 PDFpettgreentteaÎncă nu există evaluări

- Geology Is Important To Civil Engineering BecauseDocument2 paginiGeology Is Important To Civil Engineering BecauseGuilbert FajardoÎncă nu există evaluări

- UNIT III Lesson 1 (Communication and Globalization)Document4 paginiUNIT III Lesson 1 (Communication and Globalization)Photz Bayangan KatabÎncă nu există evaluări

- Business Startup Checklist 1. Creating A Business PlanDocument5 paginiBusiness Startup Checklist 1. Creating A Business PlanLeslie CatindigÎncă nu există evaluări

- Environmental Accounting: Dr.S.KALADocument23 paginiEnvironmental Accounting: Dr.S.KALADr.Satish RadhakrishnanÎncă nu există evaluări

- Feasibility Study of Waste Poly Ethylene Terephthalate (PET) Particles As Aggregate PDFDocument41 paginiFeasibility Study of Waste Poly Ethylene Terephthalate (PET) Particles As Aggregate PDFAniel Dias0% (1)

- Globalization-Operations ManagementDocument3 paginiGlobalization-Operations ManagementYlliza LinaÎncă nu există evaluări

- Chapter 5 Multiple Nuclei Model 2Document3 paginiChapter 5 Multiple Nuclei Model 2Divisional EngineerÎncă nu există evaluări

- Chapter 1embryology - Docx For StudentsDocument5 paginiChapter 1embryology - Docx For StudentsLumaho Greg Mikael DulawanÎncă nu există evaluări

- ConclusionDocument3 paginiConclusionKrishiaÎncă nu există evaluări

- A Research About Environmental Awareness of The YouthDocument4 paginiA Research About Environmental Awareness of The YouthTel TomoÎncă nu există evaluări

- Development of Bricks From Waste MaterialDocument10 paginiDevelopment of Bricks From Waste MaterialFelix Mar G. FernandezÎncă nu există evaluări

- Introduction To Operations ManagementDocument20 paginiIntroduction To Operations Managementapi-3719687Încă nu există evaluări

- Feasibility ReportDocument1 paginăFeasibility ReportBenneth ObilorÎncă nu există evaluări

- Annotated Bibliography ExampleDocument5 paginiAnnotated Bibliography ExampleAnonymous I03Wesk92Încă nu există evaluări

- Lesson 1.1 The Importance and Meaning of ArtDocument3 paginiLesson 1.1 The Importance and Meaning of ArtNicolle ImpuestoÎncă nu există evaluări

- Portfolio Management-Module One Discussion - MandoDocument2 paginiPortfolio Management-Module One Discussion - MandoDavid Luko ChifwaloÎncă nu există evaluări

- Minutes IIIDocument2 paginiMinutes IIILerma Corachea MaralitÎncă nu există evaluări

- NREE Chapter1 PDFDocument60 paginiNREE Chapter1 PDFAli WakoÎncă nu există evaluări

- Theoretical and Experimental Study On The Oil Sorption Behavior of Kapok AssembliesDocument6 paginiTheoretical and Experimental Study On The Oil Sorption Behavior of Kapok AssembliesakilanÎncă nu există evaluări

- Experimental Investigation of Using Papercrete and Recycled Aggregate As A Coarse AggregateDocument10 paginiExperimental Investigation of Using Papercrete and Recycled Aggregate As A Coarse AggregateInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Journal Printabs 4haug14esrDocument11 paginiJournal Printabs 4haug14esrBruno CarleteÎncă nu există evaluări

- Experimental Investigation On Reinforced Concrete With Plastic FiberDocument6 paginiExperimental Investigation On Reinforced Concrete With Plastic FiberIJRASETPublicationsÎncă nu există evaluări

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 paginiAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 paginiTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 paginiCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 paginiExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 paginiStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 paginiDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 paginiAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 paginiTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 paginiAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 paginiStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 paginiCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 paginiSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 paginiDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 paginiExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 paginiStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 paginiThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Soil Stabilization of Road by Using Spent WashDocument7 paginiSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- The Impact of Effective Communication To Enhance Management SkillsDocument6 paginiThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- A Digital Record For Privacy and Security in Internet of ThingsDocument10 paginiA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Performance of Short Transmission Line Using Mathematical MethodDocument8 paginiPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Document10 paginiChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 paginiA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 paginiAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 paginiA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocument12 paginiSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocument8 paginiAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocument10 paginiPredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 paginiAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Completed NGC3 ReportDocument4 paginiCompleted NGC3 ReportTiCu Constantin100% (1)

- Is 10719 (Iso 1302) - 1Document1 paginăIs 10719 (Iso 1302) - 1Svapnesh ParikhÎncă nu există evaluări

- ARISE 2023: Bharati Vidyapeeth College of Engineering, Navi MumbaiDocument5 paginiARISE 2023: Bharati Vidyapeeth College of Engineering, Navi MumbaiGAURAV DANGARÎncă nu există evaluări

- Enumerator ResumeDocument1 paginăEnumerator Resumesaid mohamudÎncă nu există evaluări

- The Voice of The Villages - December 2014Document48 paginiThe Voice of The Villages - December 2014The Gayton Group of ParishesÎncă nu există evaluări

- Marketing Management - Pgpmi - Class 12Document44 paginiMarketing Management - Pgpmi - Class 12Sivapriya KrishnanÎncă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityBhavesh PatelÎncă nu există evaluări

- Best Practices in Developing High PotentialsDocument9 paginiBest Practices in Developing High PotentialsSuresh ShetyeÎncă nu există evaluări

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Document6 paginiType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheÎncă nu există evaluări

- Community-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDocument28 paginiCommunity-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDiane Rose LacenaÎncă nu există evaluări

- RWJ Corp Ch19 Dividends and Other PayoutsDocument28 paginiRWJ Corp Ch19 Dividends and Other Payoutsmuhibbuddin noorÎncă nu există evaluări

- Tech Mahindra Sample Verbal Ability Placement Paper Level1Document11 paginiTech Mahindra Sample Verbal Ability Placement Paper Level1Madhav MaddyÎncă nu există evaluări

- Opel GT Wiring DiagramDocument30 paginiOpel GT Wiring DiagramMassimiliano MarchiÎncă nu există evaluări

- QuestionDocument7 paginiQuestionNgọc LuânÎncă nu există evaluări

- Solutions To Questions - Chapter 6 Mortgages: Additional Concepts, Analysis, and Applications Question 6-1Document16 paginiSolutions To Questions - Chapter 6 Mortgages: Additional Concepts, Analysis, and Applications Question 6-1--bolabolaÎncă nu există evaluări

- Chap 06 Ans Part 2Document18 paginiChap 06 Ans Part 2Janelle Joyce MuhiÎncă nu există evaluări

- Effect of Internet Use To Academic PerformaceDocument4 paginiEffect of Internet Use To Academic PerformaceLeonard R. RodrigoÎncă nu există evaluări

- DPC SEMESTER X B Project ListDocument2 paginiDPC SEMESTER X B Project ListVaibhav SharmaÎncă nu există evaluări

- Pradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural CitizensDocument2 paginiPradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural Citizenssairam namakkalÎncă nu există evaluări

- Finaniial AsceptsDocument280 paginiFinaniial AsceptsKshipra PrakashÎncă nu există evaluări