Documente Academic

Documente Profesional

Documente Cultură

Wood Design Sections

Încărcat de

Irfan AliDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Wood Design Sections

Încărcat de

Irfan AliDrepturi de autor:

Formate disponibile

Design of wooden PLANKS

IBC Section 2306 - "Allowable stress design" is the basis of the design

Reference to the American forest & paper Association (AF&PA) , "National design specification

for wood construction - ASD"

Bending Tension Shear Compression Compression Modulus of

Allowable stress

parrallel parrallel perpendicular parallel elasticity

to grain to grain to grain to grain

Fb(MPa) Ft(MPa) Fv(MPa) FcT(MPa) Fc(MPa) E(MPa)

MPa 6.03 2.93 0.59 4.31 4.14 8963.5

Check Bending Stresses :

Length (L) 1m

Mmax 0.2 KN.m

Vmax 1 KN

Section 200 mm X 50 mm

Area of section (A) = 10000 mm2

Sx bh2/6

83333.33 mm3

fb=M/S 2.4000 MPa

Check slenderness ratio = ((Ld)/b^2))^.5

1.12 < 50 ok no need for lateral support

Fb' = Revised allowable Bending stress

Fb((Cd)(Cr)(Cm)(Cf)(Cfu))

Where

Cd Load duration factor

0.9 Permanent (dead load)

1 Ten years (Occupancy live load)

Cr Repetitive use factor

1 For single member

1.15 if 3 or more members used in roof or floor system

Cm Moisture factor for wet use condition

1 Moisture factor content (MC)<=19%

0.85 Moisture factor content (MC)>19%

Cf from size factor for members with depth d>12"

(12/d)^1/9 if d>12"

Cfu Flat use factor if member is oriented flat , otherwise N/A

1.1 For 2X4"

1.15 For 2X6",2X8"

1.2 For 2X10",2X12"

1.05 For 4X6",4X8"

1.1 For 4X10 and deeper

Fb' = 6.03 X 1 x 1 x 1 x 1 = 6.94 MPa

> fb ok

Check Shear Stresses :

fv = 1.5V/A

0.1500 MPa

Fv' = Revised allowable shear stress parallel to grain

Fv((Cd)(Cm))

Cd Load duration factor

0.9 Permanent (dead load)

1 Ten years (Occupancy live load)

Cm Moisture factor for wet use condition

1 Moisture factor content (MC)<=19%

0.85 Moisture factor content (MC)>19%

Fv' = 0.59 X 1 x 1 = 0.59 MPa

> fv ok

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Culvert Load CalculationsDocument3 paginiCulvert Load CalculationsIrfan Ali100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Assignment 1 Due 1-16-2014Document4 paginiAssignment 1 Due 1-16-2014Evan Baxter0% (1)

- Romualdi 1964Document16 paginiRomualdi 1964Isabela LauferÎncă nu există evaluări

- Design of Pad Eye Using Check PlatesDocument3 paginiDesign of Pad Eye Using Check Plateshyoung65Încă nu există evaluări

- Reinforced Concrete Design Footings Quiz SolutionsDocument9 paginiReinforced Concrete Design Footings Quiz SolutionsIRISHÎncă nu există evaluări

- IMC Kitchen HoodDocument7 paginiIMC Kitchen HoodIrfan AliÎncă nu există evaluări

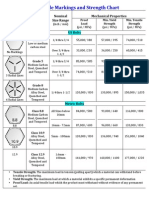

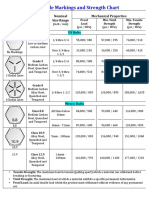

- Bolt Grade Markings and Strength Chart: Mechanical Properties Head Marking Grade and Material Nominal Size Range US BoltsDocument1 paginăBolt Grade Markings and Strength Chart: Mechanical Properties Head Marking Grade and Material Nominal Size Range US BoltsaskannancvÎncă nu există evaluări

- Capital Gate Building SystemsDocument19 paginiCapital Gate Building SystemsMartin Davis93% (15)

- Kitchen Hood DetailDocument1 paginăKitchen Hood DetailIrfan AliÎncă nu există evaluări

- Axial Roof 2019 enDocument172 paginiAxial Roof 2019 enIrfan AliÎncă nu există evaluări

- CatalogDocument36 paginiCataloganung_scribdÎncă nu există evaluări

- ANSI Standard A14.3-2000Document3 paginiANSI Standard A14.3-2000Jairo WilchesÎncă nu există evaluări

- General Comparison Between Aisc LRFD and Asd: Hamid ZandDocument107 paginiGeneral Comparison Between Aisc LRFD and Asd: Hamid Zandadnan85% (13)

- Input Data & Design Summary: Steel Stair Design Based On AISC-ASD 9thDocument50 paginiInput Data & Design Summary: Steel Stair Design Based On AISC-ASD 9thLivian TeddyÎncă nu există evaluări

- Culvert Traffic Pressure DistributionDocument1 paginăCulvert Traffic Pressure DistributionIrfan AliÎncă nu există evaluări

- Crack Width Calculation: MaterialsDocument2 paginiCrack Width Calculation: MaterialsIrfan AliÎncă nu există evaluări

- D Reinf BeamDocument1 paginăD Reinf BeamIrfan AliÎncă nu există evaluări

- Calculation of Block Wall Load On First & Second FloorDocument1 paginăCalculation of Block Wall Load On First & Second FloorIrfan AliÎncă nu există evaluări

- Plain Concrete DesignDocument1 paginăPlain Concrete DesignIrfan AliÎncă nu există evaluări

- RCC Slab Design ACI 318-08Document1 paginăRCC Slab Design ACI 318-08Irfan Ali0% (1)

- Corbel DesignDocument1 paginăCorbel DesignIrfan AliÎncă nu există evaluări

- Crack Width - Cap BeamDocument2 paginiCrack Width - Cap BeamIrfan AliÎncă nu există evaluări

- Temperature Difference ECDocument1 paginăTemperature Difference ECIrfan AliÎncă nu există evaluări

- Cmu Wall Details-1Document1 paginăCmu Wall Details-1Irfan AliÎncă nu există evaluări

- LEDGE Beam DesignDocument1 paginăLEDGE Beam DesignIrfan Ali100% (1)

- Precast Stair Connection DetailDocument1 paginăPrecast Stair Connection DetailIrfan AliÎncă nu există evaluări

- Crackwidth PredictionDocument10 paginiCrackwidth PredictionIrfan AliÎncă nu există evaluări

- 09 Design Manual ChangesDocument14 pagini09 Design Manual Changesdashne134Încă nu există evaluări

- A Design For Circular Concrete Tank Pca Design MethodDocument15 paginiA Design For Circular Concrete Tank Pca Design MethodajebÎncă nu există evaluări

- Bearing Pad EffectDocument8 paginiBearing Pad EffectAnita SheikhÎncă nu există evaluări

- Bolt Grade Markings and Strength Chart: Mechanical Properties Head Marking Grade and Material Nominal Size Range US BoltsDocument1 paginăBolt Grade Markings and Strength Chart: Mechanical Properties Head Marking Grade and Material Nominal Size Range US BoltsIrfan AliÎncă nu există evaluări

- Explorer Registration RenewalDocument1 paginăExplorer Registration RenewalIrfan AliÎncă nu există evaluări

- Mali (2015) - Design, Structural Analysis and Optimization of Crane HookDocument5 paginiMali (2015) - Design, Structural Analysis and Optimization of Crane HookGogyÎncă nu există evaluări

- Pyq of Soil SSC - Je Part - 3 1Document9 paginiPyq of Soil SSC - Je Part - 3 1sandeep singhÎncă nu există evaluări

- B500CDocument28 paginiB500CFlorin CiocanelÎncă nu există evaluări

- 2011 - Energy-Based Approach To Predict The Fatigue Life Behavior of Pre-Strained Fe-18Mn TWIP SteelDocument7 pagini2011 - Energy-Based Approach To Predict The Fatigue Life Behavior of Pre-Strained Fe-18Mn TWIP SteelJaime Andres CastañedaÎncă nu există evaluări

- RocData Users Guide PDFDocument54 paginiRocData Users Guide PDFJosé Carlos Bustamante Morales100% (1)

- Wrana 2015 4Document197 paginiWrana 2015 4Raihan LutfiantoÎncă nu există evaluări

- Client: Project: Location: BY: Date:: API RP-2FB Blast CalculationsDocument33 paginiClient: Project: Location: BY: Date:: API RP-2FB Blast CalculationsSampath Kumar KandasamyÎncă nu există evaluări

- 10 Deadliest Earthquakes in The PhilippinesDocument40 pagini10 Deadliest Earthquakes in The Philippinesberuniorolando0Încă nu există evaluări

- 23 - PCA MethodDocument64 pagini23 - PCA MethodPrashant GargÎncă nu există evaluări

- Columns and Struts - Strength of Materials - Part 1 PDFDocument9 paginiColumns and Struts - Strength of Materials - Part 1 PDFgvkpower33% (3)

- Numerical Simulation of A Deep Excavation Near A Shield TunnelDocument9 paginiNumerical Simulation of A Deep Excavation Near A Shield TunnelEfi GusfianaÎncă nu există evaluări

- Gamal Halim, Ade Faisal - Parametric Studies of Floor Rotation Performance of Assymmetrical Building Affected by Pulse Ground MotionDocument6 paginiGamal Halim, Ade Faisal - Parametric Studies of Floor Rotation Performance of Assymmetrical Building Affected by Pulse Ground MotionGamal HalimÎncă nu există evaluări

- Lecture 6 Notes 6.1 FatigueDocument82 paginiLecture 6 Notes 6.1 Fatiguerony16novÎncă nu există evaluări

- Quiz 12Document6 paginiQuiz 12John Taylor BernasÎncă nu există evaluări

- Fundamental Governing Equations For Hydraulic FracturingDocument16 paginiFundamental Governing Equations For Hydraulic FracturingRanggaÎncă nu există evaluări

- INTER Paper 49-07-01Document15 paginiINTER Paper 49-07-01Ulrich HübnerÎncă nu există evaluări

- (Final) Gravity Dam Hand CalculationDocument5 pagini(Final) Gravity Dam Hand CalculationYohannes TsegayeÎncă nu există evaluări

- Price List Per TGL 01 September 2015 Material Axter & NaueDocument2 paginiPrice List Per TGL 01 September 2015 Material Axter & NaueRopan EfendiÎncă nu există evaluări

- Transverse and Stresses in Beam: Loading On BeamsDocument38 paginiTransverse and Stresses in Beam: Loading On BeamsDr. BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- An Interface Element For The Simulation of Delamination in Unidirectional Fiber-Reinforced Composite LaminatesDocument19 paginiAn Interface Element For The Simulation of Delamination in Unidirectional Fiber-Reinforced Composite LaminatesKamal ShayedÎncă nu există evaluări

- Lec2 CIVE1144 2013Document36 paginiLec2 CIVE1144 2013Joe TangÎncă nu există evaluări

- Doubly Reinforced Simple Supported BeamDocument14 paginiDoubly Reinforced Simple Supported BeamAnonymous HJ7hmihhÎncă nu există evaluări

- Simplified Structural Analysis of Retaining Walls On Stepped FootingsDocument15 paginiSimplified Structural Analysis of Retaining Walls On Stepped Footingsalvaro sangurimaÎncă nu există evaluări

- Studi Evaluasi Usia Fatik Sisa Dan Lendutan Pada Jembatan Soekarno - Hatta Di Kota MalangDocument7 paginiStudi Evaluasi Usia Fatik Sisa Dan Lendutan Pada Jembatan Soekarno - Hatta Di Kota MalangLuqmanÎncă nu există evaluări

- Typical Detailing of Reinforcements in Beams and SlabsDocument2 paginiTypical Detailing of Reinforcements in Beams and SlabsNaveen BansalÎncă nu există evaluări

- Fractography, Fluidity, and Tensile Properties of Aluminum/Hematite Particulate CompositesDocument6 paginiFractography, Fluidity, and Tensile Properties of Aluminum/Hematite Particulate CompositesAugusto OliveiraÎncă nu există evaluări