Documente Academic

Documente Profesional

Documente Cultură

T H Hill Standard DS 2012 4 Edition

Încărcat de

manuelperdomotDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

T H Hill Standard DS 2012 4 Edition

Încărcat de

manuelperdomotDrepturi de autor:

Formate disponibile

T H Hill Standard DS-1 Fourth Edition / 2012 / 4 Volumes set

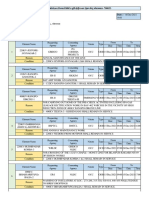

DS-1 Volume 1 Drilling Tubular Product Specification Quantity

DS-1 Volume 2 Drill Stem Design & Operation Quantity

DS-1 Volume 3 Drill Stem Inspection Quantity

DS-1 Volume 4 Drilling Specialty Tools

Volume 1:- Align DS 1 Standard Level requirements with API Specifications 7 1 and 7 2 including additionof

HWDP and stabilizers.- Add section on hardbanding includingmaterialselection, geometry and application.-

Add new NWDP and TWDP.

Volume 2:- Incorporate Connection Fatigue Index (CFI; reference IADC/SPE Paper 112105) for drill

collarconnection selection based on relative fatigue performance.- Add section on Landing StringDesign.- Add

dimensional and load capacitiesfor new NWDP, TWDP and proprietary connections.

Volume 3:- Add procedures cover hardbanding (re application and inspection) and tool joint build up.- Expand

dimensional and visual inspection procedures for new proprietary connections.- Move seven procedures

covering Specialty Tools to Volume 4.

Volume 4:- Add Volume 4 toDS 1 to addressthe unique requirementsfor qualification ofspecialty tools.-

Incorporate STC 1 and portions of DS 1 Third Edition Volume 3 to establish requirements fordesign,

inspection, assembly,function testing,shipment and use ofspecialty tools.- Provide requirements for

qualification of selected tool families.

DS-1 Volume 1 Drilling Tubular Product Specification Quantity

An easy to use manufacturing specification for drilling tubular products.

A global manufacturing standard must be comprehensive, technically sound and easy to use for both buyer

and producer. In Volume 1 of DS-1 Fourth Edition, we worked with manufacturers, buyers, and users of

drilling tubular products to create such a standard. The Drilling Tubular Product Specification is Volume 1 of

DS-1 Fourth Edition, and offers a standardized approach to the manufacturing process.

Features of the Manufacturing Standard:

Establishes requirements for two service levels: Normal and CriticalAligns DS-1 Standard Level requirements

with API Specifications 7-1, 7-2, and 5DP including addition of HWDP and stabilizersAdds new section on

hardbanding including geometry and applicationPresents all manufacturing, dimensional and metallurgical

requirements in tabular formatCovers drill pipe, HWDP, subs, stabilizers, drill collars and pup jointsAddresses

the requirements for higher grade drill pipe (DS-140 and DS-150)Includes a special category for thick-wall drill

pipe used for landing stringsProcedures for non-destructive testing of components not addressed by APINew

section on purchasing (receiving) inspectionEntire volume structured for ease of use

DS-1 Volume 2 Drill Stem Design & Operation Quantity

A revolutionary standard for drill string design and operation.

What if you could dramatically increase the fatigue life of your drill string merely by following structured design

criteria? With the DS-1 Fourth Edition Design volume, you can. Years of research have culminated in a

ground-breaking approach to drill string design that maximizes fatigue mitigation while delivering an optimal

overall design. This innovative technology can only be found in Standard DS-1 Drill Stem Design and

Operation, Volume 2 of our Fourth Edition

The Standard in Design Includes:

Innovative fatigue mitigation design methods (Connection Fatigue Index, Curvature Index and Stability

Index)Risk-based design groups for overload preventionRisk-based design groups for fatigue mitigationNew

drill pipe sizes and gradesDimensional and load capacities for new NWDP, TWDP and proprietary

connectionsSlip-cut severity and the impact on fatigueMethods for corrosion monitoringExpanded coverage for

slip crushing issuesNew section on Landing String DesignConsiderations for reactive torque and casing

wearInstructions for specifying an appropriate inspectionNew section on hardbanding including material

selection, geometry and application

DS-1 Volume 3 Drill Stem Inspection Quantity

A volume dedicated to inspection.

In the past decades, DS-1 has become the global standard for inspection by offering comprehensive

procedural detail, an easy to use inspection specification system and timely technical updates. The Fourth

Edition carries on this tradition and expands coverage.

Content Includes:

New procedures for heat checking, pup joint inspection, hardbanding, tool joint build up, wet visible contrast

method, phosphating new connections, demagnetization, and marking for inspected componentsExpanded

dimensional and visual inspection procedures for new proprietary connectionsInspection tables supplemented

with new pipe sizes, weights, and gradesInspection criteria for thick-wall drill pipe, HWDP and drill

collarsCoverage of DS-140 and DS-150 grade drill pipeManufacturer-specific connection inspection

criteriaExpansion of MUT tablesReference photographs for internal plastic coating evaluationProcedure for full

length UT inspection of drill pipe tubesHeavy duty landing string inspection category

DS-1 Volume 4 Drilling Specialty Tools

A new specification for drilling specialty tools.

As well complexity increases, so do the demands placed on drilling specialty tools to perform. The new Volume

4 of the Standard DS-1 Fourth Edition, Drilling Specialty Tools, establishes requirements for specialty tools

that will allow them to meet these demands and decrease the probability that they will fail in service, either

functionally or structurally. Our objective is to reduce NPT and the costs associated with specialty tool failures.

Highlights of the New Drilling Specialty Tool Standard:

Incorporates STC-1 and Standard DS-1 inspection procedures to address qualification of drilling specialty

toolsSpecifies requirements for select tool familiesEstablishes process for inspection, assembly and

testingCovers design limits and constraintsProvides return, repair, re-inspection, and restocking procedures

S-ar putea să vă placă și

- API Rig InspectionDocument12 paginiAPI Rig Inspectionsmithyry201493% (14)

- API 5CT (9th Ed) PSL Presentation and RequirementsDocument4 paginiAPI 5CT (9th Ed) PSL Presentation and RequirementsTanzil100% (3)

- DS 1 CatDocument38 paginiDS 1 CatMuhammad Bilal Khattak100% (1)

- Changes in DS-1Document5 paginiChanges in DS-1Chandrasekhar SonarÎncă nu există evaluări

- CameronDocument41 paginiCameronmanuelperdomot100% (1)

- Lproposal ModuspecDocument19 paginiLproposal ModuspecmanuelperdomotÎncă nu există evaluări

- Lproposal ModuspecDocument19 paginiLproposal ModuspecmanuelperdomotÎncă nu există evaluări

- Schlumberger - Bit Running GuidelinesDocument38 paginiSchlumberger - Bit Running Guidelinesmanuelperdomot100% (1)

- NS 2 PDFDocument187 paginiNS 2 PDFParviz Nasirov63% (8)

- Inspection StandardDocument3 paginiInspection StandardEmad Jamshidi100% (3)

- DS-1 VOL 3 - Drill Stem Inspection - Fifth Edition 2020 (012-013)Document2 paginiDS-1 VOL 3 - Drill Stem Inspection - Fifth Edition 2020 (012-013)DYLAN FELIPE RAMIREZ CORTES0% (1)

- VAM Field Service Training: Vallourec & Mannesmann TubesDocument117 paginiVAM Field Service Training: Vallourec & Mannesmann TubesSumesh Dethan100% (3)

- VAM® 21 Technical ReportDocument8 paginiVAM® 21 Technical ReportKonrad AdamÎncă nu există evaluări

- NS 2 PDFDocument188 paginiNS 2 PDFPrimelift Safety Resources Limited100% (1)

- DRILL PIPE Acceptance CriteriaDocument3 paginiDRILL PIPE Acceptance CriteriaYousof Abozeid100% (1)

- Fibreglass Tank and Vessel SpecificationDocument43 paginiFibreglass Tank and Vessel SpecificationJorge Andres Caro CortesÎncă nu există evaluări

- Work Instruction (Used Drill Pipe Coating) - NOVDocument17 paginiWork Instruction (Used Drill Pipe Coating) - NOVYadi Kusmayadi100% (1)

- DS-1 Training-Drill Pipe InspectionDocument180 paginiDS-1 Training-Drill Pipe InspectionSara Marzouk83% (6)

- DS-1 4th Edition-Sponsor OverviewDocument1 paginăDS-1 4th Edition-Sponsor OverviewangeliccoÎncă nu există evaluări

- FSOG 13-005 General Insp TenarisDocument10 paginiFSOG 13-005 General Insp TenarisJanderson Sanchez Castañeda0% (1)

- Well Control Academy Student Manual PDFDocument301 paginiWell Control Academy Student Manual PDFmanuelperdomotÎncă nu există evaluări

- Electrical Inspection Checklist ConstructionDocument2 paginiElectrical Inspection Checklist ConstructionAtul NikaljeÎncă nu există evaluări

- LG5002 OpsDocument20 paginiLG5002 OpsRSR_2K5364Încă nu există evaluări

- DS-1 Vol. 3 Table 2.1-2.2 Fig. 2.7 To 2.12Document11 paginiDS-1 Vol. 3 Table 2.1-2.2 Fig. 2.7 To 2.12Chandrasekhar Sonar100% (1)

- GJ-204-016 Mud Pump 2 & 3 UpgradeDocument6 paginiGJ-204-016 Mud Pump 2 & 3 UpgradeKuna Stanbekov100% (1)

- API Inspection GuideDocument14 paginiAPI Inspection Guidesouilah100% (1)

- API Drill Pipe Specs-1Document26 paginiAPI Drill Pipe Specs-1SACHIN H. DHAMAPURKARÎncă nu există evaluări

- 01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFDocument5 pagini01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFKarla HernandezÎncă nu există evaluări

- Valves HCR CameronDocument5 paginiValves HCR CameronmanuelperdomotÎncă nu există evaluări

- Shear Ram Capabilities StudyDocument61 paginiShear Ram Capabilities StudyAnshul JainÎncă nu există evaluări

- Shear Ram Capabilities StudyDocument61 paginiShear Ram Capabilities StudyAnshul JainÎncă nu există evaluări

- NS-2 Drill String Inspection Standard Bulletin #001Document7 paginiNS-2 Drill String Inspection Standard Bulletin #001Parviz Nasirov100% (2)

- API RP 8B - Procedures For Inspections, Maintenance, Repair, and Remanufacture of Hoisting EquipmentDocument8 paginiAPI RP 8B - Procedures For Inspections, Maintenance, Repair, and Remanufacture of Hoisting EquipmentRashid Ghani80% (5)

- Ds-1 Cat 5 Inspection ProgramDocument1 paginăDs-1 Cat 5 Inspection ProgramAnh Tuan Nguyen100% (4)

- Api 4G PDFDocument12 paginiApi 4G PDFAluosh AluoshÎncă nu există evaluări

- API Norsok Standardise For Well Intervention EquipmentDocument70 paginiAPI Norsok Standardise For Well Intervention EquipmentMai KawayapanikÎncă nu există evaluări

- API Standards For Pipe InspectionsDocument38 paginiAPI Standards For Pipe InspectionsNatraji100% (2)

- Doc-Ser-012 Api 16a 3RD OverviewDocument24 paginiDoc-Ser-012 Api 16a 3RD OverviewDanilo FornaroÎncă nu există evaluări

- DS1 Standards DP BHADocument3 paginiDS1 Standards DP BHAGeotag100% (1)

- API Inspection RP 7G Intervals Drilling RIG & Hoisting Equipment DS1Document2 paginiAPI Inspection RP 7G Intervals Drilling RIG & Hoisting Equipment DS1agusnurcahyo100% (2)

- Drilling String InspectionDocument7 paginiDrilling String Inspectionrais ridha100% (2)

- Field Inspection Procedure For Used GPDS Connections Revision 03 PDFDocument3 paginiField Inspection Procedure For Used GPDS Connections Revision 03 PDFJohn Dolan0% (1)

- API Inspection RP 7G Intervals Drilling RIG & Hoisting Equipment DS1Document2 paginiAPI Inspection RP 7G Intervals Drilling RIG & Hoisting Equipment DS1entramas86% (14)

- VAM Catalog 2011Document116 paginiVAM Catalog 2011Anoop SVÎncă nu există evaluări

- Intermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleDocument2 paginiIntermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleKaleem UllahÎncă nu există evaluări

- NS-5 DSFP Rig Team Handbook PDFDocument84 paginiNS-5 DSFP Rig Team Handbook PDFkellycookwpÎncă nu există evaluări

- Ds 1 Vol 5 Bit Inspection Technical StandardDocument100 paginiDs 1 Vol 5 Bit Inspection Technical StandardNgum Christopher kum100% (3)

- Rig Inspection OutlineDocument4 paginiRig Inspection OutlineAdolfo Angulo100% (1)

- Used Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TDocument44 paginiUsed Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TIvan MauricioÎncă nu există evaluări

- Drilling Rig Acceptance StandardsDocument24 paginiDrilling Rig Acceptance StandardsÖnder Büyükişcan75% (4)

- Online Bank Management SystemDocument9 paginiOnline Bank Management SystemJayshree AhirraoÎncă nu există evaluări

- BH-T2 Thread Inspection and Rework Procedure - All SizesDocument59 paginiBH-T2 Thread Inspection and Rework Procedure - All SizesIvan Mauricio100% (2)

- Drill Pipe CoatingsDocument64 paginiDrill Pipe CoatingsNicolas Roldan100% (3)

- Sop Iii-306 R00Document23 paginiSop Iii-306 R00Bepdj100% (1)

- International Limited: Certificate of Visual Examination and MpiDocument8 paginiInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaÎncă nu există evaluări

- API Drilling Related Standards From APIDocument3 paginiAPI Drilling Related Standards From APImanuelelkin100% (2)

- ADM 260 - Derrick Inspection - CAT III PDFDocument90 paginiADM 260 - Derrick Inspection - CAT III PDFMohamed Ismail100% (1)

- API RP 8B Hoisting EquipmentDocument8 paginiAPI RP 8B Hoisting EquipmentTony NietoÎncă nu există evaluări

- Ductwork SystemsDocument28 paginiDuctwork SystemsSurekanth ManikkavasagamÎncă nu există evaluări

- Well Control Drills and Exercises WIPER TRIPDocument3 paginiWell Control Drills and Exercises WIPER TRIPmanuelperdomotÎncă nu există evaluări

- Well Control Drills and Exercises WIPER TRIPDocument3 paginiWell Control Drills and Exercises WIPER TRIPmanuelperdomotÎncă nu există evaluări

- Tubing and Casing Thread Inspection 2014Document44 paginiTubing and Casing Thread Inspection 2014xmacaba100% (3)

- Best Practices Drilling 26 inDocument6 paginiBest Practices Drilling 26 inmanuelperdomotÎncă nu există evaluări

- International Limited International Limited: JC JCDocument5 paginiInternational Limited International Limited: JC JCMichael OkwuwaÎncă nu există evaluări

- API 4G Qualified Drilling Structures InspectionDocument6 paginiAPI 4G Qualified Drilling Structures InspectionranjitpandeyÎncă nu există evaluări

- 78-Bea - vt460-Tg - en Variotec 460 TracergasDocument72 pagini78-Bea - vt460-Tg - en Variotec 460 TracergasMÎncă nu există evaluări

- Tripping Operations - Best PracticesDocument3 paginiTripping Operations - Best PracticesYougchu Luan100% (1)

- QMS P 009 Procedure For Visual and Optical Inspection Revision 0 PDFDocument8 paginiQMS P 009 Procedure For Visual and Optical Inspection Revision 0 PDFmanuelperdomotÎncă nu există evaluări

- Bear - Public - JFEBEAR-TP-M-101 Rev3 Field Inspection of JFEBEARDocument5 paginiBear - Public - JFEBEAR-TP-M-101 Rev3 Field Inspection of JFEBEARGabriel Ibarra100% (2)

- Leopard General and in Stal Tion InformationDocument18 paginiLeopard General and in Stal Tion InformationChandrasekhar SonarÎncă nu există evaluări

- New Materials For Sour Gas Drill Pipe: 26 March/April 2002Document2 paginiNew Materials For Sour Gas Drill Pipe: 26 March/April 2002amigofirmÎncă nu există evaluări

- Referencias SubseaDocument19 paginiReferencias SubseaEdgar I RamirezÎncă nu există evaluări

- SSPC Standards Update PresentationDocument30 paginiSSPC Standards Update PresentationAnbalagan Ravichandran100% (1)

- Comparación Mangueras Hidráulicas SAE e ISODocument5 paginiComparación Mangueras Hidráulicas SAE e ISOJuan David Barrera FlorezÎncă nu există evaluări

- AADE 11 NTCE - 58 Hilton PrejeanDocument5 paginiAADE 11 NTCE - 58 Hilton PrejeanNicolas RoldanÎncă nu există evaluări

- ASTM D2321 14e1Document6 paginiASTM D2321 14e1tosheÎncă nu există evaluări

- 3 Party Certification Requirements Per Issuance of October 14, 2010 Code of Federal RegulationsDocument29 pagini3 Party Certification Requirements Per Issuance of October 14, 2010 Code of Federal RegulationsJosé Luis Párraga QuispeÎncă nu există evaluări

- JotneMudSystems November2014Document18 paginiJotneMudSystems November2014manuelperdomotÎncă nu există evaluări

- 4 Drilling MudDocument12 pagini4 Drilling MudSaradhi Reddy100% (1)

- Master Service Agreement: Contract Number/dateDocument7 paginiMaster Service Agreement: Contract Number/datemanuelperdomotÎncă nu există evaluări

- Master Service Agreement: Contract Number/dateDocument7 paginiMaster Service Agreement: Contract Number/datemanuelperdomotÎncă nu există evaluări

- Master Service Agreement: Contract Number/dateDocument7 paginiMaster Service Agreement: Contract Number/datemanuelperdomotÎncă nu există evaluări

- Manual Elevator Rev A Screen OpPart2Document54 paginiManual Elevator Rev A Screen OpPart2manuelperdomot100% (1)

- Bope PDFDocument1 paginăBope PDFmanuelperdomotÎncă nu există evaluări

- 9,5RWD2DT5048,625Document1 pagină9,5RWD2DT5048,625manuelperdomotÎncă nu există evaluări

- Well Planning PDFDocument63 paginiWell Planning PDFmanuelperdomotÎncă nu există evaluări

- Well Planning PDFDocument63 paginiWell Planning PDFmanuelperdomotÎncă nu există evaluări

- Manual Mtto Rams PDFDocument101 paginiManual Mtto Rams PDFmanuelperdomotÎncă nu există evaluări

- Bomba National, ManualDocument76 paginiBomba National, Manualmanuelperdomot100% (1)

- Wellplan VST&DDocument410 paginiWellplan VST&DmanuelperdomotÎncă nu există evaluări

- C-05-6F - Appendix D Offshore Drilling Well Control - A1S2W1Document76 paginiC-05-6F - Appendix D Offshore Drilling Well Control - A1S2W1hlove1Încă nu există evaluări

- AC08380998n01vt PDFDocument82 paginiAC08380998n01vt PDFmanuelperdomotÎncă nu există evaluări

- Software Engineering: UNIT-3Document41 paginiSoftware Engineering: UNIT-3Jayavarapu Karthik JÎncă nu există evaluări

- Maxi Flow TechDocument12 paginiMaxi Flow TechazkÎncă nu există evaluări

- GPON OLT (P1201 08 1.0) User Manual Quick Configuration GuideDocument34 paginiGPON OLT (P1201 08 1.0) User Manual Quick Configuration GuideFedePonceDaminatoÎncă nu există evaluări

- SAS and Excel Presentation PDFDocument98 paginiSAS and Excel Presentation PDFRakesh Reddy GopidiÎncă nu există evaluări

- Vectortechtex I-Series: Cutting Quality & PerformanceDocument2 paginiVectortechtex I-Series: Cutting Quality & Performanceperro perezÎncă nu există evaluări

- MongoDB TCO Comparison MongoDB OracleDocument12 paginiMongoDB TCO Comparison MongoDB Oracleowen liuÎncă nu există evaluări

- Total Productive Maintenance and Reliability Notes 2Document4 paginiTotal Productive Maintenance and Reliability Notes 2carr carrÎncă nu există evaluări

- PlybooSound Collection CSI Specification - 100813Document5 paginiPlybooSound Collection CSI Specification - 100813Nehru Valdenarro ValeraÎncă nu există evaluări

- Karnataka Government Insurance Department Government of Karnataka Motor Insurance Proposal Form-IDocument3 paginiKarnataka Government Insurance Department Government of Karnataka Motor Insurance Proposal Form-Isunil kumarÎncă nu există evaluări

- Taniya Rawat: ObjectiveDocument1 paginăTaniya Rawat: Objectiveanuj sharmaÎncă nu există evaluări

- The Motherboard NotesDocument5 paginiThe Motherboard NotesPritima RamalinggamÎncă nu există evaluări

- 074H Midi enDocument83 pagini074H Midi enaryaputra72Încă nu există evaluări

- Port Facilities - Spain: Page 1 of 6 Printed: 26/03/2009Document6 paginiPort Facilities - Spain: Page 1 of 6 Printed: 26/03/2009EvrenÎncă nu există evaluări

- Lecture01 IntroDocument20 paginiLecture01 IntroRijy LoranceÎncă nu există evaluări

- Phy 104 Lab ReportDocument6 paginiPhy 104 Lab ReportMd. Abdullah ZishanÎncă nu există evaluări

- Skin Disease Detection Using Machine LearningDocument59 paginiSkin Disease Detection Using Machine LearningAnita ThapaÎncă nu există evaluări

- Er Shutdown For 15.12.21 Rev1Document8 paginiEr Shutdown For 15.12.21 Rev1Gitesh PatelÎncă nu există evaluări

- A Brief History of Programming LanguagesDocument46 paginiA Brief History of Programming LanguagesZahir B. FareedÎncă nu există evaluări

- A3-PageWide F2F Deck 2 28 17 final-ENDocument129 paginiA3-PageWide F2F Deck 2 28 17 final-ENkadirÎncă nu există evaluări

- Example: Item1 Item2 Item3 Item4 Item5 Alice 5 3 4 4 User1 3 1 2 3 3 User2 4 3 4 3 5 User3 3 3 1 5 4 User4 1 5 5 2 1Document6 paginiExample: Item1 Item2 Item3 Item4 Item5 Alice 5 3 4 4 User1 3 1 2 3 3 User2 4 3 4 3 5 User3 3 3 1 5 4 User4 1 5 5 2 1Rajasekhar ReddyÎncă nu există evaluări

- General Concepts and Historical Antecedents of Science and TechnologyDocument20 paginiGeneral Concepts and Historical Antecedents of Science and TechnologyZarina PajarillagaÎncă nu există evaluări

- Computer Graphics Schaum Series PDF Download PDFDocument2 paginiComputer Graphics Schaum Series PDF Download PDFDivya SoodÎncă nu există evaluări

- MS 2701 2018 - PrepdfDocument7 paginiMS 2701 2018 - PrepdfSiti Aishah Sahul HamidÎncă nu există evaluări

- DriveCompatibility WikiDocument1 paginăDriveCompatibility Wikishida67Încă nu există evaluări

- Online Fashion Shopping Questionnaire Final VersionDocument10 paginiOnline Fashion Shopping Questionnaire Final VersionCao Mỹ HằngÎncă nu există evaluări

- Roy T. Fielding ThesisDocument7 paginiRoy T. Fielding Thesisjessicahillnewyork100% (2)

- Energy Systems TDT HD3 User ManualDocument24 paginiEnergy Systems TDT HD3 User ManualTrickyDicky2Încă nu există evaluări