Documente Academic

Documente Profesional

Documente Cultură

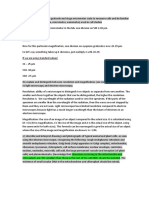

Comparison of Pathway 1 and 2

Încărcat de

InTENsity100 evaluări0% au considerat acest document util (0 voturi)

10 vizualizări1 paginăTwo different pathways of manufacturing sugar

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentTwo different pathways of manufacturing sugar

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

10 vizualizări1 paginăComparison of Pathway 1 and 2

Încărcat de

InTENsity10Two different pathways of manufacturing sugar

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

Pathway 1 Justification Pathway 2

Washing: Preparation of sugar cane Peeling:

Large amounts of rock, trash Sugar cane must be

and leaves can be removed manually fed into double

capacity peeler which

requires more labour costs

Some downtime due to 2

hours of maintenance for

every 12 hours of usage

Shredding: Crushing:

Highly efficient because Sugar cane juice loses more

cells containing juice are of its sugar content because

ruptured but its juices are of the vigorous process

not extracted

Milling: Extraction of juices Diffuser:

Good extraction rates with Mixed juice treatment is

lesser preparation needed more difficult because of

Less maintenance required high level of coloured

contaminants

Bagasse contains more

mineral impurities

Drying: Reduced costs by limiting Drying:

Only present once processes Present twice in the process

throughout process flow flow costing more to setup

and maintain the drying

drums

Cooling: Cooling:

Absent as it is an Present so a heat exchanger

unnecessary step needs to be built

Ion exchange resin: Decolourisation process Char filter:

More economical Low decoloration capacity

Easily automated so its Needed in large quantities

more hygienic

Less bulky apparatus

Double-effect evaporators: Evaporators Vacuum pan:

Lower operating costs due to Single-effect evaporator has

reduced steam consumption lesser steam economy

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Tripple Effect Evaporator Design CalculationDocument6 paginiTripple Effect Evaporator Design CalculationVirendra Bhagat100% (1)

- ASTM C 1437 - Flow of MortarsDocument2 paginiASTM C 1437 - Flow of MortarsWan T Trianto80% (5)

- Sugar Plant Energy ConservationDocument24 paginiSugar Plant Energy Conservationtsrinivasan5083100% (4)

- Ultra High Performance Concrete (Uhpc) : Npca White PaperDocument19 paginiUltra High Performance Concrete (Uhpc) : Npca White Paperphewphewphew200Încă nu există evaluări

- Budget Pie ChartDocument5 paginiBudget Pie ChartInTENsity10Încă nu există evaluări

- Design and Performance of Cost-Effective Ultra-High Performance CDocument269 paginiDesign and Performance of Cost-Effective Ultra-High Performance CInTENsity10Încă nu există evaluări

- WavesDocument35 paginiWavesInTENsity10Încă nu există evaluări

- A. Cell StructureDocument6 paginiA. Cell StructureLaylaÎncă nu există evaluări

- Types of Products Sold by Orang AsliDocument2 paginiTypes of Products Sold by Orang AsliInTENsity10Încă nu există evaluări

- Diseño de Tanque Metalico PDFDocument6 paginiDiseño de Tanque Metalico PDFnarufredÎncă nu există evaluări

- Measurement TechniquesDocument60 paginiMeasurement TechniquesInTENsity10Încă nu există evaluări

- Infectious DiseasesDocument10 paginiInfectious DiseasesLaylaÎncă nu există evaluări

- Fake Marvel Logistics LogoDocument1 paginăFake Marvel Logistics LogoInTENsity10Încă nu există evaluări

- Phases of MatterDocument16 paginiPhases of MatterLaylaÎncă nu există evaluări

- Past Years Sorted Out Chapter 2Document8 paginiPast Years Sorted Out Chapter 2InTENsity10Încă nu există evaluări

- FUG 2ndDocument2 paginiFUG 2ndInTENsity10Încă nu există evaluări

- Mammalian Transport SystemDocument1 paginăMammalian Transport SystemInTENsity10Încă nu există evaluări

- Management - Motivating EmployeesDocument2 paginiManagement - Motivating EmployeesInTENsity10Încă nu există evaluări

- Catalytic Oxidation and Thermal DecompositionDocument2 paginiCatalytic Oxidation and Thermal DecompositionInTENsity10Încă nu există evaluări

- Compilation of MUET Speaking Test TipsDocument38 paginiCompilation of MUET Speaking Test TipsInTENsity1050% (2)

- Archi Murukku RecipeDocument2 paginiArchi Murukku RecipeKayshni LingeswaranÎncă nu există evaluări

- Refrigeration COP and Capacity CalculationDocument12 paginiRefrigeration COP and Capacity CalculationxofigoÎncă nu există evaluări

- AHRI Standard 550-590 (I-P) - 2011 PDFDocument74 paginiAHRI Standard 550-590 (I-P) - 2011 PDFaashiqueo2Încă nu există evaluări

- DX Air Conditioning For Office BuildingsDocument18 paginiDX Air Conditioning For Office Buildingspadchd100% (1)

- Evaporation: Fundamentals of OperationDocument9 paginiEvaporation: Fundamentals of Operationomid khsÎncă nu există evaluări

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocument9 paginiRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimÎncă nu există evaluări

- Procesos InglesDocument4 paginiProcesos InglesMarcoDulongJaraÎncă nu există evaluări

- AWT Fundamentals and Applications Cooling Water Training: Towers, Chillers and LoopsDocument38 paginiAWT Fundamentals and Applications Cooling Water Training: Towers, Chillers and LoopsMunir AbdullahÎncă nu există evaluări

- Colmac DX Ammonia Piping Handbook 2nd EditionDocument57 paginiColmac DX Ammonia Piping Handbook 2nd EditionDaniel Puello Rodelo100% (1)

- MULTIPRESSURE SYSTEMSDocument6 paginiMULTIPRESSURE SYSTEMSeslam AtitoÎncă nu există evaluări

- Foul CondensateDocument9 paginiFoul CondensateArun YogaÎncă nu există evaluări

- Converted 277031216Document57 paginiConverted 277031216Daniel SoseÎncă nu există evaluări

- Solutions Manual Unit Operations of ChemDocument19 paginiSolutions Manual Unit Operations of ChemPutri AdantiÎncă nu există evaluări

- Mechanical Engineering Basics CourseDocument23 paginiMechanical Engineering Basics CourseMANOJKUMAR MÎncă nu există evaluări

- Roy-Mandal2020 Article Thermo-economicAnalysisAndMultDocument15 paginiRoy-Mandal2020 Article Thermo-economicAnalysisAndMultAhmed RagabÎncă nu există evaluări

- Evaporation: Types, Design, Calculation and ProcessesDocument86 paginiEvaporation: Types, Design, Calculation and ProcessesArgha TalukderÎncă nu există evaluări

- Thermosyphon CoolingDocument4 paginiThermosyphon CoolingMd Naim HossainÎncă nu există evaluări

- Hoshizaki Technical Support - Warranty Labor Claim InstructionsDocument12 paginiHoshizaki Technical Support - Warranty Labor Claim InstructionsJohn DuttingerÎncă nu există evaluări

- Equipo de Evaporación de AlimentosDocument31 paginiEquipo de Evaporación de AlimentosDomenica PozoÎncă nu există evaluări

- Junior Engineer Tool KnowledgeDocument24 paginiJunior Engineer Tool KnowledgeDennis AleaÎncă nu există evaluări

- Applied Thermal EngineeringDocument15 paginiApplied Thermal EngineeringCamilo Gutierrez DbzÎncă nu există evaluări

- Den Islam Intern ReportDocument95 paginiDen Islam Intern ReportDen Islam100% (1)

- Lecture 16Document15 paginiLecture 16Fabiha Shafi MimÎncă nu există evaluări

- Extra ProblemsDocument2 paginiExtra ProblemsHajarÎncă nu există evaluări

- Chapter 9 EvaporationDocument134 paginiChapter 9 EvaporationTÚ Cao Ngọc ThiệnÎncă nu există evaluări

- 1 s2.0 S0196890421008864 MainDocument34 pagini1 s2.0 S0196890421008864 Mainشهيد مهدي ابو العيسÎncă nu există evaluări

- Spent Acid From Chlorine DryingDocument2 paginiSpent Acid From Chlorine DryingacckypenrynÎncă nu există evaluări

- Ice Plant Theory RefrigerationDocument16 paginiIce Plant Theory RefrigerationArnulfo Jose Pi DiÎncă nu există evaluări