Documente Academic

Documente Profesional

Documente Cultură

Reference Book - Label

Încărcat de

djokanomcaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Reference Book - Label

Încărcat de

djokanomcaDrepturi de autor:

Formate disponibile

Sony DADC

Reference Book - Label

Printing Process, Labelprint without white pre-printing,

Disc variants, Tips & Tricks for Designer

Solutions by Sony DADC

Sony DADC Label

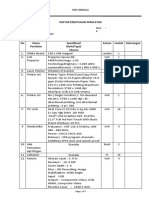

1. Printing Process

1.1. General Page 3 Information and examples

1.2. Screen Printing Page 4 Information and examples

1.2.1. PANTONE Colours Page 4 Information and examples

1.2.2. Screen colours (KNRC) Page 5 Information and examples

1.2.3. Metallic colours (8000) Page 6 Information and examples

1.2.4. Pastel colours (9000) Page 6 Information and examples

1.2.5. Fluorescent colours 801-814 Page 6 Information and examples

1.2.6. Special colour (SF) Page 6 Information and examples

1.2.7. Clear varnish Page 7 Information and examples

1.2.8. Matt varnish (DXX-0998) Page 7 Information and examples

1.2.9. Sniffle colours Page 8 Information and examples

1.2.10. Thermal varnish Page 8 Information and examples

1.2.11. Inkjet varnis Page 8 Information and examples

1.3. Offset Seite 8 Information and examples

2. Labelprint without white pre-printing

Labeldruck without white pre-printing Page 9 Information and examples

3. Disc variants

Disc variants Page 10 Information and examples

4. Tips & Tricks

4.1. Setting Black to overprint Page 10 Information and examples

4.2. Marabu Black (#34) - KNRC 65 (#54) Page 10 Information and examples

4.3. 4C Offset Black Page 10 Information and examples

4.4. Individual white base Page 10 Information and examples

4.5. Equal raster angle Page 11 Information and examples

4.6. Line Width Page 11 Information and examples

4.7. Client proofs Page 11 Information and examples

More important informations for creating Graphic-Files

Reference Book Tips for creating Grafic-Files

Reference Book Template

Reference Book PDF from InDesign including ICC Profile, Distiller Settings and Preflight

Reference Book PDF from XPress including ICC Profile, Distiller Settings and Preflight

Reference Book PDF from Corel Draw including ICC Profile, Distiller Settings and Preflight

Sony DADC Download Area

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 2/12

current version on e-doc

Sony DADC Printing Process

1. Printing Process

1.1. General

When printing a disc the company of Sony DADC distinguishes between screen- and offset printing, whereby both are

dependent on design and data build-up and each have their advantages and disadvantages.

Solid coated PANTONE colours, which we mix directly, are generally used for screen printing. This procedure is generally

used for simple designs or areas. (Fig 1)

Fig 1 Screen Print - Pantone (#34

Sony DADC also offers the picture print (4C Screen print- CMYK) in screen printing. This print is mainly used for

simple pictures that barely show gradients and have more than 6 colours (therefore nor possible in PANTONE).

(Fig 2)

Fig 2 Screen Print - Picture (#54)

The offset print allows Sony to print low tone values and all kinds of pictures. (See also Fig 3)

Fig 3 Offset (#80)

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 3/12

current version on e-doc

Sony DADC Printing Process - Screen Print

1.2. Screen Print

1.2.1. PANTONE Colours

- All Sony screen print machines are equipped with 6 print heads.

This means a max. of 6 colours can be printed.

For example: White + 4 colours + varnish

White + 5 colours....

- The PANTONE colours do not cover completely 100%, which means if two colours are printed over each other

slight colour changes can occur. This is why fine components and texts must be left out of Pantone colours.

Exceptions:

- Black and Silver (P877C) are covering

- Duplex-pictures in which a light and dark PANTONE colour are used

- The screen print PANTONE colours always have a glossy surface - that is why PANTONE references of PANTONE

UNCOATED cannot be accepted.

- PANTONE possesses a maximum screen width of 34 lines/cm (85lpi). These pantone colours are not suitable

for screening, because the screen points with such a rough screen are clearly visible. The screen points would

blur with a higher screen. The tone value should at least reach 10% since the screen points would otherwise

be too small for the screen and therefore not be printable.

- If large areas are printed in screen, the tone value should not have over 90% (also counts for KNRC colours), or

else the area could smear up, which leads to an uneven, cloudy result. For that reason a alternative PANTONE

colour (printed in 100%) is recommended for large screen areas.

- Lines must have a width of at least 0.10mm (positive) and 0.15pt (negative) to achieve an optimal result.

- The letter size of the text must at least amount to 4pt (positive) and 5pt (negative). (Fig 4)

min. 0,15mm min. 0,10mm

A a B b C c D d Ee Ff Gg

A a B b C c D d E e Ff Gg

Hh Ii Jj Kk Ll Mm Nn Oo Hh Ii Jj Kk Ll Mm Nn Oo

Pp Qq Rr Ss Tt Uu Vv Pp Qq Rr S s Tt Uu Vv

Fig 4 min. 4pt (1,50mm) min. 5pt (1,88mm)

- PANTONE colours are normally always printed on white. If this is not desirable the client has to be informed,

that the colour changes and does not match the PANTONE spectrum. (Fig 5)

without white with white

pre-print pre-print

Fig 5

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 4/12

current version on e-doc

Sony DADC Printing Process - Screen Print

- Gradients are not recommended in PANTONE, because this leads to edges that influence the result.

(Fig 6 and 7)

Fig 6 Fig 7

1.2.2. Raster colours (KNRC):

- The colours for the CMYK- screen print (= picture print = KNRC) are transparent like conventional offset

colours and consequently have the same colour mixing characteristics.

- These colours are especially designed for screen print with fine screen widths and have explicitly less dot

increase than PANTONE colours. With KNRC- colours a screen width with a max. of 54 lines/cm (133lpi)

is possible.

- But there are also severe quality losses with screen colours if designs with large areas consist of one or more

screened colours (Moire, smear effect). Such designs should be done with PANTONE if possible or the client

should be advised to switch to offset print.

- Transitions or fine elements (such as faces) should not be printed in picture, because of dot loss in the lighter

areas which changes the colour in the design. In this case one should recommend the offset print to the client

as well. (illustration bottom)

Proof Offset : equal printing Picture : high colour variation

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 5/12

current version on e-doc

Sony DADC Printing Process - Screen Print

1.2.3. Metallic colours (8000 + P871C-P877C):

The metallic colours from the 8000th- series are developed for the print without white pre-print. The reflexion

characteristic of the disc silver enhances the metallic effect. (Fig 8)

Therefore white pre- prints under metallic colours change the shade on the one hand but on the other hand the metallic

effect deteriorates (Fig 9). If the client agrees with this, it must be noted in the check sheet (subsequently abbreviated

with CHS). P877C is excluded from this regulation, because the amount of metallic pigments is very high in this colour!

ohne Wei mit Wei

Fig 8 Fig 9

1.2.4. Pastel colours (9000):

The pastel colours from the 9000th- series should always be used with white pre- print, because the disc silvers reflexion

characteristic visibly changes the shade!

1.2.5. Fluorescent colours (P801C-P814C):

The PANTONE daylight fluorescent-colours are only to be produced with white pre- print, since the fluorescent effect

would otherwise be lost! (Fig 10)

In this range the blue P801C is the colour that has the least fluorescent effect.

Fig 10

1.2.6. Special colours (SC):

Special colours can be developed for clients with particular requirements (SC...). To a great extent these colours have

very specific features- / please consult Printing with these colours.

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 6/12

current version on e-doc

Sony DADC Printing Process - Screen Print

1.2.7. Clear varnish:

The clear varnish is a transparent gloss varnish that, similar to a conventional offset-UV-varnish, intensifies the print

colours.

Especially offset prints, which make a tarnished impression because of their colour composition, can really be improved

with the following varnishes. (Fig 11)

The effect of the clear varnish is only given if smooth areas are overprinted. If for example a picture print or a pantone

screen area is overprinted with clear varnish, the result is an uneven basecoat, a kind of orange skin-effect that

influences the visual quality of the product.

with clear without clear

varnish varnish

Fig 11

1.2.8. Mattlack: (DXX-0998)

The matt varnish is a top coat that provides the product with a matt finish.

A very common combination for matt varnish is a design with glossy black on which matt varnished elements are

printed or in which elements are excluded, to achieve a matt/glossy contrast. (Fig 12)

If matt varnish is combined with clear varnish, the clear varnish is printed first. The matt varnish is then put on the clear

varnish. Reversing this order is not possible, because clear varnish on matt varnish loses its gloss.

Fig 12

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 7/12

current version on e-doc

Sony DADC Printing Process - Screen Print / Offset

1.2.9. Sniffle colours:

Sniffle colours (= Fragrance colours) consist of the mat varnish DXX in which micro scent capsules are mixed in, which

open when in contact with friction and set free the enclosed scent.

1.2.10. Thermo varnish:

Thermo varnish (Thermo1) is a varnish option that can be printed with thermo printers (for example Prism print- Rimage).

This printable varnish is shiny and has a slightly sticky surface, because the varnish should not be completely hardened

through so it can be printed on better.

1.2.11. Inkjet varnish:

Inkjet varnishes have a water soluble surface, the ability to absorb inkjet ink. The surface from ink-jet discs is slightly

sticky like the thermo varnish.

1.3. Offset

- Offset printing is only possible for the colours Cyan, Magenta, Yellow and Black. Because these colours are

purchased in addition, no special colour mixing is possible.

- The offset print has the possibility, aside from the 4 CMYK colours, to print an extra PANTONE colour on the

first and on the last place.

For example: a white pre- print and at the end another effect with diverse varnishes or also a PANTONE colour.

In doing so the order is not variable (SD / CMYK / SD)!

- Furthermore it is important, that a certain fitting inaccuracy due to the different print procedures can occur,

when combining screen print and offset print.

- The offset print uses a lower full tone density. This effect is noticeable if one prints 100% black. If larger areas

are printed, problems develop because the black seems gray and staining and irregularities appear in the area.

This effect can be corrected by depositing the black with the other CMYK- colours. Ideal are the values 60%

Cyan, 40% Magenta, 40% Yellow und 100% Black! (Fig 13)

- The offset print is not suitable for the printing of large areas. In print a bar or staining could form. If a strong

bar is formed, someone should try and find another solution, because in such cases the clear varnish would

just enhance this effect. Here for example a PANTONE print would be recommended.

Fig 13

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 8/12

current version on e-doc

Sony DADC Printing Process - Offset / Labelprint without white pre-printing

- The offset colours have a slightly matt surface. If the client does not wish this, one can improve the result with

clear varnish.

- A white pre-print is always recommended, unless the client wishes a metallic effect. Thereby one has to

consider that the colours change as well. (Fig 14 and 15)

Fig 14 with Wei Fig 15 without Wei

2. Label print without white pre-printing

- If a label is printed without a white base coat or with the separate white base, one has to pay attention that

the disc in the area between Spec. B and A has a barcode ring. (Fig 16 and 17) The visibility of the bar code

ring minimized with the white base.

This must be authorized by the client.

Fig 16 Fig 17

- The shining through of the disc silver changes the colour and does not correspond anymore with the PANTONE

colour guide. (See also1.2.1. Pantone colours)

As the different disc types (CD-R, DVD-R, AUDIO,..) have different shades of colour, the appearance of the

white base colour is changed by the reflexion characteristic.

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 9/12

current version on e-doc

Sony DADC Disc variants / Tips & tricks

3. Disc variants

Aside from the different product types at Sony DADC, there are also different disc types:

- 12 cm Disc

This disc is printable with all specifications. The max. external diameter is 117mm.

- 8 cm Disc

It is printable for all specifications. The max. external diameter is 77mm.

- Dualdisc

The disc is printed on both sides and has a DVD (Side A- max. external diameter 43.5mm) and a CD (Side B-max.

external diameter 33.5mm).

- DVD 10

The disc is printed on both sides like the dual disc, but has 2 DVD sides (mostly PAL and NTSC). The standard

DVD10-H/A-STAND (External diameter 43.2mm) and DVD10-H/B-STAND (External diameter 35mm) or the

standard DVD10 RING/SPEC.G (max. external diameter 38.5mm) is used for the white pre- print.

- VinylCD

The Vinyl CD can be produced in the most various colours (Black, gold,..). The design can have an external

diameter of 54mm or 62mm. To achieve the vinyl effect, rings out of clear varnish (with a colour vinyl disc) or

Marabu Black (with black vinyl) are printed on the end. Vinyl discs can only be printed offset.

- Blu-Ray

A special white is used for the white pre-print (Colour description = BD- White). The Blu-Ray Disc can only be

printed in offset. Special varnishes and a separate white base are not possible. The Blu- Ray logo should only

have one colour or feature gray shades.

- Super Audio

The conventional white full base colour 117mm is used for the base.

4. Tips and tricks

4.1. Black on over prints

Since Black is a covering colour, it can be printed over the PANTONE colours. This is very helpful for printing if there

is a main text or a fine design in the design. When over printing there is the so called register impreciseness avoided.

Black should if possible be set to overprint, unless this is not possible for reasons of data transfer or it does not work

with the design. (This can also be used for P877C!)

4.2. When to use Marabu Black (#34) and when to use KNRC 65 (#54)

If a design predominantly consists of an area and the screened design is very simple, it is possible to expose the films

in #34, because with Marabu Black the area print turns out nicer. If the screen design, however, predominates or the

design is very fine or rather has different gradients, it must be printed in KNRC 65 with #54 to achieve an acceptable

result.

4.3. Offset Black only in 4C

To achieve the right Black in offset (mainly with areas), the Black should be built up with four colours in 60/40/40/100

(see also Fig 13)!! Exceptions are made for very fine texts and design elements, because smearing is not possible here.

4.4. Individual white base

The indivdual white base can have a max. interior diameter of 23.3mm (with Spec.F) and an external diameter of

116.7mm. White cannot be printed on PANTONE, because colour changes occur.

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 10/12

current version on e-doc

Sony DADC Tips & tricks

4.5. Equal raster angle formation

If two screen areas are printed over each other in PANTONE colour (is allowed for exceptions- Duplex, if the client

wishes a colour change, or rather if the client was informed) it must be regarded that the raster angle is not

identical. Otherwise a strong Moire can emerge. The angle of Yellow, however, should not be used, because this

often also leads to a Moire.

4.6. Line width

When screen printing, the line width must at least have a thickness of 0.10 mm (positive) or 0.15 mm (negative).

Lines that are finer are excluded from the print.

4.7. Client proofs

If a client proof or a colour sample is enclosed, it gets compared with our proof- is there a deviation, CS must be

informed, because we do not pass on client proofs to the production. The client must either release our proof or

the data must be adjusted. The client proof or the colour sample, however, must be produced according to ISO

12647-7 with the corresponding profile ISO-Coated_v2. Only this way it can be warranted that the colours are

really displayed according to the data.

Sony DADC Austria AG Created by CKRI

V2 11/2009 (C) Public Use Only 11/12

current version on e-doc

For further informationen:

Sony DADC

Sonystrasse, 20

5081 Anif/Salzburg, Austria

Graphicstudio

Sony DADC Global

Sony DADC Global

produziert ca. 2 Mrd. Discs pro Jahr und 100.000

Produces approx. 2 billion discs per year and 100,000

digitale Assets pro Tag mit einer digitalen

digital assets per day with a 2,000 terabyte digital

Speicherkapazitt von 2.000 Terabyte an den 16

storage capacity at its 14 production facilities located

Produktionsstandorten weltweit. Sony DADC hat ca.

world-wide. Sony DADC employs approximately

6.000 Beschftigte.

6.000 people.

Sony DADC Europa

Sony DADC Europe

produziert 600 Mio. Discs pro Jahr an den

Produces 600 million discs per year at its

Produktionsstandorten in Salzburg, sterreich und

production centres in Salzburg, Austria and

Southwater, UK. Betreibt 4 Logistik-Zentren (Spanien,

Southwater, UK, with 4 logistics centres (Spain,

Deutschland, Frankreich und Grobritannien) und

Germany, France, UK). With approximately 1,600

hat ca. 1.600 Beschftigte.

employees.

www.sonydadc.com

www.sonydadc.com

S-ar putea să vă placă și

- DaspecDocument50 paginiDaspecNguyen Duc BinhÎncă nu există evaluări

- 2.1 History of The Compact DiscDocument22 pagini2.1 History of The Compact Discanon_926978759Încă nu există evaluări

- Deep Color Support of Intel Graphics: Technical White PaperDocument19 paginiDeep Color Support of Intel Graphics: Technical White PaperkbrinaldiÎncă nu există evaluări

- Fine Art Printing for Photographers: Exhibition Quality Prints with Inkjet PrintersDe la EverandFine Art Printing for Photographers: Exhibition Quality Prints with Inkjet PrintersEvaluare: 5 din 5 stele5/5 (1)

- EcoTank L210 DatasheetDocument2 paginiEcoTank L210 DatasheetRj TrinidadÎncă nu există evaluări

- Unit 1 Optical Storage: These QuestionsDocument24 paginiUnit 1 Optical Storage: These QuestionsHuỳnh Quốc ThoạiÎncă nu există evaluări

- SurCode DTS DVD Pro ManualDocument24 paginiSurCode DTS DVD Pro Manualimp1978Încă nu există evaluări

- Docuprint Cp105 B / Cp205 / Cp205 W Docuprint Cm205 B Colour Led PrinterDocument4 paginiDocuprint Cp105 B / Cp205 / Cp205 W Docuprint Cm205 B Colour Led PrinterjoseiuÎncă nu există evaluări

- I560 Bubble Jet Printer: Affordability, High Quality and Speed With Direct Photo PrintingDocument4 paginiI560 Bubble Jet Printer: Affordability, High Quality and Speed With Direct Photo PrintingsophieheeÎncă nu există evaluări

- 2022 DesignGuidebookDocument36 pagini2022 DesignGuidebookkeithdonaldsonÎncă nu există evaluări

- DCP J725DW BrochureDocument2 paginiDCP J725DW BrochureBabylyn BarquezÎncă nu există evaluări

- 2013 WSALE PL-pcs PDFDocument4 pagini2013 WSALE PL-pcs PDFRaquel Perez GomezÎncă nu există evaluări

- What The Hell Is Hardware T&LDocument10 paginiWhat The Hell Is Hardware T&LSubhodeep SadhukhanÎncă nu există evaluări

- FIOMO Manual For Preparation and Transfer of Graphic Sources V 8Document8 paginiFIOMO Manual For Preparation and Transfer of Graphic Sources V 8Nicolae GraphicÎncă nu există evaluări

- Introduction To Digital Video: Significance of The TopicDocument8 paginiIntroduction To Digital Video: Significance of The TopicsriinuÎncă nu există evaluări

- General Blur Ay Disc Format 15263Document45 paginiGeneral Blur Ay Disc Format 15263azeez_auaÎncă nu există evaluări

- U06CaptureImage PDFDocument1 paginăU06CaptureImage PDFFranciscoArandaMateuÎncă nu există evaluări

- Gateway 56inch RPTV Service ManualDocument82 paginiGateway 56inch RPTV Service ManualDoru RazvanÎncă nu există evaluări

- Difference Between Light Pen and Touch Screen IsDocument7 paginiDifference Between Light Pen and Touch Screen IsJohn MathewÎncă nu există evaluări

- Select Color Display For ESP32Document27 paginiSelect Color Display For ESP32Antonio Carlos de CarvalhoÎncă nu există evaluări

- What Is DVDDocument14 paginiWhat Is DVDPrithwish GhoshÎncă nu există evaluări

- DCP 195C BrochureDocument2 paginiDCP 195C BrochureAbdulwasi SalahudinÎncă nu există evaluări

- How DVDs and DVD Players WorkDocument16 paginiHow DVDs and DVD Players WorkDaniboy1994Încă nu există evaluări

- LG DVD Players Training ManualDocument76 paginiLG DVD Players Training ManualNichol AlcazarÎncă nu există evaluări

- VGC La38gDocument2 paginiVGC La38gNavarro Jonathan Khris100% (1)

- Blu Ray ReportDocument23 paginiBlu Ray ReportAarti Baraik0% (1)

- DBX Noise Reduction On STM32F746G Discovery DRAFTDocument5 paginiDBX Noise Reduction On STM32F746G Discovery DRAFTSercan AltunÎncă nu există evaluări

- Blu-Ray Disc: Navin Kumar Kamti Roll No 1022610037Document17 paginiBlu-Ray Disc: Navin Kumar Kamti Roll No 1022610037Rahul KumarÎncă nu există evaluări

- Section 2 Module 2.2Document11 paginiSection 2 Module 2.2An AnÎncă nu există evaluări

- Tugas 8. Mengelola Peralatan PelatihanDocument7 paginiTugas 8. Mengelola Peralatan PelatihanAndhi RispataÎncă nu există evaluări

- Blu Ray DiscDocument14 paginiBlu Ray DiscSrivenu ChinnaÎncă nu există evaluări

- Voodoo Art Manual - V2.1Document28 paginiVoodoo Art Manual - V2.1TnakÎncă nu există evaluări

- Review VAIODocument3 paginiReview VAIOsuperscribsÎncă nu există evaluări

- Customer Approval Sheet: Company Name Model Customer ApprovedDocument35 paginiCustomer Approval Sheet: Company Name Model Customer Approvedchafic WEISSÎncă nu există evaluări

- ON ON: Blu Ray Technology Blu Ray TechnologyDocument15 paginiON ON: Blu Ray Technology Blu Ray TechnologyChotu ChouhanÎncă nu există evaluări

- Canon Selphy ES30 GuideDocument102 paginiCanon Selphy ES30 GuideMonique del RosarioÎncă nu există evaluări

- 12647-6flexo Draft0Document9 pagini12647-6flexo Draft0rafael_faria_4Încă nu există evaluări

- Canon Printer CD/DVD TrayDocument14 paginiCanon Printer CD/DVD TrayJefUK100% (1)

- A Seminar Report Submitted in Fulfillment of Requirements For The Degree of Bachelor of Technology Under Maharshi Dayanand University, RohtakDocument28 paginiA Seminar Report Submitted in Fulfillment of Requirements For The Degree of Bachelor of Technology Under Maharshi Dayanand University, RohtakAnkur KalaÎncă nu există evaluări

- 2020 HSC MultimediaDocument10 pagini2020 HSC Multimediathrowawayacc4455Încă nu există evaluări

- Dahua Overseas SI GuidelineDocument86 paginiDahua Overseas SI Guidelineharsha.chutÎncă nu există evaluări

- Blu Ray DiscDocument21 paginiBlu Ray DiscRavi JoshiÎncă nu există evaluări

- Lesson 4-5Document14 paginiLesson 4-5Joey De la CruzÎncă nu există evaluări

- Before You ShootDocument7 paginiBefore You Shootcacadevaca92Încă nu există evaluări

- NBSC - NBSC Software HelpDocument3 paginiNBSC - NBSC Software HelpSebastian CostaÎncă nu există evaluări

- Color To Voice FinalDocument24 paginiColor To Voice FinalLoki AbcÎncă nu există evaluări

- Ray 8Document33 paginiRay 8Rahul SampatÎncă nu există evaluări

- Blu Ray Disc 2Document14 paginiBlu Ray Disc 2arattupuzhaÎncă nu există evaluări

- Et 2750Document2 paginiEt 2750gmtradershydÎncă nu există evaluări

- Unitii: Optical StorageDocument12 paginiUnitii: Optical StorageTu Linh NguyenÎncă nu există evaluări

- Brand Guidelines December 2015Document62 paginiBrand Guidelines December 2015João SilvaÎncă nu există evaluări

- (Asus) NB AP Price List - 20240321Document1.613 pagini(Asus) NB AP Price List - 20240321kreatifmandiriintegrasiÎncă nu există evaluări

- Separation Studio User GuideDocument56 paginiSeparation Studio User GuidemarsanÎncă nu există evaluări

- 6 Lovell PDFDocument20 pagini6 Lovell PDFJavier Martinez Cañal100% (1)

- Technical ReportDocument21 paginiTechnical ReportChristine Mae Bansagale Marbella100% (1)

- Canon Pixma Mp258Document4 paginiCanon Pixma Mp258luthfi_elhakimÎncă nu există evaluări

- Blu-Ray: Babli Mahur Mca (Ivsem) 07913304409Document30 paginiBlu-Ray: Babli Mahur Mca (Ivsem) 07913304409versha_rajputÎncă nu există evaluări

- David Busch’s Sony Alpha a6000/ILCE-6000 Guide to Digital PhotographyDe la EverandDavid Busch’s Sony Alpha a6000/ILCE-6000 Guide to Digital PhotographyEvaluare: 5 din 5 stele5/5 (4)

- Color Printers: Technology Technology Technology Technology TechnologyDocument1 paginăColor Printers: Technology Technology Technology Technology TechnologydjokanomcaÎncă nu există evaluări

- Product Reference Guide: 2012 - Volume 2Document158 paginiProduct Reference Guide: 2012 - Volume 2djokanomcaÎncă nu există evaluări

- DPCM505da User Guide English 13f4 DecryptedDocument383 paginiDPCM505da User Guide English 13f4 DecrypteddjokanomcaÎncă nu există evaluări

- DocuPrint CM505 Da Admin Guide - DecryptedDocument599 paginiDocuPrint CM505 Da Admin Guide - DecrypteddjokanomcaÎncă nu există evaluări

- Color Printers: Technology Technology Technology Technology Technology TechnologyDocument1 paginăColor Printers: Technology Technology Technology Technology Technology TechnologydjokanomcaÎncă nu există evaluări

- Docuprint Cm505 Colour Multitouch MFD: Maximises Power, Efficiency and Space at The OfficeDocument6 paginiDocuprint Cm505 Colour Multitouch MFD: Maximises Power, Efficiency and Space at The OfficedjokanomcaÎncă nu există evaluări

- impressBIND280 WebDocument142 paginiimpressBIND280 WebdjokanomcaÎncă nu există evaluări

- qp2620 20 Dfu DeuDocument292 paginiqp2620 20 Dfu DeudjokanomcaÎncă nu există evaluări

- Narqg 01CDocument1 paginăNarqg 01CdjokanomcaÎncă nu există evaluări

- Docuprint Cm505 Colour Multitouch MFD: Maximises Power, Efficiency and Space at The OfficeDocument6 paginiDocuprint Cm505 Colour Multitouch MFD: Maximises Power, Efficiency and Space at The OfficedjokanomcaÎncă nu există evaluări

- Docuprint Cm505 Colour Multitouch MFD: Maximises Power, Efficiency and Space at The OfficeDocument6 paginiDocuprint Cm505 Colour Multitouch MFD: Maximises Power, Efficiency and Space at The OfficedjokanomcaÎncă nu există evaluări

- TMIcat 2002Document38 paginiTMIcat 2002djokanomcaÎncă nu există evaluări

- Color Printers: For More Information, Contact Us, Your Xerox Authorized Channel Partner, at or VisitDocument1 paginăColor Printers: For More Information, Contact Us, Your Xerox Authorized Channel Partner, at or VisitdjokanomcaÎncă nu există evaluări

- Narqg 01CDocument1 paginăNarqg 01CdjokanomcaÎncă nu există evaluări

- HKS in CMYKDocument3 paginiHKS in CMYKdjokanomcaÎncă nu există evaluări

- Ibico Ibimaster 500 Parts ListDocument19 paginiIbico Ibimaster 500 Parts ListdjokanomcaÎncă nu există evaluări

- Heatseal H520: Product Data SheetDocument1 paginăHeatseal H520: Product Data SheetdjokanomcaÎncă nu există evaluări

- ColorFlowBrochure U.UWS.711.08.10.en.03 Lo PDFDocument4 paginiColorFlowBrochure U.UWS.711.08.10.en.03 Lo PDFRomeu NataleÎncă nu există evaluări

- PanReac AppliChem Label.0Document1 paginăPanReac AppliChem Label.0djokanomcaÎncă nu există evaluări

- PanReac AppliChem Label.0Document1 paginăPanReac AppliChem Label.0djokanomcaÎncă nu există evaluări

- TMIcat 2002Document38 paginiTMIcat 2002djokanomcaÎncă nu există evaluări

- TMIcat 2002Document38 paginiTMIcat 2002djokanomcaÎncă nu există evaluări

- Pid 332 BrochDocument4 paginiPid 332 BrochdjokanomcaÎncă nu există evaluări

- Color Management and Calibration Software For Phaser 7800: Xerox Phasermatch 5.0Document2 paginiColor Management and Calibration Software For Phaser 7800: Xerox Phasermatch 5.0djokanomcaÎncă nu există evaluări

- InkOptimizingSellsheetLo PDFDocument2 paginiInkOptimizingSellsheetLo PDFRomeu NataleÎncă nu există evaluări

- Storage and Accessories: Product Catalogue 2017Document24 paginiStorage and Accessories: Product Catalogue 2017djokanomcaÎncă nu există evaluări

- GBC HeatSeal H520Document38 paginiGBC HeatSeal H520djokanomcaÎncă nu există evaluări

- Tc-K909ES Cassette Deck SMDocument41 paginiTc-K909ES Cassette Deck SMdjokanomcaÎncă nu există evaluări

- TC W550Document29 paginiTC W550djokanomcaÎncă nu există evaluări

- Tc-K461S Cassette DeckDocument18 paginiTc-K461S Cassette DeckdjokanomcaÎncă nu există evaluări

- Zwan Mary Star of The SeaDocument2 paginiZwan Mary Star of The SeaAÎncă nu există evaluări

- 1-June 4-8Document3 pagini1-June 4-8Krizna Dingding DotillosÎncă nu există evaluări

- Briukhovetska, O. - Paradjanov - S Metamorphoses - From Versified Film To Cinema of PoetryDocument7 paginiBriukhovetska, O. - Paradjanov - S Metamorphoses - From Versified Film To Cinema of PoetryTripolina Zuk100% (1)

- Handfasting and Wedding Rituals Raven Kaldera PDFDocument425 paginiHandfasting and Wedding Rituals Raven Kaldera PDFMarian Ganciu100% (2)

- Log Horizon v04v2 - The End of The Game Part IIDocument270 paginiLog Horizon v04v2 - The End of The Game Part IIIvan Zandonà100% (2)

- Class 101 Revised 2Document35 paginiClass 101 Revised 2Samuel BetancurÎncă nu există evaluări

- Toeic Review Listening 1 UtsDocument14 paginiToeic Review Listening 1 UtsAnna FauziahÎncă nu există evaluări

- Set 1 Jingle Bell Set 2 Hark The Herald Ang Pasko Ay SumapitDocument1 paginăSet 1 Jingle Bell Set 2 Hark The Herald Ang Pasko Ay Sumapitbelinda dagohoyÎncă nu există evaluări

- Creative CartographyDocument27 paginiCreative Cartographyaniellarm100% (1)

- You Can Master RAWDocument17 paginiYou Can Master RAWMarcos Barcia100% (2)

- God Eater 2 Update 1.4 & DLC PDFDocument6 paginiGod Eater 2 Update 1.4 & DLC PDFBivaldhi Tejada SenaÎncă nu există evaluări

- The Hindu PantheonDocument496 paginiThe Hindu PantheonKodandapani Yerikalapudi100% (2)

- Davie504 Bass Drum Cover: Eric M. Carr and Davie 504 124Document1 paginăDavie504 Bass Drum Cover: Eric M. Carr and Davie 504 124Ryker KeathÎncă nu există evaluări

- Augustinian Learning Guide in English 9 Week 2: Prepared By: Ms. Juvelyn A. AbuganDocument2 paginiAugustinian Learning Guide in English 9 Week 2: Prepared By: Ms. Juvelyn A. AbuganJuvelyn Abugan LifanaÎncă nu există evaluări

- Ef Unit 12Document3 paginiEf Unit 12Prodigy 817Încă nu există evaluări

- In The Summer of 1985Document1 paginăIn The Summer of 1985Janina JaworskiÎncă nu există evaluări

- Aos Warscroll Blood Knights enDocument1 paginăAos Warscroll Blood Knights enAdam KatzÎncă nu există evaluări

- JFA TouchWood - Chennai Furniture ShowroomsDocument9 paginiJFA TouchWood - Chennai Furniture ShowroomsjfatouchwoodÎncă nu există evaluări

- Ev'ry Time We Say Goodbye-SATB, SATB, A Cappella-$2.10Document10 paginiEv'ry Time We Say Goodbye-SATB, SATB, A Cappella-$2.10alexhwangÎncă nu există evaluări

- 4th Quarter - Lesson 8 - Understanding DramaDocument12 pagini4th Quarter - Lesson 8 - Understanding DramaJubilee May ZaragozaÎncă nu există evaluări

- SM Handbook PDFDocument35 paginiSM Handbook PDFEdward CallowÎncă nu există evaluări

- 6 - Media Info Lang-Types of Codes COTDocument15 pagini6 - Media Info Lang-Types of Codes COTbeth0% (1)

- The Hare and The TortoiseDocument2 paginiThe Hare and The TortoiseElvin JuniorÎncă nu există evaluări

- Townscape As A Philosophy of Urban Design - RUDI - Resource For Urban Development InternationalDocument7 paginiTownscape As A Philosophy of Urban Design - RUDI - Resource For Urban Development InternationalmatzoyekÎncă nu există evaluări

- Name: - Date: - Score: - Subject TeacherDocument5 paginiName: - Date: - Score: - Subject TeacherBIT INTERNATIONAL COLLEGE TALIBONÎncă nu există evaluări

- TikZ Vector ArtDocument12 paginiTikZ Vector ArtRobin Red Msiska100% (1)

- Biology of The Cell Assignment - Answer KeyDocument2 paginiBiology of The Cell Assignment - Answer KeyBen-ZionWeltschÎncă nu există evaluări

- Word Jesus Was The Illegitimate Son of Mary With A SoldierDocument3 paginiWord Jesus Was The Illegitimate Son of Mary With A SoldierbingyamiracleÎncă nu există evaluări

- Rosemanualcontai 00 BuisrichDocument200 paginiRosemanualcontai 00 BuisrichkgrhoadsÎncă nu există evaluări

- Apparel - Fabric & Garment Test Procedures & Requirements ManualDocument101 paginiApparel - Fabric & Garment Test Procedures & Requirements ManualNik ChaudharyÎncă nu există evaluări