Documente Academic

Documente Profesional

Documente Cultură

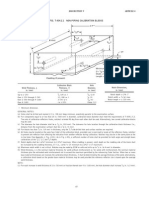

FIG. 1 Rectangular Tension Test Specimens

Încărcat de

Alvaro Alexis Mendoza PradaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FIG. 1 Rectangular Tension Test Specimens

Încărcat de

Alvaro Alexis Mendoza PradaDrepturi de autor:

Formate disponibile

E 8M 04

Dimensions, mm

Standard Specimens Subsize Specimen

Nominal Width Plate-Type Sheet-Type

6 mm

40 mm 12.5 mm

G Gage length (Note 1 and Note 2) 200.0 6 0.2 50.0 6 0.1 25.0 6 0.1

W Width (Note 3 and Note 4) 40.0 6 2.0 12.5 6 0.2 6.0 6 0.1

T Thickness (Note 5) thickness of material

R Radius of fillet, min (Note 6) 25 12.5 6

L Overall length, (Note 2, Note 7 and Note 8) 450 200 100

A Length of reduced section, min 225 57 32

B Length of grip section, (Note 8) 75 50 30

C Width of grip section, approximate (Note 4 and Note 9) 50 20 10

NOTE 1For the 40-mm wide specimen, punch marks for measuring elongation after fracture shall be made on the flat or on the edge of the specimen

and within the reduced section. Either a set of nine or more punch marks 25 mm apart, or one or more pairs of punch marks 200 mm apart, may be used.

NOTE 2When elongation measurements of 40-mm wide specimens are not required, a minimum length of reduced section (A) of 75 mm may be used

with all other dimensions similar to the plate-type specimen.

NOTE 3For the three sizes of specimens, the ends of the reduced section shall not differ in width by more than 0.10, 0.05 or 0.02 mm, respectively.

Also, there may be a gradual decrease in width from the ends to the center, but the width at each end shall not be more than 1 % larger than the width

at the center.

NOTE 4For each of the three sizes of specimens, narrower widths ( W and C) may be used when necessary. In such cases the width of the reduced

section should be as large as the width of the material being tested permits; however, unless stated specifically, the requirements for elongation in a product

specification shall not apply when these narrower specimens are used.

NOTE 5The dimension T is the thickness of the test specimen as provided for in the applicable material specifications. Minimum thickness of 40-mm

wide specimens shall be 5 mm. Maximum thickness of 12.5-mm and 6-mm wide specimens shall be 19 mm and 6 mm, respectively.

NOTE 6For the 40-mm wide specimen, a 13-mm minimum radius at the ends of the reduced section is permitted for steel specimens under 690 MPa

in tensile strength when a profile cutter is used to machine the reduced section.

NOTE 7The dimension shown is suggested as a minimum. In determining the minimum length, the grips must not extend in to the transition section

between Dimensions A and B, see Note 9.

NOTE 8To aid in obtaining axial force application during testing of 6-mm wide specimens, the overall length should be as large as the material will

permit, up to 200 mm.

NOTE 9It is desirable, if possible, to make the length of the grip section large enough to allow the specimen to extend into the grips a distance equal

to two thirds or more of the length of the grips. If the thickness of 12.5-mm wide specimens is over 10 mm, longer grips and correspondingly longer

grip sections of the specimen may be necessary to prevent failure in the grip section.

NOTE 10For the three sizes of specimens, the ends of the specimen shall be symmetrical in width with the center line of the reduced section within

2.5, 0.25, and 0.13 mm, respectively. However, for referee testing and when required by product specifications, the ends of the 12.5-mm wide specimen

shall be symmetrical within 0.2 mm.

NOTE 11For each specimen type, the radii of all fillets shall be equal to each other within a tolerance of 1.25 mm, and the centers of curvature of

the two fillets at a particular end shall be located across from each other (on a line perpendicular to the centerline) within a tolerance of 2.5 mm.

NOTE 12Specimens with sides parallel throughout their length are permitted, except for referee testing, provided: (a) the above tolerances are used;

(b) an adequate number of marks are provided for determination of elongation; and (c) when yield strength is determined, a suitable extensometer is used.

If the fracture occurs at a distance of less than 2W from the edge of the gripping device, the tensile properties determined may not be representative of

the material. In acceptance testing, if the properties meet the minimum requirements specified, no further testing is required, but if they are less than the

minimum requirements, discard the test and retest.

FIG. 1 Rectangular Tension Test Specimens

6.1.2.2 Midway from the center to the surface for products

over 40 mm in thickness, diameter, or distance between flats.

6.1.3 Specimen MachiningImproperly prepared test

specimens often are the reason for unsatisfactory and incorrect

test results. It is important, therefore, that care be exercised in

the preparation of specimens, particularly in the machining, to

maximize precision and minimize bias in test results.

6.1.3.1 The reduced sections of prepared specimens should

be free of cold work, notches, chatter marks, grooves, gouges, FIG. 2 Wedge Grips with Liners for Flat Specimens

S-ar putea să vă placă și

- Tension PlacaDocument1 paginăTension PlacajoseÎncă nu există evaluări

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersDe la EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersEvaluare: 3.5 din 5 stele3.5/5 (2)

- Astm A370Document1 paginăAstm A370Gerangaya Ray AngeloÎncă nu există evaluări

- Astm A370Document3 paginiAstm A370Kenny Wong50% (2)

- Unprotected A3702003a 5Document1 paginăUnprotected A3702003a 5kaveh-bahiraeeÎncă nu există evaluări

- Unprotected A3702003a 6Document1 paginăUnprotected A3702003a 6kaveh-bahiraeeÎncă nu există evaluări

- Round Specimens: FIG. 5 Suggested Types of Ends For Standard Round Tension Test SpecimensDocument1 paginăRound Specimens: FIG. 5 Suggested Types of Ends For Standard Round Tension Test Specimenskaveh-bahiraeeÎncă nu există evaluări

- MiscellaneousDocument49 paginiMiscellaneousjrsvalenzuelaÎncă nu există evaluări

- Din 938 - StudsDocument5 paginiDin 938 - StudsRicky WCKÎncă nu există evaluări

- E 11 - 95 - RtexlvjfraDocument6 paginiE 11 - 95 - RtexlvjfraPrakash MakadiaÎncă nu există evaluări

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 paginiB 565 - 94 R00 - Qju2ns05nfiwmamalika_00Încă nu există evaluări

- Compressive Properties-ASTM D695Document9 paginiCompressive Properties-ASTM D695Edilson Sarmiento AlonsoÎncă nu există evaluări

- Standard Tensile Test Specimen DimensionsDocument1 paginăStandard Tensile Test Specimen Dimensionsjose manuel paz fernandezÎncă nu există evaluări

- D 4146 - 96 - RdqxndytotyDocument4 paginiD 4146 - 96 - RdqxndytotyEmre DalgicÎncă nu există evaluări

- A 66 - 87 R95 Qty2lvjfra - PDFDocument5 paginiA 66 - 87 R95 Qty2lvjfra - PDFfekihassanÎncă nu există evaluări

- AJIYA-Structural Product Purlin PDFDocument4 paginiAJIYA-Structural Product Purlin PDFKartegan ElavarasuÎncă nu există evaluări

- Rolling Threads DetailsDocument0 paginiRolling Threads DetailsfastenersworldÎncă nu există evaluări

- Kristeel CatalogueDocument52 paginiKristeel CatalogueRam TejaÎncă nu există evaluări

- PoliMac Coated Gabion Mattress SpecDocument2 paginiPoliMac Coated Gabion Mattress SpecworkatarÎncă nu există evaluări

- Tensile TestDocument4 paginiTensile TestHarsha Vardhana50% (8)

- Monolayer Die For Tubes 1 MM To 6 MMDocument19 paginiMonolayer Die For Tubes 1 MM To 6 MMvenkithankamÎncă nu există evaluări

- E 676 Â " 94 R98 - RTY3NI05NFI5OADocument4 paginiE 676 Â " 94 R98 - RTY3NI05NFI5OAhans ccÎncă nu există evaluări

- Tube InspectionDocument6 paginiTube InspectionaamirsaddiqÎncă nu există evaluări

- Bore Gage: Inside Diameter MeasurementDocument12 paginiBore Gage: Inside Diameter MeasurementBhaveshBalasÎncă nu există evaluări

- 1 Scope: 1.1 Normative ReferencesDocument8 pagini1 Scope: 1.1 Normative ReferencesYenny300000Încă nu există evaluări

- Cross-Cut Tester: Dual Metal Shim Assembly ModelDocument3 paginiCross-Cut Tester: Dual Metal Shim Assembly ModelCad AutocadÎncă nu există evaluări

- Avio Print J-3 Cub User Guide 1.1Document28 paginiAvio Print J-3 Cub User Guide 1.1Sauli KlaavuÎncă nu există evaluări

- A Contribution To Phased Array Ultrasonic Inspection of Welds Part 3: Sizing CapabilityDocument7 paginiA Contribution To Phased Array Ultrasonic Inspection of Welds Part 3: Sizing CapabilityAlex MendozaÎncă nu există evaluări

- Astm E11 - 1995 (Mallas)Document7 paginiAstm E11 - 1995 (Mallas)Armando Fuentes BenitesÎncă nu există evaluări

- Tuft Height of Pile Floor Coverings: Standard Test Method ForDocument5 paginiTuft Height of Pile Floor Coverings: Standard Test Method ForJuanÎncă nu există evaluări

- Hardware Cloth (Woven or Welded Galvanized Steel Wire Fabric)Document3 paginiHardware Cloth (Woven or Welded Galvanized Steel Wire Fabric)Gabriel DuarteÎncă nu există evaluări

- Specification For Standard Sizes From Astm A53 GR B Schedule 80Document5 paginiSpecification For Standard Sizes From Astm A53 GR B Schedule 80JIMMY YOVANNY CASTRO ORTIZÎncă nu există evaluări

- B 565 - 04 - Qju2nqDocument3 paginiB 565 - 04 - Qju2nqmalika_00Încă nu există evaluări

- 14.Tds-tm-zn+Pvc Ind Eng (10x12)Document2 pagini14.Tds-tm-zn+Pvc Ind Eng (10x12)shabenoorÎncă nu există evaluări

- TDS RO GAB GL ENG Rev Jul2014 PDFDocument2 paginiTDS RO GAB GL ENG Rev Jul2014 PDFCatalin GudeiÎncă nu există evaluări

- Rockfall Mesh Technical Data SheetDocument2 paginiRockfall Mesh Technical Data SheetSudipto PaulÎncă nu există evaluări

- CW 1128/1179 Telephone Cable SpecificationDocument2 paginiCW 1128/1179 Telephone Cable SpecificationJason SecretÎncă nu există evaluări

- API 5L RT Kabul KriteriDocument2 paginiAPI 5L RT Kabul KriteriEsin DenizÎncă nu există evaluări

- Standard Metric Bolt Shank Dimensions PDFDocument2 paginiStandard Metric Bolt Shank Dimensions PDFbcvdocu100% (1)

- ASTM A370 Standard Specimen: A. Plat Type and Sheet TypeDocument8 paginiASTM A370 Standard Specimen: A. Plat Type and Sheet TypeAGnes Stephani MuntheÎncă nu există evaluări

- Manufacturing Wiring Harnesses Amp Cables PDFDocument8 paginiManufacturing Wiring Harnesses Amp Cables PDFarun.nagarkarÎncă nu există evaluări

- VW 60564 enDocument5 paginiVW 60564 enRicardo VitorianoÎncă nu există evaluări

- I - Substrate SpecificationsDocument5 paginiI - Substrate SpecificationsAnthonyÎncă nu există evaluări

- D 2209 - 95 - RdiymdktukveDocument4 paginiD 2209 - 95 - RdiymdktukvePabasara HerathÎncă nu există evaluări

- JIS K 6885:2005 Polyfluoroethylene tapesDocument8 paginiJIS K 6885:2005 Polyfluoroethylene tapesrei reiÎncă nu există evaluări

- Begg Cousland Tower InternalsDocument4 paginiBegg Cousland Tower InternalsHavocFireÎncă nu există evaluări

- Polimac Gabion - 0303042018 PDFDocument2 paginiPolimac Gabion - 0303042018 PDFSuntharathevan RamasamyÎncă nu există evaluări

- RT Projector: Portable and Mini Film ViewersDocument5 paginiRT Projector: Portable and Mini Film ViewersesltirchyÎncă nu există evaluări

- STPE600 - Dadi A ProiezioneDocument17 paginiSTPE600 - Dadi A ProiezioneLucaÎncă nu există evaluări

- Is Iso 16160 2005Document11 paginiIs Iso 16160 2005Amber HudsonÎncă nu există evaluări

- Reinforcing SteelDocument39 paginiReinforcing SteelGage Floyd Bitayo100% (1)

- Tds Gabion GalvanizedDocument2 paginiTds Gabion Galvanizeddinah musyawaroh100% (1)

- TDS US Gabion Mat, GalMac Jan19Document2 paginiTDS US Gabion Mat, GalMac Jan19johnnee98Încă nu există evaluări

- MOULDMACHINEACCESSORIESDocument19 paginiMOULDMACHINEACCESSORIESDhimas KLSÎncă nu există evaluări

- ASTM D 1587 Tubios ShelbyDocument6 paginiASTM D 1587 Tubios ShelbyCarlos PozoÎncă nu există evaluări

- 6-4. Abestos RoofingDocument8 pagini6-4. Abestos RoofingNAKSET GAMINGÎncă nu există evaluări

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 paginiGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.Încă nu există evaluări

- Tubing PDFDocument20 paginiTubing PDFTheEdgeÎncă nu există evaluări

- Eectromagnetic Nondestructive Evaluation PDFDocument321 paginiEectromagnetic Nondestructive Evaluation PDFKalai VananÎncă nu există evaluări

- Weld Seam Inspection of Thick Wall Austenitic Steel Tubes BeyondDocument8 paginiWeld Seam Inspection of Thick Wall Austenitic Steel Tubes BeyondAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Inspeccion Por RadiografiaDocument9 paginiInspeccion Por RadiografiaAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Weld Evaluation Guide - RADIOGRAFIA - PDFDocument20 paginiWeld Evaluation Guide - RADIOGRAFIA - PDFCharly Teodoro BrownÎncă nu există evaluări

- Advanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionDocument9 paginiAdvanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionAsiriHemanthaÎncă nu există evaluări

- Post Weld Heat TreatmentDocument2 paginiPost Weld Heat TreatmentgullenariÎncă nu există evaluări

- Weld Seam Inspection of Thick Wall Austenitic Steel Tubes BeyondDocument8 paginiWeld Seam Inspection of Thick Wall Austenitic Steel Tubes BeyondAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Quantitative Analysis of Eddy Current NDE DataDocument12 paginiQuantitative Analysis of Eddy Current NDE DataAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Advanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionDocument9 paginiAdvanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionAsiriHemanthaÎncă nu există evaluări

- Epp y Equipos SoldaduraDocument100 paginiEpp y Equipos SoldaduraAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- PIPING SYMBOLS AND ABBREVIATIONS GUIDEDocument1 paginăPIPING SYMBOLS AND ABBREVIATIONS GUIDEAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Optimization of The Inspection Schedule For Surface-Breaking CracksDocument15 paginiOptimization of The Inspection Schedule For Surface-Breaking CracksAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Advanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionDocument9 paginiAdvanced Process and Quality Control in Hot Rolling Mills Using Eddy Current InspectionAsiriHemanthaÎncă nu există evaluări

- Ensuring Weld Quality in Structural Applications: by Duane K. Miller, SC.D., P.EDocument16 paginiEnsuring Weld Quality in Structural Applications: by Duane K. Miller, SC.D., P.Ecentaury2013Încă nu există evaluări

- Quantitative Analysis of Eddy Current NDE DataDocument12 paginiQuantitative Analysis of Eddy Current NDE DataAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Steam Generator Inspections Faster, Cheaper and BetterDocument17 paginiSteam Generator Inspections Faster, Cheaper and BetterAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- BLOQUEDocument1 paginăBLOQUEAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- ISO's Role in Developing International StandardsDocument9 paginiISO's Role in Developing International StandardsAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Aisi and Aisc StandardDocument11 paginiAisi and Aisc StandardkonstruktorbudowlanyÎncă nu există evaluări

- Pana UT EN 201301Document52 paginiPana UT EN 201301k_sakpolachet_heartÎncă nu există evaluări

- Quantitative Analysis of Eddy Current NDE DataDocument12 paginiQuantitative Analysis of Eddy Current NDE DataAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- Evolution of NDT Personnel Qualification and Certification atDocument4 paginiEvolution of NDT Personnel Qualification and Certification atAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- UT Technotes 2011.enDocument11 paginiUT Technotes 2011.enAlexandru StefanÎncă nu există evaluări

- PA Probe Catalog en 201308Document24 paginiPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaÎncă nu există evaluări

- D 10.11Document20 paginiD 10.11Alvaro Alexis Mendoza PradaÎncă nu există evaluări

- Steel Tapping Screws For Cold-Formed Steel Framing ConnectionsDocument5 paginiSteel Tapping Screws For Cold-Formed Steel Framing ConnectionsAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- MPI Y-7 ACDC Yoke InstructionsDocument3 paginiMPI Y-7 ACDC Yoke InstructionsAlvaro Alexis Mendoza PradaÎncă nu există evaluări

- European Welding New-StandardsDocument39 paginiEuropean Welding New-StandardsJOECOOL67100% (3)

- K-Series Final 030911Document54 paginiK-Series Final 030911Alvaro Alexis Mendoza PradaÎncă nu există evaluări

- Software Test MetricsDocument8 paginiSoftware Test MetricscmarrivadaÎncă nu există evaluări

- Quad Encoder Velocity Accel with CRIOLabVIEW FPGADocument5 paginiQuad Encoder Velocity Accel with CRIOLabVIEW FPGAChâu Tinh TrìÎncă nu există evaluări

- Dynamic Programming Algorithm Explained in ECE 551 LectureDocument11 paginiDynamic Programming Algorithm Explained in ECE 551 Lectureadambose1990Încă nu există evaluări

- Homework Lesson 6-10Document9 paginiHomework Lesson 6-10Valerie YenshawÎncă nu există evaluări

- Visual Studio C++ TutorialDocument324 paginiVisual Studio C++ TutorialFahadÎncă nu există evaluări

- 11.rolling Disc SolutionDocument12 pagini11.rolling Disc SolutionAlimin AnniÎncă nu există evaluări

- Thrust Bearing CalculationsDocument162 paginiThrust Bearing Calculationslahiru1983100% (1)

- TVS Apache RTR 180 Service ManualDocument25 paginiTVS Apache RTR 180 Service ManualSandino JoseÎncă nu există evaluări

- There Is No SpoonDocument3 paginiThere Is No SpoonJason WalkerÎncă nu există evaluări

- 01 - Lesson Plan - Fractions - Decimal - PercentDocument4 pagini01 - Lesson Plan - Fractions - Decimal - PercentAnthony MontoyaÎncă nu există evaluări

- TIMO Mock 2019 卷P3fDocument9 paginiTIMO Mock 2019 卷P3fDo Yun100% (1)

- NeurophysiologyDocument364 paginiNeurophysiologyTaimoor Ul HassanÎncă nu există evaluări

- Manual Hawk 4000 PDFDocument158 paginiManual Hawk 4000 PDFNebur MtzaÎncă nu există evaluări

- Seagate Part1 PDFDocument113 paginiSeagate Part1 PDFwaranhaÎncă nu există evaluări

- Brushless DC Motor Control Using PLCDocument6 paginiBrushless DC Motor Control Using PLCvuluyen6688Încă nu există evaluări

- Metodo Fotometrico para La Determinación de La Concentración de Ozono AtmosféricoDocument8 paginiMetodo Fotometrico para La Determinación de La Concentración de Ozono AtmosféricoVarinia ZubiletaÎncă nu există evaluări

- Electronic Principles IV, 7-8. Military Curriculum Materials For Vocational and Technical Education.Document571 paginiElectronic Principles IV, 7-8. Military Curriculum Materials For Vocational and Technical Education.SolÎncă nu există evaluări

- Notes Knouckout and BanyanDocument13 paginiNotes Knouckout and BanyanmpacÎncă nu există evaluări

- Introduction To Probability: Business Statistics: Communicating With Numbers, 4eDocument52 paginiIntroduction To Probability: Business Statistics: Communicating With Numbers, 4eRetno Ajeng Anissa WidiatriÎncă nu există evaluări

- Application of Nitrous Oxide in AutomobilesDocument26 paginiApplication of Nitrous Oxide in AutomobilesMohammed NuhmanÎncă nu există evaluări

- Hysys For Aspen Plus Users PDFDocument11 paginiHysys For Aspen Plus Users PDFKarim KholeifÎncă nu există evaluări

- Smart AntennasDocument40 paginiSmart AntennasMeeraÎncă nu există evaluări

- KX-TA308-616 Operating Instructions PDFDocument131 paginiKX-TA308-616 Operating Instructions PDFDila AriÎncă nu există evaluări

- EL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENDocument4 paginiEL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENfederico4thÎncă nu există evaluări

- Dynamic Analysis of Motor Floor: Structure DataDocument6 paginiDynamic Analysis of Motor Floor: Structure Datap_ignatiusÎncă nu există evaluări

- Genetic Algorithms TutorialDocument33 paginiGenetic Algorithms Tutorialsuhas199Încă nu există evaluări

- IT407 Knowledge EngineeringDocument2 paginiIT407 Knowledge EngineeringVidya AÎncă nu există evaluări

- MT Slides Logistics (14 NovDocument24 paginiMT Slides Logistics (14 NovRyan Tw ChoumingÎncă nu există evaluări

- Chapter 5 Lennard Jones PotentialDocument6 paginiChapter 5 Lennard Jones PotentialMuhamad RayhanÎncă nu există evaluări

- Uniform ForceDocument11 paginiUniform ForcearnoldistunoÎncă nu există evaluări

- An Architect's Guide to Construction: Tales from the Trenches Book 1De la EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Încă nu există evaluări

- Markup & Profit: A Contractor's Guide, RevisitedDe la EverandMarkup & Profit: A Contractor's Guide, RevisitedEvaluare: 5 din 5 stele5/5 (11)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (241)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsDe la EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsEvaluare: 4.5 din 5 stele4.5/5 (6)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItDe la EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItEvaluare: 4 din 5 stele4/5 (16)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDe la EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationEvaluare: 4 din 5 stele4/5 (18)

- Building Construction Technology: A Useful Guide - Part 1De la EverandBuilding Construction Technology: A Useful Guide - Part 1Evaluare: 4 din 5 stele4/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe la EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDe la EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseEvaluare: 5 din 5 stele5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsDe la EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsÎncă nu există evaluări

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- Civil Engineer's Handbook of Professional PracticeDe la EverandCivil Engineer's Handbook of Professional PracticeEvaluare: 4.5 din 5 stele4.5/5 (2)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsDe la EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsEvaluare: 1 din 5 stele1/5 (4)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Building Construction Technology: A Useful Guide - Part 2De la EverandBuilding Construction Technology: A Useful Guide - Part 2Evaluare: 5 din 5 stele5/5 (1)

- Field Guide for Construction Management: Management by Walking AroundDe la EverandField Guide for Construction Management: Management by Walking AroundEvaluare: 4.5 din 5 stele4.5/5 (3)

- Real Life: Construction Management Guide from A-ZDe la EverandReal Life: Construction Management Guide from A-ZEvaluare: 4.5 din 5 stele4.5/5 (4)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDe la EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyEvaluare: 4 din 5 stele4/5 (1)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingDe la EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingEvaluare: 5 din 5 stele5/5 (2)

- Residential Construction Performance Guidelines, Contractor ReferenceDe la EverandResidential Construction Performance Guidelines, Contractor ReferenceÎncă nu există evaluări