Documente Academic

Documente Profesional

Documente Cultură

Tds Fevitite Superfast

Încărcat de

Nageshri KarhadeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tds Fevitite Superfast

Încărcat de

Nageshri KarhadeDrepturi de autor:

Formate disponibile

TECHNICAL DATASHEET

PRODUCT : FEVITITE SUPERFAST

DESCRIPTION: FEVITITE Superfast is a two component fast setting super strength

epoxy adhesive that bonds virtually anything to anything from tiny electronic parts to

large structural components. Being faster setting (2-3 Hrs at 30C) it is ideal for those

jobs which have to be finished in 3 Hrs. This multipurpose two component system

comprises of Epoxy resin and hardener which are to be mixed thoroughly in the

recommended ratio to achieve optimum results. This system does not contain volatile

matter, hence there is negligible shrinkage on curing. FEVITITE Superfast which is

internally flexiblized, provides strong joints with excellent low creep properties hence,

make it ideal for structural bonding applications.

FEVITITE Superfast is a useful tool in DIY (Do It Yourself) kit.

PRODUCT FEATURES:

Excellent adhesion to a wide range of substrates, virtually anything to anything.

These substrates include all Metals, Metal alloys, Ferrous/non Ferrous castings,

China ware, Ceramics, Glass, Marble, Granite, Kadappa, Variety of Artificial Stones,

Leather, Wood, Hardboard, Cement-Concrete, Most Plastics viz. Rigid PVC,

Filled/unfilled ABS, Polystyrene, Epoxy/Polyester FRP, Polycarbonate, Phenol-

Formaldehyde (Bakelite) molded parts, decorative /Industrial Laminates, Powder

coated metal, Asbestos, Cork, Ferrite, etc. Please note that Plastics like PTFE,

Polyethylene, Polypropylene can not be bonded without appropriate specialized

surface treatment to these surfaces.

High Cohesive Strength

Good Heat/Solvent/Chemical resistance

Negligible shrinkage on curing and hence good dimensional stability.

Good shock resistance

Long lasting bond

APPLICATION AREA:

FEVITITE Superfast is a multipurpose structural adhesive that can find applications

in virtually all industries. These applications could be in OEM or Maintenance.

GENERAL INSTRUCTIONS FOR USE:

1. Substrate Preparation: The strength and durability of bonded joint are dependent

on proper pretreatment of substrates to be bonded. At the very least surfaces to be

joined should be cleaned with a good degreasing agent such as Acetone or

Trichloroethylene in order to remove all traces of oil, grease, rust, dust, etc from the

surface. The best and most durable joints are obtained by either mechanical

abrading (Sand Blasting) or by chemical etching (pickling) the degreased surfaces.

Mechanical abrading shall be followed by a second degreasing treatment.

2. Mixing of RESIN and HARDENER : Epoxy resin (which is supplied in a jar black

cap) should be thoroughly mixed with Hardener (supplied in a jar with Red cap).

MIX RATIO PARTS BY WEIGHT PARTS BY VOLUME

RESIN 100 1:1

HARDENER 80

Resin and Hardener are to be mixed until they form a homogeneous mix. It is very

important that the above proportions are adhered as accurately as possible to achieve

optimum results. Mix, at a time, small quantity so that it can be consumed in

stipulated usable life. 100g of mixture of FEVITITE Superfast has a usable life of about

30 minutes at 30C.

3. APPLICATION OF ADHESIVE : Apply a thin layer of the mixture on the pretreated

and dry surfaces to be joined, using a spatula. An adhesive layer of .05 to .10 mm

thickness shall normally impart the highest lap shear strength. Soon after the

application of the adhesive, the components are to be positioned/aligned and

clamped together. Even contact pressure throughout is sufficient to achieve good

bond. Allow the bond to cure. This curing process is room temperature dependent

i.e. higher the temperature faster will be the process. Normally at 30C the handling

strength is achieved within 2-3 hours. Full cure will be attained in 24 hours.

TYPICAL PROPERTIES:

INDIVIDUAL PRODUCT DATA

FEVITITE Superfast

PROPERTIES RESIN HARDENER

Visual Appearance High Viscous Opaque High Viscous

Liquid Brownish Liquid

Viscosity at 25C Poise 300-500 250-400

Density g/cm3 1.15 approx. 0.9 Approx.

Flash Point C 200C approx. 110C approx.

Odour Faint Characteristic Amine Odour

Coverage Approx. 0.5 meter /100g on flat mating

2

surfaces

Minimum two years

Shelf Life from month of Mfg. in the original sealed

container

COMPOSITE PRODUCT DATA:

MIX-VISCOSITY: At very low temperatures the viscosity of resin and Hardener will be

much higher than mentioned above and hence the mixing will be slightly difficult.

Initial Viscosity at 25C : 300-450 Poise

POT-LIFE at 30C for 50g R/H mix. : Approx. 30 Minutes

Pot-Life or Usable-Life is inversely proportional to room temperature. i.e. higher the

room temperature shorter will be the Pot-Life or vice-versa. The resin/hardener mix

should be kept in a shallow container. This will prevent unnecessary exothermic

reaction that decreases usable life. The mixture should be used well within its usable

life to get good results. Soon after the mixing the chemical reaction starts and the

viscosity of the mix gradually increases and at one stage (Pot-Life) it is not possible to

apply/spread it.

TEST PROPERTY STANDARD UNIT VALUE

Overlap Shear Strength (MS-MS) ASTM

Bond cured for 24 Hrs/RT D-1002:1983 Kg/cm2 > 160

Cleavage Strength (MS-MS) ASTM

Bond cured for 24 Hrs/RT D-1062:1983 Kg/cm2 > 60

Heat Resistance ASTM

Adhesive Lap Shear Strength (MS-MS) joint D-1151:1984 Kg/cm2 > 150

Maintained at 80C for 14 days

Water Resistance -

Adhesive Lap Shear Strength (MS-MS) joint Kg/cm2 > 140

kept immersed in water at 30C for 14 days

SETTING-TIME:

Bond Strength Development at 300C

(MS-MS Adhesive Tensile Strength in Kgf/cm2 as per ASTM D-897)

Elapsed Time 1 2 3 Hrs. 4 Hrs. 5 Hrs. 6 Hrs. 7 Hrs. 8 Hrs. 9 Hrs. 24 Hrs.

Hr. Hrs.

Conventional 0 5 10 30 70 130 160 190 220

General Purpose

Epoxy Adhesives FULL

CURE

Fevitite 15 25 110 176 220 - - - -

Superfast

DOS AND DONTS:

Even though it is advised to mix Resin & Hardener until uniform colour is attained,

it is beneficial to mix for at least 2-3 minutes thoroughly. Correct R/H proportion &

thorough mixing is the secret of consistent and optimum bond strength.

Do not mix large quantity at a time.

Never dilute R/H mix with solvents to lower the viscosity.

Replace the respective caps of Resin & Hardener containers whenever they are not

in use. Hardener tends to form skin if exposed to air for long time.

Wipe off the excess oozed quantity from the bond area, when the adhesive is wet.

Do not keep the R/H mix near heat source such as hotplate.

Method by weighing is more accurate.

If mixing by volume, never pour resin & hardener over one another. Pour equal

quantity side by side. This way judgement of volume is good.

Do not disturb the bond during setting i.e. after the clamping of assembly is over.

SAFETY PRECAUTIONS : This is a non-flammable product. Generally epoxies on cure

are totally harmless. The resin component is non-toxic, hardener being based on amine

type hardener may cause irritation to sensitized skin. However hands should be

cleaned with Cleansing cream or with soap and warm water. Do not use organic

solvents for cleaning hands. All tools and equipment should be cleaned with solvents

such as Acetone, before adhesive residue cures. The removal of cured residues is very

difficult and time consuming. Dis-assembly of wrongly bonded components is very

difficult but in certain cases controlled heat or solvent like DMF may be used to

separate the parts.

STORAGE & SHELF LIFE: Store in a cool (<300C) and dry place. Under such storage

conditions the shelf life of the product is minimum 12 months in sealed unopened jars.

NOTE: We recommend that before using our product in full scale production, the customer should make his

own tests to determine the suitability of the product under his operating conditions. As the circumstances

under which our product is stored, handled and used are beyond our control, we can not assume any

responsibility for their improper use by the customer.

Status: 12/02/2007

Prepared by S.S.Mahale

PIDILITE INDUSTRIES LIMITED

Ramakrishna Mandir Road, Andheri (East)

MUMBAI - 400059

Phone: 91-22-28367085-89, 28357237

S-ar putea să vă placă și

- Washing MachinesDocument6 paginiWashing MachinesAnonymous wK36hLÎncă nu există evaluări

- Epoxy Bonding AgentDocument2 paginiEpoxy Bonding AgentbarunÎncă nu există evaluări

- Epoxy Resin Arts and Crafts for BeginnersDe la EverandEpoxy Resin Arts and Crafts for BeginnersEvaluare: 3 din 5 stele3/5 (5)

- FGRU URAN 08.12.2015 Rev.02Document3 paginiFGRU URAN 08.12.2015 Rev.02Hitendra PanchalÎncă nu există evaluări

- Epilux 5: Product DescriptionDocument2 paginiEpilux 5: Product DescriptionShyam ShrishÎncă nu există evaluări

- Creative Resin: Easy techniques for contemporary resin artDe la EverandCreative Resin: Easy techniques for contemporary resin artÎncă nu există evaluări

- Epimastic 4100Document2 paginiEpimastic 4100Moin AltafÎncă nu există evaluări

- MBR Presentation LatestDocument12 paginiMBR Presentation LatestRuchi GuptaÎncă nu există evaluări

- RFCC KBR FeaturesDocument24 paginiRFCC KBR FeaturesKannanGK100% (1)

- Bluefix Super Strong Epoxy AdhesiveDocument4 paginiBluefix Super Strong Epoxy AdhesivesuryaÎncă nu există evaluări

- Fevitite Super Strong Epoxy AdhesivesDocument3 paginiFevitite Super Strong Epoxy AdhesivesTARUNÎncă nu există evaluări

- Fevitite Rapid and Clear Epoxy AdhesivesDocument2 paginiFevitite Rapid and Clear Epoxy AdhesivesSahil YOUSUFÎncă nu există evaluări

- TDS Araldite Standard 2016 enDocument2 paginiTDS Araldite Standard 2016 endantewow1Încă nu există evaluări

- Transpoxy Tankguard 118 ESDocument5 paginiTranspoxy Tankguard 118 ESFadi MagdyÎncă nu există evaluări

- Epoxy Red Oxide PrimerDocument2 paginiEpoxy Red Oxide PrimerBalakrishna ChowdaryÎncă nu există evaluări

- Epimastic 7200: Product DescriptionDocument2 paginiEpimastic 7200: Product DescriptionSu KaÎncă nu există evaluări

- Pds Epilux 218 VocDocument2 paginiPds Epilux 218 VocmuthukumarÎncă nu există evaluări

- Scotch-Weld Neoprene High Performance Rubber and Gasket Adhesive 1300L TFDocument5 paginiScotch-Weld Neoprene High Performance Rubber and Gasket Adhesive 1300L TFQUALITYÎncă nu există evaluări

- EPIMASTIC 5100-March 2019 Version 2Document2 paginiEPIMASTIC 5100-March 2019 Version 2PraveenÎncă nu există evaluări

- M Seal PhataphatDocument2 paginiM Seal PhataphatKuldeep KumarÎncă nu există evaluări

- Epilux 155Document2 paginiEpilux 155Allana100% (1)

- Epimastic 7200 SRDocument2 paginiEpimastic 7200 SRqc_531040655Încă nu există evaluări

- Apcodur Ehb 500-VocDocument2 paginiApcodur Ehb 500-VocMoin AltafÎncă nu există evaluări

- Floor Patch Fast CureDocument2 paginiFloor Patch Fast CureStevenFerrelÎncă nu există evaluări

- Pds Epilux 218 Hs VocDocument2 paginiPds Epilux 218 Hs VocmuthukumarÎncă nu există evaluări

- EcoPoxy Resin Build HardenerDocument2 paginiEcoPoxy Resin Build HardenerCarlos AgrizziÎncă nu există evaluări

- Art Resin Epoxy Resin 2022 - TDSDocument2 paginiArt Resin Epoxy Resin 2022 - TDSfatoucamara0205Încă nu există evaluări

- Apcotherm Epn 200Document2 paginiApcotherm Epn 200Moin AltafÎncă nu există evaluări

- Epilux 800Document2 paginiEpilux 800anandÎncă nu există evaluări

- Epilux 218: Product DescriptionDocument2 paginiEpilux 218: Product DescriptionMoin AltafÎncă nu există evaluări

- EPILUX 850 SF VOC Jan-2017Document2 paginiEPILUX 850 SF VOC Jan-2017PraveenÎncă nu există evaluări

- Steel Shield 1200Document2 paginiSteel Shield 1200Moin AltafÎncă nu există evaluări

- SUP10HT MasterbondDocument2 paginiSUP10HT MasterbondShai KvetnyÎncă nu există evaluări

- Tekafiks Super MS Transparent enDocument2 paginiTekafiks Super MS Transparent enEzeval GráficaÎncă nu există evaluări

- Epilux 8: Product DescriptionDocument2 paginiEpilux 8: Product DescriptionMoin AltafÎncă nu există evaluări

- EC TDS EL160 High Temperature Laminating ResinDocument2 paginiEC TDS EL160 High Temperature Laminating ResinDILIGENT AM11Încă nu există evaluări

- Epoxy For Concrete FloorDocument2 paginiEpoxy For Concrete FloormdabumahammadalmasÎncă nu există evaluări

- Epilux 219: Product DescriptionDocument2 paginiEpilux 219: Product DescriptionMoin AltafÎncă nu există evaluări

- Pds Luxathane 5000 VocDocument2 paginiPds Luxathane 5000 Vocmuthukumar100% (1)

- Epimastic 5200: Product DescriptionDocument2 paginiEpimastic 5200: Product DescriptionsreeÎncă nu există evaluări

- Metal Putty Polyester PuttyDocument2 paginiMetal Putty Polyester PuttyabdullahÎncă nu există evaluări

- MSDS - ASMACO RTV GasketDocument2 paginiMSDS - ASMACO RTV GasketadminÎncă nu există evaluări

- Berger: Product SpecificationsDocument2 paginiBerger: Product SpecificationsAabhas UpadhyayaÎncă nu există evaluări

- pm002 4446Document2 paginipm002 4446Dhanush Kumar RamanÎncă nu există evaluări

- Pds Hempadur Speed-Dry ZP 500 En-GbDocument3 paginiPds Hempadur Speed-Dry ZP 500 En-GbDHANOOPÎncă nu există evaluări

- RobbiathaneDocument2 paginiRobbiathaneAnson FranklinÎncă nu există evaluări

- Berger: Product SpecificationsDocument2 paginiBerger: Product SpecificationsAabhas UpadhyayaÎncă nu există evaluări

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 paginiTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngÎncă nu există evaluări

- E MULTIFILL EPOXY THIXO 12Document4 paginiE MULTIFILL EPOXY THIXO 12Dimitrija GalapchevÎncă nu există evaluări

- Ripstar 122: SpecificationDocument3 paginiRipstar 122: SpecificationAnkita Baban GavadeÎncă nu există evaluări

- Araldite PW 1036 Hardener HW 1036: Product Data SheetDocument4 paginiAraldite PW 1036 Hardener HW 1036: Product Data SheetAhmed HusseinÎncă nu există evaluări

- Scotch-Weld: Epoxy AdhesiveDocument6 paginiScotch-Weld: Epoxy AdhesiveJun Bryan Ramirez AbangÎncă nu există evaluări

- Epilux 58 M.I.O.: Product DescriptionDocument2 paginiEpilux 58 M.I.O.: Product DescriptionMoin AltafÎncă nu există evaluări

- MS GF 35870 en-GBDocument2 paginiMS GF 35870 en-GBLinnie McleodÎncă nu există evaluări

- Luxathane 5160Document2 paginiLuxathane 5160shameelÎncă nu există evaluări

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 paginiWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriÎncă nu există evaluări

- Luxathane 5160-Voc March 2021 V1Document2 paginiLuxathane 5160-Voc March 2021 V1PraveenÎncă nu există evaluări

- Plasite 4310 PDS 1-06Document2 paginiPlasite 4310 PDS 1-06Gerardo FloresÎncă nu există evaluări

- Hempadur Multi-Strength GF 35870 PDFDocument3 paginiHempadur Multi-Strength GF 35870 PDFAnuar SalehÎncă nu există evaluări

- Zincanode 620 Voc v1 Jan 2018Document2 paginiZincanode 620 Voc v1 Jan 2018Moin AltafÎncă nu există evaluări

- Pds Zincanode 620 VocDocument2 paginiPds Zincanode 620 VocmuthukumarÎncă nu există evaluări

- Hempadur Zinc 17380Document2 paginiHempadur Zinc 17380sizmaruÎncă nu există evaluări

- Luxatherm 6200Document2 paginiLuxatherm 6200PraveenÎncă nu există evaluări

- Particle Packing in Concrete 30-04-20Document49 paginiParticle Packing in Concrete 30-04-20b ramachandraÎncă nu există evaluări

- CBB Exam Preparation CourseDocument2 paginiCBB Exam Preparation CourseaadmaadmÎncă nu există evaluări

- Riphah Project GuidelinesDocument14 paginiRiphah Project GuidelinesTanveer AhmedÎncă nu există evaluări

- Chopra Scm5 Ch13Document58 paginiChopra Scm5 Ch13Faried Putra SandiantoÎncă nu există evaluări

- 23 Electromagnetic Waves: SolutionsDocument16 pagini23 Electromagnetic Waves: SolutionsAnil AggaarwalÎncă nu există evaluări

- NASA MissionsDocument62 paginiNASA MissionsRoman FlorinÎncă nu există evaluări

- Edited - Meenakshi Kumari RaiDocument1 paginăEdited - Meenakshi Kumari RaiThunderBird GamerÎncă nu există evaluări

- SFP Module PDFDocument2 paginiSFP Module PDFMario PatarroyoÎncă nu există evaluări

- Invisible EyeDocument16 paginiInvisible EyeSushmita Paul0% (1)

- Soliphant T FTM20, FTM21: Technical Information VibronicDocument16 paginiSoliphant T FTM20, FTM21: Technical Information VibronicmichaelÎncă nu există evaluări

- MARINO WORLD MAGAZINE July-August IssueDocument52 paginiMARINO WORLD MAGAZINE July-August IssueNhal LopezÎncă nu există evaluări

- Syllabus New PDFDocument107 paginiSyllabus New PDFmassÎncă nu există evaluări

- Causes of Boiler Tube Leakage and MeasuresDocument19 paginiCauses of Boiler Tube Leakage and MeasuresNhật TuấnÎncă nu există evaluări

- Tech Datasheet AXTT 2VDocument2 paginiTech Datasheet AXTT 2VALEX MATHEUS DA SILVA FERRAZÎncă nu există evaluări

- Kendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14Document8 paginiKendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14ombidasarÎncă nu există evaluări

- 28L059 PDFDocument9 pagini28L059 PDFone_blanche6175Încă nu există evaluări

- ActiveScale P100 Installation GuideDocument97 paginiActiveScale P100 Installation GuideZhou QianÎncă nu există evaluări

- Scania TruckAndBus 2023Document403 paginiScania TruckAndBus 2023Piotr ZiąbkowskiÎncă nu există evaluări

- Lesson 1 DataDocument4 paginiLesson 1 Dataapi-435318918Încă nu există evaluări

- Colphenebswh 1816Document2 paginiColphenebswh 1816vinoth kumar SanthanamÎncă nu există evaluări

- SMAC CA12 BrochureDocument2 paginiSMAC CA12 BrochureElectromateÎncă nu există evaluări

- TechTrax 09 2003 ScreenReaderVersionDocument84 paginiTechTrax 09 2003 ScreenReaderVersionMCKINNONBÎncă nu există evaluări

- SSMT Solution ManualDocument12 paginiSSMT Solution ManualPraahas Amin0% (1)

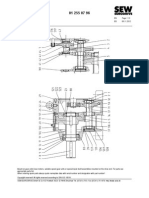

- Parts List 01 255 07 96: Helical Gear Unit R107Document3 paginiParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- ST 010 ISBT 128 Standard Product Description Code Database v6.0.0Document34 paginiST 010 ISBT 128 Standard Product Description Code Database v6.0.0Patrick Ramos100% (1)

- Your Profile 16personalitiesDocument3 paginiYour Profile 16personalitiesapi-583293897Încă nu există evaluări