Documente Academic

Documente Profesional

Documente Cultură

ABB Unit Trip EMAX PR112-PD PDF

Încărcat de

Pedro MartinsTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ABB Unit Trip EMAX PR112-PD PDF

Încărcat de

Pedro MartinsDrepturi de autor:

Formate disponibile

Installation and Installation, service and maintenance

service instructions instructions for the fixed part of withdrawable

version circuit-breakers

RH0287002 L0849 Emax

Index

1. Description ............................................................................................................................................................. page 1

1.1 General characteristics ................................................................................................................................................................. 1

1.2 Fixed part construction characteristics ........................................................................................................................................ 1

2. Checking on receipt ............................................................................................................................................... 1

3. Storage, lifting and weights .................................................................................................................................... 1

4. Installation .............................................................................................................................................................. 2

4.1 Installation room ............................................................................................................................................................................. 2

4.2 Installation of the fixed part of withdrawable circuit-breaker ........................................................................................................ 2

4.2.1 Preparation of the fixed part .......................................................................................................................................................... 2

4.2.2 Installation of the fixed part ............................................................................................................................................................ 3

4.2.3 Installation of the fixed part on board a ship .................................................................................................................................. 4

4.3 Installation of the flange on the compartment door ....................................................................................................................... 4

5. Electrical connections ............................................................................................................................................ 5

5.1 Connections to the power circuit ................................................................................................................................................... 5

5.1.1 Shapes of the terminals ................................................................................................................................................................. 5

5.1.2 Examples of layout of the connection busbars according to the types of terminals ................................................................... 5

5.1.3 Assembly procedures of the connection busbars ........................................................................................................................ 6

5.2 Earthing ........................................................................................................................................................................................... 7

5.3 Cabling the circuit-breaker auxiliary circuits ................................................................................................................................. 7

5.3.1 Withdrawable circuit-breaker ......................................................................................................................................................... 7

6. Fixed part accessories ........................................................................................................................................... 8

6.1 Electrical accessories .................................................................................................................................................................... 8

6.1.1 Auxiliary contacts ........................................................................................................................................................................... 8

6.2 Mechanical accessories ................................................................................................................................................................ 8

6.2.1 Accessory for shutter padlock ...................................................................................................................................................... 8

6.2.2 Compartment door mechanical lock .............................................................................................................................................. 8

6.2.3 Mechanical interlock ...................................................................................................................................................................... 8

7. Overall dimensions ................................................................................................................................................ 9

8. Electrical circuit diagrams ...................................................................................................................................... 16

Dwg. Resp.Off. Title

Language

Installation, service and maintenance

App. Take-over Off. instructions for the fixed part of

withdrawable version circuit-breakers

en

Model L0849 Apparatus Scale

Emax

Doc. N

ABB SACE RH0287002

1. Description

1.1 General characteristics

The SACE Emax series of circuit-breakers are made up of a steel sheet structure which houses the operating mechanism, the poles and the auxiliary

parts. Each pole, insulated from the others, contains the interrupting parts and the current transformer of the corresponding phase.

The structure of the poles differs according to whether the circuit-breaker is selective or current limiting.

The fixed version circuit-breaker has its own terminals for connection to the power circuit. In the withdrawable version, the circuit-breaker makes

up the moving part of the apparatus which is completed with a fixed part fitted with the terminals for connection to the power circuit of the installation.

Coupling between moving part and fixed part takes place by means of special pliers mounted in the fixed part.

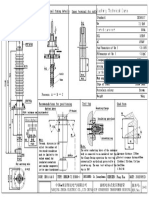

1.2 Fixed part construction characteristics

1 5

1 Supporting structure made of steel sheet

9 2 Earthing pliers (a: for all versions; b: for

E4, E6)

4 3 Safety shutters (IP20 degree of protection)

4 Insulating terminal support base

8 5 Terminals

3

6 Contacts for signalling racked-in/isolated

for test/racked-out (on request)

7 Sliding contacts

2b 8 Padlock for safety shutters (on request)

9 Anti-racking-in lock for circuit-breakers of

2a different size

Fig. 1

2. Checking on receipt

Examine the state of the material received and its correspondence with what was foreseen at the time of ordering. Should any damage or irregularity

be found on unpacking, which must be carried out carefully, make the relative notification within and not over 5 days from receipt of the material.

The notification must indicate the number of the shipping note.

3. Storage, lifting and weights

The fixed part, protected by an external wooden housing, is fixed by means of screws to the transport plate or to the bottom of the packing case.

If the fixed part has to remain in the warehouse even for a short time before being put into service, after checking it on receipt, it must be put back

in its container, and covered with a waterproof sheet.

Caution

Use a dry, dust-free room free of aggressive chemical agents as the storage room

Position the fixed part on a horizontal surface, not in direct contact with the floor, but on a suitable support surface (fig. 2)

The maximum number of stackable packs is indicated in figure 3.

Fig. 2 Fig. 3

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 1/24

With regard to lifting, follow these instructions: the fixed part must be placed on a sturdy resting surface and lifted, preferably by means of a special

fork-lift truck. However, the use of ropes is allowed. In this case, the lifting ropes must be hooked up as shown in the figure.

Fig. 4

Tab le of the weights of the fixed par ts

Fixed part Withdrawable 3 poles Withdrawable 4 poles

kg kg

E1 25 28

E2 28 32

E3 38 45

E4 50 48

E4/f 50

E6 70 80

E6/f 85

Note

The table regards fixed parts with horizontal rear terminals.

4. Installation

4.1 Installation room

Install the circuit-breaker in a dry, dust-free, non-corrosive room, and in such a way that it is not subject to shocks or vibrations. Where this is

not possible, use assembly in switchgear with a suitable degree of protection.

For preparation of the installation room, please refer to paragraph 6: Overall dimensions, which gives information on the following points:

minimum installation volumes of the circuit-breakers and derived versions

distances to be respected for circuit-breakers in compartments

overall dimensions of the circuit-breakers

fixing drillings

compartment door drillings.

The operation of installation, put in service and eventually ordinary and straordinary maintenance have to be done by skilled personel, that has

the detailed knowledge of the apparatus.

4.2 Installation of the fixed part of a withdrawable circuit-breaker

4.2.1 Preparation of the fixed part

Assembly of the anti-racking-in lock

Before installing the fixed part, it is necessary to check the presence of the anti-racking-in lock of circuit-breakers with different electrical

characteristics from those of the fixed part itself. Should the anti-racking-in lock have been supplied separately, proceed to assemble it as follows:

On the self-adhesive plate (4), find the assembly position of the stop bolts in relation to the circuit-breaker which is to be housed in the fixed part

Insert the two hexagonal-head screws (1) in the holes found in the previous point as shown in figure

Fix the two screws with the washers (2) and the hexagonal stops (3).

Check that the anti-racking-in lock corresponding to the one installed on the fixed part is present on the circuit-breaker (moving part).

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 2/24

Example for E1B 08 according to the plate diagram

Fig. 5 Fig. 6

4.2.2 Installation of the fixed part

Fix the fixed part by means of the screws (1), washers (2) and nuts (3) (M8 x 16), supplied by ABB SACE. If other screws are used, check that

the head of the screws does not extend more than 5.5 mm from the base of the fixed part.

Note

(*) For the E1-E2 and E3

fixed parts, there are four

fixing points, whereas there

are six for E4 and E6.

Fig. 7

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 3/24

4.2.3 Installation of the fixed part on board a ship

Regarding the fixing points of the SACE Emax withdrawable version air circuit-breakers, for applications on board a ship, additional fixing on the

sides of the fixed part itself is recommended (the M12 screws and the spacers are not provided in the supply).

E1 - E2 - E3 Spacers

E4 - E6 Spacers

Fig. 8

4.3 Installation of the flange on the compartment door (Fig. 9)

Make the compartment door drillings foreseen in the Overall dimensions paragraph.

Apply the flange (1) onto the front of the compartment door, fixing it from the inside by means of the self-threading screws (2).

1 2

Fig. 9

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 4/24

5. Electrical connections

5.1 Connections to the power circuit

5.1.1 Shapes of the terminals

Horizontal rear terminals Vertical rear ter minals Front terminals Flat terminals

Note

The drawings are made to show the type of ter minal in diagram for m. The exact shape of the terminals is given in the Over all dimensions

chapter.

Fig. 10

5.1.2 Examples of positioning the connection busbars according to the types of terminals

The connection busbars allow connection between the terminals of the fixed parts and the busbars of the switchgear. Their sizing must be carefully

studied by the switchgear designer.

Some examples of possible constructions in relation to the shape and size of the circuit-breaker terminals are given in this paragraph.

The various types of terminals are of constant dimensions per size of circuit-breaker: it is normally advisable to exploit the whole contact surface

of the terminal, so the width of the connection busbar should be the same as that of the terminal. Different capacities for the connections can be

made by working on the thickness and on the number of busbars in parallel. In some cases, reductions in the width of the connection in relation

to that of the terminal are allowed, as is shown in the following examples.

Vertical terminals Horizontal and front terminals

Continuous current-carrying Busbar cross-section Continuous current-carrying Busbar cross-section

Iu [A] capacity [A] [mm2] capacity [A] [mm2]

35C 45C 55C 35C 45C 55C

E1B/N 08 800 800 800 800 1x(60x10) 800 800 800 1x(60x10)

E1B/N 12 1250 1250 1250 1250 1x(80x10) 1250 1250 1200 2x(60x8)

E2N 12 1250 1250 1250 1250 1x(60x10) 1250 1250 1250 1x(60x10)

E2B/N 16 1600 1600 1600 1600 2x(60x10) 1600 1600 1530 2x(60x10)

E2B/N 20 2000 2000 2000 1800 3x(60x10) 2000 2000 1750 3x(60x10)

E2L 12 1250 1250 1250 1250 1x(60x10) 1250 1250 1250 1x(60x10)

E2L 16 1600 1600 1600 1500 2x(60x10) 1600 1490 1400 2x(60x10)

E3S/H 12 1250 1250 1250 1250 1x(60x10) 1250 1250 1250 1x(60x10)

E3S/H 16 1600 1600 1600 1600 1x(100x10) 1600 1600 1600 1x(100x10)

E3S/H 20 2000 2000 2000 2000 2x(100x10) 2000 2000 2000 2x(100x10)

E3N/S/H 25 2500 2500 2500 2500 2x(100x10) 2500 2490 2410 2x(100x10)

E3N/S/H 32 3200 3200 3100 2800 3x(100x10) 3000 2880 2650 3x(100x10)

E3L 20 2000 2000 2000 2000 2x(100x10) 2000 2000 1970 2x(100x10)

E3L 25 2500 2500 2390 2250 2x(100x10) 2375 2270 2100 2x(100x10)

E4H 32 3200 3200 3200 3200 3x(100x10) 3200 3200 3020 3x(100x10)

E4S/H 40 4000 4000 3980 3500 4x(100x10) 3600 3510 3150 6x(60x10)

E6V 32 3200 3200 3200 3200 3x(100x10) 3200 3200 3200 3x(100x10)

E6V 40 4000 4000 4000 4000 4x(100x10) 4000 4000 4000 4x(100x10)

E6H/V 50 5000 5000 4850 4600 6x(100x10) 4850 4510 4250 6x(100x10)

E6H/V 63 6300 6000 5700 5250 7x(100x10) - - - -

As an example, the table shows the continuous current-carrying capacity values of the circuit-breakers installed in switchgear with the

dimensions indicated below. These values refer to apparatus in the withdrawable version in unsegregated switchgear with degree of

protection up to IP31 and the following dimensions:

2300x800x900 (HxWxD) for E1-E2-E3;

2300x1400x1500 (HxWxD) for E4-E6.

The values refer to a maximum temperature of 120C on the terminals.

For withdrawable circuit-breakers with 6300A rated current, the use of vertical rear terminals is recommended.

Note: The tables given are and indicative reference for selection of the products. The many different possible for ms of switchgear and the

conditions which can affect the behaviour of the apparatus always require the solutions used to be verified.

Fig. 11

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 5/24

Positioning the first anchoring baffle of the busbars according to the short-circuit current

Anchoring to the switchgear

HORIZONTAL FRONT

VERTICAL

FLAT

P E1-E2 E3-E4-E6 E1-E6

HORIZONTAL 250 150

VERTICAL 250 150

FRONT 250

FLAT 250

Fig. 12

5.1.3 Assembly procedures for the connection busbars

Check the state of the contact surfaces of the connections very carefully: these must be very clean and free of burrs, dents or traces of oxidation,

which must be eliminated using a fine file or an emery cloth to prevent localized increases in temperature. On completion of the operation, remove

all traces of grease or dust with a cloth soaked in a suitable solvent.

In the case where copper connections are used, it is advisable to tin-plate the contact surfaces. When aluminium connections are used it is advisable

to apply a thin layer of Vaseline over the contact surfaces.

The connections must not exert any force in any direction on the terminals.

Always interpose a flat washer of good diameter and a spring washer between them (to spread the tightening pressure over a greater area).

Make the contact between connection and terminal and fully tighten the fixing screws.

Always use two wrenches (so as not to stress the insulating parts excessively), applying the tightening torque indicated in figure 11. Check tightening

after 24 hours.

M12 high resistance screws

Tightening torque of the main terminals: 70 Nm.

Fixed part terminals No. screws

for phase

No. screws

for neutral

2 2

3 3

4 2

4 4

6 3

6 6

Fig. 13

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 6/24

5.2 Earthing

The fixed part of the withdrawable circuit-breaker has one or two terminals on the rear, marked with the special symbol, for connection to earth

(fig. 9). Each terminal is complete with a bolt for fixing the connection.

A conductor with cross-section conforming to the Standards in force must be used for the connection. Before assembling the connection, clean

and degrease the area around the screw. After assembly, tighten the bolt with a torque of 70 Nm.

5.3 Cabling the circuit-breaker auxiliary circuits

5.3.1 Withdrawable circuit-breaker

For connection of the moving part to the auxiliary circuits, a connector with sliding contacts is available on the fixed part (see figure), identified

by code X on the electrical circuit diagram.

There is immediate access to the terminals of the fixed connector with the compartment door open.

Furthermore, for connection of the position contacts of the moving part in relation to the fixed part, a terminal box is available, identified by code

XF.

The connector and terminal box have screw terminals.

3

2

E1 - E2 - E3

1

1 3

E1 - E2 - E3 E4 - E6

5 contacts in position 10 contacts in position

Caption

1) Sliding contacts (X)

2) Ter minal box for position contacts (XF)

3) Position contacts

Fig. 14

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 7/24

6. Fixed part accessories

6.1 Electrical accessories

6.1.1 Auxiliary contacts

Auxiliary contacts installed on the circuit-breaker are available, which allow indication of the circuit breaker status (are also available in gold plated

contact version for digital signal).

Characteristics

Un In max T

125 V DC 0,3 A 10 ms

250 V DC 0,15 A

Un In max

cos

250 V AC 5A 0,3

Electrical signalling for circuit-breaker racked-in/racked-out test/racked-out (fig. 14)

In addition to the mechanical signalling about the position of the circuit-breaker, it is possible to have electrical signalling by means of 5 or 10 auxiliary

contacts which are installed on the fixed part.

This is only available for circuit-breakers in the withdrawable version, to be installed on the fixed part.

The auxiliary contacts have the following configurations:

5 contacts: group made up of 2 contacts for signalling racked-in, 2 contacts for signalling racked-out and 1 contact signalling the test position

(main pliers isolated, but sliding contacts connected)

10 contacts: group made up of 4 contacts for signalling racked-in, 4 contacts for signalling racked-out and 2 contacts for signalling the test position

(main pliers isolated, but sliding contacts connected).

Reference figures in the electrical circuit diagrams:

S75I (31-32) - S75T (31-32) - S75E (31-32)

6.2 Mechanical accessories

6.2.1 Accessory for shutter padlock (fig. 15)

This allows the shutters (installed on the fixed part) to be padlocked in the closed position.

It is only available for circuit-breakers in the withdrawable version, to be installed on the fixed part.

6.2.2 Compartment door mechanical lock

This prevents compartment door opening with the circuit-breaker closed (and circuit-breaker racked-in for withdrawable circuit-breakers) and

locks circuit breaker closing with the compartment door open.

Fig. 14 Fig. 15

6.2.3 Mechanical interlock

This mechanism carries out the mechanical interlock between two or three circuit-breakers (even of different sizes and in any fixed/withdrawable

version) by means of a flexible cable. The electrical circuit diagram for electrical switching by means of a relay (to be provided by the customer)

is supplied with the mechanical interlock. The installation of the circuit-breakers can be either vertical or horizontal.

4 types of interlocks are available:

type A: between 2 circuit-breakers (power supply group + emergency)

type B: between 3 circuit-breakers (group of 2 power supplies + emergency)

type C: between 3 circuit-breakers (group of 2 power supplies + bus-tie)

type D: between 3 circuit-breakers (group of 3 power supplies / a single circuit-breaker closed)

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 8/24

7. Overall dimensions

Withdrawable circuit-breaker

Basic version with horizontal rear terminals

5 3

34 13

5,5 Max

6

Y A E1 E2/E3/E4/E6

A 4 POLES

B 3 POLES

E E

10

465 465

461 465 min 465 min

X X X

140 E 140 E

199.5 10 199.5

124.5 124.5 E

1SDC200220F0001

C 3 POLES

18 18

D 4 POLES 348 348

Y

Caption

1 Inside edge of E1/E2 E3

compartment door

View A Y

View A

Y

2 Segregation(where

327 435 3 POLES

foreseen) 3 POLES 126 126

90 90

60 35 13 96 35 35 13

3 Fixing fixed part 10

drilling (use M8 screws) 2 2

4 No. 1 M12 screw (E1, E2, 6

4 4

E3) or no. 2 M12 screws

100 200

(E4, E6) for earthing 138 240

(included in the supply) 129 183

4 POLES 4 POLES

417 561

5 Run from connected for a 15 90 90 90 15 126 126 126

TEST to isolated 60 35 96 35 35

33 33

6 Alternative drilling with 25 N N

45 63

mm pitch for fixing fixed 174

309

part 33

393.5

3 393.5 3

40

7 Ventilation drilling on the 380 225 380 225

switchgear 240 84 240

122

70 49 70 49

1SDC200221F0001

175 10 325 10

1 6 220 7 1 370

Y F

Y

A B C D E F

3 poles 4 poles

E1 414 324 162 162 10

E2 414 324 162 162 8

E3 558 432 216 216 8 370 490

E4 684 594 252 342 8 530 610

E4/f 774 - - 342 8 700

E6 936 810 342 468 8 750 870

E6/f 1062 - - 468 8 - 1000

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 9/24

Withdrawable circuit-breaker

Basic version with horizontal rear terminals

E4 Y

View A 597 3 POLES (E4)

180

150 35 35 35 13

45

2

528 4

200 200

3

687 4 POLES (E4)

15 135 180 180

60 150 13

33

N

618

3

245 245

777 4 POLES (E4/f)

15 180 180 180

150 35 35 35 13

33

N

708

33

393.5 40

3

380 240

84

122

49

1SDC200222F0001

45 10

7 1 290 290

F

Y

E6

Y

View A

813 3 POLES (E6)

252 252

222 35 35 56 35 35 13

63

2

744

4

310 310

3

939 4 POLES (E6)

189 252 252

15 96 222 35 35 56 35 35 13

33

N

870

370 370 3

1065 4 POLES (E6/f)

252 252 252

15 222 35 35 56 35 35 13

33

N

996

33

393.5 40

3

380 240

84

122

49

1SDC200223F0001

63 10

7 1 433 433

F

Y

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 10/24

Withdrawable circuit-breaker

Version with ver tical rear terminals

E1 E2/E4 E3/E6

A A A

13 13 13

80 80

100

114 114

134

35 35

35

137.5 137.5

127.5

20 20 20

50 3 50 3 50 3

E2

E1 E3

View A

View A View A

90 90 126

10

12 12 12

10 10

10 10

10

90 90

N N 126

N

M12 captive

screws included

in the supply

E4 E4/f E6 E6/f

View A View A View A View A

180 90 180 90

10 10 252 252

10 10

10 10 12 12

1012 1012

90 90 10 10

12 12

135 126 126

180

N 189

N 31 252 31

N

M12 captive

screws included N

in the supply

1SDC200224F0001

M12 captive

screws included

in the supply

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 11/24

Withdrawable circuit-breaker

Basic version with front terminals

E1

460

35.5 20

35 60

10 13

71 90 90

E2

10

10 N

460

35.5 20

35 60

20 20 13

91

90 90

E3

10

10 N

460

35.5 20

1SDC200225F0001

35 35 100

20 20 13

91

126 126

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 12/24

Withdrawable circuit-breaker

Basic version with front terminals

E4 E4 E4/f

10

10 N N

460

35.5

20 20

35 60 60 60 35 60 60 60 60

20 20 13 13

70 70

91

180 135 180 180

E6 E6 E6/f

10

10 N

N N

460

1SDC200226F0001

35.5 20 20

35 35 100 35 35 100

13 13

20 20 126 126 126 126

91

252 189 252 252

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 13/24

Withdrawable circuit-breaker

Version with flat terminals

E1 E2-E3-E4-E4/f-E6-E6/f

A A

M12 M12

114 114

137.5 137.5

3 3

45 62

E1 E2 E3

View A View A View A

90 90

126

35 35

35

90 90

35

60 N 60 N

126

96 N

E4 E4/f E6 E6/f

View A View A View A View A

180 180

35 35 252 252

35 35

150 35 150 35

35 35 35 35

135

180 222 56 222 56

35 35

60 35 N 60

189

N

252

96 N

N

1SDC200227F0001

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 14/24

Compartment dimensions Compartment door drilling

Y

316

306

5 100 100

5

100

500 X 339 100 374 384 X

Depth 100

R2

380 No. 2 holes for

IP54 protection

150

A 3 POLES 168.5

B 4 POLES

Y

Tightening torque of the fixing screws: 20 Nm

A B Tightening torque of the main terminals: 70 Nm

Tightening torque of the earthing screw: 70 Nm

E1 400 490

E2 400 490

High resistance M12 screw

E3 500 630

Quantity per terminal

E4 700 790

PHASE NEUTRAL

E4/f - 880

E6 1000 1130

N E1-E2 2 2

E6/f - 1260

N

E3 3 3

N E4-E4/f 4 2-4

N E6-E6/f 6 3-6

Compartment door mechanical lock

Door drillings Minimum distance between the circuit-breaker and the side of the switchgear

A

3 Poles 4 Poles

E1 180 180

E2 180 180

E3 234 234

E4 270 360

E4/f - 360

E6 360 486

E6/f - 486

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 15/24

8. Electrical circuit diagrams

State of operation shown

The diagram is shown in the following conditions:

withdrawable version circuit-breaker, open and racked-in

circuits de-energized

releases not tripped

motor operator with springs discharged.

Versions

The diagram shows a withdrawable version circuit-breaker, but is also valid for fixed v ersion circuit-breakers.

Fixed version

The control circuits are included between the XV terminals (the X connector is not supplied).

The applications indicated in figures 31, 32 and 51 cannot be supplied with this version.

Withdrawable version

The control circuits are included between the poles of the X connector (the XV terminal box is not supplied).

The application indicated in figure 52 cannot be supplied with this version.

Version without overcurrent release

The applications indicated in figures 3, 5, 13, 41, 42, 43, 44, 51, 52, 53 and 62 cannot be supplied with this version.

Version with electronic PR111 release

The PR111 overcurrent release is fitted only with the protection unit.

The applications indicated in the figures 3, 5, 41, 42, 43, 44, 53 and 62 cannot be supplied with this version.

Version with electronic PR112/P release

The PR112/P overcurrent release is fitted only with the protection unit.

The applications indicated in the figures 3, 5, 22, 42, 43, 44 and 53 cannot be supplied with this version.

Version with electronic PR112/PD release

The PR112/PD overcurrent release is fitted with the protection and dialogue unit.

The applications indicated in the figures 22, 41, 43, 44 and 53 cannot be supplied with this version.

Version with electronic PR113/P release

The PR113/P overcurrent release is fitted only with the protection unit.

The applications indicated in the figures 3, 5, 22, 41, 42 and 44 cannot be supplied with this version.

Version with electronic PR113/PD release

The PR113/PD overcurrent release is fitted with the protection and dialogue unit.

The applications indicated in the figures 22, 41, 42 and 43 cannot be supplied with this version.

Caption

= Number of figure of the diagram

* = See the note indicated by the letter

A1 = Applications of the circuit-breaker

A13 = PR020/K signalling unit (only provided with PR112/P, PR112/PD, PR113/P or PR113/PD release)

A3 = Applications located on the fixed part of the circuit-breaker (only provided with withdrawable version circuit-breakers)

A4 = Indicative apparatus and connections for control and signalling, outside the circuit-breaker

AY = SACE SOR TEST UNIT: control/monitoring unit (see note R)

D = Electronic time-delay device of the undervoltage release, outside the circuit-breaker

F1 = Fuse with delayed intervention

K51 = PR111, PR112/P, PR112/PD, PR113/P or PR113/PD type electronic overcurrent release with the following protection functions

(see note G):

- L against overload with inverse long delay trip - adjustment I1

- S against short-circuit with inverse or definite short delay trip - adjustment I2

- I against short-circuit with instantaneous trip - adjustment I3

- G against earth fault with inverse short delay trip - adjustment I4

K51/P = Electrical alarm signalling for operating anomalies of the microprocessor (only provided with Uaux. and PR112/P, PR112/PD,

PR113/P or PR113/PD release)

K51/1...8 = PR020/K signalling unit contacts

K51/GZin = Zone selectivity: input for protection G or input in inverse direction for protection D

(DBin) (only provided with Uaux. and PR113/P or PR113/PD release)

K51/GZout = Zone selectivity: output for protection G or output in inverse direction for protection D

(DBout) (only provided with Uaux. and PR113/P or PR113/PD release)

K51/P1 = Programmable electrical signalling (only provided with Uaux. and PR112/P,PR112/PD, PR113/P or PR113/PD release)

K51/P2 = Programmable electrical signalling (only provided with Uaux. and PR113/P release)

K51/SZin = Zone selectivity: input for protection S or input in direct direction for protection D

(DFin) (only provided with Uaux. and PR113/P or PR113/PD release)

K51/SZout = Zone selectivity: output for protection S or output in direct direction for protection D

(DFout) (only provided with Uaux. and PR113/P or PR113/PD release)

K51/YC = Closing control from PR112/PD or PR113/PD electronic release

K51/Y0 = Opening control from PR112/PD or PR113/PD electronic release

K51/Y01 = Electrical alar m signalling for Y01 release TRIPPED (only provided with PR112/P, PR112/PD, PR113/P or PR113/PD release)

K51/Zin = Zone selectivity: input (only provided with Uaux. and PR112/P or PR112/PD release)

K51/Zout = Zone selectivity: output (only provided with Uaux. and PR112/P or PR112/PD release)

M = Motor for closing spring charging

Q = Circuit-breaker

Q/1...25 = Circuit-breaker auxiliary contacts

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 16/24

S33M/1 = Limit contact of spring charging motor

S33M/2 = Contact for electrical signalling of springs charged

S43 = Changeover switch for setting remote/local control

S51 = Contact for bell alarm of circuit-breaker open due to trip of the overcurrent release. Circuit-breaker closing can only take place

after having pressed the reset pushbutton

S75E/14 = Contacts for electrical signalling of circuit-breaker in position of racked-out (only provided with withdrawable version circuit-

breakers)

S75I/14 = Contacts for electrical signalling of circuit-breaker in position of racked-in (only provided with withdrawable version circuit-breakers)

S75T/14 = Contacts for the electrical signalling of circuit-breaker in position of test (only provided with withdrawable version circuit-breakers)

SC = Pushbutton or contact for circuit-breaker closing

SO = Pushbutton or contact for circuit-breaker opening

SO1 = Pushbutton or contact for circuit-breaker opening with delayed trip

SO2 = Pushbutton or contact for circuit-breaker opening with instantaneous trip

TI/L1 = Current transformer located on phase L1

TI/L2 = Current transformer located on phase L2

TI/L3 = Current transformer located on phase L3

TI/N = Current transformer located on the neutral

TI/O = Homopolar current transformer located on the conductor which connects the MV/LV transformer star centre to earth (see note G)

TU = Insulation transformer

Uaux. = Voltage of auxiliary power supply (see note F)

UI/L1 = Current sensor (Rogowski coil) located on phase L1

UI/L2 = Current sensor (Rogowski coil) located on phase L2

UI/L3 = Current sensor (Rogowski coil) located on phase L3

UI/N = Current sensor (Rogowski coil) located on the neutral

W1 = Serial interface with the control system (external bus): EIA RS485 interface (see note E)

W2 = Serial interface with the accessories of the PR112/P, PR112/PD, PR113/P and PR113/PD (inter nal bus) releases

X = Delivery connector for withdrawable version circuit-breaker auxiliary circuits

X1...X7 = Connectors for the circuit-breaker applications

XF = Delivery terminal box for the withdrawable version circuit-breaker position contacts (located on the fixed part of the circuit-breaker)

XK1 = Connector for the power circuits of the PR111, PR112/P, PR112/PD, PR113/P and PR113/PD releases

XK2 - XK3 = Connectors for the auxiliar y circuits of the PR112/P, PR112/PD, PR113/P and PR113/PD releases

XO = Connector for the YO1 release

XV = Delivery terminal box for fixed version circuit-breaker auxiliary circuits

YC = Shunt closing release

YO = Shunt opening release

YO1 = Overcurrent release

YO2 = Overcurrent release (see note Q)

YU = Undervoltage release (see notes B and Q)

Description of figures

Fig. 1 = Closing spring charging motor circuit

Fig. 2 = Shunt closing release circuit

Fig. 3 = Shunt closing release circuit with control from the dialogue unit of the PR112/PD or PR113/PD release

Fig. 4 = Shunt opening release

Fig. 5 = Shunt opening release circuit with control from the dialogue unit of the PR112/PD or PR113/PD release

Fig. 6 = Instantaneous undervoltage release (see notes B and Q)

Fig. 7 = Undervoltage release with electronic time-delay device, outside the circuit-breaker (see notes B and Q)

Fig. 8 = Second shunt opening release (see note Q)

Fig. 11 = Contact for electrical signalling of springs charged.

Fig. 12 = Contact for electrical signalling of undervoltage release energized (see notes B, L and S)

Fig. 13 = Contact for bell alarm of circuit-breaker open due to trip of the overcurrent release. Circuit-breaker closing can only take place after the

reset pushbutton has been pressed.

Fig. 21 = First pack of circuit-breaker auxiliary contacts

Fig. 22 = Second pack of circuit-breaker auxiliary contacts (not available with the PR112/P, PR112/PD, PR113/P and PR113/PDA releases).

Fig. 23 = Third pack of additional circuit-breaker auxiliary contacts outside the circuit-breaker

Fig. 31 = First pack of contacts for electrical signalling of circuit-breaker in racked-in, test or racked-out position

Fig. 32 = Second pack of contacts for electrical signalling of circuit-breaker in racked-in, test or racked-out position

Fig. 41 = Auxiliary circuits of the PR112/P release (see note F)

Fig. 42 = Auxiliar y circuits of the PR112/PD release (see note D, F and M)

Fig. 43 = Auxiliary circuits of the PR113/P release (see note F)

Fig. 44 = Auxiliary circuits of the PR113/PD release (see notes F and M)

Fig. 51 = Circuit of the current transformer on the neutral conductor outside the circuit-breaker, for withdrawable version circuit-breaker

Fig. 52 = Circuit of the current transformer on the neutral conductor outside the circuit-breaker, for fixed version circuit-breaker (see note C)

Fig. 53 = Circuit valid in the case of three-pole circuit-breaker with PR113/P or PR113/PD release without current transformer on the neutral

conductor outside the circuit-breaker (see note H)

Fig. 61 = SACE SOR TEST UNIT: control/monitoring unit (see note R)

Fig. 62 = PR020/K signalling unit (only provided with PR112/P, PR112/PD, PR113/P or PR113/PD release)

Incompatibility

The circuits shown in the following figures cannot be provided on the same circuit-breaker at the same time:

2-3

4-5

6-7-8

22 - 41 - 42 - 43 - 44

31 - 51

51 - 52 - 53

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 17/24

Notes

A) The circuit-breaker is only fitted with the applications specified in the ABB order confirmation. To make out the order, please consult the apparatus

catalogue.

B) The undervoltage release is provided for power supply branched on the supply side of the circuit-breaker or from an independent source: circuit-

breaker closing is only allowed with the trip energized (the lock on closing is made mechanically).

In the case where there is the same power supply for the shunt closing releases and undervoltage releases and automatic circuit-breaker closing

is required, on return of the auxiliary voltage, it is necessary to introduce a delay of 30 milliseconds between the instant of consent of the

undervoltage release and energisation of the shunt closing release. This can be carried out by means of a circuit outside the circuit-breaker including

a per manent closing contact, the contact indicated in figure 12 and a time-delay relay.

C) In the case of a fixed version circuit-breaker with current transformer on the neutral conductor outside the circuit-breaker, when the circuit-breaker

is to be removed, it is necessary to short-circuit the terminals of the TI/N transformer.

D) Connect the S33M/2 contact indicated in fig. 11, one of the closing contacts and one of the opening contacts of the circuit-breaker indicated in fig.

21 in the way shown in fig. 42.

E) For connection of the EIA RS485 serial line, see the following documentation:

- RH0297 for LON communication

- RH0298 for MODBUS communication

F) The auxiliar y voltage Uaux. allows actuation of all operations of the PR112/P, PR112/PD, PR113/P and PR113/PD releases. In this regard, refer to

the corresponding user manuals. Having requested a Vaux insulated from earth, one must use galvanically separated converters in compliance

with IEC 60950 (UL 1950) or equivalent standards that ensure a common mode current or leakage current [(see IEC 478/1 CEI 22/3) not greater

than 3.5 mA], IEC 60364-41 and CEI 64-8.

G) Protection against earth fault is available with the PR112/P, PR112/PD, PR113/P and PR113/PD releases b y means of a current transformer located

on the conductor which connects the MV/LV transformer star centre to earth. The connection between terminals 1 and 2 of the TI/O current

transformer and the T5 and T6 poles of the X (or XV) connector, must be made using a shielded and corded two-pole cable (see instruction manual)

not longer than 15 m. The shield must be earthed on the circuit-breaker side and on the current transformer side.

H) In the case of PR113/P or PR113/PD releases mounted on a three-pole circuit-breaker without connection to the neutral outside, the T3 and T4

poles of the X (or XV) connector must be short-circuited (by the customer).

I) The contact cannot be used if the PR112/PD and PR113/PD unit is present.

L) The contact cannot be used if the PR113/P or PR113/PD unit is present.

M) Connect one of the S75I contacts indicated in fig. 31 or 51 in the way shown in figs. 42-44.

In the case of fixed version circuit-breakers, connect the XV-K14 terminal directly to the XV-K16 terminal (contact S75I does not exist).

N) With PR112/P, PR112/PD, PR113/P and PR113/PD releases , the connections to the zone selectivity inputs and outputs must be made using a

shielded and corded two-pole not longer than 300m. The shield must be earthed on the selectivity input side.

O) With PR113/P and PR113/PD releases, the connection between the voltage sensors (TV) and the circuit-breaker must be made using a shielded

and corded two-pole cable not longer than 15 m.

The shield must be earthed on both sides (sensor and circuit-breaker).

P) With PR112/PD and PR113/PD releases, the power supply of the YO and YC coils must not be branched from the main one.

The coils can be controlled directly from the K51/YO and K51/YC contacts with maximum voltage values of 60VDC and 240-250VAC for PR112/PD,

240-250VDC and 240-250VAC for PR113/PD.

Q) The second shunt opening release must be installed as an alternative to the undervoltage trip.

R) The oper ation of the SACE SOR TEST UNIT system + shunt opening release (YO) is guaranteed starting from 75% of the Uaux of the shunt opening

release.

Dur ing closing of the power supply contact to YO (short-circuit of terminals 4 and 5), the SACE SOR TEST UNIT is not able to determine the state

of the opening coil.

For this reason:

- In the case of an opening coil supplied continuously, the TEST FAILED and ALARM signals will be activated.

- If the control of the opening coil is carr ied out impulsively, the TEST FAILED signal may be activated at the same moment. In this case, the TEST

FAILED signal should only be considered an actual alar m signal if it remains for longer than 20s.

S) Also available in the normally closed contact version.

T) Configuration valid for four-pole or three-pole circuit-breaker with external neutral. For other installation configurations, please see par. 15.3.2.

Instructions to follow for replacement of the PR111, PR112/P, PR112/PD, PR113/P or PR113/PD releases:

Take special notice of the notes indicated on the electrical circuit diagrams provided

The contact for electrical signalling of undervoltage release energized (Fig. 12 of the enclosed diagrams) must be removed from the terminal box.

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 18/24

Graphic symbols for electrical circuit diagrams (IEC 60617 and CEI 3-14...3-26 Standards)

Shield (can be Ter minal or clamp Changeover position

drawn in any shape) contact with momentary trip

(limit switch)

Timing Socket and plug Power molded case switch

(female and male) with automatic opening

Mechanical connection Motor Molded case switch

(general symbol)

Manual mechanical Current transformer Control coil

operating mechanism (general symbol)

(general case)

Rotary handle Voltage transformer Instantaneous

operating mechanism trip unit

Pushbutton operating Three-phase transformer Trip unit with shor t

mechanism winding, star connection adjustable time-delay

characteristic

Equipotentiality Make contact Trip unit with inverse shor t

time-delay characteristic

Converter separated Break contact with Trip unit with inverse long

galvanically with automatic trip time-delay characteristic

Conductors in shielded Changeover contact Trip unit for ground fault

cable (e.g. three with inverse short

conductors) time-delay characteristic

Conductors or corded Make position contact Fuse

cables (e.g. 3 conductors) (limit switch) (general symbol)

Connection of conductors Break position contact Current sensor

(limit switch)

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 19/24

State of operation

Three-pole or four-pole circuit-breaker with electronic PR111, Three-pole or four-pole switch-

PR112/P, PR112/PD, PR113/P and PR113/PD release disconnector

1SDC200243F0001

1SDC200242F0001

Three-pole circuit-breaker with electronic PR111, PR112/P,

PR112/PD, PR113P, PR113/PD release and current tr ansformer

on neutral conductor outside the circuit-breaker

1SDC200244F0001

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 20/24

Motor operator, shunt opening release, shunt closing release and undervoltage release

Signalling contacts

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 21/24

Signalling contacts

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 22/24

Auxiliary circuits of the PR112/P release

Auxiliary circuits of the PR112/PD release

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 23/24

Auxiliary circuits of the PR113/P release

Auxiliary circuits of the PR113/PD release

Model L0849 Apparatus Scale

Emax

Doc. N Pag. N

RH0287002 24/24

L0849

RH0287002

Due to possible developments of standards as well as of

materials, the characteristics and dimensions specified in

the present catalogue may only be considered binding after

confirmation by ABB SACE.

ABB SACE S.p.A.

L.V. Breakers

Via Baioni, 35 - 24123 Bergamo - Italy

Tel.: +39 035.395.111 - Telefax: +39 035.395.306-433

http://www.abb.com

S-ar putea să vă placă și

- Regulador Marathon Magnamax PM100Document33 paginiRegulador Marathon Magnamax PM100Manuel OteroÎncă nu există evaluări

- NW16 H1 MasterparketDocument172 paginiNW16 H1 MasterparketPedro MartinsÎncă nu există evaluări

- S26001S28001Document232 paginiS26001S28001Nguyen Anh TuÎncă nu există evaluări

- Square D CatalogDocument32 paginiSquare D CatalogNdubisi AgomoÎncă nu există evaluări

- Installation & Service Instructions For Fixed Part of Withdrawable ACBDocument29 paginiInstallation & Service Instructions For Fixed Part of Withdrawable ACBKARTIKEYA MISRAÎncă nu există evaluări

- Module 06Document24 paginiModule 06rajuanthati100% (1)

- Advance Tech Guide - Power MV GearDocument48 paginiAdvance Tech Guide - Power MV GearNiraj SrivastavaÎncă nu există evaluări

- ACS600 Hardware ManualDocument92 paginiACS600 Hardware ManualTomvranckxÎncă nu există evaluări

- Danfoss Handbook On Electrical DrivesDocument166 paginiDanfoss Handbook On Electrical DrivesKik0510100% (1)

- Voltage Regulator Equipment: InstructionsDocument28 paginiVoltage Regulator Equipment: Instructionslxd.hepÎncă nu există evaluări

- Low Voltage Motors Installation Operation Maintenance PDFDocument184 paginiLow Voltage Motors Installation Operation Maintenance PDFMohamedAhmedFawzyÎncă nu există evaluări

- Analog Circuit Design - Operational Amplifiers, Analog To Digital Convertors, Analog Computer Aided Design (PDFDrive)Document447 paginiAnalog Circuit Design - Operational Amplifiers, Analog To Digital Convertors, Analog Computer Aided Design (PDFDrive)Fernando Sánchez HernándezÎncă nu există evaluări

- INU Hardware ManualDocument212 paginiINU Hardware Manualjuan_set8822Încă nu există evaluări

- Cutler Hammer VCP W VCBDocument68 paginiCutler Hammer VCP W VCBsquelcheÎncă nu există evaluări

- A Taste of Tubes - The Connoisseur's Cookbook - 1997, 67pDocument67 paginiA Taste of Tubes - The Connoisseur's Cookbook - 1997, 67pEMVSÎncă nu există evaluări

- 3.5100334-01 - Salwico Cargo Addressable - Service & Maintenance Manual - M - EN - 2013 - GDocument76 pagini3.5100334-01 - Salwico Cargo Addressable - Service & Maintenance Manual - M - EN - 2013 - GSerhiiÎncă nu există evaluări

- 1SDC200023D0204 - Emax2 enDocument306 pagini1SDC200023D0204 - Emax2 enValéria CarraroÎncă nu există evaluări

- PowerFlex AC Drives - Fault F13 (Ground Fault)Document3 paginiPowerFlex AC Drives - Fault F13 (Ground Fault)zulfikar rochim100% (1)

- Leroy Somer Rating Chart 4607j - enDocument24 paginiLeroy Somer Rating Chart 4607j - enEmraan MughalÎncă nu există evaluări

- Siemens WL II 3200Document40 paginiSiemens WL II 3200felipe0% (2)

- Owners Manual Kubota Silent-Comap Amf20Document27 paginiOwners Manual Kubota Silent-Comap Amf20CarlosÎncă nu există evaluări

- Mas711 FLYGTDocument150 paginiMas711 FLYGTRafael GaleasÎncă nu există evaluări

- Sace f1Document31 paginiSace f1Antonio Carlos Cardoso100% (2)

- Ndbu Card en - Neta - 01 - Um - G PDFDocument104 paginiNdbu Card en - Neta - 01 - Um - G PDFshekhar yadavÎncă nu există evaluări

- Micologic 2 5 6 7.0A ManualDocument31 paginiMicologic 2 5 6 7.0A Manualmanind_123Încă nu există evaluări

- MA5800-X15 Quick Installation Guide 02Document21 paginiMA5800-X15 Quick Installation Guide 02Edson ViníciusÎncă nu există evaluări

- Gek 86132GDocument44 paginiGek 86132GEren Çağatay Akkaya100% (1)

- Operation Manual Invertronic Compact Inverter: Operating InstructionsDocument102 paginiOperation Manual Invertronic Compact Inverter: Operating Instructionsenrique mendozaÎncă nu există evaluări

- Hyundai ACB Catalog SP HATDocument68 paginiHyundai ACB Catalog SP HATtommagne100% (1)

- Magnetic Contactor Overload Relay: HYUNDAI U-SeriesDocument72 paginiMagnetic Contactor Overload Relay: HYUNDAI U-Serieshakera7536Încă nu există evaluări

- Instr. Use RollarcDocument30 paginiInstr. Use RollarccatalinccÎncă nu există evaluări

- Basler DECS 125-15 Digital Excitation Controller ManualDocument71 paginiBasler DECS 125-15 Digital Excitation Controller ManualEugene RadulianÎncă nu există evaluări

- GENERIC DDocument81 paginiGENERIC DngocanhvyÎncă nu există evaluări

- Flatpack2 24V-2 PDFDocument2 paginiFlatpack2 24V-2 PDFFURIVANÎncă nu există evaluări

- Stamford PI734FDocument8 paginiStamford PI734FTaz UddinÎncă nu există evaluări

- BB64 Ad 01Document92 paginiBB64 Ad 01mpereirapintoÎncă nu există evaluări

- ACB MahleDocument40 paginiACB MahlesintarisaÎncă nu există evaluări

- Kap2 EnerdisDocument16 paginiKap2 EnerdiskailasamvvÎncă nu există evaluări

- B37581 - TM - Easygen 3400 3500 XT P2 - E PDFDocument1.311 paginiB37581 - TM - Easygen 3400 3500 XT P2 - E PDFAshraf AbdelrahmanÎncă nu există evaluări

- Abb BrochureDocument12 paginiAbb BrochurewindaidenÎncă nu există evaluări

- General Catalog LenoirElecDocument164 paginiGeneral Catalog LenoirElecjipix7850% (2)

- PVB Outdoor Vacuum Circuit Breaker (Catalogue)Document27 paginiPVB Outdoor Vacuum Circuit Breaker (Catalogue)Prashanth Chandrashekar100% (1)

- 3kW 5kW Inverter GREEFDocument17 pagini3kW 5kW Inverter GREEFCleber Souza de OliveiraÎncă nu există evaluări

- Operation Manual Dse 5220Document32 paginiOperation Manual Dse 5220Jose TomassettiÎncă nu există evaluări

- Max 31.5V at 24V Max 61.0V at 48V: Main FeaturesDocument1 paginăMax 31.5V at 24V Max 61.0V at 48V: Main FeaturesTakudzwa CeeÎncă nu există evaluări

- DSE8003 MKII Operator ManualDocument74 paginiDSE8003 MKII Operator ManualEdgar GonzalezÎncă nu există evaluări

- 3adw000175r0101 - ddc2000 - NT - Read FirstDocument32 pagini3adw000175r0101 - ddc2000 - NT - Read FirstAhmed MoustafaÎncă nu există evaluări

- System Manual SENTRON 3WL - 3VL Circuit Breakers With Communication Capability - MODBUS PDFDocument3 paginiSystem Manual SENTRON 3WL - 3VL Circuit Breakers With Communication Capability - MODBUS PDFAnonymous 3h38P9RQÎncă nu există evaluări

- Cat SR4B HR GeneratorDocument40 paginiCat SR4B HR Generatorlinkangjun0621Încă nu există evaluări

- VLT 5000 Series Operating InstructionDocument192 paginiVLT 5000 Series Operating InstructionDraganBelosevacÎncă nu există evaluări

- PSO 600 - ManualDocument54 paginiPSO 600 - ManualRAJESHÎncă nu există evaluări

- Surge Counters Type SC12 and SC13Document2 paginiSurge Counters Type SC12 and SC13Muhammad RidhoÎncă nu există evaluări

- SecoGear 24-27kV Manual (Eng) 20130816Document36 paginiSecoGear 24-27kV Manual (Eng) 20130816PalyyÎncă nu există evaluări

- Toshiba PLCDocument10 paginiToshiba PLCMohsin RazaÎncă nu există evaluări

- Soft Drive 200 DesignDocument22 paginiSoft Drive 200 DesignMine RHÎncă nu există evaluări

- Excel ApodysDocument4 paginiExcel ApodysjeremiahÎncă nu există evaluări

- APC Symmetra PX Operation Manual 208V (10kW - 80kW)Document42 paginiAPC Symmetra PX Operation Manual 208V (10kW - 80kW)Goran JovanovicÎncă nu există evaluări

- Advc N-Series InstallationDocument77 paginiAdvc N-Series InstallationFadly Fachrul RozyÎncă nu există evaluări

- Manual Motor Siemens 1la8Document174 paginiManual Motor Siemens 1la8Jair ArmandoÎncă nu există evaluări

- Circuit - Breaker - System - HEK-1-6 - CH-HS 1176 87 - 002 PDFDocument65 paginiCircuit - Breaker - System - HEK-1-6 - CH-HS 1176 87 - 002 PDFDoan Anh TuanÎncă nu există evaluări

- Masterpact NW-NTDocument184 paginiMasterpact NW-NTCarito Ahumada100% (1)

- TriadDocument14 paginiTriadhoangvanquan_ac749Încă nu există evaluări

- Gutor UPS System GlossaryDocument33 paginiGutor UPS System Glossarybookbum100% (4)

- ACS880 ManualDocument632 paginiACS880 ManualpavankeeralaÎncă nu există evaluări

- Abb SaceemaxDocument34 paginiAbb SaceemaxSreenath VarmaÎncă nu există evaluări

- Super Ae: AE1000 - 6300-SS AE4000-SSA/SSC AE1000 - 3200-SHDocument150 paginiSuper Ae: AE1000 - 6300-SS AE4000-SSA/SSC AE1000 - 3200-SHMuhammad Shoaib HussainÎncă nu există evaluări

- Chassis KS9C-N-MI Manual de Servicio PDFDocument73 paginiChassis KS9C-N-MI Manual de Servicio PDFCristian ChavezÎncă nu există evaluări

- Panasonic AC Servo Driver Technical ReferenceDocument121 paginiPanasonic AC Servo Driver Technical ReferenceHamdiÎncă nu există evaluări

- 1SDC200006D0209 - Emax enDocument276 pagini1SDC200006D0209 - Emax enArun KumarÎncă nu există evaluări

- 3WL CB SW en 129769828379337186 PDFDocument34 pagini3WL CB SW en 129769828379337186 PDFPedro MartinsÎncă nu există evaluări

- Catálogo CV1 PDFDocument144 paginiCatálogo CV1 PDFPedro MartinsÎncă nu există evaluări

- 3TL Siemens PDFDocument50 pagini3TL Siemens PDFPedro Martins100% (1)

- XR2 Telemecanique PDFDocument22 paginiXR2 Telemecanique PDFPedro MartinsÎncă nu există evaluări

- XR2 Telemecanique PDFDocument22 paginiXR2 Telemecanique PDFPedro MartinsÎncă nu există evaluări

- K K-Indus-E2 744-761 en PDFDocument18 paginiK K-Indus-E2 744-761 en PDFUzzieel StalinÎncă nu există evaluări

- Sentron 3WL PDFDocument59 paginiSentron 3WL PDFPedro MartinsÎncă nu există evaluări

- PBL Project: Ultrasonic Blind Walking StickDocument7 paginiPBL Project: Ultrasonic Blind Walking Stickkrishnum khodkeÎncă nu există evaluări

- 417-01 Exterior Lighting: Stop and Reverse LampsDocument11 pagini417-01 Exterior Lighting: Stop and Reverse Lampsolyga mgolÎncă nu există evaluări

- An Introduction To Coding Theory: Adrish BanerjeeDocument15 paginiAn Introduction To Coding Theory: Adrish BanerjeeharryÎncă nu există evaluări

- Paolo Castro-WEEK 3Document5 paginiPaolo Castro-WEEK 3Paolo CastroÎncă nu există evaluări

- Specification Sheet 4649Document3 paginiSpecification Sheet 4649edgmundarayÎncă nu există evaluări

- GSD 24 Transducer Adapter Installation InstructionsDocument20 paginiGSD 24 Transducer Adapter Installation InstructionsJose AlvarezÎncă nu există evaluări

- Philips 54XP43 Projector 7573 PDFDocument567 paginiPhilips 54XP43 Projector 7573 PDFCaptain444Încă nu există evaluări

- Sony kdl-22cx520 kdl-32cx520 cx523 kdl-40cx520 523 Chassis Az2g SM PDFDocument98 paginiSony kdl-22cx520 kdl-32cx520 cx523 kdl-40cx520 523 Chassis Az2g SM PDFBoKi PoKiÎncă nu există evaluări

- MicroprocessorDocument626 paginiMicroprocessorElisée Ndjabu DHÎncă nu există evaluări

- Daikin Fan Coil FWWDocument48 paginiDaikin Fan Coil FWWJesus Molina Ylla100% (2)

- Logarithmic-Periodic Multiband Antenna 440 - 512 / 824 - 960 MHZ 739 990Document1 paginăLogarithmic-Periodic Multiband Antenna 440 - 512 / 824 - 960 MHZ 739 990Jason LiewÎncă nu există evaluări

- Raw 3Document31 paginiRaw 3Apik SubagyaÎncă nu există evaluări

- Graham C. Goodwin, Stefan F. Graebe, Mario E. Salgado - Control System Design - Prentice Hall (2000) - 14Document1 paginăGraham C. Goodwin, Stefan F. Graebe, Mario E. Salgado - Control System Design - Prentice Hall (2000) - 14Soumen LayekÎncă nu există evaluări

- JVC Av-28eh1sug Chassis cp830Document33 paginiJVC Av-28eh1sug Chassis cp830Paun Rusalin LucianÎncă nu există evaluări

- EAMCDocument149 paginiEAMCvspd2010Încă nu există evaluări

- Manual Agilient 8960Document614 paginiManual Agilient 8960Karina SouzaÎncă nu există evaluări

- Logic Gates PowerpointDocument27 paginiLogic Gates Powerpointferkevin04100% (1)

- Anixter Data Center Solutions Brochure enDocument8 paginiAnixter Data Center Solutions Brochure enchristian kurniawanÎncă nu există evaluări

- 01 0 SIN Family - EDocument15 pagini01 0 SIN Family - Eetri CahyaÎncă nu există evaluări

- BR4144A.8 英 (conector)Document1 paginăBR4144A.8 英 (conector)Victor GuzmanÎncă nu există evaluări

- NEY VULCAN Instruction ManualDocument48 paginiNEY VULCAN Instruction ManualAlfredo MarcanoÎncă nu există evaluări

- 1 Gill Wind Sensor With Heating Installation Manual 172235KDocument18 pagini1 Gill Wind Sensor With Heating Installation Manual 172235KTonyÎncă nu există evaluări

- App User Guide: Cgn-Dp2Document88 paginiApp User Guide: Cgn-Dp2Ciro Gonzales MariñoÎncă nu există evaluări

- SIL, Ferranti Effect and Power Circle Diagram PDFDocument6 paginiSIL, Ferranti Effect and Power Circle Diagram PDFdubuli123Încă nu există evaluări