Documente Academic

Documente Profesional

Documente Cultură

Tech - Note - Miragrid GX - Direct Shear Test (100 203)

Încărcat de

মোঃ হাসান ইমামDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tech - Note - Miragrid GX - Direct Shear Test (100 203)

Încărcat de

মোঃ হাসান ইমামDrepturi de autor:

Formate disponibile

TECHNICAL NOTE

Evaluation of coefficient of direct sliding (Cds) for Miragrid GX Geogrids by

direct shear test

This Technical Note is a summary of direct shear test carried out on Miragrid GX geogrids to determine the sliding resistance between

soil and geogrids at Bathurst, Clarabut Geotechnical Testing (BCGT) Inc. in Kingston, Ontario.

Introduction

100

Miragrid GX Geogrid are a bi-directional geogrid 90

composed of 100% polyester multifilament <2mmSand

80

yarns. The yarns are coated with a polymeric

compound to form a structured and stable 70 <65mmCrushedStone

grid. 60

% P assing

A direct shear test was used to simulate the 50

sliding of a portion of soil mass across a layer of 40

geogrid reinforcement.

30

The objective of the direct shear test was to 20

determine the sliding resistance between the

soil and geogrid, and thus the coefficient of 10

direct sliding, Cds. To evaluate Cds for a 0

particular geogrid, the results from a series of 0.001 0.01 0.1 1 10 100

tests on geogrid reinforced soil were compared

with results for a series of tests carried out on Particle Size (mm)

unreinforced soil.

Figure 1: Particle size distribution curve of the investigated soil

Test Program

Investigated soils (refer to Figure 1): box is instrumented to record displacement of

A series of direct shear box tests were - < 2mm sand the lower box while the vertical and horizontal

conducted using large direct shear box appa- - < 65mm crushed stone loads are recorded using load cells.

ratus comprised of top and bottom steel box

sections measuring 1m x 1m in plan area and The configuration of the test with the

0.5m in height. The test program was carried respective soil types and geogrids is shown in

out in accordance with ASTM D 5321-92. Table 1. Soil Type

The following geogrids and soils were For all tests, a geogrid specimen measuring < 2mm Sand <65 mm Crushed

investigated: 1830mm long and 1000mm wide (25 longitu- Stone

100 203-tn-02l07 (PF_Asia)

Geogrids: dinal strands) was laid on the soil/shear

interface. The tests were conducted over a Miragrid GX 40/40 Miragrid GX 60/30

- Miragrid GX 40/40

- Miragrid GX 60/30 range of vertical stress, 20kPa to 120kPa. The Miragrid GX 80/30 Miragrid GX 100/30

- Miragrid GX 80/30 bottom box is seated on a set of rollers

advanced at a rate of 5mm/minute and the top Miragrid GX 130/30

- Miragrid GX 100/30

- Miragrid GX 130/30 box is restrained laterally during each test. The Table 1: Test Configuration

* Miragrid GX geogrids are a re-branding of Polyfelt GX Geogrids.

The information given in this brochures is to the best of our knowledge true and correct. However new research results and practical experience can make revisions necessary.

No guarantee or liability can be drawn from the information mentioned herein. Furthermore, it is not our intention to violate any patents or licenses.

TenCate Geosynthetics Asia Sdn. Bhd. (264232-U)

14, Jalan Sementa 27/91, Seksyen 27

40400 Shah Alam, Selangor Darul Ehsan, Malaysia

Tel +60 3 5192 8568, Fax +60 3 5192 8575

info.asia@tencate.com, www.tencate.com

TECHNICAL NOTE

Test Result and Evaluation

Shear Stress, t (k N/m ^2)

A typical failure envelope from a direct shear

t = c + s tan f

test is shown in Figure 2. The failure envelope

is represented by the straight line corresponds

to the Coulombs equation:

f'

= c + s tan f

Where

t = shear stress

Normal Stress, s' (kN/m ^2)

s = normal stress

f = interaction friction angle Figure 2: Shear stress vs normal stress from Coulombs law

c = cohesion of soil

Soil Type Miragrid GX Geogrids tan f soil tan f soil/geogrid Cds Cds (design)

In order to assess the interaction factor, the GX 40/40 0.55 0.55 1.00

ratio of: < 2mm Sand

GX 80/30 0.51 0.53 1.04 1.00

tan f soil/geogrid

C ds = GX 130/30 0.51 0.49 0.96

tan f soil

< 65 mm Crushed GX 60/30 0.93 0.84 0.90

has been calculated for each test. The results Stone 0.86

of Cds together with the recommended mean GX 100/30 0.93 0.75 0.81

values for design are given in Table 2. Table 2: Summary of coefficient of direct sliding from direct shear test

Conclusion

1. It is important to have a high value of Cds since the greater the Cds the higher the sliding resistance of the geogrid reinforcement overthe soil.

The sliding resistance is required in resisting the sliding of the reinforced soil generated by the earth pressure .

2. Based on the tests reported above, for design purposes, Cds = 1.00 for < 2mm sand and Cds = 0.86 for < 65mm crushed stone are

recommended for all grades of Miragrid GX Geogrids.

References

1. ASTM D 5321-92 - Standard Test Method for Determining the Coefficient of Soil and Geosynthetic Friction by Direct Shear Method.

* Miragrid GX geogrids are a re-branding of Polyfelt GX Geogrids.

The information given in this brochures is to the best of our knowledge true and correct. However new research results and practical experience can make revisions necessary.

No guarantee or liability can be drawn from the information mentioned herein. Furthermore, it is not our intention to violate any patents or licenses.

TenCate Geosynthetics Asia Sdn. Bhd. (264232-U)

14, Jalan Sementa 27/91, Seksyen 27

40400 Shah Alam, Selangor Darul Ehsan, Malaysia

Tel +60 3 5192 8568, Fax +60 3 5192 8575

info.asia@tencate.com, www.tencate.com

S-ar putea să vă placă și

- Pressuremeter Testing: Methods and InterpretationDe la EverandPressuremeter Testing: Methods and InterpretationEvaluare: 5 din 5 stele5/5 (2)

- 01 Eurogeo 2000 - PavimentosDocument4 pagini01 Eurogeo 2000 - PavimentosRômulo GomesÎncă nu există evaluări

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingDe la EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingÎncă nu există evaluări

- Effects of Compaction in The Subgrade of The Reinforced SandDocument8 paginiEffects of Compaction in The Subgrade of The Reinforced SandDipendra AwasthiÎncă nu există evaluări

- Geomembrane) Geotextile Interface Shear Properties As Determined by Inclined Board and Direct Shear Box TestsDocument13 paginiGeomembrane) Geotextile Interface Shear Properties As Determined by Inclined Board and Direct Shear Box Testsjavad khosraviÎncă nu există evaluări

- 2005 McCartney - Zornberg - Swan - Geomembrane Texture Effect On GCL InterfaceDocument11 pagini2005 McCartney - Zornberg - Swan - Geomembrane Texture Effect On GCL InterfaceCarlos CedeoÎncă nu există evaluări

- Settlement and Bearing Capacity of Geogrid-Reinforced Sand Over Collapsible SoilDocument14 paginiSettlement and Bearing Capacity of Geogrid-Reinforced Sand Over Collapsible Soiljavad khosraviÎncă nu există evaluări

- 1980 S. Marchetti Marchetti JNL of The Geotechn. Engineering Division, ASCEDocument30 pagini1980 S. Marchetti Marchetti JNL of The Geotechn. Engineering Division, ASCEKarla CaÎncă nu există evaluări

- Tenax: Technical Reference GRID-DE-6Document15 paginiTenax: Technical Reference GRID-DE-6sudhakar vermaÎncă nu există evaluări

- GeojaxDocument12 paginiGeojaxhuudaÎncă nu există evaluări

- 5.04 Sai Singh KhongrymmaiDocument27 pagini5.04 Sai Singh Khongrymmaij krishnanÎncă nu există evaluări

- GeoGauge - As CBR Index PDFDocument15 paginiGeoGauge - As CBR Index PDFOmar CarlosÎncă nu există evaluări

- Chapter 1 - Aggregate: SurfaceDocument3 paginiChapter 1 - Aggregate: SurfaceAmit KumarÎncă nu există evaluări

- TH 03 057Document8 paginiTH 03 057Claudio Juan PorcuÎncă nu există evaluări

- NormalLightWeigthConcrete PDFDocument12 paginiNormalLightWeigthConcrete PDFPabloÎncă nu există evaluări

- AUEJ Volume 15 Issue 55 Pages 573-583Document11 paginiAUEJ Volume 15 Issue 55 Pages 573-583Okello StevenÎncă nu există evaluări

- Road NR32 Geosynthetics Design Using BS 8006 2010Document26 paginiRoad NR32 Geosynthetics Design Using BS 8006 2010SyedÎncă nu există evaluări

- RMT Lab WorkDocument21 paginiRMT Lab WorkChandradeep Singh ShekhawatÎncă nu există evaluări

- 8.03 Experimental Evaluation of A Polyester Geogrid As Anti-Reflective Cracking Interlayer On OverlaysDocument8 pagini8.03 Experimental Evaluation of A Polyester Geogrid As Anti-Reflective Cracking Interlayer On OverlaysDanilo Rojas MartinezÎncă nu există evaluări

- Home Work - Cem605Document5 paginiHome Work - Cem605neelÎncă nu există evaluări

- 2020 ACEGrid GG (Uniaxial)Document1 pagină2020 ACEGrid GG (Uniaxial)Raka BachtiaraÎncă nu există evaluări

- Experimental, Numerical Analysis of Bitumen Coated Pile: Khare M. G. Himabindu D. Gandhi S. RDocument4 paginiExperimental, Numerical Analysis of Bitumen Coated Pile: Khare M. G. Himabindu D. Gandhi S. RJose Leo MissionÎncă nu există evaluări

- Shear Behaviour of HDPgeomembraneDocument14 paginiShear Behaviour of HDPgeomembraneAnandha Kumar SÎncă nu există evaluări

- Calcium Carbonate Filled PolyethyleneDocument7 paginiCalcium Carbonate Filled PolyethyleneXuân Giang NguyễnÎncă nu există evaluări

- Improvement of Soil Using Geogrids To Resist Eccentric LoadsDocument11 paginiImprovement of Soil Using Geogrids To Resist Eccentric LoadsEmad ElsaidÎncă nu există evaluări

- Unit 2 AggregateDocument38 paginiUnit 2 Aggregatehrushikesh dhokaleÎncă nu există evaluări

- A Simplified Method For Geogrid-Reinforced Unpaved Roads With Two Geogrid LayersDocument4 paginiA Simplified Method For Geogrid-Reinforced Unpaved Roads With Two Geogrid Layersferchov_coÎncă nu există evaluări

- Compressive Strength TestDocument8 paginiCompressive Strength TestBeaver CaraÎncă nu există evaluări

- Progrid ® Compo GB: Glass Fibre Asphalt GeocompositeDocument1 paginăProgrid ® Compo GB: Glass Fibre Asphalt Geocompositesukhoi474614Încă nu există evaluări

- Punching Behavior of Strengthened and Repaired RC Slabs With CFRP - Make It Numerical....Document7 paginiPunching Behavior of Strengthened and Repaired RC Slabs With CFRP - Make It Numerical....Haris MahmoodÎncă nu există evaluări

- Journal Support DeisgnDocument6 paginiJournal Support DeisgnAlem AnissaÎncă nu există evaluări

- Strain Measurement and Interpretation of Stabilising Force in Geogrid ReinforcementDocument18 paginiStrain Measurement and Interpretation of Stabilising Force in Geogrid Reinforcementjavad khosraviÎncă nu există evaluări

- 1 s2.0 S0263822322007024 MainDocument12 pagini1 s2.0 S0263822322007024 MainVivek ChanpaÎncă nu există evaluări

- Designing With GeogridsDocument24 paginiDesigning With GeogridsAceÎncă nu există evaluări

- FS Required (Design) Property Allowable (Test) Property: Astm, Iso or GriDocument4 paginiFS Required (Design) Property Allowable (Test) Property: Astm, Iso or GriJohn Philip GarciaÎncă nu există evaluări

- Quay Walls - Combined - Wall - Buckling - TubesDocument12 paginiQuay Walls - Combined - Wall - Buckling - TubesHugo LeiteÎncă nu există evaluări

- TNZ F/7: 2003: SP/SF7:030822 Specification For Geotextiles Page 1 of 11Document11 paginiTNZ F/7: 2003: SP/SF7:030822 Specification For Geotextiles Page 1 of 11Afra AfseenÎncă nu există evaluări

- Resource Guidance Protective Layer Design StandardsDocument3 paginiResource Guidance Protective Layer Design StandardsEricke Nandita MaharaniÎncă nu există evaluări

- Shaft Design Q-SystemDocument17 paginiShaft Design Q-SystemcoldplateÎncă nu există evaluări

- Combination of SDMT and CPT Results For Effective Analysis of Soil Parameters at A Site Near Piacenza, ItalyDocument6 paginiCombination of SDMT and CPT Results For Effective Analysis of Soil Parameters at A Site Near Piacenza, ItalyDiego P.Încă nu există evaluări

- GlasGrid CatalogueDocument25 paginiGlasGrid CatalogueYuda OktoramdaniÎncă nu există evaluări

- Behaviour of The Cut-and-Cover TunnelDocument9 paginiBehaviour of The Cut-and-Cover TunnelsukutricaÎncă nu există evaluări

- GFRP Strengthening of Natural Masonry Walls Resisting Axial and Lateral Loads Using GFRP Anchor SpikesDocument10 paginiGFRP Strengthening of Natural Masonry Walls Resisting Axial and Lateral Loads Using GFRP Anchor SpikesBahira Abdul-RahmanÎncă nu există evaluări

- Rajmi Geoexploration & Engineering PVT LTDDocument11 paginiRajmi Geoexploration & Engineering PVT LTDsanjay vermaÎncă nu există evaluări

- Lecture 4 Characterization of GeotextilesDocument71 paginiLecture 4 Characterization of GeotextilesChin Thau WuiÎncă nu există evaluări

- Tugas MektanDocument28 paginiTugas MektanIrshan Knight DoortotheMoonÎncă nu există evaluări

- For TofiqDocument10 paginiFor Tofiqtofik abaduraÎncă nu există evaluări

- Ultimate Bearing Strength On Rectangular Footing Resting Over Geogrid Reinforced Sand Under Eccentric LoadDocument5 paginiUltimate Bearing Strength On Rectangular Footing Resting Over Geogrid Reinforced Sand Under Eccentric LoadEditor IJTSRDÎncă nu există evaluări

- Conn Strength Recon24 Miragrid 8xtDocument9 paginiConn Strength Recon24 Miragrid 8xtJimmy ThomasÎncă nu există evaluări

- Resilient Modulus of Compacted Lateritic Soils From Senegal at OPM ConditionsDocument7 paginiResilient Modulus of Compacted Lateritic Soils From Senegal at OPM ConditionslindauraÎncă nu există evaluări

- Rock Reinforcement Modelling - Cable Bolts in PLAXIS 2DDocument12 paginiRock Reinforcement Modelling - Cable Bolts in PLAXIS 2Dchaymaa MRHARÎncă nu există evaluări

- Investigation of GFRP-concrete Bond: Experimental and Numerical StudiesDocument6 paginiInvestigation of GFRP-concrete Bond: Experimental and Numerical StudiesMongi Ben OuezdouÎncă nu există evaluări

- Determining The Fracture Energy of Asphalt Mixtures Using The Semicircular Bend Geometry (SCB)Document14 paginiDetermining The Fracture Energy of Asphalt Mixtures Using The Semicircular Bend Geometry (SCB)Ashish PatelÎncă nu există evaluări

- Han 2013Document10 paginiHan 2013Benjamin GonzalezÎncă nu există evaluări

- Pullout Tests of Geogrids Embedded in Non-CohesiveDocument14 paginiPullout Tests of Geogrids Embedded in Non-Cohesiveacko80Încă nu există evaluări

- Test Procedure-25-08-06Document49 paginiTest Procedure-25-08-06Hariom GuptaÎncă nu există evaluări

- Wa0006Document8 paginiWa0006kiran a rÎncă nu există evaluări

- Mechanical Properties of Unsaturated Polyester ResinDocument5 paginiMechanical Properties of Unsaturated Polyester ResinNGokce100% (1)

- CTM Geosynthetics Uniaxial-UnlockedDocument1 paginăCTM Geosynthetics Uniaxial-UnlockedGautam RaiÎncă nu există evaluări

- Aggregate Impact Value TestDocument15 paginiAggregate Impact Value Testmd khajaÎncă nu există evaluări

- Unconfined Compression TestDocument1 paginăUnconfined Compression Testমোঃ হাসান ইমামÎncă nu există evaluări

- Academic Profile of Faculty Member: (As Per BAETE Format)Document6 paginiAcademic Profile of Faculty Member: (As Per BAETE Format)মোঃ হাসান ইমামÎncă nu există evaluări

- Geo Lab EquipDocument1 paginăGeo Lab Equipমোঃ হাসান ইমামÎncă nu există evaluări

- DetermineDocument3 paginiDetermineমোঃ হাসান ইমামÎncă nu există evaluări

- DetermineDocument3 paginiDetermineমোঃ হাসান ইমামÎncă nu există evaluări

- Undergrad Fall 2011 CIVILDocument136 paginiUndergrad Fall 2011 CIVILমোঃ হাসান ইমামÎncă nu există evaluări

- Notice For Workshop in 3 CIVIL FEST-2017Document2 paginiNotice For Workshop in 3 CIVIL FEST-2017মোঃ হাসান ইমামÎncă nu există evaluări

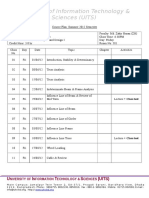

- University of Information Technology & Sciences (UITS) : U I T S (UITS)Document1 paginăUniversity of Information Technology & Sciences (UITS) : U I T S (UITS)মোঃ হাসান ইমামÎncă nu există evaluări

- Total Settlement Check For Design of Indivisual Foundation System For 6-Storied BuildingDocument3 paginiTotal Settlement Check For Design of Indivisual Foundation System For 6-Storied Buildingমোঃ হাসান ইমামÎncă nu există evaluări

- Soil SuctionDocument5 paginiSoil Suctionমোঃ হাসান ইমামÎncă nu există evaluări

- Paper On Floating ColumnDocument8 paginiPaper On Floating Columnমোঃ হাসান ইমামÎncă nu există evaluări

- Felicitate People Heartily ! Magnify Their Strength, Not Their Weaknesses ! A Sincere Compliment Boosts One's Morale. Understand ?!Document1 paginăFelicitate People Heartily ! Magnify Their Strength, Not Their Weaknesses ! A Sincere Compliment Boosts One's Morale. Understand ?!মোঃ হাসান ইমামÎncă nu există evaluări

- Progressive Collapse Analysis of Building Structure GuidelinesDocument3 paginiProgressive Collapse Analysis of Building Structure Guidelinesমোঃ হাসান ইমামÎncă nu există evaluări

- Lecture Notes On Environmental Studies: Institute of Aeronautical EngineeringDocument72 paginiLecture Notes On Environmental Studies: Institute of Aeronautical EngineeringRashmi Ranjan PanigrahiÎncă nu există evaluări

- The Study of Fixture Stiffness Part IDocument12 paginiThe Study of Fixture Stiffness Part IMohsin RashidÎncă nu există evaluări

- Surface ExcessDocument3 paginiSurface ExcessashwinsrvÎncă nu există evaluări

- Chapter6-Mechanical Properties of MetalsDocument44 paginiChapter6-Mechanical Properties of MetalsBuğra Han UysalÎncă nu există evaluări

- Steel Strengthening - ElyasDocument61 paginiSteel Strengthening - ElyasdilrangiÎncă nu există evaluări

- FDS One Standard-FKN-114099Document8 paginiFDS One Standard-FKN-114099Jack TsaiÎncă nu există evaluări

- Composite Material & Structures 3Document62 paginiComposite Material & Structures 3Adrian ArasuÎncă nu există evaluări

- 353 Version 7thDocument1 pagină353 Version 7thDuc NguyenÎncă nu există evaluări

- Paper 3 CHEM Form 4 P1 2016Document7 paginiPaper 3 CHEM Form 4 P1 2016Phang Hui KienÎncă nu există evaluări

- 04 CreepDocument58 pagini04 Creepzaneliu100% (1)

- Lecture 6 - Design of RC SlabsDocument21 paginiLecture 6 - Design of RC SlabsTuan Jalai100% (1)

- Rak-50 3149 L. l12 - Hardening Soil Model PDFDocument111 paginiRak-50 3149 L. l12 - Hardening Soil Model PDFMinhLêÎncă nu există evaluări

- Week 4 - 1 SlidesDocument17 paginiWeek 4 - 1 SlidesEr Rajesh BuraÎncă nu există evaluări

- Gearsand GearingDocument57 paginiGearsand Gearingcamohunter71Încă nu există evaluări

- Bitoner Resin C5 BT-1200H TDSDocument2 paginiBitoner Resin C5 BT-1200H TDSdamiendamÎncă nu există evaluări

- 0.87445500 1342463990 Foto4 Mackol Cas-100n PdsDocument2 pagini0.87445500 1342463990 Foto4 Mackol Cas-100n PdsmjmorcelliÎncă nu există evaluări

- 4 Elastic Modulus and Strength of Hollow Concrete Block Masonry With Refrence To The Effect of Lateral TiesDocument10 pagini4 Elastic Modulus and Strength of Hollow Concrete Block Masonry With Refrence To The Effect of Lateral Tiessunil reddy0% (1)

- EO Product Stewardship Manual Figures Amp Tables PDFDocument29 paginiEO Product Stewardship Manual Figures Amp Tables PDFBayu Khalifa MuttaqinÎncă nu există evaluări

- Statics of Rigid Bodies 03 Rigid BodiesDocument10 paginiStatics of Rigid Bodies 03 Rigid BodiesArlie LobrigoÎncă nu există evaluări

- 4140 Final Exam Fa16Document2 pagini4140 Final Exam Fa16AdamÎncă nu există evaluări

- Espertise: Making Better ImpressionsDocument13 paginiEspertise: Making Better ImpressionsionutmbÎncă nu există evaluări

- Plugin Chapter16Document45 paginiPlugin Chapter16Akshay GatkalÎncă nu există evaluări

- CR BearingsDocument24 paginiCR Bearingsharshal161987Încă nu există evaluări

- Sieve Analysis of Fine and Coarse Aggregates: Standard Test Method ForDocument5 paginiSieve Analysis of Fine and Coarse Aggregates: Standard Test Method ForAkkshay ChadhaÎncă nu există evaluări

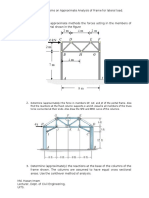

- 8sem Civil Structural Engineering Design-1 DineshChandra AssignmentsDocument10 pagini8sem Civil Structural Engineering Design-1 DineshChandra AssignmentsAnitha Hassan KabeerÎncă nu există evaluări

- Chapter 2.4 Poissons RatioDocument11 paginiChapter 2.4 Poissons Ratiogillianminano9Încă nu există evaluări

- Machine Elements DesignDocument281 paginiMachine Elements DesignsgmdoÎncă nu există evaluări

- RWPR 900 Pellet Mill BrochureDocument4 paginiRWPR 900 Pellet Mill Brochuregrupa2904Încă nu există evaluări

- Development of An Erosion Testing Machine 06Document34 paginiDevelopment of An Erosion Testing Machine 06Omprakash ManharÎncă nu există evaluări

- Kyocera TN6020 - PV7020 - BrochureDocument12 paginiKyocera TN6020 - PV7020 - BrochuresdhgwdÎncă nu există evaluări

- Hand BoringDocument10 paginiHand BoringRaihan Alisha NabilaÎncă nu există evaluări