Documente Academic

Documente Profesional

Documente Cultură

Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)

Încărcat de

Mohammed Attia0 evaluări0% au considerat acest document util (0 voturi)

663 vizualizări1 paginăCALCULATION OF TANK VENTING USING EXCEL SHEET

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentCALCULATION OF TANK VENTING USING EXCEL SHEET

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

663 vizualizări1 paginăAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)

Încărcat de

Mohammed AttiaCALCULATION OF TANK VENTING USING EXCEL SHEET

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

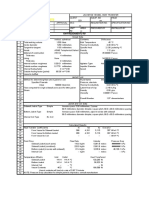

API STD 2000-2009, Calculation for max.

flow rates for Normal Inbreathing

(Refer Section 4.3.2, 'Calculation of maximum flow rates for normal outbreathing & normal inbreathing)

Common Inuslation Average Thermal

Materials Conductivity, W/m-K

Inputs Cellular glass 0.05

Tank Volume, Vtk 1131 m3 Use maximum capacity per sketch below Mineral Fiber 0.04

3

Pump-Out Rate, Vpe 290 m /h Calcium Silicate 0.06

Latitude 40 Below 42 Perlite 0.07

Avg. Storage Temp. 20 C <25 VPHexane

VP range VPHexane VP>Hexane

Ins. Thickness, lin 0m (Enter 0 if tank uninsulated) C-factor for various conditions

Insulation Type Cellular glass Vapour Pressure (VP)

Thermal Cond. of Insulation, in --- W/m-K Latitude Hexane or similar > than Hexane or unknown

Selected Thermal Cond. of Insulation, in,S --- W/m-K Average Storage temperature, C

2

Inside heat transfer coefficient, h 4 W/m K (Typical value for tanks: 4 W/m2-K) <25 25 <25 25

Total surface area, A TTS 452.16 m

2

Below 42 4 6.5 6.5 6.5

Insulated surface area, A inp 2

0m (Enter 0 if tank uninsulated) Between 42 & 58 3 5 5 5

Uninsulated Above 58 2.5 4 4 4

Calculations

Inbreathing due to Liquid movement out, V ip 290 Nm3/h of Air

Thermal Inbreathing

C-Factor 4

Reduction factor, R i 1.00

Thermal inbreathing, V IT 548.9 Nm3/h of Air

3

Total Normal Inbreathing 838.9 Nm /h of Air

Top of shell height

Overfill slot

Design liquid level

Overfill protection level requirement

______ m3 or ______ mm

Normal fill level

Maximum capacity

_____ m3

Net Working Capacity

_____ m3

Minimum fill level

Min. Operating Volume remaining in the tank

m3 ____ or ____ mm

Top of bottom plate at shell

Reference Appendix L-6 of API STD 650

S-ar putea să vă placă și

- Atmospheric Storage Tanks Venting Required API 2000 (6th ED 2009)Document18 paginiAtmospheric Storage Tanks Venting Required API 2000 (6th ED 2009)ganeshdhageÎncă nu există evaluări

- Venting-CalculationsDocument3 paginiVenting-CalculationsKartik PatelÎncă nu există evaluări

- Heating Coil Sizing For Fuel Oil TankDocument2 paginiHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- PVV Cal Sheet LabixDocument45 paginiPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Venting Requirement According To Api 2000, Seventh Edition, Mar 2014Document5 paginiVenting Requirement According To Api 2000, Seventh Edition, Mar 2014sahirprojectsÎncă nu există evaluări

- Inbreathing OutbreathingDocument17 paginiInbreathing OutbreathingInggit100% (2)

- Atm Sto Tanks Venting Req API2000 2009 Rev1 - TESTDocument18 paginiAtm Sto Tanks Venting Req API2000 2009 Rev1 - TESTRanjit PaulÎncă nu există evaluări

- Calculo Venteo API 2000Document3 paginiCalculo Venteo API 2000Produccion Vegetal100% (1)

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Document9 paginiInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivÎncă nu există evaluări

- ASME Venting Calculation FB-2007 - PDFDocument3 paginiASME Venting Calculation FB-2007 - PDFjaganÎncă nu există evaluări

- Tank Venting According API 2000Document27 paginiTank Venting According API 2000Pouria Sabbagh100% (1)

- Vent Capacity (API Standard 2000)Document1 paginăVent Capacity (API Standard 2000)Vince Bagsit PolicarpioÎncă nu există evaluări

- Tank Normal Venting (API)Document1 paginăTank Normal Venting (API)ام يمنى ايمنÎncă nu există evaluări

- Storage Tank Normal Venting Capacity Calculations PDFDocument1 paginăStorage Tank Normal Venting Capacity Calculations PDFNathan MoralesÎncă nu există evaluări

- API 650 Datasheet 1Document16 paginiAPI 650 Datasheet 1alwacsÎncă nu există evaluări

- Internal Coil CalculationDocument19 paginiInternal Coil CalculationMr Incognito100% (3)

- Venteo API 2000 (Amine)Document8 paginiVenteo API 2000 (Amine)Produccion VegetalÎncă nu există evaluări

- API 2000 Spread SheetDocument43 paginiAPI 2000 Spread Sheetjagan100% (3)

- Vent Calculation API STD 2000Document2 paginiVent Calculation API STD 2000massive85Încă nu există evaluări

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocument2 paginiSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1Încă nu există evaluări

- 3191-CS-01 Rev A-009-011Document3 pagini3191-CS-01 Rev A-009-011Syed Zain AliÎncă nu există evaluări

- PRG - GG - GEN - 0001 - R00 - e - Design Pressure N TempeDocument19 paginiPRG - GG - GEN - 0001 - R00 - e - Design Pressure N TempeKorcan ÜnalÎncă nu există evaluări

- Crude Oil Storage Tank Heating CoilDocument3 paginiCrude Oil Storage Tank Heating CoilbadelitamariusÎncă nu există evaluări

- API2000 Tank Venting CalcsDocument5 paginiAPI2000 Tank Venting Calcsruhul01Încă nu există evaluări

- Premium TankDocument26 paginiPremium TankAnonymous p0iwBo100% (1)

- Api 650 Tank Design: One Foot MethodDocument4 paginiApi 650 Tank Design: One Foot MethodRafaelxxxÎncă nu există evaluări

- Vent SizingDocument5 paginiVent SizingPrashant Malve0% (1)

- Inbreathing Outbreathing of TanksDocument30 paginiInbreathing Outbreathing of Tanksomesh2008Încă nu există evaluări

- Vessel Sizing SpreadsheetDocument28 paginiVessel Sizing SpreadsheetEmamokeÎncă nu există evaluări

- Venting Calculation - PDFDocument3 paginiVenting Calculation - PDFAmruta100% (1)

- Venting: As Per Section 4.3 of API 2000, InbreathingDocument2 paginiVenting: As Per Section 4.3 of API 2000, InbreathingJoshue AdeleÎncă nu există evaluări

- API 2000 Venting1Document5 paginiAPI 2000 Venting1aw_ae100% (1)

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 paginiStorage Tank Design Calculation - Api 650: Close Floating RoofhgagÎncă nu există evaluări

- Heating Coil Sizing For Fuel Oil TankDocument2 paginiHeating Coil Sizing For Fuel Oil TankAhmed Mujtaba93% (14)

- Venting As Per Api 2000Document6 paginiVenting As Per Api 2000Joshue Adele100% (1)

- API2000Document39 paginiAPI2000Sudhanshu Shekhar50% (2)

- API 620 Tank CalculationsDocument11 paginiAPI 620 Tank CalculationsPrashant Malve64% (11)

- Sample Calc - API 620Document13 paginiSample Calc - API 620Natarajan RavisankarÎncă nu există evaluări

- Tank Volume CalculationDocument9 paginiTank Volume CalculationMangesh MandgeÎncă nu există evaluări

- Tank Vessel Overflow Line SizingDocument4 paginiTank Vessel Overflow Line SizingSteve Wan100% (1)

- Maz - Design - Separator Capacity EvaluationDocument5 paginiMaz - Design - Separator Capacity EvaluationNaeem HussainÎncă nu există evaluări

- API-650 Water Storage Tank TK-2Document27 paginiAPI-650 Water Storage Tank TK-2Athira ZahraÎncă nu există evaluări

- API STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingDocument2 paginiAPI STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingFendy ShirahÎncă nu există evaluări

- API STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingDocument2 paginiAPI STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingFendy ShirahÎncă nu există evaluări

- Chemical & Process Technology Tank Normal Venting Rate Estimation Using Latest Method As in API STD 2000Document16 paginiChemical & Process Technology Tank Normal Venting Rate Estimation Using Latest Method As in API STD 2000mostafagalal22Încă nu există evaluări

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document15 paginiAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)HyungTae JangÎncă nu există evaluări

- R V C V: API STD 2000-2014, Calculation For Max. Flow Rates For Normal InbreathingDocument10 paginiR V C V: API STD 2000-2014, Calculation For Max. Flow Rates For Normal InbreathingAnonymous a4Jwz14W0% (1)

- Venting CalculationsDocument3 paginiVenting CalculationsernestoÎncă nu există evaluări

- Steam CoilDocument6 paginiSteam CoilMyung Ho SynÎncă nu există evaluări

- RF-SJ104L3H-063N04D: CondenserDocument2 paginiRF-SJ104L3H-063N04D: CondenserAndreeaÎncă nu există evaluări

- OEM Diff Erential Pressure Transmitter: Type 401Document4 paginiOEM Diff Erential Pressure Transmitter: Type 401minh2305Încă nu există evaluări

- 道康宁Dow DOWSIL™ SE 4430白色 导热硅脂 导热胶-附TDS下载Document3 pagini道康宁Dow DOWSIL™ SE 4430白色 导热硅脂 导热胶-附TDS下载walter karl Nuñez AngoÎncă nu există evaluări

- Ta2958 Rhi XX XX CA e 1001 - Draft Pro Cons IzhDocument25 paginiTa2958 Rhi XX XX CA e 1001 - Draft Pro Cons IzhBack to SumateraÎncă nu există evaluări

- M /H M /H M /H M /H KG/M: Operation Capacity X Pump, at P, TDocument1 paginăM /H M /H M /H M /H KG/M: Operation Capacity X Pump, at P, TEduard cadavidÎncă nu există evaluări

- M /H M /H M /H M /H KG/M: 1 Bomba de Agua Potable P-004Document1 paginăM /H M /H M /H M /H KG/M: 1 Bomba de Agua Potable P-004Eduard cadavidÎncă nu există evaluări

- 0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XXDocument1 pagină0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XXPhượng NguyễnÎncă nu există evaluări

- API 12j SizingDocument1 paginăAPI 12j SizingAdewunmi OlufemiÎncă nu există evaluări

- Minimum DistanceDocument1 paginăMinimum DistanceWahono KrismantonoÎncă nu există evaluări

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 paginiWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Document4 pagini3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizÎncă nu există evaluări

- What Is NanoWatt TechnologyDocument1 paginăWhat Is NanoWatt Technologyfolk_sharathÎncă nu există evaluări

- HDMI To MIPI and LVDS To MIPI Converter Rotator Board Solutions From Q VioDocument2 paginiHDMI To MIPI and LVDS To MIPI Converter Rotator Board Solutions From Q VioSubham KumarÎncă nu există evaluări

- Technik: RefraDocument54 paginiTechnik: Reframustaf100% (1)

- Software Requirements CompressDocument9 paginiSoftware Requirements CompressApni Duniya100% (1)

- Oleg Losev NegativeDocument2 paginiOleg Losev NegativeRyan LizardoÎncă nu există evaluări

- FeCl3 Msds - VISCOSITYDocument9 paginiFeCl3 Msds - VISCOSITYramkesh rathaurÎncă nu există evaluări

- Axis Bank - Group 4Document34 paginiAxis Bank - Group 4Deep Ghose DastidarÎncă nu există evaluări

- Intern JanataDocument59 paginiIntern JanataKhairul IslamÎncă nu există evaluări

- Alburg-Caldwell Manor 1784-1826 Draft by Fay YoungDocument3 paginiAlburg-Caldwell Manor 1784-1826 Draft by Fay YoungNancy Cunningham100% (1)

- Coca-Cola BeverageDocument17 paginiCoca-Cola BeverageMahmood SadiqÎncă nu există evaluări

- Comprehension: The Boy Is Playing With A Fire TruckDocument79 paginiComprehension: The Boy Is Playing With A Fire Truckbhupendra singh sengarÎncă nu există evaluări

- AM2020-AFP1010 Installation Programming OperatingDocument268 paginiAM2020-AFP1010 Installation Programming OperatingBaron RicthenÎncă nu există evaluări

- TV ExplorerDocument2 paginiTV Explorerdan r.Încă nu există evaluări

- 2015.15009.fundamental Principles of Physical Chemistry - Text PDFDocument782 pagini2015.15009.fundamental Principles of Physical Chemistry - Text PDFAnoif Naputo Aidnam100% (1)

- Flexure Hinge Mechanisms Modeled by Nonlinear Euler-Bernoulli-BeamsDocument2 paginiFlexure Hinge Mechanisms Modeled by Nonlinear Euler-Bernoulli-BeamsMobile SunÎncă nu există evaluări

- LAC BrigadaDocument6 paginiLAC BrigadaRina Mae LopezÎncă nu există evaluări

- Product Management Software Director in Austin TX Resume Chad ThreetDocument2 paginiProduct Management Software Director in Austin TX Resume Chad ThreetChad ThreetÎncă nu există evaluări

- Demand Management in Global Supply Chain - Disertasi S3Document166 paginiDemand Management in Global Supply Chain - Disertasi S3Ahmad BuchoriÎncă nu există evaluări

- Syllabus Financial AccountingDocument3 paginiSyllabus Financial AccountingHusain ADÎncă nu există evaluări

- Paper 5Document4 paginiPaper 5hbyhÎncă nu există evaluări

- Recruitment of Officers in Grade B' (General) - DR - By-2019Document2 paginiRecruitment of Officers in Grade B' (General) - DR - By-2019Shalom NaikÎncă nu există evaluări

- Modeling and Simulation of The Temperature Profile Along Offshore Pipeline of An Oil and Gas Flow: Effect of Insulation MaterialsDocument8 paginiModeling and Simulation of The Temperature Profile Along Offshore Pipeline of An Oil and Gas Flow: Effect of Insulation MaterialsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Honeymoon in Vegas Word FileDocument3 paginiHoneymoon in Vegas Word FileElenaÎncă nu există evaluări

- Datasheet d801001Document6 paginiDatasheet d801001Hammad HussainÎncă nu există evaluări

- The Art of Starting OverDocument2 paginiThe Art of Starting Overlarry brezoÎncă nu există evaluări

- Nava LunchDocument3 paginiNava LuncheatlocalmenusÎncă nu există evaluări

- Review Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFDocument3 paginiReview Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFBilal SalaamÎncă nu există evaluări

- Waste SM4500-NH3Document10 paginiWaste SM4500-NH3Sara ÖZGENÎncă nu există evaluări

- Annual Premium Statement: Bhupesh GuptaDocument1 paginăAnnual Premium Statement: Bhupesh GuptaBhupesh GuptaÎncă nu există evaluări

- Advertisement For Recruitment of Non-Teaching StaffDocument3 paginiAdvertisement For Recruitment of Non-Teaching StaffGoogle AccountÎncă nu există evaluări