Documente Academic

Documente Profesional

Documente Cultură

Discoloration in Lube Oil

Încărcat de

dabir123Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Discoloration in Lube Oil

Încărcat de

dabir123Drepturi de autor:

Formate disponibile

Discoloration in Lube oil

Color can be used as an indicator of oil health, and in many cases it is

a reliable field indicator. However, color alone cannot tell the whole

story of the oils condition. For a complete understanding of oil

condition, it is important to use an appropriate test slate.

A change in oil color signifies a change in the chemistry of the oil or

the presence of contaminants. For example, oil oxidation, mixing two

dissimilar types of oil, and carbon insolubles from thermal failure can

all darken oil. There is also a possibility that the oil darkening is due to

a photochemical reaction from sunlight exposure.

Measuring color is based on a visual comparison of the amount of light

transmitted through a defined depth of oil. This can be done with a

predefined test method and instrumentation or a subjective view of

the oil with reference to a color gauge. In either case, there may be a

number of variables to monitor for quality results.

The ASTM D1500-07 test method can be used to compare the color of

an oil sample to a glass slide. This test is used in lubricant

manufacturing for quality-control purposes. It is performed using a

standard light source to match a sample to a glass slide. Values for the

glass range from 0.5 to 8.0 in 0.5 increments. If the sample falls

between two colors, the higher number is reported. If no color gauge

is available, the oil color is compared to a previous sample or a new oil

sample.

Contamination

Maintaining proper oil quality is essential for satisfactory operation and

longevity of oil film bearings. Oil discoloration is a sign of potentially

harmful contamination or degradation. There are three main causes of

oil discoloration in oil film bearings: particulate contamination (external

and internal), liquid contamination, and oxidation.

Each cause has some unique characteristics, but discoloration is often a

combination of the three. This article discusses each cause of

discoloration, and makes recommendations on proper oil type and oil

analysis.

Oxidation

Oil oxidation is one last source of oil discoloration. Oil oxidation is a

process of chemical degradation that naturally occurs in oil over time

when it is exposed to air. Some of its by-products are sludge, varnish,

and acid, which cause the oil to thicken and darken. Higher

temperatures (above 160 F for mineral oils) accelerate oxidation, as well

as other contaminates such as water, iron, and copper. Synthetic oils

are available which have better oxidation resistance than conventional

oils and can be considered to extend oil change intervals.

Light Exposure

Extended exposure to sunlight can cause oil to suffer accelerated

oxidation and may lead to shortened drain intervals. On a molecular

level, the long chain lubricant hydrocarbon reacts with oxygen in the

presence of ultraviolet (UV) radiation from the sun. As a result, it

forms chromophores - conjugated aldehydes, ketones and esters.

These absorb visible light to appear yellow at low concentrations and

brown at higher concentrations after extended exposure to sunlight. To

avoid this situation, one should protect the exposed oil from the

ultraviolet energy in direct sunlight.

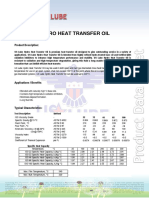

Viscosity @ Oxidation Induction Rotating Pressure

Acid Number

Product 40C cSt Time by PDSC Minutes Vessel Oxidation

ASTM D974

ASTM D445 190C ASTM D6186 Minutes ASTM D2272

A - new 0.07 30.19 19 1,707

A - aged 0.11 30.21 11 916

A - aged (glass) --- 30.18 --- ---

B - new 0.04 29.81 10 367

B - aged 0.07 28.88 13* 409

C - new 0.07 30.18 22 1,840

C - aged 0.11 30.27 22 1,530

Hydraulic new 0.1 43.78 17 566

Hydraulic aged 0.13 43.94 17 474

Table 1

A = Group II turbine oil with R&O additive package

B = Hydrotreated (Group I) with R&O additive package

C = Carefully selected base oil (as worded on product description) with R&O package

D = Highly refined base stock (as worded on product description) with antiwear package

* Considered to be within the reproducibility of the test method

Analysis

The ultraviolet portion of the sunlight spectrum has shorter and higher

energy wavelengths than visible or infrared portions. Upon direct

exposure, UV rays can break chemical bonds and damage skin,

plastics and mineral oil-based lubricants. The ozone layer in the

stratosphere absorbs 99 percent of the UV rays coming from the sun.

The remaining one percent can cause damage unless UV stabilizers are

added to skin creams and plastics or the exposed object is shaded.

Some plastics are inherently stable to UV rays, such as the butyrate

reservoirs in various gravity feed lubricators and polyethylene

terephthalate (PET) sample bottles, however they do allow UV

radiation to pass through, causing damage to the contained

hydrocarbon fluid.

A simulation of reported dark turbine oils in outdoor gravity feed

reservoirs was performed by placing various turbine oils, including a

synthetic, in PET bottles in outdoor sunlight for five days. The increase

in color can be seen in Figures 1 through 5. Turbine oil A was also

exposed to sunlight in a glass bottle. The change in viscosity and color

were essentially the same between glass and plastic.

Oxidation Test Methods

Degradation is observed by small increases in acid number, viscosity

and in some cases, a substantial decrease in oxidation resistance

through the use of Pressurized Differential Scanning Calorimetry

(PDSC) and Rotary Pressure Vessel Oxidation Test (PRVOT). With

PDSC, the sample is subjected to 500 PSI of oxygen and isothermally

heated.1 As the onset of oxidation occurs, there is a phase change in

the base oil that is characterized by an exothermic reaction,

considered to be the onset of oxidation time. With RPVOT, the sample

is subjected to 90 PSI pure oxygen purge in a pressure vessel

containing a copper coil and moisture catalyst, and heated to 150C.

The point at which pressure stabilizes after reaching 150C marks the

initiation of test timeline. Oxygen pressure in the vessel decreases

with the onset of oxidation. The test concludes once the pressure

drops by 25 PSI. The test duration is noted in minutes.2

These same samples did not show any color change when exposed to

indoor fluorescent light or sunlight coming through a UV-protected

glass window.

Conclusion

Ultraviolet light can damage lubricants in a short period of time. The

first sign of damage in this study was the oxidation resistance of the

oil. This may seem all right if the system is a once-through drip

lubricant where there is no need for high levels of oxidation stability.

However, if the oil feed system is used as a constant leveler for a

small reservoir, one may be adding bad oil to good oil!

S-ar putea să vă placă și

- Temperature and Velocity Effects in Naphthenic Acid Corrosion (51300-96603-SG)Document13 paginiTemperature and Velocity Effects in Naphthenic Acid Corrosion (51300-96603-SG)Wahyu HidayatÎncă nu există evaluări

- Product Data Energol THB: DescriptionDocument2 paginiProduct Data Energol THB: Descriptionkarim karimÎncă nu există evaluări

- Pds Sinopec Compressor Oil Dab 1Document3 paginiPds Sinopec Compressor Oil Dab 1gofino.drÎncă nu există evaluări

- Axel Elgi 2013Document18 paginiAxel Elgi 2013Virender KumarÎncă nu există evaluări

- Demulsibility of Additive OilsDocument4 paginiDemulsibility of Additive OilsAbdurrhman AlzhraniÎncă nu există evaluări

- The Difference Between Gasoline, Kerosene, DieselDocument6 paginiThe Difference Between Gasoline, Kerosene, Dieselebrahem gamerÎncă nu există evaluări

- Aw Hydraulic Oil: Applications Selection GuideDocument2 paginiAw Hydraulic Oil: Applications Selection GuideMassimiliano VolaÎncă nu există evaluări

- Doble TOPS 2008 and CCD TestDocument14 paginiDoble TOPS 2008 and CCD TestDeepak VermaÎncă nu există evaluări

- L-TSA Classic Turbine OilDocument3 paginiL-TSA Classic Turbine OilQuy NguyenÎncă nu există evaluări

- PAPER CIGRE Experiences From On Site Transformer Oil Reclaiming 2002Document6 paginiPAPER CIGRE Experiences From On Site Transformer Oil Reclaiming 2002txr qcÎncă nu există evaluări

- Transformer Oil Analysis: Water ContentDocument12 paginiTransformer Oil Analysis: Water ContentSanjeev DhariwalÎncă nu există evaluări

- Process Notes: Final ProjectDocument8 paginiProcess Notes: Final ProjectCluisantony Jayco DizeÎncă nu există evaluări

- Detect and Control Water in OilDocument9 paginiDetect and Control Water in OilAbdul AzisÎncă nu există evaluări

- 4506 Synthetic Compressor OilDocument2 pagini4506 Synthetic Compressor OilYoong TanÎncă nu există evaluări

- Transformer: Oil Condition MonitoringDocument6 paginiTransformer: Oil Condition MonitoringKhushdeep SohiÎncă nu există evaluări

- L-TSA Turbine OilDocument3 paginiL-TSA Turbine OilQuy NguyenÎncă nu există evaluări

- L-CKD Heavy Duty Industrial Gear OilDocument3 paginiL-CKD Heavy Duty Industrial Gear OilDavidÎncă nu există evaluări

- A Guide To Transformer Oil AnalysisDocument13 paginiA Guide To Transformer Oil Analysiskrcdewanew100% (1)

- Heat Transfer Oil SheetDocument1 paginăHeat Transfer Oil SheetShamim SazzadÎncă nu există evaluări

- AquaFlow NHS 300-EDocument4 paginiAquaFlow NHS 300-ESyed Faiz Ul Hasan RizviÎncă nu există evaluări

- DN Turbine OilDocument2 paginiDN Turbine OilPrapat SabsinthaweelapÎncă nu există evaluări

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pagini93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaÎncă nu există evaluări

- SuperS InhibitedTransformerOil SpecDocument2 paginiSuperS InhibitedTransformerOil Spechhahn01Încă nu există evaluări

- L-TSE Turbine OilDocument3 paginiL-TSE Turbine OilYoong TanÎncă nu există evaluări

- Material and Equipment Standard: IPS-M-TP-672Document7 paginiMaterial and Equipment Standard: IPS-M-TP-672RezaÎncă nu există evaluări

- Optigear 1100 RangeDocument3 paginiOptigear 1100 RangeResistenciaDisidenteÎncă nu există evaluări

- 9 - Paul B AMS - Presentation - 1!4!2012Document50 pagini9 - Paul B AMS - Presentation - 1!4!2012anhntran4850Încă nu există evaluări

- Chromaflo Technologies Chroma Chem 866 Product Sheet Rev 01 20 - Americas - PDF?DL 0Document2 paginiChromaflo Technologies Chroma Chem 866 Product Sheet Rev 01 20 - Americas - PDF?DL 0Juan GpÎncă nu există evaluări

- US3029298Document2 paginiUS3029298Muhammad Akbar FahleviÎncă nu există evaluări

- TT Turbine Oil Condition Monitoring Training Guide PDFDocument8 paginiTT Turbine Oil Condition Monitoring Training Guide PDFalvaedison00Încă nu există evaluări

- Part03-Physical & Physicochemical Petroleum 451Document46 paginiPart03-Physical & Physicochemical Petroleum 451Oracal OrÎncă nu există evaluări

- PV 1425 (2008) Lubricating Oil Corrosivity TestDocument4 paginiPV 1425 (2008) Lubricating Oil Corrosivity TestMatthew TaylorÎncă nu există evaluări

- L-CKC Medium Duty Industrial Gear OilDocument3 paginiL-CKC Medium Duty Industrial Gear OilYoong TanÎncă nu există evaluări

- Turbine Oil - SpecDocument2 paginiTurbine Oil - SpecEid EeidÎncă nu există evaluări

- L-TSELF Long Service Life Extreme Pressure Turbine OilDocument3 paginiL-TSELF Long Service Life Extreme Pressure Turbine OilQuy NguyenÎncă nu există evaluări

- Astm1884 Ressol Versa Ht3Document6 paginiAstm1884 Ressol Versa Ht3Matteo DMÎncă nu există evaluări

- Zic Supervis AwDocument2 paginiZic Supervis AwMohammed Abdul GhafoorÎncă nu există evaluări

- Vegetable Oil As FuelDocument21 paginiVegetable Oil As FuelmvasilÎncă nu există evaluări

- Compressor Oil 32 46 68 100 150Document1 paginăCompressor Oil 32 46 68 100 150Sharrife JÎncă nu există evaluări

- Shell Turbo 46 Oil SpecDocument2 paginiShell Turbo 46 Oil SpecHyungTae JangÎncă nu există evaluări

- Study of The Comportment of Fatty AcidsDocument7 paginiStudy of The Comportment of Fatty AcidsAhmed AllamÎncă nu există evaluări

- Biodeisel Using FuelProDocument4 paginiBiodeisel Using FuelProSylab InstrumentsÎncă nu există evaluări

- Product Data Sheet: Apsco Technology LubricantsDocument1 paginăProduct Data Sheet: Apsco Technology LubricantsMuhannadÎncă nu există evaluări

- Corrosive Sulphur IECDocument61 paginiCorrosive Sulphur IECLaurentiu Viorel Badicu0% (1)

- ASTMD2440 - Standard Test Method For Oxidation Stability of Mineral Insulating Oil PDFDocument6 paginiASTMD2440 - Standard Test Method For Oxidation Stability of Mineral Insulating Oil PDFMohan RaoÎncă nu există evaluări

- Maintenance of TransformerDocument80 paginiMaintenance of Transformerajaynmenon100% (2)

- Practical TBPDocument8 paginiPractical TBPHalben A Nerway0% (1)

- Naphthenic Acid CorrosionDocument6 paginiNaphthenic Acid CorrosionCristian Otivo100% (1)

- Data For Oil Used in TransformerDocument31 paginiData For Oil Used in TransformerPlanning EngineeringÎncă nu există evaluări

- Shell Tellus Oils: High Performance Hydraulic OilDocument2 paginiShell Tellus Oils: High Performance Hydraulic Oilsamar209Încă nu există evaluări

- Astmd2272 02Document12 paginiAstmd2272 02karlitox123Încă nu există evaluări

- DGA Test Report: Energypac Engineering LTDDocument5 paginiDGA Test Report: Energypac Engineering LTDMonirÎncă nu există evaluări

- Super Tauro: DescriptionDocument2 paginiSuper Tauro: DescriptionSaurav SharmaÎncă nu există evaluări

- 1 Sinopec Insulated Transformer Oil IEC 60296 2003Document3 pagini1 Sinopec Insulated Transformer Oil IEC 60296 2003kavish malakaÎncă nu există evaluări

- Tugas Proteksi Dan PengamananDocument7 paginiTugas Proteksi Dan PengamananArman Amardi PutraÎncă nu există evaluări

- HASTELLOY® C-22HS™alloyDocument16 paginiHASTELLOY® C-22HS™alloyYudha SatriaÎncă nu există evaluări

- Refining Q&ADocument41 paginiRefining Q&Ashashwatchaurasia83Încă nu există evaluări

- GC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsDe la EverandGC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsÎncă nu există evaluări

- Biogas Production SystemsDocument22 paginiBiogas Production SystemsEmiliano Rodriguez TellezÎncă nu există evaluări

- 3100 P TDocument196 pagini3100 P TTim FowlerÎncă nu există evaluări

- bw-G1030 USDocument24 paginibw-G1030 USEuojrÎncă nu există evaluări

- Bul-Spent Mushroom Substrate (SMS)Document56 paginiBul-Spent Mushroom Substrate (SMS)Manoj Patel100% (1)

- Notes Gas AbsorptionDocument15 paginiNotes Gas AbsorptionPeter Paul BucsitÎncă nu există evaluări

- WPS (Gtaw)Document2 paginiWPS (Gtaw)Ramadhan AdityaÎncă nu există evaluări

- Inspeccion Visual de Treminales Crimpeado PDFDocument2 paginiInspeccion Visual de Treminales Crimpeado PDFCarlos ChirinosÎncă nu există evaluări

- Aci y Sus NormasDocument14 paginiAci y Sus NormasJUAN AGUILARÎncă nu există evaluări

- Electrolysis 2Document5 paginiElectrolysis 2trickster jonasÎncă nu există evaluări

- 4013 Stability TestingDocument5 pagini4013 Stability TestingtghonsÎncă nu există evaluări

- Datasheet Altro-AquariusDocument8 paginiDatasheet Altro-AquariusPaola Cares MoralesÎncă nu există evaluări

- Full Isolation of M-State ElementsDocument2 paginiFull Isolation of M-State ElementsWigwammanÎncă nu există evaluări

- Lab ReportDocument8 paginiLab ReportHenrique PradoÎncă nu există evaluări

- Bondstrand™ LD Series: ApplicationsDocument4 paginiBondstrand™ LD Series: ApplicationsMathan KumarÎncă nu există evaluări

- Pocket Handbook For VI & Weld DiscontinuitiesDocument17 paginiPocket Handbook For VI & Weld Discontinuitiesixotee100% (2)

- Tablas TermodinámicasDocument5 paginiTablas TermodinámicasSarahí CabreraÎncă nu există evaluări

- Trislot Reactor Internal Part PDFDocument12 paginiTrislot Reactor Internal Part PDFjonathanÎncă nu există evaluări

- AHMSW 8 Fiche de PhaseDocument12 paginiAHMSW 8 Fiche de PhaseBOUBAKER LOGBIÎncă nu există evaluări

- Er MonitoringDocument8 paginiEr MonitoringAsma SedÎncă nu există evaluări

- Location Risk Assessment Form-Part A: Basic Information & Hazard ListDocument3 paginiLocation Risk Assessment Form-Part A: Basic Information & Hazard Listapi-330049796Încă nu există evaluări

- Blast FurnaceDocument28 paginiBlast Furnaceavanisharma_1991Încă nu există evaluări

- 4200 459 D62 18139 Code 4 Rev 7Document4 pagini4200 459 D62 18139 Code 4 Rev 7rcpuram01Încă nu există evaluări

- Paracetamol e Ibuprofeno Como Contaminantes EmergentesDocument27 paginiParacetamol e Ibuprofeno Como Contaminantes EmergentesElmer VargasÎncă nu există evaluări

- FORCE & PRESSURE NotesDocument1 paginăFORCE & PRESSURE NotesPraveen KumarÎncă nu există evaluări

- Coordination CompoundDocument76 paginiCoordination Compoundashok pradhanÎncă nu există evaluări

- Catalogo Rieles PDFDocument133 paginiCatalogo Rieles PDFWilliam AguilarÎncă nu există evaluări

- Advantages and Disadvantages of Hydraulic SystemsDocument3 paginiAdvantages and Disadvantages of Hydraulic SystemsTina MilovanovićÎncă nu există evaluări

- 2019 MFG Industries India 667Document6 pagini2019 MFG Industries India 667Uday kumarÎncă nu există evaluări

- Chemical Exergy Calculation CharpterDocument10 paginiChemical Exergy Calculation CharpterFernanda PerezÎncă nu există evaluări

- Distillation of Creosote and Creosote-Coal Tar Solutions: Standard Test Method ForDocument5 paginiDistillation of Creosote and Creosote-Coal Tar Solutions: Standard Test Method ForCasey RybackÎncă nu există evaluări