Documente Academic

Documente Profesional

Documente Cultură

QAQC Objective & Key Career Achievements

Încărcat de

saffririzal4237Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QAQC Objective & Key Career Achievements

Încărcat de

saffririzal4237Drepturi de autor:

Formate disponibile

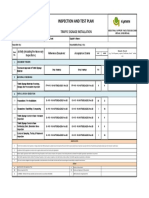

QAQC Kick Off Meeting

Does the project understand the work scope of each site subcontractor and has it been defined in the

Planning &

project scheduling. This is especially important for the completion of As-Built Dossiers for project Turn Over

Scheduling

Purposes.

Constructability Has the Project Identified major constructability site issues that will impact upon the completion of the site

Items Identified quality inspections and subsequently delay the turnover of Quality Dossiers to the customer.

Procurement Has the Project Identified all sub-contractors procured items that might not conform to the customers

Inspection Technical Specifications? Have these items been identified on a procurement matrix and receipt inspections

Activities been coordinated prior to release for site use.

Does each subcontractor have a designated team of Quality Control Inspectors with organization freedom to

QC organization

reject and accept nonconforming material? Do these inspectors have sufficient qualifications and experience

Chart Defined

to complete the scope of work.

Point of

The Project QA/QC team must identify points of contacts with the customer, Prime Contractor, Sub

Contacts

contractors and Third Party Inspection bodies on site to ensure timely completion of site inspections.

Defined

All the site subcontractors must understand and implement their site approved Quality Control Inspection &

QC Inspection

Test Plan (QCIP) to ensure the inspection of the work is undertaken during process and without any

Plan Reviewed

schedule delays.

Health & Safety

of Radioactive All subcontractors that use radioactive sources must be aware of the site safety procedures and emergency

Sources evacuation procedures.

Reviewed

Objective & Key Career Achievements

CAREER OBJECTIVE:

To acquire a responsible position in a well-established company that where I can apply my

excellent knowledge, expertise and experience gained from my previous employment,

education and professional trainings.

PROFESSIONAL STRENGHT & COMPETENCIES:

Im a high caliber performing Construction, Quality, QA/QC, Welding Engineering and QHSE

Professional with extensive expertise in cross functional areas of Engineering, Construction,

Fabrication, Quality, Inspection, Testing, Commissioning, Shutdown, Maintenance, Warehouse

Operation, Inventory Control and General Management, Third Party Representations, ISO 9001

QMS, ISO 14001 Audits and API Q1 Audits. I had been played several management and junior

role such as Construction Manager, Senior Quality Manager, Project Quality Manager, Quality

Manager, QA/QC Manager, QHSE Manager, Project Engineer, NDT Inspector, NDT Engineer,

Welding Engineer, Welding Inspector, Piping Engineer, Piping Supervisor, Structural

Supervisor, Site Supervisor, Fabrication Supervisor, Pressure Testing Engineer, Piping System

Flushing Supervisor and Technical Sales Executive which provided me a unique, broad and

cross functional expertise.My 21 years plus of experience as Construction, QA/QC and QHSE

professional in multiple large EPCM and EPC companies have equipped me with the right skills

and knowledge in managing, inspecting and constructing FPSO, FSO, Semi-submersible,

SURF, Fixed Platforms, Topsides, Jackets, Drilling Rigs, Shipbuilding, Pharmaceutical,

Chemical, Petrochemical, Waste Water, Waste Gas, Solar, Power, LNG, Environmental,

Semiconductor, Cross Country Pipeline, Infrastructure, Tunnel, MRT railways, Bridges,

Buildings and Network Satellites, Oil and Gas refineries. Well informed to the international

construction codes and quality related method that commonly used in industrial projects such as

(ASME, NBIC, ANSI, API, AWS, ABS, JIS, CNS, GB, DIN, Norsok, Euro codes, DVS, ISO 9001:

2000, 5S, Lean, Six Sigma, BCA CONQUAS, ISO TS 29001, OHSA 18001 Certification & ISO

14001: 1996). Well versed in all type of construction drawing such as Isomeric, P & ID, plan lay-

out and etc.

Quality Assurance & HSE:

Quality Management, QHSE Management, QMS Manual Development. QMS, ISO, ISM

external and internal auditing.

Development of QMS & HSE Procedures.

Client QA representation, Supply chain QA.

Carried out internal, sub-contractor & vendors audits.

Involvement for ASME-U, U2, A, PP, S, R, & NB, API 5CT & Q1 & ISO

certification.

Qualification & Approval of different Vendors & Sub Contractors. Risk

Assessments & HAZOP

Preparation of Project Quality Plan, Procedures, ITP, TDC and MS

Vendor document review

Carried out Management Review(MR)

Conducting Various Training Quality Control:

Carried out different inspection activities

Manpower Planning, TPI coordination,

Receiving Material Inspection,

Equipment Inspection, Tray Internals Inspection, Punch listing and line checking of

Piping & Pipeline, Welding Inspection, Bending Inspection.

Painting, Coating and Insulation Inspection, Hydro test and flushing inspection.

Test Package Preparation and Manufacturer Data Record Book (MDR) preparation

Hand over certification Welding:

PQR Qualification.

WPS/PQR preparation.

Welder Qualification.

Weld & Test Plan Preparation

Consumable Planning & Estimation

Repair procedure preparation

Sub-contractor & vendors document review & approval.

Manpower approval.

Vacuumed packed.

Process GTAW, SMAW, GMAW, SAW, FCAW, Orbital, Hot Gas, Extrusion,

Heated Tool

Overlay welding.

Manufacturing stage wise inspection of:

Heat exchangers , Pressure Vessels, Fin Fan cooler, Blower, Columns, Boilers, Fired

Heaters, Filter Press, Hopper, Silo, Demister, WESP, Mixer / Agitator, Compressor, Kiln,

Conveyor, Scrubbers, Clarifier, Storage Tanks, Skids, Duct, Pipes, Piping Spools

Fabrication, Pipe Bending, Pontoon, Subsea Structure, Umbilical System, Flow lines,

Subsea Manifold, Mud line Template System, Specialty Casing Connector, Surface and

Subsea Wellhead Christmas Tree Fabrication etc.

Construction & Erection inspection:

Pipings works, Pipelines- Under Ground & Above Ground, Structures, Process

Equipments

Equipments Internals, Storage tanks,

Fired Heaters, Beam Pumps, GRE crew qualification, testing and Jointing Civil & E

& I involvement:

Trail Mix as per design.

Soil Testing

Anchor Bolt Pulling Testing

Concrete Cube Testing

Excavation, back filling, Reinforcement, Form work, Concrete Works & grouting

etc.

Cables, Motors, transformer, earthling, control panels & testing of motors etc.

Review and approval of subcontractor ITP, procedures Materials(Entry

removed to protect privacy)

Involvement in different type of steel and thermoplastic materials for construction and

manufacturing.

Carbon steel, Low Alloy Steel

Stainless Steel, Duplex SS, Nickel, Titanium

Inconel, GRP/FRP/FEP, HDPE, HDPP, PVDF etc.

NDT and DT:

Preparation of NDT plan & Procedure

Sub-contractor manpower Qualification

RT interpretation

DPT, MPT, RT, UT and mechanical testing

S-ar putea să vă placă și

- Mechanical Engineer With 4.6 Years QA/QC Experience Seeks New OpportunityDocument5 paginiMechanical Engineer With 4.6 Years QA/QC Experience Seeks New Opportunityvishal bailur100% (1)

- Method Statement of Mass Concrete Block Precast WorksDocument41 paginiMethod Statement of Mass Concrete Block Precast WorksShams JogÎncă nu există evaluări

- Presentation Induction Quaity NewDocument31 paginiPresentation Induction Quaity Newkbldam67% (6)

- Quality Assurance Plan For Building ConstructionDocument18 paginiQuality Assurance Plan For Building ConstructionAmit Kumar Pandey100% (1)

- Top Quality Engineer Job Interview Questions That You Should KnowDocument4 paginiTop Quality Engineer Job Interview Questions That You Should KnowUsman ShahidÎncă nu există evaluări

- Inspection and Test Plan (Itp) For Staircase Handrail 1 & 2Document3 paginiInspection and Test Plan (Itp) For Staircase Handrail 1 & 2Environ Support100% (1)

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDocument53 paginiA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDan CosacÎncă nu există evaluări

- Nawaz Khan - Civil InspectorDocument4 paginiNawaz Khan - Civil InspectormlÎncă nu există evaluări

- QAQC Monthly Report (April 2022)Document10 paginiQAQC Monthly Report (April 2022)Mohamed FaroukiÎncă nu există evaluări

- ITP For Handrail WeldingDocument2 paginiITP For Handrail WeldingKumar AbhishekÎncă nu există evaluări

- Quality InductionDocument15 paginiQuality InductionaleemmurtazaÎncă nu există evaluări

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Document9 paginiMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- Standard Operating Procedure For On Site Meter TestingDocument4 paginiStandard Operating Procedure For On Site Meter TestingsanjayÎncă nu există evaluări

- Quality PlanDocument21 paginiQuality PlanQianlei ZhuÎncă nu există evaluări

- QAQC Monthly ReportDocument52 paginiQAQC Monthly ReportMohammad Hadoumi Saldan100% (4)

- Method Statement For Sign Board Excavation & Installation - Safe Work Method of StatementDocument2 paginiMethod Statement For Sign Board Excavation & Installation - Safe Work Method of StatementUmair AslamÎncă nu există evaluări

- Method Statement Process Flow DiagramDocument1 paginăMethod Statement Process Flow DiagramUbaid Mazhar Abidi SyedÎncă nu există evaluări

- PD-CL-021 - 1 Precast Panel InstallationDocument1 paginăPD-CL-021 - 1 Precast Panel Installationkimura takuyaÎncă nu există evaluări

- Method Statement For Cement Board Dry Wall PartitionsDocument10 paginiMethod Statement For Cement Board Dry Wall PartitionsComet GroupÎncă nu există evaluări

- Quality Plan Method StatementDocument10 paginiQuality Plan Method Statementjamie542350% (2)

- QAQC GuidelinesDocument19 paginiQAQC GuidelinesBonaventure Nzeyimana100% (1)

- Quality Plan for GPL Construction ProjectDocument23 paginiQuality Plan for GPL Construction Projectmayank dixitÎncă nu există evaluări

- Surface GI Conduit Installation Method StatementDocument4 paginiSurface GI Conduit Installation Method StatementJaneÎncă nu există evaluări

- SITE-SPECIFIC QC PLANDocument3 paginiSITE-SPECIFIC QC PLANloveanbu24100% (1)

- ITP 63113 XX Stockpile ITP (Working)Document6 paginiITP 63113 XX Stockpile ITP (Working)soni10483Încă nu există evaluări

- ITP For Civil WorksDocument8 paginiITP For Civil WorksOsama WaheedÎncă nu există evaluări

- Khulud Gas Development Project FabricationDocument5 paginiKhulud Gas Development Project FabricationRana AsifÎncă nu există evaluări

- Method Statement Steel Structure 1 4 Meg PDFDocument26 paginiMethod Statement Steel Structure 1 4 Meg PDFemeka2012Încă nu există evaluări

- Quality Assurance and ControlDocument55 paginiQuality Assurance and ControlACHESÎncă nu există evaluări

- Presentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)Document55 paginiPresentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)kbldamÎncă nu există evaluări

- Quality Control for Concrete Block WallsDocument11 paginiQuality Control for Concrete Block WallsYash Sharma100% (2)

- Civil Works Inspection - QA - QC-Construction LTDDocument1 paginăCivil Works Inspection - QA - QC-Construction LTDNashrul KarimÎncă nu există evaluări

- PQP EpldtDocument8 paginiPQP Epldtmartin leeÎncă nu există evaluări

- ISO QMS PresentationDocument29 paginiISO QMS PresentationFarid B. Mahali100% (1)

- ITP-CI-026a-02 (Building Finishing Works)Document4 paginiITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyÎncă nu există evaluări

- CG – AQUA Quality ReportDocument20 paginiCG – AQUA Quality Reportganesh100% (1)

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument18 paginiLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyÎncă nu există evaluări

- Quality Manual: M. Barbisotti & Sons LTDDocument20 paginiQuality Manual: M. Barbisotti & Sons LTDengsam777100% (1)

- 70.control of NCR Issued To Subcon (Flow Chart)Document1 pagină70.control of NCR Issued To Subcon (Flow Chart)Syerifaizal Hj. Mustapha100% (1)

- Vinothkumar-Qaqc CVDocument6 paginiVinothkumar-Qaqc CVsoorajÎncă nu există evaluări

- QC PROCEDURESDocument37 paginiQC PROCEDURESRen Salazar100% (2)

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 paginiInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoÎncă nu există evaluări

- Shaik Yousufuddin (Welding Inspector)Document3 paginiShaik Yousufuddin (Welding Inspector)Mohamed AdelÎncă nu există evaluări

- QM501FA - Nonconformance ReportDocument1 paginăQM501FA - Nonconformance ReportRio Handoko100% (1)

- 8 Field Quality PlanDocument18 pagini8 Field Quality Plangeorge_hem100% (1)

- Shamil MEP QC MechanicalDocument3 paginiShamil MEP QC MechanicalHaneefa ChÎncă nu există evaluări

- ITP For Domestic Water Piping InstallationDocument1 paginăITP For Domestic Water Piping InstallationBelal AlrwadiehÎncă nu există evaluări

- 7-QC-QA Plan For ProjectDocument99 pagini7-QC-QA Plan For ProjectJaouad Id BoubkerÎncă nu există evaluări

- Mubeen Ahmed CVDocument7 paginiMubeen Ahmed CVMonis Hyder100% (1)

- Water Proofing SpecificationDocument1 paginăWater Proofing Specificationprabhu81Încă nu există evaluări

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 paginiA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONÎncă nu există evaluări

- Procedure For Control of Non Confirming ProductDocument7 paginiProcedure For Control of Non Confirming ProductAvijit DebnathÎncă nu există evaluări

- 027 ITP For Pre Cast Concrete PDFDocument27 pagini027 ITP For Pre Cast Concrete PDFlinga2014Încă nu există evaluări

- Traffic Signage Installation ITPDocument1 paginăTraffic Signage Installation ITPmoytabura96Încă nu există evaluări

- METHOD OF BLINDING CONCRETE WORKSDocument6 paginiMETHOD OF BLINDING CONCRETE WORKSMohd Muksin100% (1)

- Inspection and Test Plan For Internal Gypsum Plaster: Oberoi Maxima ProjectDocument5 paginiInspection and Test Plan For Internal Gypsum Plaster: Oberoi Maxima Projectlokesh.kukadiya100% (1)

- Method Statement For Casting Blinding ConcreteDocument2 paginiMethod Statement For Casting Blinding ConcreteCrazyBookWorm100% (2)

- Inspection Engineer Grade 1Document43 paginiInspection Engineer Grade 1ahmad taiyabiÎncă nu există evaluări

- Handramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceDocument5 paginiHandramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceANIL PLAMOOTTILÎncă nu există evaluări

- Qa/Qc Engineer or Inspector-Piping/Tanks/Rtr: Go To Recruitment ProductsDocument8 paginiQa/Qc Engineer or Inspector-Piping/Tanks/Rtr: Go To Recruitment ProductsrafiuddinÎncă nu există evaluări

- QC Document SpopeDocument1 paginăQC Document Spopesaffririzal4237Încă nu există evaluări

- Kamaruddin - Salary Adjusment Rev.0Document1 paginăKamaruddin - Salary Adjusment Rev.0saffririzal4237Încă nu există evaluări

- ZLNG - ACTION ITEM LIST - CCCC KOM 20230718 - CCCC Reply - Att-4Document9 paginiZLNG - ACTION ITEM LIST - CCCC KOM 20230718 - CCCC Reply - Att-4saffririzal4237Încă nu există evaluări

- Epcc of MBC Pilot Plant Project at Terengganu Gas Terminal (Tgast)Document2 paginiEpcc of MBC Pilot Plant Project at Terengganu Gas Terminal (Tgast)saffririzal4237Încă nu există evaluări

- 001 Daily Site Report TemplateDocument2 pagini001 Daily Site Report Templatesaffririzal4237Încă nu există evaluări

- Ra Movement 2Document1 paginăRa Movement 2saffririzal4237Încă nu există evaluări

- Request for Inspection Form for Gas Pipeline Replacement ProjectDocument2 paginiRequest for Inspection Form for Gas Pipeline Replacement Projectsaffririzal4237Încă nu există evaluări

- Petronas Gas Berhad RFI Register for EPCC ProjectDocument9 paginiPetronas Gas Berhad RFI Register for EPCC Projectsaffririzal4237Încă nu există evaluări

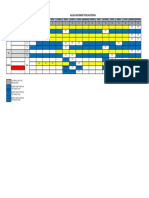

- WPQT Schedule Plan Rev.1aDocument1 paginăWPQT Schedule Plan Rev.1asaffririzal4237Încă nu există evaluări

- Punchlist BYPASSDocument1 paginăPunchlist BYPASSsaffririzal4237Încă nu există evaluări

- Mock Up Test Question For Graphite MMC Qaqc TeamDocument7 paginiMock Up Test Question For Graphite MMC Qaqc Teamsaffririzal4237Încă nu există evaluări

- ISO 9001:2015 Audit Checklist in MS Excel (Preview)Document7 paginiISO 9001:2015 Audit Checklist in MS Excel (Preview)Centauri Business Group Inc.56% (18)

- GPR Survey Procedure DocDocument10 paginiGPR Survey Procedure Docsaffririzal4237Încă nu există evaluări

- Punchlist FW T3-622Document1 paginăPunchlist FW T3-622saffririzal4237Încă nu există evaluări

- EPCC MBC Pilot Plant Skid Test PackDocument1 paginăEPCC MBC Pilot Plant Skid Test Packsaffririzal4237Încă nu există evaluări

- Demystifying Salt Measurement LabelsDocument3 paginiDemystifying Salt Measurement LabelsJohnÎncă nu există evaluări

- Epcc MBC Pilot Plant Skid For Tgast-Electrical & Instrumentation WorksDocument11 paginiEpcc MBC Pilot Plant Skid For Tgast-Electrical & Instrumentation Workssaffririzal4237Încă nu există evaluări

- WELDER LIST (12 Pax) : InternalDocument2 paginiWELDER LIST (12 Pax) : Internalsaffririzal4237Încă nu există evaluări

- Qa/Qc Procedure: PGB/HO/19/2015/0094Document2 paginiQa/Qc Procedure: PGB/HO/19/2015/0094saffririzal4237Încă nu există evaluări

- Design Mix G30PDocument1 paginăDesign Mix G30Psaffririzal4237Încă nu există evaluări

- NDT Req D914Document184 paginiNDT Req D914saffririzal4237Încă nu există evaluări

- API6D Valve Inspection Test PDFDocument4 paginiAPI6D Valve Inspection Test PDFPalkesh TrivediÎncă nu există evaluări

- Dipetro Synergy Engineering SDN BHD: Visual Inspection ReportDocument2 paginiDipetro Synergy Engineering SDN BHD: Visual Inspection Reportsaffririzal4237Încă nu există evaluări

- NDT Req D914Document184 paginiNDT Req D914saffririzal4237Încă nu există evaluări

- Q3-201 MFL June 2016Document103 paginiQ3-201 MFL June 2016saffririzal4237Încă nu există evaluări

- Patching VerifiedDocument1 paginăPatching Verifiedsaffririzal4237Încă nu există evaluări

- Qa/Qc Procedure: PGB/HO/19/2015/0094Document2 paginiQa/Qc Procedure: PGB/HO/19/2015/0094saffririzal4237Încă nu există evaluări

- Claim FormDocument1 paginăClaim Formsaffririzal4237Încă nu există evaluări

- API 6D Valve Inspection TestDocument2 paginiAPI 6D Valve Inspection Testsaffririzal4237Încă nu există evaluări

- List of Inspection Tools (Qaqc)Document7 paginiList of Inspection Tools (Qaqc)saffririzal4237Încă nu există evaluări

- Circulation in Vacuum Pans: January 2004Document18 paginiCirculation in Vacuum Pans: January 2004REMINGTON SALAYAÎncă nu există evaluări

- Portfolio Management Banking SectorDocument133 paginiPortfolio Management Banking SectorNitinAgnihotri100% (1)

- Tabel Condenstatori SMDDocument109 paginiTabel Condenstatori SMDAllYn090888Încă nu există evaluări

- Indian Banking SystemDocument10 paginiIndian Banking SystemSony ChandranÎncă nu există evaluări

- ReportDocument4 paginiReportapi-463513182Încă nu există evaluări

- Swilliams Lesson6Document11 paginiSwilliams Lesson6api-276783092Încă nu există evaluări

- G.R. No. 226140 - People Vs EspirituDocument24 paginiG.R. No. 226140 - People Vs EspirituAlfred Robert BabasoroÎncă nu există evaluări

- Tds Uniqflow 372s enDocument1 paginăTds Uniqflow 372s enm daneshpourÎncă nu există evaluări

- Instructions Manual Skatey 150/250/400/600Document19 paginiInstructions Manual Skatey 150/250/400/600Denys GavrylovÎncă nu există evaluări

- Solar Winds OrionAPM DatasheetDocument4 paginiSolar Winds OrionAPM DatasheetArun J D'SouzaÎncă nu există evaluări

- NYU Stern Evaluation NewsletterDocument25 paginiNYU Stern Evaluation NewsletterCanadianValueÎncă nu există evaluări

- Opening Up The Prescriptive Authority PipelineDocument10 paginiOpening Up The Prescriptive Authority PipelineJohn GavazziÎncă nu există evaluări

- Working Capital Management, EleconDocument56 paginiWorking Capital Management, Eleconrrpatel_idol100% (1)

- Martillo Komac KB1500 Parts ManualDocument12 paginiMartillo Komac KB1500 Parts ManualJOHN FRADER ARRUBLA LOPEZ100% (1)

- BVM Type B Casing Tong ManualDocument3 paginiBVM Type B Casing Tong ManualJuan Gabriel GomezÎncă nu există evaluări

- Lecture 2 Leader-Centred PerspectivesDocument24 paginiLecture 2 Leader-Centred PerspectivesLIVINGSTONE CAESARÎncă nu există evaluări

- Wealth-Lab Developer 6.9 Performance: Strategy: Channel Breakout VT Dataset/Symbol: AALDocument1 paginăWealth-Lab Developer 6.9 Performance: Strategy: Channel Breakout VT Dataset/Symbol: AALHamahid pourÎncă nu există evaluări

- TT1 2lecture SpinningDocument29 paginiTT1 2lecture SpinninghaiÎncă nu există evaluări

- DLL Tle 6 Ict Entrepreneurship 6Document32 paginiDLL Tle 6 Ict Entrepreneurship 6Jewels Garcia100% (1)

- POLS219 Lecture Notes 7Document7 paginiPOLS219 Lecture Notes 7Muhammad Zainal AbidinÎncă nu există evaluări

- Project Proposal: Retail Environment Design To Create Brand ExperienceDocument3 paginiProject Proposal: Retail Environment Design To Create Brand ExperienceMithin R KumarÎncă nu există evaluări

- IPR GUIDE COVERS PATENTS, TRADEMARKS AND MOREDocument22 paginiIPR GUIDE COVERS PATENTS, TRADEMARKS AND MOREShaheen TajÎncă nu există evaluări

- Wireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossDocument5 paginiWireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossN Azzati LabibahÎncă nu există evaluări

- Bridge Ogres Little Fishes2Document18 paginiBridge Ogres Little Fishes2api-246705433Încă nu există evaluări

- Error 500 Unknown Column 'A.note' in 'Field List' - Joomla! Forum - Community, Help and SupportDocument1 paginăError 500 Unknown Column 'A.note' in 'Field List' - Joomla! Forum - Community, Help and Supportsmart.engineerÎncă nu există evaluări

- Paulson 2007 Year End Report Earns Nearly 600Document16 paginiPaulson 2007 Year End Report Earns Nearly 600Tunaljit ChoudhuryÎncă nu există evaluări

- Kitchen in The Food Service IndustryDocument37 paginiKitchen in The Food Service IndustryTresha Mae Dimdam ValenzuelaÎncă nu există evaluări

- OspndDocument97 paginiOspndhoangdo11122002Încă nu există evaluări

- Landmark Philippine and international cases on human rights, elections, and other legal issuesDocument4 paginiLandmark Philippine and international cases on human rights, elections, and other legal issuesSachieCasimiroÎncă nu există evaluări

- BurhanresumeDocument1 paginăBurhanresumeAbdul Rangwala0% (1)