Documente Academic

Documente Profesional

Documente Cultură

Welding Procedure Specifications-Bsen

Încărcat de

Abraham AbyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Welding Procedure Specifications-Bsen

Încărcat de

Abraham AbyDrepturi de autor:

Formate disponibile

11/9/2014 Welding Procedure Specifications

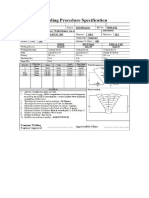

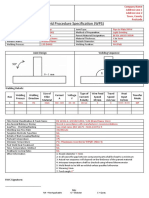

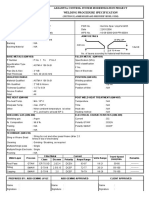

Welding Procedure Specification:- Example

Weld Procedure Number 30 P1 TIG 01 Issue A

Qualifying Welding Procedure (WPAR) WP T17/A

Method Of Preparation Machine and

Manufacturer: National Fabs Ltd

and Cleaning: Degrease

25 Lane End

Birkenshaw Parent Metal Specification: Grade 304L

Leeds Stainless Steel

Parent Metal Thickness 3 to 8mm Wall

Location: Workshop Pipe Outside Diameter 25 to 100mm

Welding Process: Manual TIG Welding Position: All Positions

Joint Type: Single Sided Butt Weld

Welding Progression: Upwards

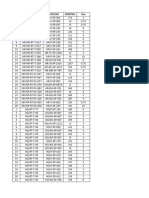

Joint Design Welding Sequences

Size Of Wire

Current Voltage Type Of Travel Heat

Run Process Filler Feed

A V Current/Polarity Speed Input

Metal Speed

1

TIG 1.2mm 70 - 90 DC-

2 And N/A N/A N/A N/A

TIG 1.6mm 80 - 140 DC-

Subs

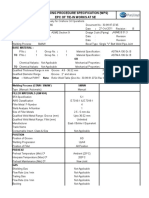

Welding Consumables:- Production Sequence

Type, Designation Trade Name: BS 2901 Part 2 : 308S92

Any Special Baking or Drying: No 1. Clean weld and 25mm

borders to bright metal

Gas Flux: Argon 99.99% Purity using approved solvent.

Gas Flow Rate - Shield: 8 - 12 LPM

2. Position items to be welded

- Backing: 5 LPM

ensuring good fit up and

apply purge

http://www.gowelding.com/wp/wps1.html 1/2

11/9/2014 Welding Procedure Specifications

Tungsten Electrode Type/ Size: 2% Thoriated 2.4mm Dia 3. Tack weld parts together

Details of Back Gouging/Backing: Gas Backing using TIG, tacks to at least

5mm min length

Preheat Temperature: 5C Min 4. Deposit root run using

Interpass temperature: 200C Max 1.2mm dia. wire.

Post Weld Heat Treatment Not Required 5. Inspect root run internally

Time, temperature, method: 6. Complete weld using

Heating and Cooling Rates*: 1.6mm dia wire using

stringer beads as required.

7. 100% Visual inspection of

completed weld

Revision History

Date Issue Changes Authorization

26/11/2000 A First Issue Jack Straw Jack Straw

Welding Procedure Specifications

Welding Qualifications Sub Menu

Page last updated 26 November 2000

http://www.gowelding.com/wp/wps1.html 2/2

S-ar putea să vă placă și

- Welding Procedure Specification ExampleDocument2 paginiWelding Procedure Specification ExampleShajahan ShagulÎncă nu există evaluări

- Toaz - Info Welding Procedure Specification Sample PRDocument2 paginiToaz - Info Welding Procedure Specification Sample PRKarim ZahranÎncă nu există evaluări

- Welding Procedure SpecificationDocument3 paginiWelding Procedure SpecificationGodwin A.udo-akanÎncă nu există evaluări

- Welding Procedure SpecificationDocument101 paginiWelding Procedure SpecificationNhien ManÎncă nu există evaluări

- WQRDocument3 paginiWQRMascot InternationalÎncă nu există evaluări

- WpsDocument2 paginiWpsjsmargate100% (1)

- Welding Procedure SpecificationsDocument2 paginiWelding Procedure SpecificationsGerhard Kemp0% (1)

- P WPSDocument3 paginiP WPSAnilkumar G NairÎncă nu există evaluări

- WPS & PQR - LTM - QW - PipeDocument7 paginiWPS & PQR - LTM - QW - PipeKAMALÎncă nu există evaluări

- Kaushik Shah Date: 2011 Form 001 - Format CDocument6 paginiKaushik Shah Date: 2011 Form 001 - Format CsriramÎncă nu există evaluări

- WPS SampleDocument6 paginiWPS SampleAshishÎncă nu există evaluări

- WPS SampleDocument6 paginiWPS SampleAshishÎncă nu există evaluări

- 螢幕截圖 2022-12-30 上午9.17.25Document1 pagină螢幕截圖 2022-12-30 上午9.17.25Dave CheungÎncă nu există evaluări

- Welding Procedure Specification: Monday, April 27, 2009 Page 1 of 2Document2 paginiWelding Procedure Specification: Monday, April 27, 2009 Page 1 of 2srb metallurgÎncă nu există evaluări

- DraftDocument32 paginiDraftAnilkumarÎncă nu există evaluări

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 paginiAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliÎncă nu există evaluări

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 paginiWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- A53 WPSDocument1 paginăA53 WPSNaqqash SajidÎncă nu există evaluări

- Welding Processes & InspectionDocument52 paginiWelding Processes & InspectionKaung Htet Cho100% (1)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 paginiWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEÎncă nu există evaluări

- ASTM Welding Tips A410 To A643Document20 paginiASTM Welding Tips A410 To A643MARIO HUAMANÎncă nu există evaluări

- Pwps Jo Wps Asme 016 Rev.001Document2 paginiPwps Jo Wps Asme 016 Rev.001Bagandi ManurungÎncă nu există evaluări

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 paginăWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraÎncă nu există evaluări

- Wps Format Tube Welding Cs With Tig V&s JalashawaDocument3 paginiWps Format Tube Welding Cs With Tig V&s JalashawaVISAKHAPATNAM MALAYALEES WELFARE ASSOCIATIONÎncă nu există evaluări

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 paginiWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 paginăWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamÎncă nu există evaluări

- New Microsoft Office Word DocumentDocument16 paginiNew Microsoft Office Word DocumentsarathÎncă nu există evaluări

- Preliminary Welding Procedure Specification (PWPS)Document2 paginiPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- WPS Welding Performance SpecialistDocument2 paginiWPS Welding Performance SpecialistGobinath GovindarajÎncă nu există evaluări

- Arl-Al - WPS-001 PDFDocument2 paginiArl-Al - WPS-001 PDFrajuajiÎncă nu există evaluări

- WQTDocument1 paginăWQTRamkunwar YadavÎncă nu există evaluări

- WPS Format For AWS D1.1 - WPS - SAWDocument1 paginăWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityÎncă nu există evaluări

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 paginiWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataÎncă nu există evaluări

- Wps Pqrwelding SCSP COUPON Phpapp02Document14 paginiWps Pqrwelding SCSP COUPON Phpapp02Oladimeji TaiwoÎncă nu există evaluări

- WPARDocument2 paginiWPARSc TanÎncă nu există evaluări

- Draft WPSDocument32 paginiDraft WPSAnilkumar G NairÎncă nu există evaluări

- WPS - 600 MW ChampaDocument7 paginiWPS - 600 MW ChampaAmjad PathanÎncă nu există evaluări

- WPS 2-A36 Rudder Shaft To FlangeDocument2 paginiWPS 2-A36 Rudder Shaft To FlangeNuwan RanaweeraÎncă nu există evaluări

- Template Pipe PlateDocument1 paginăTemplate Pipe PlateFarhan AmzarÎncă nu există evaluări

- Welding Procedure Specification (WPS)Document2 paginiWelding Procedure Specification (WPS)Ramadhan AdityaÎncă nu există evaluări

- QC E7018 CJP B-L1a OverheadDocument1 paginăQC E7018 CJP B-L1a Overheadwmajordan13Încă nu există evaluări

- FSIWPSREV0Document2 paginiFSIWPSREV0sooomilÎncă nu există evaluări

- WCBDocument5 paginiWCBSuresh KrishnanÎncă nu există evaluări

- Welding Positions: Section 2 PA PB PC PF PG PE PDDocument15 paginiWelding Positions: Section 2 PA PB PC PF PG PE PDPeter Beckwith100% (1)

- Piping WpsDocument37 paginiPiping WpsZulfokar FahdawiÎncă nu există evaluări

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 paginiPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluÎncă nu există evaluări

- 4 2WPSDocument2 pagini4 2WPSsaravanans18910% (1)

- Applications and Benefits of Adaptive Pulsed GMAWDocument140 paginiApplications and Benefits of Adaptive Pulsed GMAWroostercockburnÎncă nu există evaluări

- WPS-2 InchDocument2 paginiWPS-2 InchKarthikeyan MpÎncă nu există evaluări

- PQR - Gmaw BCCDocument2 paginiPQR - Gmaw BCCBasel MohammadÎncă nu există evaluări

- Welding: Debasis Mitra Inspection DepartmentDocument31 paginiWelding: Debasis Mitra Inspection DepartmentSanjoy Kr. DeyÎncă nu există evaluări

- Procedure Qualification SpecificationDocument4 paginiProcedure Qualification Specificationriyas.hvacworkÎncă nu există evaluări

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pagini011 WPS ASME TOP F 2022 - Rev.0megantara maromÎncă nu există evaluări

- WC9Document5 paginiWC9Suresh KrishnanÎncă nu există evaluări

- WPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWDocument1 paginăWPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWRaja HoneÎncă nu există evaluări

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 paginiWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaÎncă nu există evaluări

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 paginiIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Manual Standard WeldingDocument192 paginiManual Standard WeldingGEORGE IVAN0% (1)

- Missing Joint RTDocument16 paginiMissing Joint RTAbraham AbyÎncă nu există evaluări

- European Welding New-StandardsDocument39 paginiEuropean Welding New-StandardsJOECOOL67100% (3)

- Production Coordination Procedure (PSI)Document4 paginiProduction Coordination Procedure (PSI)Abraham AbyÎncă nu există evaluări

- ASME Code Requirements PDFDocument5 paginiASME Code Requirements PDFsusanwebÎncă nu există evaluări

- Al Nimr Tech Booklet PDFDocument52 paginiAl Nimr Tech Booklet PDFarnab mandalÎncă nu există evaluări

- Key Concepts 2 Heat InputDocument4 paginiKey Concepts 2 Heat InputBama RamachandranÎncă nu există evaluări

- Material Data Sheets and Element Data Sheets For PipingDocument133 paginiMaterial Data Sheets and Element Data Sheets For PipingJorge Durão100% (1)

- AWS - Welding SymbolsDocument1 paginăAWS - Welding SymbolsAli Saifullizan IsmailÎncă nu există evaluări

- Wps For 914 PipeDocument1 paginăWps For 914 PipeAbraham AbyÎncă nu există evaluări

- Wps For 914 PipeDocument1 paginăWps For 914 PipeAbraham AbyÎncă nu există evaluări

- Steel Standards PDFDocument50 paginiSteel Standards PDFstallone21Încă nu există evaluări

- Construction WastageDocument25 paginiConstruction WastageAbraham AbyÎncă nu există evaluări

- BS En-12285-1Document159 paginiBS En-12285-1shaggeruk85% (13)

- Manual Ultrasonic Inspection of Thin Metal WeldsDocument16 paginiManual Ultrasonic Inspection of Thin Metal WeldsSimon LeeÎncă nu există evaluări

- JIS G3131 Hot Roll Mild Steel Plates Sheet and StripDocument9 paginiJIS G3131 Hot Roll Mild Steel Plates Sheet and StripAnonymous uYGle1vucÎncă nu există evaluări

- Aws D1.1 D1.1M-2010Document569 paginiAws D1.1 D1.1M-2010Abraham Aby100% (4)

- HydroweldDocument1 paginăHydroweldAbraham AbyÎncă nu există evaluări

- T 6061Document5 paginiT 6061Zoran DanilovÎncă nu există evaluări

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFDocument2 paginiISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFWega Wahyu100% (2)

- Daman ListDocument936 paginiDaman Listashishpal2k20% (1)

- HC-97G FactsheetDocument1 paginăHC-97G FactsheettylerturpinÎncă nu există evaluări

- Pipe Supports PDFDocument10 paginiPipe Supports PDFleotvrdeÎncă nu există evaluări

- Good Construction Practice Book CBRI 2017Document36 paginiGood Construction Practice Book CBRI 2017Muhammed NaseefÎncă nu există evaluări

- Passmart PDFDocument3 paginiPassmart PDFdinhvu100% (1)

- AW139 Flight Manual POHDocument1.858 paginiAW139 Flight Manual POHAlp Erdem100% (9)

- Fraport AG KO Meeting Minutes HFB CompleteDocument32 paginiFraport AG KO Meeting Minutes HFB CompleteΡήγαςΑνδρέαςÎncă nu există evaluări

- ACI Limited-Final SlidesDocument22 paginiACI Limited-Final SlidestoxictouchÎncă nu există evaluări

- Insurance Service PPT MbaDocument23 paginiInsurance Service PPT MbaBabasab Patil (Karrisatte)100% (3)

- Large Surface MinersDocument6 paginiLarge Surface MinersNaveen Tiwari100% (1)

- Catalog RexnordDocument208 paginiCatalog RexnordBogdan Dumitrescu100% (1)

- Jiteendra Piping ForemanDocument7 paginiJiteendra Piping Foremanhitanshu100% (1)

- Aircraft Characteristics Unit 5Document10 paginiAircraft Characteristics Unit 5Hanamant HunashikattiÎncă nu există evaluări

- IBR 353-359 FlangesDocument5 paginiIBR 353-359 FlangesRajivharolikarÎncă nu există evaluări

- Appendix B Tonnage Measurement and Conversion FactorsDocument4 paginiAppendix B Tonnage Measurement and Conversion FactorsNitinShepurÎncă nu există evaluări

- Chapter 1 DescDocument22 paginiChapter 1 DescshambhoiÎncă nu există evaluări

- Bridge Design in FinlandDocument10 paginiBridge Design in Finlandअरुण कुमार सोनीÎncă nu există evaluări

- Airbus Family CCQMMF JOEB Report (120304)Document36 paginiAirbus Family CCQMMF JOEB Report (120304)pedatiÎncă nu există evaluări

- Product Catalogue 2016Document24 paginiProduct Catalogue 2016sineadÎncă nu există evaluări

- NDT Weld Visual Inspection ProcedureDocument4 paginiNDT Weld Visual Inspection ProcedureAvneet MaanÎncă nu există evaluări

- Strategic Report On National Inland Waterways in IndiaDocument76 paginiStrategic Report On National Inland Waterways in IndiaSaurabh SinhaÎncă nu există evaluări

- Indroduction To Supply Chain 1Document38 paginiIndroduction To Supply Chain 1Tansen John100% (2)

- Extended Downtime ChecklistDocument4 paginiExtended Downtime Checklistsigmasundar100% (1)

- Method Statement For Plastering WorkDocument15 paginiMethod Statement For Plastering Workstrikersam100% (9)

- Aws WJ 201409Document166 paginiAws WJ 201409German Favela100% (2)

- GALVALUMEDocument3 paginiGALVALUMETravis WoodÎncă nu există evaluări

- Lec 17 Highway Engineering - Rigid Pavemen DesignDocument14 paginiLec 17 Highway Engineering - Rigid Pavemen DesignDr Firas Asad80% (5)

- Injection MoldingDocument23 paginiInjection MoldingAditya DhikaÎncă nu există evaluări