Documente Academic

Documente Profesional

Documente Cultură

Begineers Guide - Connection Design2

Încărcat de

Manoj JaiswalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Begineers Guide - Connection Design2

Încărcat de

Manoj JaiswalDrepturi de autor:

Formate disponibile

A Beginners Guide to the Steel Construction Manual, 14th ed.

last modified: 9 Aug 2007

Example 5.2 by: TBQ

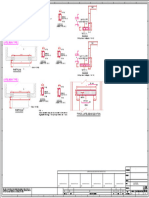

Given: The single angle connection shown. A992 steel and E70 electrodes are used. The

gusset plate is 3/8 inch thick. The Tension load is 25 k Dead Load and 40 k Wind Load. Use

LRFD.

Loads Material

D 25 k Fy 50 ksi

W 40 k Fu 65 ksi

FEXX 70 ksi

Gusset Angle

t 0.375 in Ag 2.86 in^2

leg 4 in

t 0.375 in

y 1.13 in

Wanted: Determine the size and required lengths of the welds so as to minimize the lap of the

connection.

a) All fillet welds are the same size

b) Fillet welds may be different sizes

Solution:

Pu 94 k (LRFD LC-4)

part (a): The largest weld size will be controlled either by the thickness of the angle leg

or shear rupture in the base metal.

amin 0.1875 in a(max effective) 0.4925 in

amax 0.3125 in

use, a 0.3125 in

Weld Strength Base Metal Strength

0.75 0.75

te 0.221 in tbm 0.375 in

rn 9.279 k/in rn 14.625 k/in

rn 6.960 k/in rn 10.969 k/in

Controlling strength, rn = 6.96 k/in (the weld metal controls over the base metal.)

req'd length of weld 13.51 in

Balance the Welds

Length Arm, y Ly

(in) (in) (in2)

L2 4.000 2 8.000

L3 1.816 4 7.263

L1 7.691 0 0.000

13.507 1.13 15.263

moments taken about "base", L1

part (b): For this part use the largest effective weld for L1 and the max allowed for L2 and L3.

Leg a rn Length Capacity Arm, y Moment

(in) (k/in) (in) (k) (in) (in-k)

L2 0.3125 6.960 4.000 27.84 2 55.68

L3 0.3125 6.960 1.816 12.64 4 50.54

L1 0.5000 10.969 4.880 53.53 0 0.00

94.00 1.13 106.22

You might observe that all we did was change the size and length of L1 in

both parts (a) and (b) the welds have the same capacities.

You need to complete drawings with appropriate weld symbols!

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Conc Grade DesignDocument1 paginăConc Grade DesignManoj JaiswalÎncă nu există evaluări

- Conc Footing DesignDocument1 paginăConc Footing DesignManoj JaiswalÎncă nu există evaluări

- Stair Connection - Metal Detail 2Document1 paginăStair Connection - Metal Detail 2Manoj JaiswalÎncă nu există evaluări

- Stair Connection - Metal Detail 1Document1 paginăStair Connection - Metal Detail 1Manoj JaiswalÎncă nu există evaluări

- Notches Shapes and DetailsDocument1 paginăNotches Shapes and DetailsManoj JaiswalÎncă nu există evaluări

- Detail 2 - Concrete Beam DetailsDocument1 paginăDetail 2 - Concrete Beam DetailsManoj JaiswalÎncă nu există evaluări

- Stair Connection - Metal Detail 2Document1 paginăStair Connection - Metal Detail 2Manoj JaiswalÎncă nu există evaluări

- ASCE 7-22 NotesDocument4 paginiASCE 7-22 NotesManoj JaiswalÎncă nu există evaluări

- Stair Connection - Metal Detail 5Document1 paginăStair Connection - Metal Detail 5Manoj JaiswalÎncă nu există evaluări

- Stair Connection - Metal Detail 3Document1 paginăStair Connection - Metal Detail 3Manoj JaiswalÎncă nu există evaluări

- Stair Connection - Metal Detail 3Document1 paginăStair Connection - Metal Detail 3Manoj JaiswalÎncă nu există evaluări

- Stair Connection - Metal Detail 5Document1 paginăStair Connection - Metal Detail 5Manoj JaiswalÎncă nu există evaluări

- General Sheet NotesDocument1 paginăGeneral Sheet NotesManoj JaiswalÎncă nu există evaluări

- Detail 4-Lintel 4Document1 paginăDetail 4-Lintel 4Manoj JaiswalÎncă nu există evaluări

- Pile DesignDocument65 paginiPile DesignManoj JaiswalÎncă nu există evaluări

- Duct Anchorage SupportDocument8 paginiDuct Anchorage SupportManoj JaiswalÎncă nu există evaluări

- SandyRA5DesignAboveBFE 508 FINAL2Document12 paginiSandyRA5DesignAboveBFE 508 FINAL2Manoj JaiswalÎncă nu există evaluări

- Duct Anchorage SupportDocument8 paginiDuct Anchorage SupportManoj JaiswalÎncă nu există evaluări

- Foundation Analysis and Design: Michael Valley, S.EDocument52 paginiFoundation Analysis and Design: Michael Valley, S.Esalahaddinsharif100% (3)

- Design Consideration in FLood PRoofing PDFDocument52 paginiDesign Consideration in FLood PRoofing PDFManoj JaiswalÎncă nu există evaluări

- ASCE 7 - 10 Page Component & Cladding ForcesDocument1 paginăASCE 7 - 10 Page Component & Cladding ForcesManoj JaiswalÎncă nu există evaluări

- P-752 Unit5Document94 paginiP-752 Unit5Josh JoshuaÎncă nu există evaluări

- Equivalent Frame Analysis For Slab Design Corley W.G., Jirsa J.O.Document10 paginiEquivalent Frame Analysis For Slab Design Corley W.G., Jirsa J.O.fukuroxyz100% (1)

- Flood Map - 12086C0612L Florida AreaDocument1 paginăFlood Map - 12086C0612L Florida AreaManoj JaiswalÎncă nu există evaluări

- Bond Development Lengths and Hook-7-2-2016v1 PDFDocument11 paginiBond Development Lengths and Hook-7-2-2016v1 PDFManoj JaiswalÎncă nu există evaluări

- Linterp 101 Rev1.1Document32 paginiLinterp 101 Rev1.1Manoj JaiswalÎncă nu există evaluări

- FLorida Code Flood Resistant ConstructionDocument9 paginiFLorida Code Flood Resistant ConstructionManoj JaiswalÎncă nu există evaluări

- AAI invites bids for Snack Bar facility at Kullu Manali AirportDocument22 paginiAAI invites bids for Snack Bar facility at Kullu Manali AirportManoj JaiswalÎncă nu există evaluări

- ACI APP D Supplemental Reinf PDFDocument2 paginiACI APP D Supplemental Reinf PDFManoj JaiswalÎncă nu există evaluări

- Pile Foundation DesignDocument82 paginiPile Foundation Designcuongnguyen89% (28)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- S2 RANGER Slag-Analyzer SolutionDocument30 paginiS2 RANGER Slag-Analyzer SolutionYassine ZamzamiÎncă nu există evaluări

- Matrix Acidizing of SandstonesDocument24 paginiMatrix Acidizing of SandstoneslapinÎncă nu există evaluări

- IEC20091118133046Document5 paginiIEC20091118133046SEANMÎncă nu există evaluări

- Class 10 Science Chapter 4 Carbon and Its Compounds Revision NotesDocument30 paginiClass 10 Science Chapter 4 Carbon and Its Compounds Revision NotesNanhe SinghÎncă nu există evaluări

- Development of An Electrochemical Metal-Ion Biosensor Using Self-Assembled Peptide NanofibrilsDocument7 paginiDevelopment of An Electrochemical Metal-Ion Biosensor Using Self-Assembled Peptide NanofibrilsRenan Guilherme de Oliveira GuihÎncă nu există evaluări

- Sodra Green - Safety Data SheetDocument2 paginiSodra Green - Safety Data Sheetibrahim sanlıÎncă nu există evaluări

- (L17) Twinning F12 PlagioklasDocument30 pagini(L17) Twinning F12 PlagioklasRadhitya Adzan HidayahÎncă nu există evaluări

- Laboratory 9 - Soil Classification Accdg To AASHTO and USCSDocument3 paginiLaboratory 9 - Soil Classification Accdg To AASHTO and USCSVincent GuiaÎncă nu există evaluări

- Gas and Oil - ExploitationDocument12 paginiGas and Oil - ExploitationAnonymous puv25NQenÎncă nu există evaluări

- Lab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Document20 paginiLab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Sunny BbaÎncă nu există evaluări

- Corona Treater: Operation and MainenanceDocument34 paginiCorona Treater: Operation and MainenanceJUAN RODRIGUEZÎncă nu există evaluări

- Lintels and ArchesDocument49 paginiLintels and Arches18 Architects50% (2)

- Villanova Torsion Test ReportDocument19 paginiVillanova Torsion Test ReportwaleedkhalillahmedÎncă nu există evaluări

- Liquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationDocument11 paginiLiquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationRajendrasinh PuvarÎncă nu există evaluări

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDocument1 paginăASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaÎncă nu există evaluări

- Compact C Pump Flyer v2Document2 paginiCompact C Pump Flyer v2GonzalezElizaÎncă nu există evaluări

- Brosur Globond Alumunium Composite PanelDocument8 paginiBrosur Globond Alumunium Composite PanelDede SubhanÎncă nu există evaluări

- Temperature Distribution in Concrete Bridges by E C Hambly PDFDocument6 paginiTemperature Distribution in Concrete Bridges by E C Hambly PDFAnonymous dxsNnL6S8hÎncă nu există evaluări

- Accurate Self-Damage Detection by Electrically Conductive Epoxy/graphene Nanocomposite FilmDocument12 paginiAccurate Self-Damage Detection by Electrically Conductive Epoxy/graphene Nanocomposite FilmAaron ChandÎncă nu există evaluări

- Injection Molding of XIAMETER™ Liquid Silicone Rubber: Consumer SolutionsDocument20 paginiInjection Molding of XIAMETER™ Liquid Silicone Rubber: Consumer SolutionsMustafa ŞENÎncă nu există evaluări

- Mechanical Design-Material PropertiesDocument61 paginiMechanical Design-Material Propertiesgaza001Încă nu există evaluări

- 04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Document420 pagini04 Nowy-Styl-Group Price-List Office-Furniture EXP-CZ-SK en BNOS-RG E06 2018Marin IonutÎncă nu există evaluări

- Advanced Nanotechnology Unlocks Potential of Thermoelectric GeneratorsDocument3 paginiAdvanced Nanotechnology Unlocks Potential of Thermoelectric GeneratorsmarijpotÎncă nu există evaluări

- ZOLLERN-Broschuere ZGF Legierungen ENGDocument16 paginiZOLLERN-Broschuere ZGF Legierungen ENGPablo PadillaÎncă nu există evaluări

- Hardness Conversion Chart, Carbide DepotDocument4 paginiHardness Conversion Chart, Carbide DepotMiguel A. FloresÎncă nu există evaluări

- Assessment PN1096617Document14 paginiAssessment PN1096617Amr TarekÎncă nu există evaluări

- WWW Visionalloys Com Stainless Steel Fasteners HTMLDocument4 paginiWWW Visionalloys Com Stainless Steel Fasteners HTMLNikhil JainÎncă nu există evaluări

- Rockwool Vs GlasswoolDocument8 paginiRockwool Vs Glasswooly2karein100% (1)

- Feng 2020Document9 paginiFeng 2020Gerapi EraÎncă nu există evaluări

- Analysis and Design of Steel I-Girder Bridge Using CSI-Bridge SoftwareDocument300 paginiAnalysis and Design of Steel I-Girder Bridge Using CSI-Bridge SoftwareChinmay TejaswiÎncă nu există evaluări