Documente Academic

Documente Profesional

Documente Cultură

GF Gravel Filter - EN

Încărcat de

MariusCapraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GF Gravel Filter - EN

Încărcat de

MariusCapraDrepturi de autor:

Formate disponibile

REMOVAL OF COARSE PARTICLES AND FOAM FROM

BIOGAS/SEWAGE GAS

CONDENSATE SEPARATION

FLASHBACK PROTECTION DEVICE

LOW MAINTENANCE

OPTIONAL DIFFERENTIAL PRESSURE GAUGING AND GRAVEL

REMOVAL

ENTIRELY MADE FROM 1.4571 STAINLESS STEEL

MADE IN AUSTRIA

ENVIRONTECS GRAVEL FILTER GF

Biogas from fermentation vessels or biogas cleaning nozzles or by flushing without the

reactors is saturated with water and partially need to open the filter.

loaded with dirt particles. In addition, foam

may enter the pipeline system. EnvironTec offers gravel filters for different flow

volumes and pressures. The gravel filter can

The EnvironTec GF gravel filter ensures the optionally be fitted with a gravel removal flange

simple coarse cleansing of the biogas. The gas as well as differential pressure gauging.

flows through a gravel filter layer during which

process dirt, foam and condensate droplets are EnvironTec gravel filters are entirely made from

separated out. 1.4571 stainless steel.

In the case of normal debris levels, the gravel

can be cleaned by water injection via the

APPLICATIONS AND SPECIFICATIONS

GAS COARSE CLEANING ON FERMENTATION GAS OR BIOGAS PLANTS

MADE FROM 1.4571 STAINLESS STEEL

OPTIONAL EQUIPMENT AVAILABLE

1

2

1 1 SOCKET FOR FLUSHING

2 GAS OUTLET

3 GRAVEL CONTAINER

3

4 SIPHON (INTERNAL)

5 BASE / CONDENSATE TANK

7

4

6 CONDENSED WATER DRAIN

5

7 GRAVEL REMOVAL (OPTIONAL)

6

8 GAS INLET

Gas inlet /

Diameter Height Flow rate

Model size outlet

A in mm B in mm Nm/h C in DN

GF 80 480 1400 80 50

GF 150 480 1400 150 65

GF 250 480 1400 250 80

GF 350 640 1400 350 100

GF 500 800 1400 500 125

GF 750 950 1500 750 150

GF 1000 1270 1500 1000 200

GF 1400 1600 1500 1400 250

TYPE SPECIFICATION

GF 80 XXX Y Z

Size Accessories

Gas outlet connection Cleaning equipment

XXX DIN DN DN

Y basic) basic specification with ball valve

d) incl. 2 cleaning nozzles in the lid

Z 0 standard

1 2 pressure gauges (gas inlet and outlet)

S-ar putea să vă placă și

- Filter Separators FACET F-Series-Clay-Treater-HousingsDocument2 paginiFilter Separators FACET F-Series-Clay-Treater-HousingsvaraÎncă nu există evaluări

- Fuel Dispensing and Transfer Filtration: Racor Filter Division EuropeDocument16 paginiFuel Dispensing and Transfer Filtration: Racor Filter Division EuropeFERNANDO LARAÎncă nu există evaluări

- Hps Blowdown TanksDocument4 paginiHps Blowdown TankssiswantoÎncă nu există evaluări

- KVS Diaphragm Valves Technical SpecificationsDocument8 paginiKVS Diaphragm Valves Technical SpecificationsThinh Chu100% (1)

- HV Two Stage Horizontal Liquid Filter SeparatorDocument2 paginiHV Two Stage Horizontal Liquid Filter SeparatorAnshul DhimanÎncă nu există evaluări

- Max Flow: 100 GPM (379 LPM) : SP80/90 Spin-On Filters Working Pressures To: Rated Static Burst To: Flow Range ToDocument4 paginiMax Flow: 100 GPM (379 LPM) : SP80/90 Spin-On Filters Working Pressures To: Rated Static Burst To: Flow Range Tofrancis_15inÎncă nu există evaluări

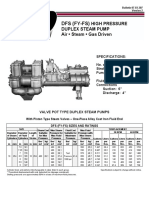

- Dag (Fg-Ag) : High Pressure Duplex Steam Pump Air - Steam - Gas DrivenDocument2 paginiDag (Fg-Ag) : High Pressure Duplex Steam Pump Air - Steam - Gas DrivenMaria Julieta Calderon OrtizÎncă nu există evaluări

- Butterfly Valve Type 567/578: Product DescriptionDocument9 paginiButterfly Valve Type 567/578: Product DescriptionshafeeqmÎncă nu există evaluări

- Pge101-420 RBQ1-N-3700Document12 paginiPge101-420 RBQ1-N-3700SyaifulIslamÎncă nu există evaluări

- Operation Instructions For Duplex-Body Flow Meter SkidDocument21 paginiOperation Instructions For Duplex-Body Flow Meter SkidGeorge GuoÎncă nu există evaluări

- Bulbioskid 01 enDocument4 paginiBulbioskid 01 enHenry WicaksanaÎncă nu există evaluări

- CP Condensate Pot - ENDocument2 paginiCP Condensate Pot - ENMariusCapraÎncă nu există evaluări

- SAVECO GCV Vertical Screw ScreenDocument4 paginiSAVECO GCV Vertical Screw ScreenDamir MatešićÎncă nu există evaluări

- Biogas Dehumidification System - ENDocument4 paginiBiogas Dehumidification System - ENkiller120Încă nu există evaluări

- O Rings CatalogueDocument87 paginiO Rings CatalogueVictor A. Claure ManzoniÎncă nu există evaluări

- Quality Thermal Expansion Tanks Under 40 CharactersDocument2 paginiQuality Thermal Expansion Tanks Under 40 CharactersLuis Elvis Bocanegra GarciaÎncă nu există evaluări

- BSF CatalogDocument2 paginiBSF CatalogKailas NimbalkarÎncă nu există evaluări

- Strainer Type 305Document5 paginiStrainer Type 305alexiel1806Încă nu există evaluări

- HERODocument2 paginiHEROozéias salvino cardosoÎncă nu există evaluări

- Model THE: Horizontal Drilling Duty PumpDocument2 paginiModel THE: Horizontal Drilling Duty PumpzhujianglongÎncă nu există evaluări

- DPCVDocument4 paginiDPCVjamil voraÎncă nu există evaluări

- 5/2 Air Operated, Spring/ Return Valve: Series: 32PDocument2 pagini5/2 Air Operated, Spring/ Return Valve: Series: 32PGaurav TripathiÎncă nu există evaluări

- Ficha Técnica d200Document2 paginiFicha Técnica d200ventas3Încă nu există evaluări

- Victaulic Flexible Hose Connecting To Regular Reliable SprinklerDocument27 paginiVictaulic Flexible Hose Connecting To Regular Reliable SprinklerOwais AhmedÎncă nu există evaluări

- 250YTDocument1 pagină250YTjesus_manrique2753Încă nu există evaluări

- NGA-PRO Stainless Steel Pumps for Oil, Water and Industrial UseDocument5 paginiNGA-PRO Stainless Steel Pumps for Oil, Water and Industrial UseRamil LazÎncă nu există evaluări

- Challenger enDocument2 paginiChallenger enluis miguel escobar rondinelÎncă nu există evaluări

- Twin Mac CQ ArcoDocument5 paginiTwin Mac CQ ArcoNitin SeenauthÎncă nu există evaluări

- Deublin Series 1690-1790-1890Document2 paginiDeublin Series 1690-1790-1890Noréddine DoumÎncă nu există evaluări

- Series CR: ApplicationsDocument6 paginiSeries CR: ApplicationsRaymond LimÎncă nu există evaluări

- 200rb Solenoid-Valves-Catalog-En-Us-4763170Document4 pagini200rb Solenoid-Valves-Catalog-En-Us-4763170desenvolvimentoÎncă nu există evaluări

- 4Document2 pagini4waseemybÎncă nu există evaluări

- Hoja de Datos para Conjunto Motor-Acople-Bomba Ansi 2196 Watercol 4X6-13 Mto 200522 Agua CorrosivaDocument4 paginiHoja de Datos para Conjunto Motor-Acople-Bomba Ansi 2196 Watercol 4X6-13 Mto 200522 Agua CorrosivaArturo Camacho SalazarÎncă nu există evaluări

- 13 - SRK S-PlatformDocument46 pagini13 - SRK S-PlatformLassané KINDOÎncă nu există evaluări

- FlowMon Catalogue 2 PDFDocument12 paginiFlowMon Catalogue 2 PDFsimbamikeÎncă nu există evaluări

- ITAP SpA's Technical Catalogue for Automatic Air-Vent ValvesDocument14 paginiITAP SpA's Technical Catalogue for Automatic Air-Vent ValvesCarlos EspÎncă nu există evaluări

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 paginiModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaÎncă nu există evaluări

- Bombas HydacDocument16 paginiBombas HydacTiago CamposÎncă nu există evaluări

- Gate-Valves Mud KingDocument13 paginiGate-Valves Mud KingWilson RiveraÎncă nu există evaluări

- VEL2105R2 0813 VF61 VF61E VF62 Small HousingDocument4 paginiVEL2105R2 0813 VF61 VF61E VF62 Small HousingGiovanny MosqueraÎncă nu există evaluări

- AGF SAND MEDIA FILTER GUIDEDocument16 paginiAGF SAND MEDIA FILTER GUIDECastoriadisÎncă nu există evaluări

- Dfs (Fy-Fs) : High Pressure Duplex Steam Pump Air - Steam - Gas DrivenDocument2 paginiDfs (Fy-Fs) : High Pressure Duplex Steam Pump Air - Steam - Gas DrivenMaria Julieta Calderon OrtizÎncă nu există evaluări

- 31 Stoddard-Silencers CatalogDocument16 pagini31 Stoddard-Silencers Catalogthanhhuyen100% (1)

- Spec He Urea P-4Document144 paginiSpec He Urea P-4M Aditya Regisyah PÎncă nu există evaluări

- Liquid Receivers: Refrigeration Research Vertical ReceiversDocument1 paginăLiquid Receivers: Refrigeration Research Vertical ReceiversMod KaewdaengÎncă nu există evaluări

- Reductor Presiune Abur RP45 DN15-100Document2 paginiReductor Presiune Abur RP45 DN15-100vvlad34Încă nu există evaluări

- ITT N-Series Pump CurveDocument8 paginiITT N-Series Pump CurvePumpdesignÎncă nu există evaluări

- Curb Stop Ball Valves: Features and UsesDocument2 paginiCurb Stop Ball Valves: Features and UsesVijay DaeÎncă nu există evaluări

- IM_en_8_260_110_F68V_F68YDocument2 paginiIM_en_8_260_110_F68V_F68Y2m8vzmsz5qÎncă nu există evaluări

- JRS Series TablasDocument4 paginiJRS Series TablascarlosÎncă nu există evaluări

- Pumping Solutions Slurry Pump CatalogueDocument39 paginiPumping Solutions Slurry Pump CatalogueCardoso MalacaoÎncă nu există evaluări

- CH 10 Additional ProductsDocument47 paginiCH 10 Additional Productssaddam khanÎncă nu există evaluări

- Amal Cast Arrester CatalogueDocument8 paginiAmal Cast Arrester CatalogueTifano KhristiyantoÎncă nu există evaluări

- Valvula de Seguridad RxsoDocument3 paginiValvula de Seguridad RxsoDavid MoleroÎncă nu există evaluări

- Catalog Series nl1 Aventics en 6911180Document172 paginiCatalog Series nl1 Aventics en 6911180Marcelo GarayÎncă nu există evaluări

- Series: Water SeparatorDocument46 paginiSeries: Water SeparatordAvId rObLeSÎncă nu există evaluări

- Drilling Fluids Processing HandbookDe la EverandDrilling Fluids Processing HandbookEvaluare: 4.5 din 5 stele4.5/5 (4)

- The Weir Direct-Acting Feed Pump - Working InstructionsDe la EverandThe Weir Direct-Acting Feed Pump - Working InstructionsÎncă nu există evaluări

- Working Guide to Drilling Equipment and OperationsDe la EverandWorking Guide to Drilling Equipment and OperationsEvaluare: 5 din 5 stele5/5 (9)

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsDe la EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsÎncă nu există evaluări

- BL On Line Analyzers 160 01 GBDocument5 paginiBL On Line Analyzers 160 01 GBMariusCapraÎncă nu există evaluări

- IBC 225084 Cubic Conatiner in Metal Crate Technical Data enDocument2 paginiIBC 225084 Cubic Conatiner in Metal Crate Technical Data enCesar VinciprovaÎncă nu există evaluări

- Sludge Dewatering Screw Press Szk1Document2 paginiSludge Dewatering Screw Press Szk1MariusCapraÎncă nu există evaluări

- Rotary Screen Removes Solids From WastewaterDocument3 paginiRotary Screen Removes Solids From WastewaterMariusCapraÎncă nu există evaluări

- Aquasystem Aerator Karistirici Brosur PDFDocument8 paginiAquasystem Aerator Karistirici Brosur PDFMariusCapraÎncă nu există evaluări

- VODATECH Flotation Units Remove Organic PollutionDocument2 paginiVODATECH Flotation Units Remove Organic PollutionMariusCapraÎncă nu există evaluări

- Waste Water Treatment MixerDocument8 paginiWaste Water Treatment MixerNaw AzÎncă nu există evaluări

- Aldec Decanter CentrifugeDocument4 paginiAldec Decanter CentrifugejailtonpierreÎncă nu există evaluări

- Technologies and Solutions For Handling of Contaminated Sediments State of The Art ReviewDocument132 paginiTechnologies and Solutions For Handling of Contaminated Sediments State of The Art ReviewMariusCapraÎncă nu există evaluări

- Fat and Oi L Ski Mmer Belt: Www. Pulsoni Ctechnologi Es. ComDocument2 paginiFat and Oi L Ski Mmer Belt: Www. Pulsoni Ctechnologi Es. ComMariusCapraÎncă nu există evaluări

- Compact and transport screenings with VODATECH screw presses and conveyorsDocument2 paginiCompact and transport screenings with VODATECH screw presses and conveyorsMariusCapraÎncă nu există evaluări

- Compact and transport screenings with VODATECH screw presses and conveyorsDocument2 paginiCompact and transport screenings with VODATECH screw presses and conveyorsMariusCapraÎncă nu există evaluări

- Drum Screen SDocument2 paginiDrum Screen SMariusCapraÎncă nu există evaluări

- Rotary Screen Removes Solids From WastewaterDocument3 paginiRotary Screen Removes Solids From WastewaterMariusCapraÎncă nu există evaluări

- Gashoder Generic DrawingDocument1 paginăGashoder Generic DrawingMariusCapraÎncă nu există evaluări

- Parabolic Screen Sps2Document2 paginiParabolic Screen Sps2MariusCapraÎncă nu există evaluări

- BDP Biological Desulphurisation - EN PDFDocument2 paginiBDP Biological Desulphurisation - EN PDFMariusCapraÎncă nu există evaluări

- Chemical Units Chu1Document2 paginiChemical Units Chu1MariusCapraÎncă nu există evaluări

- DMG Double Membrane Gasholder - ENDocument2 paginiDMG Double Membrane Gasholder - ENMariusCapraÎncă nu există evaluări

- FAII Biogas Flare - ENDocument2 paginiFAII Biogas Flare - ENMariusCapraÎncă nu există evaluări

- TN 010-Drip Traps Rev ADocument6 paginiTN 010-Drip Traps Rev AMariusCapraÎncă nu există evaluări

- SEPARATION OF ULTRAFINE PARTICLES AND HUMIDITY FROM BIOGASDocument2 paginiSEPARATION OF ULTRAFINE PARTICLES AND HUMIDITY FROM BIOGASMariusCapraÎncă nu există evaluări

- Metals RemovalDocument1 paginăMetals RemovalMariusCapraÎncă nu există evaluări

- CP Condensate Pot - ENDocument2 paginiCP Condensate Pot - ENMariusCapraÎncă nu există evaluări

- 245 VB12Document2 pagini245 VB12MariusCapraÎncă nu există evaluări

- Ion Exchange Design - Hand Calculation: Brian Windsor (Purolite International LTD)Document43 paginiIon Exchange Design - Hand Calculation: Brian Windsor (Purolite International LTD)Octiva100% (4)

- Brenntaplus VP1 MsdsDocument5 paginiBrenntaplus VP1 MsdsMariusCapraÎncă nu există evaluări

- Sea Containers SizeDocument1 paginăSea Containers SizeMariusCapraÎncă nu există evaluări

- Kaiser Water CalculatorDocument34 paginiKaiser Water CalculatorMariusCapraÎncă nu există evaluări

- Structural Optimization Procedure of A Composite Wind Turbine Blade For Reducing Both Material Cost and Blade WeightDocument20 paginiStructural Optimization Procedure of A Composite Wind Turbine Blade For Reducing Both Material Cost and Blade WeightNasser ShelilÎncă nu există evaluări

- Design Handbook IRC112Document111 paginiDesign Handbook IRC112zulfekharÎncă nu există evaluări

- COLUMN DESIGN REPORTDocument13 paginiCOLUMN DESIGN REPORTdongshengÎncă nu există evaluări

- Yamaha FZS600 Fazer 1999 Parts CatalogueDocument49 paginiYamaha FZS600 Fazer 1999 Parts CatalogueAndr224Încă nu există evaluări

- Product Information: Diesel Extra LD 15W40Document2 paginiProduct Information: Diesel Extra LD 15W40movie hunterÎncă nu există evaluări

- Hand Operated Can CrusherDocument60 paginiHand Operated Can CrusherParen Trivedi100% (2)

- Caterpillar C13 C15 C18 Engine Fault Codes DTCDocument55 paginiCaterpillar C13 C15 C18 Engine Fault Codes DTCMiguel Angel Escobedo Reyes100% (2)

- Check List-For LMI-on Bypassing Protn & Interlocks-OGN/OPS/SYST/005-021Document13 paginiCheck List-For LMI-on Bypassing Protn & Interlocks-OGN/OPS/SYST/005-021rudra singhÎncă nu există evaluări

- Finite Element Analysis of Unreinforced Masonry Walls: MahammedDocument14 paginiFinite Element Analysis of Unreinforced Masonry Walls: MahammedSaad HneidiÎncă nu există evaluări

- PIBCVDocument8 paginiPIBCVmdalt9180Încă nu există evaluări

- Handbook of Practical Gear DesignDocument7 paginiHandbook of Practical Gear DesignPooria1989Încă nu există evaluări

- Cessna 172M CHECKLISTDocument3 paginiCessna 172M CHECKLISTDev ShahÎncă nu există evaluări

- Pumps and SystemsDocument5 paginiPumps and SystemsDhi AdhiÎncă nu există evaluări

- V2607-DI-T-E3B: Kubota 07 SeriesDocument2 paginiV2607-DI-T-E3B: Kubota 07 SeriesRodrigoThuLokithoPkmz0% (1)

- 2006 VA Powertrain SprinterDocument292 pagini2006 VA Powertrain Sprinteractuator79100% (2)

- Gravity Sewer Acceptance Testing Results Sheet: Sewer Pipeline Pressure TestDocument1 paginăGravity Sewer Acceptance Testing Results Sheet: Sewer Pipeline Pressure TestLulouch Raiz100% (1)

- BULLET 350 KS TECHNICAL SPECSDocument2 paginiBULLET 350 KS TECHNICAL SPECSKamsutra YogiÎncă nu există evaluări

- INSTRUMENTED PILE LOAD TEST REPORTDocument24 paginiINSTRUMENTED PILE LOAD TEST REPORTsandrock92Încă nu există evaluări

- Steel Interstop Stopper Rod Mechanism Type SRM L 1812 en 181206 MonDocument3 paginiSteel Interstop Stopper Rod Mechanism Type SRM L 1812 en 181206 MonAdarsh JhaÎncă nu există evaluări

- (Datasheet) Eriks - Ketron Peek-1000Document2 pagini(Datasheet) Eriks - Ketron Peek-1000Carlos AlbertoÎncă nu există evaluări

- Axial flow fan guideDocument2 paginiAxial flow fan guideThanhÎncă nu există evaluări

- Rail Transportation Safety Investigation Report R21C0070Document7 paginiRail Transportation Safety Investigation Report R21C0070CTV CalgaryÎncă nu există evaluări

- 4.DB Flats (1-7) & SMDB TypicalDocument9 pagini4.DB Flats (1-7) & SMDB TypicalhpzenÎncă nu există evaluări

- Api Bottom Load ValveDocument2 paginiApi Bottom Load ValveMạnh Ngô ĐứcÎncă nu există evaluări

- Owners manual for Maveric GK-32A go kartDocument18 paginiOwners manual for Maveric GK-32A go kartedgar santanaÎncă nu există evaluări

- MT 2010Document8 paginiMT 2010kokonunezÎncă nu există evaluări

- Self-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMDocument219 paginiSelf-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMblue4882Încă nu există evaluări

- 6100 6200 Tractors Europe Edition IntroductionDocument16 pagini6100 6200 Tractors Europe Edition Introductionceli gimÎncă nu există evaluări

- Tokico P.D. Oil Flowmeter KatalogDocument6 paginiTokico P.D. Oil Flowmeter KatalogPRIMA UTAMA MULYAÎncă nu există evaluări

- Flushmate 501B Series Owners Service ManualDocument6 paginiFlushmate 501B Series Owners Service ManualiloÎncă nu există evaluări