Documente Academic

Documente Profesional

Documente Cultură

KTR Mounting Inst. 200-201

Încărcat de

sinamicsDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

KTR Mounting Inst. 200-201

Încărcat de

sinamicsDrepturi de autor:

Formate disponibile

KTR Kupplungstechnik CLAMPEX KTR-N 40813 EN

GmbH KTR 200 / KTR 201 sheet: 1

D-48407 Rheine mounting instructions edition: 5

The CLAMPEX clamping set is a frictionally engaged, detachable shaft - hub connection for cylindrical

shafts and bores without feather key.

General Hints

Please read through these mounting instructions carefully before assembling the clamping set.

Please pay special attention to the safety instructions!

The mounting instructions are part of your product. Please keep them carefully and close to the

clamping set.

The copyright for these mounting instructions remains with KTR Kupplungstechnik GmbH.

Safety and Advice Hints

STOP DANGER! Danger of injury to persons.

! CAUTION! Damages on the machine possible.

) ATTENTION! Pointing to important items.

PRECAUTION! Hints concerning explosion protection.

General Hints to Danger

DANGER!

STOP

With assembly and disassembly of the clamping set it has to be made sure that the

entire drive train is protected against unintentional engagement. You can be

seriously hurt by rotating parts. Please make absolutely sure to read through and

observe the following safety instructions.

All operations on and with the clamping set have to be performed taking into account "safety first".

Please make sure to disengage the power pack before you perform your work at the clamping set.

Protect the power pack against unintentional engagement, e. g. by providing hints at the place of

engagement or removing the fuse for current supply.

Do not touch the operation area of the machine as long as it is in operation.

Please protect the rotating drive parts against unintentional touch. Please provide for the necessary

protection devices and caps.

Proper Use

You may only assemble, operate and maintain the coupling if you

carefully read through the mounting instructions and understood them

had technical training

are authorized to do so by your company

The clamping set may only be used in accordance with the technical data (see table 1 and 2).

Unauthorized modifications on the clamping set are not admissible. We do not take any warranty for

resulting damages. To further develop the product we reserve the right for technical modifications.

The CLAMPEX clamping set described in here corresponds to the technical status at the time of

printing of these mounting instructions.

Schutzvermerk Gezeichnet: 23.01.09 Pz/Hg Ersatz fr: KTR-N vom 14.02.08

ISO 16016 beachten. Geprft: 23.01.09 Pz Ersetzt durch:

KTR Kupplungstechnik CLAMPEX KTR-N 40813 EN

GmbH KTR 200 / KTR 201 sheet: 2

D-48407 Rheine mounting instructions edition: 5

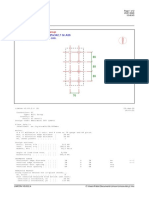

Technical Data KTR 200

1) These are the maximum screw

tightening torques. They can be

reduced to max. 40 % of the

aforementioned figures with T,

Fax and PW , PN being reduced

picture 1: CLAMPEX KTR 200 proportionally.

Table 1:

clamping screws transmittable surface pressure

dimensions

DIN EN 4762 12.9 torque or between clamping

[mm] weight

total = 0,14 axial force set [N/mm2]

1) ~ kg

z TA T Fax shaft hub

dxD B B1 B2 B3 D1 M

No. [Nm] [Nm] [kN] PW PN

20 x 47 48 42 31 26 53 M6 6 17 513 51 291 124 0,41

22 x 47 48 42 31 26 53 M6 6 17 564 51 264 124 0,38

24 x 50 48 42 31 26 56 M6 6 17 616 51 242 116 0,42

25 x 50 48 42 31 26 56 M6 6 17 641 51 233 116 0,41

28 x 55 48 42 31 26 61 M6 6 17 718 51 208 106 0,50

30 x 55 48 42 31 26 61 M6 6 17 769 51 194 106 0,47

32 x 60 48 42 31 26 66 M6 8 17 1094 68 242 129 0,56

35 x 60 48 42 31 26 66 M6 8 17 1197 68 222 129 0,53

38 x 65 48 42 31 26 71 M6 8 17 1299 68 204 119 0,62

40 x 65 48 42 31 26 71 M6 8 17 1368 68 194 119 0,57

42 x 75 59 51 35 30 81 M8 6 41 1990 95 222 124 1,01

45 x 75 59 51 35 30 81 M8 6 41 2132 95 207 124 0,98

48 x 80 59 51 35 30 86 M8 8 41 3033 126 259 155 1,09

50 x 80 59 51 35 30 86 M8 8 41 3159 126 248 155 1,07

55 x 85 59 51 35 30 91 M8 8 41 3475 126 226 146 1,15

60 x 90 59 51 35 30 96 M8 8 41 3791 126 207 138 1,23

65 x 95 59 51 35 30 101 M8 8 41 4107 126 191 131 1,32

70 x 110 70 60 45 40 119 M10 8 83 7023 201 211 134 2,18

75 x 115 70 60 45 40 124 M10 8 83 7524 201 197 129 2,30

80 x 120 70 60 45 40 129 M10 8 83 8026 201 185 123 2,44

85 x 125 70 60 45 40 134 M10 10 83 10659 251 217 148 2,55

90 x 130 70 60 45 40 139 M10 10 83 11286 251 205 142 2,67

95 x 135 66 60 45 40 144 M10 10 83 11373 239 186 131 2,80

100 x 145 80 68 52 45 155 M12 8 145 14607 292 191 132 3,90

110 x 155 80 68 52 45 165 M12 8 145 16068 292 174 123 4,20

120 x 165 80 68 52 45 175 M12 10 145 21910 365 199 145 4,50

130 x 180 80 68 52 45 188 M12 12 145 28483 438 221 159 5,50

140 x 190 90 76 58 50 199 M14 10 210 32023 457 193 142 6,60

150 x 200 90 76 58 50 209 M14 12 210 41173 549 216 162 6,90

160 x 210 90 76 58 50 219 M14 12 210 43918 549 202 154 7,40

170 x 225 90 76 58 50 234 M14 14 210 54440 640 222 168 8,60

180 x 235 90 76 58 50 244 M14 14 210 57642 640 210 161 9,10

Schutzvermerk Gezeichnet: 23.01.09 Pz/Hg Ersatz fr: KTR-N vom 14.02.08

ISO 16016 beachten. Geprft: 23.01.09 Pz Ersetzt durch:

KTR Kupplungstechnik CLAMPEX KTR-N 40813 EN

GmbH KTR 200 / KTR 201 sheet: 3

D-48407 Rheine mounting instructions edition: 5

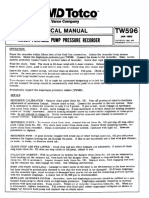

Technical Data KTR 201

1) These are the maximum screw

tightening torques. They can be

reduced to max. 40 % of the

aforementioned figures with T,

Fax and PW , PN being reduced

picture 2: CLAMPEX KTR 201 proportionally.

Table 2:

clamping screws transmittable surface pressure

dimensions

DIN EN 4762 12.9 torque or between clamping

[mm] weight

total = 0,14 axial force set [N/mm2]

1) ~ kg

z TA T Fax shaft hub

dxD B B1 B2 B3 D1 M

No. [Nm] [Nm] [kN] PW PN

20 x 47 48 42 31 26 53 M6 6 17 332 33 178 76 0,42

22 x 47 48 42 31 26 53 M6 6 17 366 33 162 76 0,39

24 x 50 48 42 31 26 56 M6 6 17 399 33 149 71 0,43

25 x 50 48 42 31 26 56 M6 6 17 415 33 143 71 0,42

28 x 55 48 42 31 26 61 M6 6 17 465 33 127 65 0,51

30 x 55 48 42 31 26 61 M6 6 17 466 33 119 65 0,48

32 x 60 48 42 31 26 66 M6 8 17 709 44 149 79 0,57

35 x 60 48 42 31 26 66 M6 8 17 776 44 136 79 0,54

38 x 65 48 42 31 26 71 M6 8 17 842 44 125 73 0,63

40 x 65 48 42 31 26 71 M6 8 17 886 44 119 73 0,58

42 x 75 59 51 35 30 81 M8 6 41 1290 61 136 76 1,02

45 x 75 59 51 35 30 81 M8 6 41 1382 61 127 76 0,99

48 x 80 59 51 35 30 86 M8 8 41 1965 82 159 95 1,10

50 x 80 59 51 35 30 86 M8 8 41 2047 82 152 95 1,08

55 x 85 59 51 35 30 91 M8 8 41 2252 82 139 90 1,16

60 x 90 59 51 35 30 96 M8 8 41 2456 82 127 85 1,24

65 x 95 59 51 35 30 101 M8 8 41 2661 82 117 80 1,33

70 x 110 70 60 45 40 119 M10 8 83 4550 130 130 83 2,29

75 x 115 70 60 45 40 124 M10 8 83 4875 130 121 79 2,41

80 x 120 70 60 45 40 129 M10 8 83 5200 130 113 76 2,56

85 x 125 70 60 45 40 134 M10 10 83 6907 163 133 91 2,67

90 x 130 70 60 45 40 139 M10 10 83 7313 163 126 87 2,80

95 x 135 66 60 45 40 144 M10 10 83 7501 158 116 82 2,93

100 x 145 80 68 52 45 155 M12 8 145 9465 189 117 81 4,10

110 x 155 80 68 52 45 165 M12 8 145 10411 189 107 76 4,40

120 x 165 80 68 52 45 175 M12 10 145 14197 237 122 89 4,72

130 x 180 80 68 52 45 188 M12 12 145 18456 284 136 98 5,74

140 x 190 90 76 58 50 199 M14 10 230 22726 325 130 95 6,92

150 x 200 90 76 58 50 209 M14 12 230 29219 390 145 109 7,24

160 x 210 90 76 58 50 219 M14 12 230 31167 390 136 104 7,76

170 x 225 90 76 58 50 234 M14 14 230 38634 455 149 113 8,98

180 x 235 90 76 58 50 244 M14 14 230 40907 455 141 108 9,50

Schutzvermerk Gezeichnet: 23.01.09 Pz/Hg Ersatz fr: KTR-N vom 14.02.08

ISO 16016 beachten. Geprft: 23.01.09 Pz Ersetzt durch:

KTR Kupplungstechnik CLAMPEX KTR-N 40813 EN

GmbH KTR 200 / KTR 201 sheet: 4

D-48407 Rheine mounting instructions edition: 5

The clamping set is generally delivered in assembled condition.

Tolerances, surfaces

A good rotating process is sufficient: Highest permissible tolerance:

Rz 16m d = h8/H8 - shaft/hub

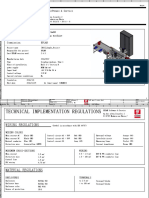

Components of CLAMPEX KTR 200 / KTR 201

Component Quantity Designation

1 1 external ring (slotted)

2 1 internal ring (slotted)

3 1 axial ring

4 see table 1 and 2 cap screw DIN EN ISO 4762

picture 3: CLAMPEX KTR 200 picture 4: CLAMPEX KTR 201

)

ATTENTION!

Dirty or used clamping sets must be disassembled, cleaned and afterwards oiled

with thin-bodied oil (e. g. Castrol 4 in 1 or Klber Quietsch-Ex) before the assembly.

The bodied oil assembly of the clamping set is to be effected acc. to picture 3 and

picture 4.

CAUTION!

! When assembling the internal ring (part 2) and the external ring (part 1) please

make sure that the slots are staggered. The forcing thread of the internal ring

(part 2) must not be congruent with the slot of the external ring (part 1).

Assembly

Check the position of shaft and hub regarding the stipulated tolerance (h8/H8).

Clean the hub bore and the shaft and afterwards oil them with thin-bodied oil (e. g. Castrol 4 in 1 or

Klber Quietsch-Ex).

CAUTION!

! Do not use oils and greases with molybdenum disulphide or high pressure

additions as well as slide grease pastes.

Unscrew the clamping screws slightly and insert the clamping set KTR 200 / KTR 201 between

shaft and hub.

Slightly tighten the clamping screws manually and align the clamping set with hub part.

Schutzvermerk Gezeichnet: 23.01.09 Pz/Hg Ersatz fr: KTR-N vom 14.02.08

ISO 16016 beachten. Geprft: 23.01.09 Pz Ersetzt durch:

KTR Kupplungstechnik CLAMPEX KTR-N 40813 EN

GmbH KTR 200 / KTR 201 sheet: 5

D-48407 Rheine mounting instructions edition: 5

Assembly

Continuation:

Regarding KTR 201 please make sure that the axial supporting ring (component 3) fits closely and

evenly.

Tighten the clamping screws evenly and crosswise. Increase the tightening torque step by step.

This procedure must be repeated until the tightening torque indicated in table 3 is reached with all

clamping screws.

Table 3:

type of clamping set 200 / 201 200 / 201 200 / 201 200 / 201 200 201

screw size M M6 M8 M10 M12 M14 M14

tightening torque TA [Nm] 17 41 83 145 210 230

)

ATTENTION!

During the assembly of the KTR 200 an axial displacement of the hub is effected.

Disassembly

DANGER!

STOP

Loosened or falling drive parts can cause injuries to persons or damages to the

machines.

Safe the drive parts before the disassembly.

Loose all clamping screws evenly one after the other and unscrew them.

Screw the clamping screws into the threads of the internal ring (component 2).

Tighten the clamping screws evenly and crosswise. Increase the tightening torque step by step until

the external ring (component 1) and the internal ring (component 2) are separated.

Remove the unscrewed clamping set between shaft and hub.

picture 5: unscrew the clamping set KTR 200 picture 6: unscrew the clamping set KTR 201

CAUTION!

! In case of non-observance of these hints or in case of non-considerance of the

operating conditions regarding the selection of the clamping set, the function of the

clamping set can be influenced.

Disposal of waste: Defective clamping sets must be cleaned and scrapped.

Schutzvermerk Gezeichnet: 23.01.09 Pz/Hg Ersatz fr: KTR-N vom 14.02.08

ISO 16016 beachten. Geprft: 23.01.09 Pz Ersetzt durch:

KTR Kupplungstechnik CLAMPEX KTR-N 40813 EN

GmbH KTR 200 / KTR 201 sheet: 6

D-48407 Rheine mounting instructions edition: 5

Remark for the use in explosive applications according to ATEX 95

For the use in explosive applications the type and size of clamping set (applying for category 3 only)

has to be selected in a way that starting from the peak torque of the machine including all operating

parameters to the rated torque of the clamping set there is a service factor of at least s = 2.

CLAMPEX clamping sets are not part of the standard 94/9/EG, since

this product is a torsionally rigid, backlash-free, frictionally engaged connection with one or more

taper clamping ring(s) by means of several screws.

(Clamping screws have to be secured, e. g. by means of a medium strength adhesive).

due to the design of clamping sets a fracture/failure does not have to be expected (frictional heat is

only caused by improper assembly/tightening torques, i. e. not in case of proper use).

Schutzvermerk Gezeichnet: 23.01.09 Pz/Hg Ersatz fr: KTR-N vom 14.02.08

ISO 16016 beachten. Geprft: 23.01.09 Pz Ersetzt durch:

S-ar putea să vă placă și

- S42SXG - Parts Book - 03 - 09 - 07Document265 paginiS42SXG - Parts Book - 03 - 09 - 07Emad M. NaguibÎncă nu există evaluări

- VulkanCoupling (Wartsila)Document37 paginiVulkanCoupling (Wartsila)Denisse100% (2)

- Home Sewing Machine Parts Reference GuideDocument25 paginiHome Sewing Machine Parts Reference Guide20574370Încă nu există evaluări

- Spec 45440Document2 paginiSpec 45440ger80Încă nu există evaluări

- Gearless MDX26MLDocument4 paginiGearless MDX26MLAndres GonzalezÎncă nu există evaluări

- Machine Elements Design Guide for Threaded Joints and Power ScrewsDocument72 paginiMachine Elements Design Guide for Threaded Joints and Power Screwsf2012265Încă nu există evaluări

- Deh P3000RDocument68 paginiDeh P3000Rpite3Încă nu există evaluări

- Catalog Full KTM 65 (2012)Document40 paginiCatalog Full KTM 65 (2012)ichsan uyeeÎncă nu există evaluări

- Task 2.2Document15 paginiTask 2.2Mordecai de ValoisÎncă nu există evaluări

- Lug - On - FlangeDocument17 paginiLug - On - Flangeshaishav100% (1)

- 10148755Document2 pagini10148755kev YÎncă nu există evaluări

- Connection DesignDocument17 paginiConnection Designrekcah ehtÎncă nu există evaluări

- En 21 171Document1 paginăEn 21 171pham tamÎncă nu există evaluări

- Fan duct system sound power levels and noise criteriaDocument1 paginăFan duct system sound power levels and noise criteriaAhmed AliÎncă nu există evaluări

- Enerpacp 141Document4 paginiEnerpacp 141MARCO HernándezÎncă nu există evaluări

- TorqueDocument25 paginiTorquesami4330100% (3)

- Backstay connection design and analysisDocument4 paginiBackstay connection design and analysisRené Mella CidÎncă nu există evaluări

- S10148930Document2 paginiS10148930kev YÎncă nu există evaluări

- John Deere - Parts Catalog - Frame 5 - 60D Power Flow HeadDocument2 paginiJohn Deere - Parts Catalog - Frame 5 - 60D Power Flow Headbruno.menezesÎncă nu există evaluări

- CONNECTION: G1 - Bolt Group: Gusset Plate (Min.) : 152,2x25x342,7 Gr.A36 Bolts: 8 X 1" A325ST/N in 2 ColsDocument2 paginiCONNECTION: G1 - Bolt Group: Gusset Plate (Min.) : 152,2x25x342,7 Gr.A36 Bolts: 8 X 1" A325ST/N in 2 ColsmascalzoneÎncă nu există evaluări

- DME Slide Retainer - AllDocument5 paginiDME Slide Retainer - AllAmit RawatÎncă nu există evaluări

- MWM 616V16Document107 paginiMWM 616V16Dhudhik Arief Hadiyanto100% (2)

- Tiller Arm (Gas Strut) - Combilift Spare PartsDocument3 paginiTiller Arm (Gas Strut) - Combilift Spare PartsCristian Elías Cruces CaamañoÎncă nu există evaluări

- Dextra: System DescriptionDocument10 paginiDextra: System DescriptionHiba SolimanÎncă nu există evaluări

- Anchor and Base Plate CalculationDocument6 paginiAnchor and Base Plate Calculationselahattin_erturk06Încă nu există evaluări

- Hea160 Ebsp 1Document4 paginiHea160 Ebsp 1Bùi Trọng QuỳnhÎncă nu există evaluări

- 8999 2118 00 Diagrams and DrawingsDocument60 pagini8999 2118 00 Diagrams and DrawingsJorge ChapoñanÎncă nu există evaluări

- Hydraulic Cylinders CHDocument8 paginiHydraulic Cylinders CHStoianovici CristianÎncă nu există evaluări

- Tdkelectronicsinc B41695a5687q9 Datasheets 2672Document17 paginiTdkelectronicsinc B41695a5687q9 Datasheets 2672СергейВойчукÎncă nu există evaluări

- Fin Plate Connection DesignDocument3 paginiFin Plate Connection DesignihpeterÎncă nu există evaluări

- T21 Thread Dimensions Tightening Torque Values and Dimensions For Cable GlandsDocument2 paginiT21 Thread Dimensions Tightening Torque Values and Dimensions For Cable GlandsYÎncă nu există evaluări

- Akn Series: Metal Bellows CouplingDocument1 paginăAkn Series: Metal Bellows CouplingSueli ZaniÎncă nu există evaluări

- Pioneer Deh 3100r Deh 3130rDocument69 paginiPioneer Deh 3100r Deh 3130revagualdaÎncă nu există evaluări

- Pioneer DEH 1330R, DeH 1300R, DeH 1310 Service ManualDocument75 paginiPioneer DEH 1330R, DeH 1300R, DeH 1310 Service Manualmomi201150% (2)

- FWD Transfer Box Repair Manual SectionsDocument116 paginiFWD Transfer Box Repair Manual Sectionsroparts cluj100% (1)

- Report_13735842251518450386Document4 paginiReport_13735842251518450386noe mattaÎncă nu există evaluări

- WT WR: Connecting Main and Secondary Timber BeamsDocument7 paginiWT WR: Connecting Main and Secondary Timber BeamsvelucciÎncă nu există evaluări

- Pioneer Deh-P3300 crt2689Document27 paginiPioneer Deh-P3300 crt2689Rob RuzÎncă nu există evaluări

- M/D Totco:r I: Psi IsDocument6 paginiM/D Totco:r I: Psi IsLuis AlbarracinÎncă nu există evaluări

- Roomside Calculation SheetDocument7 paginiRoomside Calculation Sheetsunii19847908Încă nu există evaluări

- Design of Keys, Splines, BearingsDocument20 paginiDesign of Keys, Splines, BearingsSankit IngaleÎncă nu există evaluări

- DBM 2000 XS, DBM 2000 EV and DBM 2500 EV: Engine Removal FromDocument28 paginiDBM 2000 XS, DBM 2000 EV and DBM 2500 EV: Engine Removal FromNicoleta CosteaÎncă nu există evaluări

- Acumulador.Document3 paginiAcumulador.Teobaldo Silva CascaÎncă nu există evaluări

- CPT Clampel 03Document16 paginiCPT Clampel 03trevorwoestÎncă nu există evaluări

- Drive Train Model RR640Document87 paginiDrive Train Model RR640Nicoleta Costea83% (6)

- Industrial Low Voltage Cables: Construction: ResistanceDocument2 paginiIndustrial Low Voltage Cables: Construction: ResistanceFer F. Rodriguez CÎncă nu există evaluări

- Grundfosliterature 2616Document22 paginiGrundfosliterature 2616Sal MendezÎncă nu există evaluări

- Agitator Design 5 PDF FreeDocument36 paginiAgitator Design 5 PDF FreeMeisam MomeniÎncă nu există evaluări

- CATERPILLAR Progressive ReferencesDocument6 paginiCATERPILLAR Progressive ReferencesRobert HutapeaÎncă nu există evaluări

- Hydrostatic Transmission Circuit "Rexroth" System On: DBM2000 XS DBM2000 EV DBM2500 EV DBM3500 EVDocument39 paginiHydrostatic Transmission Circuit "Rexroth" System On: DBM2000 XS DBM2000 EV DBM2500 EV DBM3500 EVNicoleta Costea100% (1)

- 350REOZDD: Model: Spec: GroupDocument2 pagini350REOZDD: Model: Spec: GroupTom LeonardÎncă nu există evaluări

- New Holland TF TX Combine Service ManualDocument1.050 paginiNew Holland TF TX Combine Service ManualAndrew DaviesÎncă nu există evaluări

- Trio TV85B VSI Parts Manual AbelDocument34 paginiTrio TV85B VSI Parts Manual AbelvictorpalaciossÎncă nu există evaluări

- Tas Lockingassemblie Eng r03-3012Document2 paginiTas Lockingassemblie Eng r03-3012प्रवीण देशारÎncă nu există evaluări

- Essieu Roue CarrosserieDocument60 paginiEssieu Roue Carrosserielionel henriquesÎncă nu există evaluări

- Pioneer Deh p4100r, p3110Document94 paginiPioneer Deh p4100r, p3110bluesysÎncă nu există evaluări

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeDe la EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeEvaluare: 4 din 5 stele4/5 (9)

- 3 Way Valve - DSDocument1 pagină3 Way Valve - DSsinamicsÎncă nu există evaluări

- BA200PENDocument32 paginiBA200PENsinamicsÎncă nu există evaluări

- Actuator MANDocument30 paginiActuator MANsinamicsÎncă nu există evaluări

- Check Valve DSDocument2 paginiCheck Valve DSsinamicsÎncă nu există evaluări

- Assembly Line 1 Palletizer Electrical SchematicsDocument13 paginiAssembly Line 1 Palletizer Electrical SchematicssinamicsÎncă nu există evaluări

- TI028CENDocument12 paginiTI028CENsinamicsÎncă nu există evaluări

- TI085CENDocument16 paginiTI085CENsinamicsÎncă nu există evaluări

- TI110CENDocument8 paginiTI110CENsinamicsÎncă nu există evaluări

- Endress Hauser LC301 ManualDocument24 paginiEndress Hauser LC301 Manualtopaz45Încă nu există evaluări

- 38352cable ListDocument9 pagini38352cable ListsinamicsÎncă nu există evaluări

- (ESS) Sample ProjectDocument239 pagini(ESS) Sample ProjectsinamicsÎncă nu există evaluări

- Lift3 Oben PDFDocument2 paginiLift3 Oben PDFsinamicsÎncă nu există evaluări

- M W Plan PDFDocument1 paginăM W Plan PDFsinamicsÎncă nu există evaluări

- Konsole PDFDocument1 paginăKonsole PDFsinamicsÎncă nu există evaluări

- Konsole PDFDocument1 paginăKonsole PDFsinamicsÎncă nu există evaluări

- Sand Control in Well Construction and OperationDocument205 paginiSand Control in Well Construction and OperationPisethÎncă nu există evaluări

- Orrcon National Product CatalogueDocument84 paginiOrrcon National Product CatalogueEswaran RajamaniÎncă nu există evaluări

- Flow 7 DiagramsDocument12 paginiFlow 7 DiagramsIne Florez PalaciozÎncă nu există evaluări

- Ambuja Cement LTD C/o Wartsila India LTD., (Unit-Rawan)Document4 paginiAmbuja Cement LTD C/o Wartsila India LTD., (Unit-Rawan)rajsekharkvÎncă nu există evaluări

- sEW20Document78 paginisEW20Wan AzmiÎncă nu există evaluări

- Hydrostatic Forces On A Submerged Curved PlaneDocument10 paginiHydrostatic Forces On A Submerged Curved PlaneBlack SkyÎncă nu există evaluări

- Engineering MCQs and D.C. Generators QuestionsDocument31 paginiEngineering MCQs and D.C. Generators QuestionsNitin MauryaÎncă nu există evaluări

- Principles of steel design compression members part 2Document12 paginiPrinciples of steel design compression members part 2Cristina HaliliÎncă nu există evaluări

- QAP For Conical StrainerDocument2 paginiQAP For Conical StrainersatishchidrewarÎncă nu există evaluări

- Distribution Blocks PDFDocument3 paginiDistribution Blocks PDFAbelino Vargas TenjoÎncă nu există evaluări

- Properties of Matter: Extensive vs IntensiveDocument16 paginiProperties of Matter: Extensive vs IntensiveCentener CalcetaÎncă nu există evaluări

- Installation & Maintenance Manual: Inverter-Driven Split System Heat Pump Air Conditioners - DC Inverter Utopia IvxDocument35 paginiInstallation & Maintenance Manual: Inverter-Driven Split System Heat Pump Air Conditioners - DC Inverter Utopia IvxJose Mosquera100% (1)

- Ооо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RDocument53 paginiОоо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RSiva baalan50% (2)

- Section - Iv: Damodar Valley CorporationDocument3 paginiSection - Iv: Damodar Valley CorporationabhishekÎncă nu există evaluări

- Electric VehiclesDocument1 paginăElectric VehiclesVINCENCIUS S Y PÎncă nu există evaluări

- Massey Ferguson Mf4263 Part CatalogueDocument20 paginiMassey Ferguson Mf4263 Part Cataloguescott100% (52)

- HPHT Completion Hardware (2023.05.05)Document54 paginiHPHT Completion Hardware (2023.05.05)New Auto TVÎncă nu există evaluări

- Doosan DX140W PDFDocument32 paginiDoosan DX140W PDFjoseph anthony marca jacinto0% (1)

- Installation and Operation Manual: VRV IV System Air ConditionerDocument36 paginiInstallation and Operation Manual: VRV IV System Air Conditionerelectrowat engineeringÎncă nu există evaluări

- Sample Calculation-BDocument14 paginiSample Calculation-BEdrielleÎncă nu există evaluări

- EGR Valve Emulator EML810/24 Installation Guide: BrownDocument1 paginăEGR Valve Emulator EML810/24 Installation Guide: BrownРадослав БошковÎncă nu există evaluări

- Pros and Cons of Engineering BranchesDocument6 paginiPros and Cons of Engineering BranchesAnuj KansalÎncă nu există evaluări

- Weld Capacity CalculationDocument6 paginiWeld Capacity CalculationjaineranaÎncă nu există evaluări

- RK-2001E2 English TraductionDocument2 paginiRK-2001E2 English TraductionwxcvbnnbvcxwÎncă nu există evaluări

- BS 4504-Part 3.2Document31 paginiBS 4504-Part 3.2Simon LawÎncă nu există evaluări

- Pilot Boat PO - Sea Trial ReportDocument16 paginiPilot Boat PO - Sea Trial ReportKyaw Oo100% (2)

- Power SteeringDocument4 paginiPower SteeringFarhan Mat Nasir0% (1)

- Greenfield OwnersManual FastCutTractorDocument31 paginiGreenfield OwnersManual FastCutTractorjim STAM100% (1)

- 1 - Calcuquick D.Ginsky 6.6.2005 EnglishDocument82 pagini1 - Calcuquick D.Ginsky 6.6.2005 EnglishRahul ChandrawarÎncă nu există evaluări

- Cummins Big Cam I Big Cam III Shop ManualDocument20 paginiCummins Big Cam I Big Cam III Shop Manualhilda100% (46)