Documente Academic

Documente Profesional

Documente Cultură

Page

Încărcat de

r_zoro87Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Page

Încărcat de

r_zoro87Drepturi de autor:

Formate disponibile

Flyovers WD7 and WD8 on the

Sucharski Route

The construction of the Sucharski Route was part of the creation and modernisation of Gdasks road

system in 2007-2013 in order to connect the city with the national road network (A1 and S7) and part of the

project of the European E75 and E77 routes in Poland. Optimisation of the steel structure solution involved

collaboration between the general contractor SKANSKA S.A., the design agency EUROPROJEKT Gdask

S.A and the steel structure contractor ArcelorMittal. 2,040 tonnes of ArcelorMittal's HISTAR460 steel was

used in the objects.

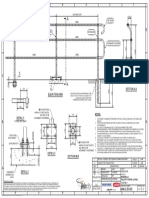

The WD8 consists of two independent constructions (each for one carriageway), 10.6m wide and around

390m long. It has 11 spans, the central span measuring 40m and the lateral ones 25m. The WD7 is shorter,

i.e. has a length of about 170m, but the structure is wider - 11.2m across. It is a 5-span bridge with span

lengths of 30-40m. The height of the deck above the ground surface is approximately 12m in the center of

viaduct WD7. Both objects are built with continuous beams and have foundations in the form of poles of a

diameter of 1.5m and lengths of 22-32m.

The bridges take the road over railway lines and local roads, and were designed as plain girder VFT

(Prefabricated Composite Construction Method) objects in S355 steel grade with slenderness ratios 25-28.

With the surface covering over a hectare, the choice of technology was of key importance from a technical

and economic point of view. Due to the ground conditions and obstacles in the form of railway lines, a

central span of approximately 40m was decided upon along with a complex transversal structure made from

prefabricated elements as being a more effective solution than pre-stressed.

Replacement project: HISTAR rolled beams instead of S355 steel welded girders

Instead of the S355 steel welded girders, it was decided to use HISTAR460 rolled steel beams, which led to

the creation of Polands first objects using VFT technology with rolled sections in this steel grade. At the

same time the WD8, with nearly 400m length, is the longest VFT object in the country.

There were several factors suggesting it would be more beneficial to use HISTAR460 rolled sections rather

than welded S355 steel girders. Rolled beams enables tonnage reduction by around 10% or even more when

optimization of the finishing of individual beams is envisaged in an object.

The sections delivered to the construction site were 41m long, eliminating the need for any welding on site.

The total amount of welding was reduced by 80%. Using rolled beams ensures a long fatigue life for an

object, which is why static schemes in the form of frames or beams from continuous S460 steel is justified

from a technical and economic point of view. The rolled sections are characterised by a smaller surface

than with welded plate girders the surface for anti-corrosion protection divided by the mass of the

structure is usually around 15-30% compared to welded plate girders (an advantage as far as maintenance

is concerned).

For the requirements of this project, in June 2011 the Differdange plant in Luxembourg produced 137 beams

of lengths between 25 and 41m, these were HL1100 beams (type of sections used for the construction of

bridges). After adding the pre-cambering, the finishing involving welding the necessary reinforcing plates to

the lower flange in the support area, the end plates, shear studs and painting were also completed at the

plant. This efficient action resulted in the first fully finished beams of the WD7 viaduct being delivered to

Gdask in August 2011 (by rail to Gdask and on the road to the construction site).

The concrete transom solution

The concrete transom solution

In the case of the WD7 and WD8, as with most VFT beam structures in Poland, the contractor decided to

construct a prefabricated C40/50 concrete deck onto the steel beams before positioning them in the

structure. The innovation in the case of the WD7 and WD8 was the introduction of a staged process of

completing the transoms, making assembly towers unnecessary at the supports.

Once the beams are positioned correctly, with the prefabricated deck forming a lost formwork for the in-situ

deck, the concrete for the deck was poured on the slab. This way, the construction of the bridge deck was a

simple process completed in 3 stages. First the assembly of the prefabricated slab on top of the beam,

which covers around a third of the concrete deck's total height and acts like a formwork for the concrete

poured in the second stage. In the third stage, the finishing of the bridge deck was completed in traditional

manner.

Span construction

The complex prefabricated structures were placed in their intended location using a crane, and their mass

reached 50 tonnes. The individual spans were completed in one week on average.

The bridge deck and transoms are made of C35/45 concrete. The span structure was completed in June

2013, and the objects were opened to traffic in October 2013.

Summary based on the common work of:

Riccardo ZANON, Oliver HECHLER, Wojciech OCHOJSKI ArcelorMittal Long Carbon Europe

Pawe Klimaszewski - EUROPROJEKT

Wojciech Lorenc Politechnika Wrocawska

Copyright 2014 Constructalia. All rights reserved

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Analysis of Plates On Elastic Foundations PDFDocument97 paginiAnalysis of Plates On Elastic Foundations PDFchristos032Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- 047017465X 1Document4 pagini047017465X 1r_zoro87Încă nu există evaluări

- PLAXIS Scientific Manual 2019Document61 paginiPLAXIS Scientific Manual 2019tkno813Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Punching Shear PDFDocument1 paginăPunching Shear PDFr_zoro87Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- BC-10 - 11 Method ADocument3 paginiBC-10 - 11 Method Ar_zoro87Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Figure 1 Problem GeometryDocument4 paginiFigure 1 Problem Geometryr_zoro87Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- 01 - Calcestruzzo - Dispense Di Tecnica Delle Costruzioni PDFDocument33 pagini01 - Calcestruzzo - Dispense Di Tecnica Delle Costruzioni PDFr_zoro87Încă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- 15 - Acciaio - Esempio Di Calcolo Di Una Trave Soggetta A NM PDFDocument11 pagini15 - Acciaio - Esempio Di Calcolo Di Una Trave Soggetta A NM PDFr_zoro87Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- 295-R ZiaieMoayedandM AliBolandiDocument4 pagini295-R ZiaieMoayedandM AliBolandir_zoro87Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- ACI 318 - Interaction Diagram P - M: Material PropertiesDocument25 paginiACI 318 - Interaction Diagram P - M: Material Propertiesr_zoro87Încă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Analysis of Double Layer Grids With Material Non-linearities!IIW - A Practical ApproachDocument8 paginiAnalysis of Double Layer Grids With Material Non-linearities!IIW - A Practical Approachr_zoro87Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- 16 - Acciaio - Tensioni Nei Gusci PDFDocument2 pagini16 - Acciaio - Tensioni Nei Gusci PDFr_zoro87Încă nu există evaluări

- 02 - Calcestruzzo - Compendio Sul Calcolo Del CA PDFDocument155 pagini02 - Calcestruzzo - Compendio Sul Calcolo Del CA PDFr_zoro87Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Validation Bending of Plates 2016Document4 paginiValidation Bending of Plates 2016ajiboydÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Mit PDFDocument156 paginiMit PDFr_zoro87Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Minimum Reinforcement For Crack Width Control in Restrained Concrete Members Considering The Deformation CompatibilityDocument13 paginiMinimum Reinforcement For Crack Width Control in Restrained Concrete Members Considering The Deformation Compatibilityr_zoro87Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Pdftest PDFDocument1 paginăPdftest PDFr_zoro87Încă nu există evaluări

- Pdftest2 PDFDocument1 paginăPdftest2 PDFr_zoro87Încă nu există evaluări

- Karihaloo1987 PDFDocument9 paginiKarihaloo1987 PDFr_zoro87Încă nu există evaluări

- Punching ShearDocument10 paginiPunching Shearr_zoro87Încă nu există evaluări

- Comparison of Various Treatment Modalities For Acute TinnitusDocument7 paginiComparison of Various Treatment Modalities For Acute Tinnitusr_zoro87Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Comparison of Various Treatment Modalities For Acute TinnitusDocument7 paginiComparison of Various Treatment Modalities For Acute Tinnitusr_zoro87Încă nu există evaluări

- 3778 - Advances in Architectural Geometry 2016 - OA PDFDocument408 pagini3778 - Advances in Architectural Geometry 2016 - OA PDFJhon BeltranÎncă nu există evaluări

- Coa N 73 1958Document10 paginiCoa N 73 1958r_zoro87Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Rclect10 12Document25 paginiRclect10 12Abera MamoÎncă nu există evaluări

- Comparison of One-And Two-Way Slab Minimum Thickness Provisions in Building Codes and StandardsDocument7 paginiComparison of One-And Two-Way Slab Minimum Thickness Provisions in Building Codes and StandardsM Refaat FathÎncă nu există evaluări

- Elastic ADocument47 paginiElastic Ar_zoro87Încă nu există evaluări

- Parametric Structural Modeling: User Manual For Version 1.2.2Document142 paginiParametric Structural Modeling: User Manual For Version 1.2.2Marco Della Pelle100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- 1etdarafat PDFDocument206 pagini1etdarafat PDFNguyen Danh TuyenÎncă nu există evaluări

- ! - Pay No Fine - A User Guide To Successfully Fighting Traffic TicketsDocument93 pagini! - Pay No Fine - A User Guide To Successfully Fighting Traffic Ticketsdude0213557% (7)

- Cywg PDFDocument20 paginiCywg PDFzacklawsÎncă nu există evaluări

- Proposed Santragachi Railway Station For S. E. RailwayDocument36 paginiProposed Santragachi Railway Station For S. E. RailwayHitesh Khanna100% (3)

- Power Front Disc Conversion Instructions MDC62DCDocument11 paginiPower Front Disc Conversion Instructions MDC62DCandrakin8Încă nu există evaluări

- Barandas 4Document1 paginăBarandas 4Victor HigueraÎncă nu există evaluări

- Tier 1 Bridge Heavy Load Assessment Criteria - 2013 (Main Road)Document85 paginiTier 1 Bridge Heavy Load Assessment Criteria - 2013 (Main Road)yyanan1118Încă nu există evaluări

- Rediff DataDocument4 paginiRediff Dataamitdesai92Încă nu există evaluări

- Technical Report On SiwesDocument24 paginiTechnical Report On SiwesIbrahimÎncă nu există evaluări

- Tort LiabilityDocument14 paginiTort LiabilityTADHLKÎncă nu există evaluări

- Using GIS To Measure ConnectivityDocument43 paginiUsing GIS To Measure ConnectivityVictor ElguetaÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Body Control System: SectionDocument65 paginiBody Control System: SectionAdam WashingtonÎncă nu există evaluări

- Monorail System: A Seminar Report OnDocument18 paginiMonorail System: A Seminar Report OnANUJITH V SÎncă nu există evaluări

- Man TGS/TGXDocument370 paginiMan TGS/TGXSan91% (11)

- 2014 3 TextDocument5 pagini2014 3 TextSimoncarter LawÎncă nu există evaluări

- John Deere CatalogDocument49 paginiJohn Deere CatalogShannon HornÎncă nu există evaluări

- Shin Thant Aung Highway Engineering Assignment-1 HND: 1854CDocument14 paginiShin Thant Aung Highway Engineering Assignment-1 HND: 1854CCupid Phung100% (1)

- Park Note Creswick Regional ParkDocument3 paginiPark Note Creswick Regional ParkSam DekokÎncă nu există evaluări

- Design of Flexible and Rigid PavementsDocument29 paginiDesign of Flexible and Rigid PavementssanchayÎncă nu există evaluări

- Specimen 3 ValuationDocument11 paginiSpecimen 3 ValuationLight BearerÎncă nu există evaluări

- Sagarmala ProjectDocument3 paginiSagarmala Projectankur sharmaÎncă nu există evaluări

- Chapter 1 Exercises: CS 487 Simulation and Modeling Second Semester 2007Document4 paginiChapter 1 Exercises: CS 487 Simulation and Modeling Second Semester 2007Curtis SmithÎncă nu există evaluări

- TRL - Overseas Road Note 17 PDFDocument27 paginiTRL - Overseas Road Note 17 PDFamintaka1025100% (1)

- Construction Methodology of DLC PDFDocument11 paginiConstruction Methodology of DLC PDFsubhra narayan pradhan SikunÎncă nu există evaluări

- WWW Kolbusopedia Com Bus RoutesDocument20 paginiWWW Kolbusopedia Com Bus Routesgsourav8642Încă nu există evaluări

- Ethiopian Roads Authority, Geometric Design Manual 2013Document273 paginiEthiopian Roads Authority, Geometric Design Manual 2013Samuel TibebuÎncă nu există evaluări

- Pietro LunardiDocument5 paginiPietro LunardimadeÎncă nu există evaluări

- Rishipal SinghDocument17 paginiRishipal SinghJason RoyÎncă nu există evaluări

- SECTION 26 05 19 Low-Voltage Electrical Power Conductors and CablesDocument9 paginiSECTION 26 05 19 Low-Voltage Electrical Power Conductors and CablesDenyÎncă nu există evaluări

- Pdf-Xchange Editor Demo Pdf-Xchange Editor DemoDocument563 paginiPdf-Xchange Editor Demo Pdf-Xchange Editor DemoSiva NarayanaÎncă nu există evaluări

- Thunder Roads Colorado July 2011Document21 paginiThunder Roads Colorado July 2011Linda McCartneyÎncă nu există evaluări

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- A Welder’s Handbook to Robotic ProgrammingDe la EverandA Welder’s Handbook to Robotic ProgrammingEvaluare: 5 din 5 stele5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- Structural Cross Sections: Analysis and DesignDe la EverandStructural Cross Sections: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (19)

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)