Documente Academic

Documente Profesional

Documente Cultură

Anchorage in Concrete With Threaded Rod (MIT600RE) : Ef Ef

Încărcat de

julio1051Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Anchorage in Concrete With Threaded Rod (MIT600RE) : Ef Ef

Încărcat de

julio1051Drepturi de autor:

Formate disponibile

Chemical Products

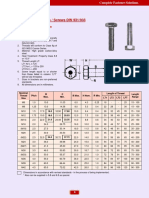

Anchorage in concrete with threaded rod (MIT600RE)

Steel failure Recommended loads in concrete C20/25 Threaded rods in uncracked concrete Threaded rods in cracked concrete

Embedment depth hef (mm) Embedment depth hef (mm)

60 96 60 120 70 144 80 192 90 240 96 288 108 324 120 360 70 144 80 192 90 240 96 288

M 8 10 12 16 20 24 27 30 12 16 20 24

Recommended centrical tensile strength, steel grade 5.8 Nrec

[kN] 8.6 13.8 20.0 37.1 58.1 83.8 109.5 133.3 20.0 37.1 58.1 83.8

Recommended centrical tensile strength, steel grade 8.8 Nrec

[kN] 13.8 21.9 31.9 59.5 93.3 134.3 175.2 213.8 31.9 59.5 93.3 134.3

Partial safety factor 1.5 1.5

Recommended centrical tensile strength, steel

grade A4 and HCR, 50 (>M42) and 70 (<=M24) Nrec [kN] 9.9 15.7 22.5 42.0 65.3 94.3 57.4 70.2 22.5 42.0 65.3 94.3

Partial safety factor 1.87 2.86 1.87

Combined failure by pull-out and concrete cone failure Recommended centrical tensile strength

Temperature I: 40C/24C

(dry and wet concrete) Nrec [kN] 9.0 14.411.222.415.732.322.353.629.277.834.5 103.4 43.6 130.9 53.9 169.6 7.9 16.210.424.911.530.813.540.6

Temperature II: 60C/43C

(dry and wet concrete) Nrec [kN] 5.7 9.1 7.1 14.2 9.4 19.413.632.618.047.921.5 64.6 27.3 81.8 33.7 101.0 4.7 9.7 6.4 15.3 6.7 18.0 8.6 25.9

Temperature III: 72C/43C

(dry and wet concrete) Nrec [kN] 5.1 8.1 6.4 12.7 8.4 17.212.028.715.741.920.1 60.3 23.6 70.9 29.2 87.5 4.2 8.6 5.6 13.4 5.8 15.4 7.4 22.2

Partial safety factor (dry and wet concrete) 1.8 2.1 1.8 2.1

Partial safety factor (water flooded borehole) 2.1 2.1

C30/37 1.04 1.04

Increasing factor for uncracked concrete C40/50 1.08 1.08

C50/60 1.1 1.1

Steel failure without lever arm Threaded rods in cracked and uncracked concrete

M 8 10 12 16 20 24 27 30

Recommended shear load, steel grade 5.8 Vrec [kN] 5.1 8.6 12.0 22.3 34.9 50.3 65.7 80.0

Recommended shear load, steel grade 8.8 Vrec [kN] 8.6 13.1 19.4 36.0 56.0 80.6 105.1 128.0

Partial safety factor 1.25

Recommended shear load, steel grade A4 and HCR, 50 (>M42) and 70 (<=M24) Vrec [kN] 6.0 9.2 13.7 25.2 39.4 56.8 34.5 42.0

Partial safety factor 1.56 2.38

Steel failure with lever arm

Recommended bending moment, steel grade 5.8 Mrec [Nm] 10.9 21.1 37.1 94.9 185.1 320.0 476.0 641.7

Recommended bending moment, steel grade 8.8 Mrec [Nm] 17.1 34.3 60.0 152.0 296.6 512.0 761.7 1026.9

Partial safety factor 1.25

Recommended bending moment, steel grade A4 and HCR, 50 (>M42) and 70 (<=M24) Mrec [Nm] 11.9 23.8 42.1 106.2 207.9 359.0 249.7 337.6

Partial safety factor 1.56 2.38

Filling volume for fixings with threaded rods For the change of mixers and cartridges an additional quantity has to be calculated

Threaded rod M Drill mm Filling volume (ml)

8 10 2.3 2.4 2.7 3.0 3.4 3.6 3.8 4.1 4.2 4.6 4.9 5.5 6.1 7.3 7.6 9.1 10.9 11.4 12.3 - -

10 12 2.9 3.1 3.4 3.9 4.4 4.7 4.9 5.3 5.4 5.9 6.3 7.1 7.9 9.4 9.8 11.8 14.1 14.7 15.9 17.7 -

12 14 - - 4.3 4.9 5.5 5.9 6.1 6.6 6.7 7.4 7.8 8.8 9.8 11.8 12.3 14.7 17.6 18.4 19.8 22.1 30.6

16 18 - - - 6.8 7.6 8.1 8.5 9.2 9.3 10.2 10.8 12.2 13.6 16.3 16.9 20.3 24.4 25.4 27.5 30.5 42.4

20 24 - - - - 16.8 18.0 18.7 20.2 20.6 22.5 24.0 27.0 29.9 35.9 37.4 44.9 53.9 56.2 60.6 67.4 93.6

24 28 - - - - - 22.5 23.4 25.3 25.7 28.1 29.9 33.7 37.4 44.9 46.8 56.1 67.4 70.2 75.8 84.2 116.9

27 32 - - - - - - - 34.7 35.3 38.5 41.1 46.2 51.4 61.6 64.2 77.1 92.5 96.3 104.0 115.6 160.5

30 35 - - - - - - - - - 44.4 47.3 53.3 59.2 71.0 74.0 88.8 106.5 110.9 119.8 133.1 184.9

Setting depth mm 60 64 70 80 90 96 100 108 110 120 128 144 160 192 200 240 288 300 324 360 500

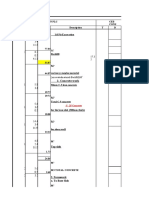

Anchorage in concrete with rebar (MIT600RE)

Steel failure Rebar in uncracked concrete Rebar in cracked concrete

Embedment depth hef (mm) Embedment depth hef (mm)

60 96 60 120 70 144 75 168 80 192 90 240 100 300 112 336 128 384 70 144 75 168 80 192 90 240 100 300

d 8 10 12 14 16 20 25 28 32 12 14 16 20 25

Recommended centrical tensile strength,

BST 500 S, according to DIN 488- Nrec [kN] 14.3 21.9 31.6 43.4 56.6 88.3 137.8 173.0 225.5 31.6 43.4 56.6 88.3 137.8

2:1986 or E DIN 488-2:2006

Partial safety factor 1.4 1.4

Combined failure by pull-out and concrete cone failure Recommended centrical tensile strength

Temperature I: 40C/24C

(dry and wet concrete) Nrec [kN] 6.6 10.5 8.2 16.5 10.5 21.5 13.1 29.3 15.2 36.4 17.3 46.224.0 72.1 28.5 85.537.2111.6 5.811.8 5.9 13.2 7.2 17.2 7.7 20.5 9.3 28.0

Temperature II: 60C/43C

(dry and wet concrete) Nrec [kN] 3.9 6.2 4.9 9.7 6.8 14.0 7.9 17.6 9.6 23.0 10.6 28.2 14.7 44.1 16.8 50.321.9 65.7 3.1 6.5 3.9 8.8 4.0 9.6 4.8 12.8 5.3 16.0

Temperature III: 72C/43C

(dry and wet concrete) Nrec [kN] 3.6 5.7 4.5 9.0 5.8 11.8 7.2 16.1 8.8 21.1 9.6 25.6 12.0 36.1 15.1 45.219.7 59.1 3.1 6.5 3.3 7.3 4.0 9.6 3.8 10.3 5.3 16.0

Partial safety factor (dry and wet concrete) 1.8 2.1 1.8 2.1

Partial safety factor (water flooded borehole) 2.1 2.1

C30/37 1.04 1.04

Increasing factor for uncracked C40/50 1.08 1.08

concrete

C50/60 1.1 1.1

Steel failure without lever arm Rebar in cracked and uncracked concrete

d 8 10 12 14 16 20 25 28 32

Recommended shear load, BST 500 S, according to DIN 488-2:1986 V rec [kN] 6.7 10.5 14.8 20.0 26.2 41.0 64.3 80.5 105.2

or E DIN 488-2:2006

Partial safety factor 1.5

Steel failure with lever arm

Recommended bending moment, BST 500 S, according to DIN 488-2:1986

or E DIN 488-2:2006 Mrec [Nm] 15.7 31.0 53.3 84.8 126.2 246.7 481.9 677.1 1011.0

Partial safety factor 1.5

Filling volume for fixings with rebar For the change of mixers and cartridges an additional quantity has to be calculated

Rebar d (mm) Drill mm Filling volume (ml)

8 12 3.8 4.4 4.7 5.0 5.7 6.0 6.3 7.0 7.5 8.0 9.0 9.4 10.1 10.6 12.1 15.1 18.8 21.1 24.1 -

10 14 4.5 5.3 5.7 6.0 6.8 7.2 7.5 8.4 9.0 9.7 10.9 11.3 12.1 12.7 14.5 18.1 22.6 25.3 29.0 37.7

12 16 - 6.2 6.6 7.0 7.9 8.4 8.8 9.9 10.6 11.3 12.7 13.2 14.1 14.8 16.9 21.1 26.4 29.6 33.8 44.0

14 18 - - 7.5 8.0 9.0 9.7 10.1 11.3 12.1 12.9 14.5 15.1 16.1 16.9 19.3 24.1 30.2 33.8 38.6 50.3

16 20 - - - 9.0 10.2 10.9 11.3 12.7 13.6 14.5 16.3 17.0 18.1 19.0 21.7 27.1 33.9 38.0 43.4 56.5

20 24 - - - - 12.4 13.3 13.8 15.5 16.6 17.7 19.9 20.7 22.1 23.2 26.5 33.2 41.5 46.4 53.1 69.1

25 32 - - - - - - 31.3 35.1 37.6 40.1 45.1 47.0 50.1 52.6 60.2 75.2 94.0 105.3 120.3 156.7

28 35 - - - - - - - 38.8 41.6 44.3 49.9 52.0 55.4 58.2 66.5 83.1 103.9 116.4 133.0 173.2

32 40 - - - - - - - - - 57.9 65.1 67.9 72.4 76.0 86.9 108.6 135.7 152.0 173.7 226.2

Setting depth mm 60 70 75 80 90 96 100 112 120 128 144 150 160 168 192 240 300 336 384 500

The orange marked fields show the approved areas of the setting depths

The technical data are only valid for single fixings without consideration of edge and anchor distances

The partial safety factors of the resistances as well as a partial safety factor of the effect of F = 1.4 are considered

In combination of pull and shear loads, with edge distance and anchor groups please observe ETA-09/0340

Shear load without limitation by failure of the building material

The data refer to the correct procedure by which hammer drilling and cleaning produce the clean holes required for the setting of the anchors

Mungo Befestigungstechnik AG 2011 69

Anchorage in concrete with threaded rod (MIT-SE Plus)

Chemical Products

Steel failure Recommended loads in concrete C20/25 Threaded rods in uncracked concrete

Embedment depth hef (mm)

60 160 60 200 70 240 80 320 90 400 96 480 108 540 120 600

M 8 10 12 16 20 24 27 30

Recommended centrical tensile strength, steel grade 5.8 Nrec [kN] 8.6 13.8 20.0 37.1 58.1 83.8 109.5 133.3

Recommended centrical tensile strength, steel grade 8.8 Nrec [kN] 13.8 21.9 31.9 59.5 93.3 134.3 175.2 213.8

Partial safety factor 1.5

Recommended centrical tensile strength, steel grade A4 and HCR,

50 (>M42) and 70 (<=M24) Nrec [kN] 9.9 15.7 22.5 42.0 65.3 94.3 57.4 70.2

Partial safety factor 1.87 2.86

Combined failure by pull-out and concrete cone failure Recommended centrical tensile strength

Temperature I: 40C/24C (dry and wet concrete) Nrec [kN] 7.2 19.9 9.0 29.9 12.6 43.1 19.1 76.6 26.9 119.7 31.6 158.0 36.4 181.8 40.4 202.0

Temperature II: 80C/50C (dry and wet concrete) Nrec [kN] 5.4 14.4 6.7 22.4 9.4 32.3 14.4 57.4 20.2 89.8 24.4 122.1 27.3 136.3 29.2 145.9

Partial safety factor (dry and wet concrete) 1.5 1.8

Partial safety factor (water flooded borehole) 2.1

C30/37 1.04

Increasing factor for uncracked concrete C40/50 1.08

C50/60 1.1

Steel failure without lever arm Threaded rods in uncracked concrete

M 8 10 12 16 20 24 27 30

Recommended shear load, steel grade 5.8 Vrec [kN] 5.1 8.6 12.0 22.3 34.9 50.3 65.7 80.0

Recommended shear load, steel grade 8.8 Vrec [kN] 8.6 13.1 19.4 36.0 56.0 80.6 105.1 128.0

Partial safety factor 1.25

Recommended shear load, steel grade A4 and HCR, 50 (>M42) and 70 (<=M24) Vrec [kN] 6.0 9.2 13.7 25.2 39.4 56.8 34.5 42.0

Partial safety factor 1.56 2.38

Steel failure with lever arm

Recommended bending moment, steel grade 5.8 Mrec [Nm] 10.9 21.1 37.1 94.9 185.1 320.0 476.0 641.7

Recommended bending moment, steel grade 8.8 Mrec [Nm] 17.1 34.3 60.0 152.0 296.6 512.0 761.7 1026.9

Partial safety factor 1.25

Recommended bending moment, steel grade A4 and HCR, 50 (>M42) and 70 (<=M24) Mrec [Nm] 11.9 23.8 42.1 106.2 207.9 359.0 249.7 337.6

Partial safety factor 1.56 2.38

Filling volume for fixings with threaded rods For the change of mixers and cartridges an additional quantity has to be calculated

Threaded rod M Drill mm Filling volume (ml)

8 10 2.3 2.7 3.0 3.4 3.6 4.1 4.6 6.1 7.6 9.1 9.5 11.4 12.1 13.3 15.2 17.1 18.2 19.0 20.5 - -

10 12 2.9 3.4 3.9 4.4 4.7 5.3 5.9 7.9 9.8 11.8 12.3 14.7 15.7 17.2 19.6 22.1 23.6 24.6 26.5 27.0 -

12 14 - 4.3 4.9 5.5 5.9 6.6 7.4 9.8 12.3 14.7 15.3 18.4 19.6 21.4 24.5 27.6 29.4 30.6 33.1 33.7 36.8

16 18 - - 6.8 7.6 8.1 9.2 10.2 13.6 16.9 20.3 21.2 25.4 27.1 29.7 33.9 38.1 40.7 42.4 45.8 46.6 50.8

20 24 - - - 16.8 18.0 20.2 22.5 29.9 37.4 44.9 46.8 56.2 59.9 65.5 74.9 84.2 89.8 93.6 101.1 102.9 112.3

24 28 - - - - 22.5 25.3 28.1 37.4 46.8 56.1 58.5 70.2 74.8 81.8 93.5 105.2 112.3 116.9 126.3 128.6 140.3

27 32 - - - - - 34.7 38.5 51.4 64.2 77.1 80.3 96.3 102.7 112.4 128.4 144.5 154.1 160.5 173.4 176.6 192.6

30 35 - - - - - - 44.4 59.2 74.0 88.8 92.4 110.9 118.3 129.4 147.9 166.4 177.5 184.9 199.7 203.4 221.9

Setting depth mm 60 70 80 90 96 108 120 160 200 240 250 300 320 350 400 450 480 500 540 550 600

Anchorage in concrete with rebar (MIT-SE Plus)

Steel failure Rebar in uncracked concrete

Embedment depth hef (mm)

60 160 60 200 70 240 75 280 80 320 90 400 100 480 112 540 128 640

d 8 10 12 14 16 20 25 28 32

Recommended centrical tensile strength, BST 500 S, according to

DIN 488-2:1986 or E DIN 488-2:2006 Nrec [kN] 14.3 21.9 31.6 43.4 56.6 88.3 137.8 173.0 225.5

Partial safety factor 1.4

Combined failure by pull-out and concrete cone failure Recommended centrical tensile strength

Temperature I: 40C/24C

(dry and wet concrete) Nrec [kN] 6.1 16.3 7.5 24.9 10.5 35.9 13.1 48.9 16.0 63.8 22.4 99.7 28.0 134.6 31.3 150.8 35.7 178.7

Temperature II: 80C/50C

(dry and wet concrete) Nrec [kN] 4.3 11.5 5.6 18.7 7.9 26.9 9.8 36.7 12.0 47.9 16.8 74.8 21.8 104.7 23.5 113.1 25.5 127.7

Partial safety factor (dry and wet concrete) 1.5 1.8

Partial safety factor (water flooded borehole) 2.1

C30/37 1.04

Increasing factor for uncracked concrete C40/50 1.08

C50/60 1.1

Steel failure without lever arm Rebar in uncracked concrete

d 8 10 12 14 16 20 25 28 32

Recommended shear load, BST 500 S, according to DIN 488-2:1986 or

E DIN 488-2:2006 Vrec [kN] 6.7 10.5 14.8 20.0 26.2 41.0 64.3 80.5 105.2

Partial safety factor 1.5

Steel failure with lever arm

Recommended bending moment, BST 500 S, according to DIN 488-2:1986 or

E DIN 488-2:2006 Mrec [Nm] 15.7 31.0 53.3 84.8 126.2 246.7 481.9 677.1 1011.0

Partial safety factor 1.5

Filling volume for fixings with rebar For the change of mixers and cartridges an additional quantity has to be calculated

Rebar d (mm) Drill mm Filling volume (ml)

8 12 3.8 4.4 4.7 5.0 5.7 6.3 7.0 8.0 10.1 12.6 15.1 17.6 18.8 20.1 22.0 25.1 - - - -

10 14 4.5 5.3 5.7 6.0 6.8 7.5 8.4 9.7 12.1 15.1 18.1 21.1 22.6 24.1 26.4 30.2 36.2 37.7 40.7 -

12 16 - 6.2 6.6 7.0 7.9 8.8 9.9 11.3 14.1 17.6 21.1 24.6 26.4 28.1 30.8 35.2 42.2 44.0 47.5 56.3

14 18 - - 7.5 8.0 9.0 10.1 11.3 12.9 16.1 20.1 24.1 28.1 30.2 32.2 35.2 40.2 48.3 50.3 54.3 64.3

16 20 - - - 9.0 10.2 11.3 12.7 14.5 18.1 22.6 27.1 31.7 33.9 36.2 39.6 45.2 54.3 56.5 61.1 72.4

20 24 - - - - 12.4 13.8 15.5 17.7 22.1 27.6 33.2 38.7 41.5 44.2 48.4 55.3 66.4 69.1 74.6 88.5

25 32 - - - - - 31.3 35.1 40.1 50.1 62.7 75.2 87.7 94.0 100.3 109.7 125.3 150.4 156.7 169.2 200.6

28 35 - - - - - - 38.8 44.3 55.4 69.3 83.1 97.0 103.9 110.8 121.2 138.5 166.3 173.2 187.0 221.7

32 40 - - - - - - - 57.9 72.4 90.5 108.6 126.7 135.7 144.8 158.3 181.0 217.1 226.2 244.3 289.5

Setting depth mm 60 70 75 80 90 100 112 128 160 200 240 280 300 320 350 400 480 500 540 640

The orange marked fields show the approved areas of the setting depths

The technical data are only valid for single fixings without consideration of edge and anchor distances

The partial safety factors of the resistances as well as a partial safety factor of the effect of F = 1.4 are considered

In combination of pull and shear loads, with edge distance and anchor groups please observe ETA-10/0130

Shear load without limitation by failure of the building material

The data refer to the correct procedure by which hammer drilling and cleaning produce the clean holes required for the setting of the anchors

70 Mungo Befestigungstechnik AG 2011

S-ar putea să vă placă și

- Aluminum Structures: A Guide to Their Specifications and DesignDe la EverandAluminum Structures: A Guide to Their Specifications and DesignEvaluare: 5 din 5 stele5/5 (2)

- Cab - Wit Vm250 Part2Document1 paginăCab - Wit Vm250 Part2Mandar KadamÎncă nu există evaluări

- Stainless Steel Products: Bolt Anchor AN BZ Plus A4Document3 paginiStainless Steel Products: Bolt Anchor AN BZ Plus A4أبومحمدالزياتÎncă nu există evaluări

- Reo 502Document4 paginiReo 502ashish sahaÎncă nu există evaluări

- Wit-Vm 250 MDocument24 paginiWit-Vm 250 MQCÎncă nu există evaluări

- HVZ Adhesive Anchor: Basic Loading Data (For A Single Anchor) : HAS - (E-) TZDocument10 paginiHVZ Adhesive Anchor: Basic Loading Data (For A Single Anchor) : HAS - (E-) TZBogdanBÎncă nu există evaluări

- +696wxgdqfkru: HSV Stud AnchorDocument9 pagini+696wxgdqfkru: HSV Stud AnchorThang VoÎncă nu există evaluări

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Document8 paginiNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaÎncă nu există evaluări

- Anchor Fastening Technology Manual: HSV M8 HSV M10 HSV M12 HSV M16 Application in ConcreteDocument10 paginiAnchor Fastening Technology Manual: HSV M8 HSV M10 HSV M12 HSV M16 Application in Concreteraju9991Încă nu există evaluări

- BKL - R+W CouplingsDocument4 paginiBKL - R+W Couplingsgökhan tanrıseverÎncă nu există evaluări

- Chemical Anchor BoltDocument1 paginăChemical Anchor BoltdeepuVNITÎncă nu există evaluări

- MIQ Technical Data Table Technical Information ASSET DOC LOC 7258698Document1 paginăMIQ Technical Data Table Technical Information ASSET DOC LOC 7258698Laura LÎncă nu există evaluări

- Torque Details-Hex Bolt DIN 933Document2 paginiTorque Details-Hex Bolt DIN 933coolkaisy100% (2)

- Project Data: Project Name Project Number Author Description Date 17/06/2020 Design Code AISC 360-16Document9 paginiProject Data: Project Name Project Number Author Description Date 17/06/2020 Design Code AISC 360-16Pham DuctrungÎncă nu există evaluări

- Sambungan Atap Dan BaseplateDocument36 paginiSambungan Atap Dan Baseplatedinal031Încă nu există evaluări

- Hexagon Head Bolts/Screws: Metric Series-DimensionsDocument7 paginiHexagon Head Bolts/Screws: Metric Series-DimensionsVishal MistryÎncă nu există evaluări

- 024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFDocument1 pagină024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFRonak RanaÎncă nu există evaluări

- Mechanical Properties of Fasteners Made of Carbon Steel and Alloy SteelDocument1 paginăMechanical Properties of Fasteners Made of Carbon Steel and Alloy SteelVarun KumarÎncă nu există evaluări

- Project: Project No: AuthorDocument37 paginiProject: Project No: Authorabdullah_23320666Încă nu există evaluări

- Detail 61Document5 paginiDetail 61SantosoÎncă nu există evaluări

- THRUMAXX ZPL DoP 30551rev1 EngDocument3 paginiTHRUMAXX ZPL DoP 30551rev1 EngRicardo MagalhãesÎncă nu există evaluări

- Punching For RaftDocument1 paginăPunching For Raftmohd sumerÎncă nu există evaluări

- Type of Calculation Date Customer Name Ref: Roller Chain Drives 29/08/2012 07:50:08 ModelDocument6 paginiType of Calculation Date Customer Name Ref: Roller Chain Drives 29/08/2012 07:50:08 Modelgrupa2904Încă nu există evaluări

- Table of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3Document9 paginiTable of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3DEIVASIHAMANI PERUMALÎncă nu există evaluări

- Ek Spec 180 Cu-Conductor, Stranded, Hard: 1 DimensionsDocument1 paginăEk Spec 180 Cu-Conductor, Stranded, Hard: 1 DimensionsfikeiÎncă nu există evaluări

- CF 1000Document4 paginiCF 1000Anonymous 3eHGEDbxÎncă nu există evaluări

- BS en 15048 8.8Document7 paginiBS en 15048 8.8MinhÎncă nu există evaluări

- 26-HVU Adhesive With HAS RodDocument9 pagini26-HVU Adhesive With HAS RodAdam ChougleÎncă nu există evaluări

- Sleeve Anchor Data Sheet - For SubmittalDocument3 paginiSleeve Anchor Data Sheet - For SubmittalvtalexÎncă nu există evaluări

- Attachment 3.2 - Horizontal Member For Supporting of Grating Between Grid 03 and 2C VerificationDocument16 paginiAttachment 3.2 - Horizontal Member For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgÎncă nu există evaluări

- Calculation Sheet For Ramset AnchorsDocument7 paginiCalculation Sheet For Ramset AnchorsJohnMichaelM.ManaloÎncă nu există evaluări

- Aor Cantilever 6m SignDocument6 paginiAor Cantilever 6m SignDaljit624Încă nu există evaluări

- Project Data: Project Name Project Number Author Description Date 8.6.2019. Design Code ENDocument3 paginiProject Data: Project Name Project Number Author Description Date 8.6.2019. Design Code ENfilipbarisic4Încă nu există evaluări

- Project: Project No: AuthorDocument31 paginiProject: Project No: Authorabdullah_23320666Încă nu există evaluări

- Yes 1Document56 paginiYes 1Frank Appiah-KusiÎncă nu există evaluări

- Delta Ia-Asda Asda-400Document1 paginăDelta Ia-Asda Asda-400alahassancoÎncă nu există evaluări

- Hvu HasDocument9 paginiHvu Hassri_amartÎncă nu există evaluări

- Beam To BeamDocument6 paginiBeam To BeamShaikh ImranÎncă nu există evaluări

- Bolt Strength in Working and Limit StateDocument1 paginăBolt Strength in Working and Limit Statemsn sastryÎncă nu există evaluări

- RITZ Screw Specification PDFDocument12 paginiRITZ Screw Specification PDFThawatchai DanwangkhawÎncă nu există evaluări

- TITLE: Bending in Beam: DeflectionDocument12 paginiTITLE: Bending in Beam: Deflectionpitt87Încă nu există evaluări

- HKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EDocument8 paginiHKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EsorengbhanuÎncă nu există evaluări

- Base PlateDocument6 paginiBase PlateLangit BumiÎncă nu există evaluări

- Calc Note Report-R2Document19 paginiCalc Note Report-R2layaljamal2Încă nu există evaluări

- Member #1 (Section Position 4750.0 MM) Beam Design Report: Project DetailsDocument10 paginiMember #1 (Section Position 4750.0 MM) Beam Design Report: Project DetailscdmaaÎncă nu există evaluări

- SPTfoundationDocument3 paginiSPTfoundationDAWITÎncă nu există evaluări

- SPTfoundationDocument3 paginiSPTfoundationKhaled Abdel SalamÎncă nu există evaluări

- Toaz - Info Septic Tank Boq PRDocument8 paginiToaz - Info Septic Tank Boq PRKunal SeeboruthÎncă nu există evaluări

- Gantry Design Report R3 - 2022.09.10Document134 paginiGantry Design Report R3 - 2022.09.10Rojith DevasurendraÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 77Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 77danieldumapitÎncă nu există evaluări

- Stub - temelj П portalDocument15 paginiStub - temelj П portalBobanÎncă nu există evaluări

- HST TensionDocument10 paginiHST Tensionnu.arabiaÎncă nu există evaluări

- Wurth WIT-PE - 500Document26 paginiWurth WIT-PE - 500Igor DzuklevskiÎncă nu există evaluări

- BP01ADocument6 paginiBP01AElancheliyanÎncă nu există evaluări

- SBC 506Document10 paginiSBC 506Amr HassanÎncă nu există evaluări

- Z-Purlins: Technical DocumentationDocument11 paginiZ-Purlins: Technical Documentationardit bedhiaÎncă nu există evaluări

- Production Technology: Processes, Materials and PlanningDe la EverandProduction Technology: Processes, Materials and PlanningEvaluare: 5 din 5 stele5/5 (1)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDe la EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityÎncă nu există evaluări

- Planta: 25635-320-C4K-0220-000140s1 - 0220 - 25635-320-G83-GCE-12548Document1 paginăPlanta: 25635-320-C4K-0220-000140s1 - 0220 - 25635-320-G83-GCE-12548julio1051Încă nu există evaluări

- Rockburst Control Using Destress BlastingDocument250 paginiRockburst Control Using Destress Blastingjulio1051Încă nu există evaluări

- Analysis of Roof Bolt Systems PDFDocument8 paginiAnalysis of Roof Bolt Systems PDFjulio1051Încă nu există evaluări

- Paper MahonyHagan ShearRockboltsDocument8 paginiPaper MahonyHagan ShearRockboltsjulio1051Încă nu există evaluări

- TUST2006 DisturbanceDocument8 paginiTUST2006 Disturbancejulio1051Încă nu există evaluări

- Analysis of Swellex Bolt PerformanceDocument143 paginiAnalysis of Swellex Bolt PerformanceespipopiesÎncă nu există evaluări

- Effect of Bar Shape On The Pull-OutDocument6 paginiEffect of Bar Shape On The Pull-Outjulio1051Încă nu există evaluări

- Improvement of Rock Bolt Profiles Using Analytical and NumericalDocument8 paginiImprovement of Rock Bolt Profiles Using Analytical and Numericaljulio1051Încă nu există evaluări

- Hossein Jalali Thesis ChaptersDocument355 paginiHossein Jalali Thesis Chaptersjulio1051Încă nu există evaluări

- Improved Safety and Efficiency With Ground Support and Rehabilitation Practices at The X41 Copper Mine, Mount Isa MinesDocument9 paginiImproved Safety and Efficiency With Ground Support and Rehabilitation Practices at The X41 Copper Mine, Mount Isa Minesjulio1051Încă nu există evaluări

- Variation in Load Transfer Along The Length of FullyDocument9 paginiVariation in Load Transfer Along The Length of Fullyjulio1051Încă nu există evaluări

- Mechanisms of Shotcrete Roof Support: C. Banton, M.S. Diederichs, D.J. Hutchinson S. EspleyDocument6 paginiMechanisms of Shotcrete Roof Support: C. Banton, M.S. Diederichs, D.J. Hutchinson S. Espleyjulio1051Încă nu există evaluări

- Improvement of Rock Bolt Profiles Using Analytical and NumericalDocument8 paginiImprovement of Rock Bolt Profiles Using Analytical and Numericaljulio1051Încă nu există evaluări

- Effect of Bar Shape On The Pull-OutDocument8 paginiEffect of Bar Shape On The Pull-Outjulio1051Încă nu există evaluări

- Towards An Understanding of DynamicDocument10 paginiTowards An Understanding of Dynamicjulio1051Încă nu există evaluări

- Bolt ProfileDocument272 paginiBolt Profilejulio1051Încă nu există evaluări

- 42obrienbrendan 2003Document1 pagină42obrienbrendan 2003julio1051Încă nu există evaluări

- Bolt ProfileDocument272 paginiBolt Profilejulio1051Încă nu există evaluări

- Dynamic Testing of ThreadbarDocument14 paginiDynamic Testing of Threadbarjulio1051Încă nu există evaluări

- Effect of Bar Shape On The Pull-OutDocument6 paginiEffect of Bar Shape On The Pull-Outjulio1051Încă nu există evaluări

- Numerical Modeling of Brittle Rock Failure Around Undergroundgolchinfar - Nader - Master - ThesisDocument158 paginiNumerical Modeling of Brittle Rock Failure Around Undergroundgolchinfar - Nader - Master - Thesisjulio1051Încă nu există evaluări

- Revision 1-S2.0-S1674775514000225-MainDocument13 paginiRevision 1-S2.0-S1674775514000225-Mainjulio1051Încă nu există evaluări

- 19 Barreras+DinámicasDocument78 pagini19 Barreras+Dinámicasjulio1051Încă nu există evaluări

- Improvement of Rock Bolt Profiles Using Analytical and NumericalDocument8 paginiImprovement of Rock Bolt Profiles Using Analytical and Numericaljulio1051Încă nu există evaluări

- Sostenimiento Con Shotcrete1Document21 paginiSostenimiento Con Shotcrete1julio1051Încă nu există evaluări

- CAP SEM Diseno Durabilidad-Shotcrete 01 JOLIN DesignModeling PDFDocument69 paginiCAP SEM Diseno Durabilidad-Shotcrete 01 JOLIN DesignModeling PDFjulio1051Încă nu există evaluări

- Ore Pass Practice in Canadian Mines: by J. Hadjigeorgiou, J.F. Lessard, and F. Mercier-LangevinDocument8 paginiOre Pass Practice in Canadian Mines: by J. Hadjigeorgiou, J.F. Lessard, and F. Mercier-Langevinjulio1051Încă nu există evaluări

- Tesis Estudio Geotecnico DiamantinaDocument179 paginiTesis Estudio Geotecnico DiamantinaAldo Villacorta DiazÎncă nu există evaluări

- Yieldlok Brochure PDFDocument2 paginiYieldlok Brochure PDFjulio1051Încă nu există evaluări

- Yoga MatDocument13 paginiYoga MatAnanthÎncă nu există evaluări

- Al-Cu-Si General Purpose Casting Alloy: WeldabilityDocument1 paginăAl-Cu-Si General Purpose Casting Alloy: Weldabilitymanjunath k sÎncă nu există evaluări

- Cement: Is A Complex Mixture of Dicalcium Silicate (C2S)Document18 paginiCement: Is A Complex Mixture of Dicalcium Silicate (C2S)Pratik AgajÎncă nu există evaluări

- Natural Bed Company Assembly InstructionsDocument3 paginiNatural Bed Company Assembly InstructionsFabian DeeÎncă nu există evaluări

- AWWA M22 SpreadsheetDocument2 paginiAWWA M22 SpreadsheetmassodiqÎncă nu există evaluări

- Circular Water Tank DesignDocument15 paginiCircular Water Tank Designsujit naikwadi100% (1)

- Bolts,: Threaded Parts TensionDocument2 paginiBolts,: Threaded Parts TensionMary MarasiganÎncă nu există evaluări

- Editorial and Resource StandardsDocument3 paginiEditorial and Resource StandardsjvanandhÎncă nu există evaluări

- PT - Bumi Laut Perkasa: AWS D1.1 Welding Procedure Specification (WPS)Document2 paginiPT - Bumi Laut Perkasa: AWS D1.1 Welding Procedure Specification (WPS)Wahyu Lailil FaisÎncă nu există evaluări

- AHSP 2019 Semester IDocument156 paginiAHSP 2019 Semester IFaisal Satyadi yusuf100% (1)

- PVA Fibre Reinforced High-Strength Cementitious Composite For 3D Printing Mechanical Properties and DurabilityDocument12 paginiPVA Fibre Reinforced High-Strength Cementitious Composite For 3D Printing Mechanical Properties and Durabilityhamed sadaghianÎncă nu există evaluări

- BOQ For Block WorkDocument16 paginiBOQ For Block Workbaboonijj100% (1)

- TDS-US-ParaWeb M, Nov15Document1 paginăTDS-US-ParaWeb M, Nov15Ammarah AzmatÎncă nu există evaluări

- Dupa Cost Estimate-MrfDocument23 paginiDupa Cost Estimate-MrfJonathanÎncă nu există evaluări

- Normas AlumínioDocument45 paginiNormas AlumíniovanessaÎncă nu există evaluări

- Alluminium Composite Panel-FlexibondDocument4 paginiAlluminium Composite Panel-Flexibondedars08Încă nu există evaluări

- Astm C 270 - 03Document14 paginiAstm C 270 - 03EliKax!Încă nu există evaluări

- Pricelist-Tubes & ValvesDocument39 paginiPricelist-Tubes & ValvesHKRajesh100% (1)

- The Earthquake Resistance of Traditional Timber and Masonry Dwellings in TurkeyDocument15 paginiThe Earthquake Resistance of Traditional Timber and Masonry Dwellings in TurkeyIvan LiewÎncă nu există evaluări

- Abrasive Water Jet MachiningDocument23 paginiAbrasive Water Jet MachiningMedal AnkhÎncă nu există evaluări

- 01 Vacuum ComponentsDocument84 pagini01 Vacuum ComponentsNick LaveryÎncă nu există evaluări

- Analysis of Full Depth Precast Concrete Bridge Deck PanelsDocument12 paginiAnalysis of Full Depth Precast Concrete Bridge Deck PanelsMedi EyobÎncă nu există evaluări

- Fdocuments - in - Automatic Ingot Feeder For BoundaryDocument5 paginiFdocuments - in - Automatic Ingot Feeder For BoundaryPooja BanÎncă nu există evaluări

- R901085028P00Document1 paginăR901085028P00Rene HebaÎncă nu există evaluări

- WOR8462 Handbook On SolderingDocument63 paginiWOR8462 Handbook On SolderingVigneswaranÎncă nu există evaluări

- WTA Bellow Sealed Valve MaintenanceDocument1 paginăWTA Bellow Sealed Valve MaintenanceicingrockÎncă nu există evaluări

- Vulcan WB10 / WB12 Vertical Weatherboard: Sheet Index Sheet No: Revision: Sheet NameDocument44 paginiVulcan WB10 / WB12 Vertical Weatherboard: Sheet Index Sheet No: Revision: Sheet NameLiam DevineÎncă nu există evaluări

- Material List and Cost EstimateDocument23 paginiMaterial List and Cost EstimateHein Zin HanÎncă nu există evaluări

- Final Presentation of Akaki Basic Metal Industry (ABMI) By. Workisa TemesgenDocument62 paginiFinal Presentation of Akaki Basic Metal Industry (ABMI) By. Workisa TemesgenWorkisa Temesgen100% (6)

- Updated SP-511Document7 paginiUpdated SP-511Feroz GullÎncă nu există evaluări