Documente Academic

Documente Profesional

Documente Cultură

WPS For WPQ - 6G

Încărcat de

Zouhair BenmabroukDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

WPS For WPQ - 6G

Încărcat de

Zouhair BenmabroukDrepturi de autor:

Formate disponibile

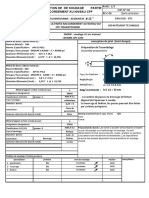

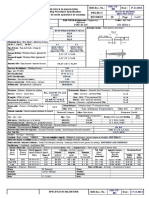

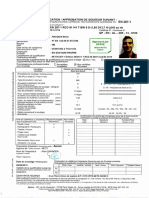

WPS No. / N DMOS : Rev.

WELDING PROCEDURE SPECIFICATION

DMOS 167-2016 0

ASME Section IX

Page / Page 1/2

Company name Supporting PQR(s)

Nom de la socit

ARENA LIBYA Construction Bas sur PQR(s)

PQR 43 / ASME IX

Product designation Drawing no.

Dsignation du produit

WPQ - 6G Schma N

Order no. Part no.

N Affaire Rf. pice

Joints / Type de joint (QW-402) Specific Joint Detail(s) / Prparation des joints

Dimensions / Dimensions Joint design / Schma de prparation Welding sequence / Disposition des passes

t = 7.62 mm

= 88.9 mm 3

u = 2 mm

= 60

b = 3 mm 2

t

u

b

1

Notes / Remarques

Backing / Support envers None / (Aucun) Material / Matriau None / (Aucun)

Retainers / Soutien du bain de fusion None / (Aucun) Material / Matriau

Base metals / Matriaux de base (QW-403)

P-No. 1, Group No. 1, SA-106 B welded to: / soud sur: P-No. 1, Group No. 1, SA-106 B

Other / Autre /

Groove / Soudure bout

Thickness Range / Plage d'paisseur

bout

5-12 mm Fillet / Soudure dangle ALL

Groove / Soudure bout

range qualified / Plage de diamtre qualifie

bout

ALL Fillet / Soudure dangle ALL

Thickness Range Impact / Plage d'paisseur avec Groove / Soudure bout

essai de choc bout

NA Fillet / Soudure dangle NA

Filler metals / Matriau d'apport (QW-404) Deposited weld metal Thickness range / Plage d'paisseur qualifie du mtal fondu

Groove / Soudure bout

1) SMAW

bout

3 mm Fillet / Soudure dangle NA

Groove / Soudure bout

2) SMAW

bout

2 mm Fillet / Soudure dangle NA

Groove / Soudure bout

3) SMAW

bout

2 mm Fillet / Soudure dangle NA

Welding Process(es) / Procd de soudage 1) SMAW 2) SMAW 3) SMAW

Spec. No. (SFA) SFA/AWS A5.1 SFA/AWS A5.1 SFA/AWS A5.1

AWS No. (Class) E6010 E 7018-1 H4 E 7018-1 H4

F-No. / A-No. / / /

Filler metal size / Dimensions MA 2.5 mm 2.5 mm 2.5 mm

Manufacturer / Fabricant SAF-FRO SAF-FRO

Trade name / Marque commerciale SAFER NF 510 S SAFER NF 510 S

Rebaking / Etuvage Time: 2 h Time: 2 h Time: 2 h

Temperature: 350 C Temperature: 350 C Temperature: 350 C

of Filler Metal > 1/4" (6 mm) not used not used not used

Matriau d'apport > 1/4 " (6 mm) (Non utilis) (Non utilis) (Non utilis)

Other / Autres / / /

Preheat / Prchauffage (QW-406)

Preheat Temp. Min 10 min C Interpass Temp. max. 250 max C Preheat Maintenace Flame / (Flamme)

Temp. prchauffage mini Temp. entre-passes maxi Type de prchauffage

Post Weld Heat Treatment / Post-traitement thermique (QW-407) Without / (Sans)

- not a welding variable for this process

ARENA WELDING DEPARTMENT

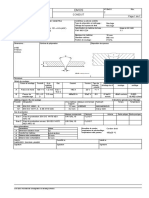

WPS No. / N DMOS : Rev.

WELDING PROCEDURE SPECIFICATION

DMOS 167-2016 0

ASME Section IX

Page / Page 2/2

Gas / Gas (QW-408) Type / Composition Flow Rate Pre / post purge time Product Name Manufacturer

Type / Composition Volume Dures pr-/post-gaz Nom Produit Fabricant

Backing

1) without / (sans) /

Gaz de protection envers

Backing

2) without / (sans) /

Gaz de protection envers

Backing

3) without / (sans) /

Gaz de protection envers

Welding data / Donne de soudage

Welding Process(es) / Procd de soudage 1) SMAW 2) SMAW 3) SMAW

Weld layers / Passes de soudage Root pass

ALL ALL

(Passe de fond)

Type / Type manual welding manual welding manual welding

(manuel) (manuel) (manuel)

Position(s) of Groove / Positions soudure bout 6G 6G 6G

bout

Weld Progression Groove / Sens de soudage NA NA NA

soudure bout bout

Position(s) of Fillet / Positions soudure dangle NA NA NA

Weld Progression Fillet / Sens de soudage NA NA NA

soudure dangle

Type + Polarity / Type et polarit =/- =/+ =/+

Current / Courant 45-60 A 85-100 A 85-100 A

Volts / Tension 24-26 V 22-24 V 22-24 V

Travel speed / Vitesse de soudage 12-16 cm/min 12-16 cm/min 11-15 cm/min

Heat input / Apport de chaleur 0.405 - 0.78 kJ/mm 0.701 - 1.2 kJ/mm 0.748 - 1.309 kJ/mm

String or Weave bead / Cordon droit/oscillant string bead string bead string bead

(Cordon droit) (Cordon droit) (Cordon droit)

Multiple or Single Pass (per side) multiple multiple multiple

Soudage monopasse/multipasse (par ct) (Soudage (Soudage (Soudage

multipasse) multipasse) multipasse)

Maximum (t) for one pass < than 6 mm < than 6 mm < than 6 mm

Maximum (t) pour un cordon de soudure (< de 6 mm) (< de 6 mm) (< de 6 mm)

Remark 1 / Remarque 1 / / /

Remark 2 / Remarque 2 / / /

Technique / Procd (QW-410)

Peening / Martelage not allowed / (Interdit)

Initial and interpass Cleaning Meulage + Brossage

Nettoyage initiale et entre-passes

Method of back Gouging Grinding / (Meulage)

Type de gougeage arrire

Use of thermal processes not used / (Non utilis)

Procd thermique

Prepared / Auteur BACEM AMAR Checked / Vrifi par ABDALLAH KALLEBI Released / Valid par FATHI AMAR

Date / Date 17/10/2016 Date / Date 19/04/2016 Date / Date 19/04/2016

Signature / Signature Signature / Signature Signature / Signature

- not a welding variable for this process

ARENA WELDING DEPARTMENT

S-ar putea să vă placă și

- Règles FB (P92-701)Document71 paginiRègles FB (P92-701)Pan Panam100% (1)

- QTCUT2Document25 paginiQTCUT2Rafik Thaalbi100% (1)

- Rédaction D'un D.M.O.S (EN ISO 15609 - 1)Document6 paginiRédaction D'un D.M.O.S (EN ISO 15609 - 1)sakina laabid50% (2)

- Guide Soudabilité Matériaux Par GroupeDocument115 paginiGuide Soudabilité Matériaux Par GroupePetitloup2013100% (2)

- Catabolisme Acides GrasDocument11 paginiCatabolisme Acides GrascepÎncă nu există evaluări

- Codification Européenne Des Types de Soudure Soudage 2000Document3 paginiCodification Européenne Des Types de Soudure Soudage 2000Mhéîdô ColoryoÎncă nu există evaluări

- Support de CoursDocument43 paginiSupport de CoursSalah Jallali0% (1)

- CHIMIEDocument108 paginiCHIMIEdazeÎncă nu există evaluări

- Diagnostique Des Reseaux d'AEPDocument174 paginiDiagnostique Des Reseaux d'AEPhaouachem100% (2)

- 10-Lesassemblages Par Éléments FiletésDocument9 pagini10-Lesassemblages Par Éléments FiletésSegaAlainCoulibalyÎncă nu există evaluări

- Welding InspectorDocument38 paginiWelding InspectorMalek RekikÎncă nu există evaluări

- WPS-P 5Document2 paginiWPS-P 5Touil HoussemÎncă nu există evaluări

- Assistant de Soudage Et ASMEDocument11 paginiAssistant de Soudage Et ASMEDanem Halas100% (1)

- RAPPORT Final PDFDocument86 paginiRAPPORT Final PDFAnass El Kasmaoui100% (2)

- PV de Controle Visuel Gr6Document48 paginiPV de Controle Visuel Gr6Kali Abdennour100% (1)

- Certificat de Qualification Du Mode Opératoire de Soudage Cevital MS QMOS N3Document3 paginiCertificat de Qualification Du Mode Opératoire de Soudage Cevital MS QMOS N3Danem Halas100% (1)

- ASME IX Positions de SoudageDocument2 paginiASME IX Positions de SoudageFethi BELOUISÎncă nu există evaluări

- Controle Soudage Globale 2016Document129 paginiControle Soudage Globale 2016walid walid100% (1)

- Diaporama 9606 1 PDFDocument28 paginiDiaporama 9606 1 PDFZouhair BenmabroukÎncă nu există evaluări

- Diaporama 9606 1 PDFDocument28 paginiDiaporama 9606 1 PDFZouhair BenmabroukÎncă nu există evaluări

- 1 Dossier Constructeur Index FrenchDocument2 pagini1 Dossier Constructeur Index FrenchSaidÎncă nu există evaluări

- Procédure APGV 2017Document27 paginiProcédure APGV 2017rahmaniÎncă nu există evaluări

- Format de Qualification de SoudeurDocument1 paginăFormat de Qualification de SoudeurScribdTranslationsÎncă nu există evaluări

- WPS SmawDocument1 paginăWPS SmawTouil HoussemÎncă nu există evaluări

- NF P 84-500 Géomombranes PDFDocument20 paginiNF P 84-500 Géomombranes PDFbastopheÎncă nu există evaluări

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document0 paginiPipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Siddiqui Abdul KhaliqÎncă nu există evaluări

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document0 paginiPipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Siddiqui Abdul KhaliqÎncă nu există evaluări

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document0 paginiPipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Siddiqui Abdul KhaliqÎncă nu există evaluări

- WPS Spécimen CSC ASME IXDocument5 paginiWPS Spécimen CSC ASME IXMenad SalahÎncă nu există evaluări

- WPS 01Document3 paginiWPS 01Zouhair BenmabroukÎncă nu există evaluări

- PQR 06-19 PDFDocument34 paginiPQR 06-19 PDFbouchoucha jebaliÎncă nu există evaluări

- WPS N°4 Oc 7010Document2 paginiWPS N°4 Oc 7010Said100% (1)

- WQR Saf 015Document1 paginăWQR Saf 015Radj SoLoÎncă nu există evaluări

- WPs Magi Inx11111Document7 paginiWPs Magi Inx11111Danem HalasÎncă nu există evaluări

- Plan D'Inspection QualiteDocument4 paginiPlan D'Inspection QualiteAldany Berancy Dorvela BitsindouÎncă nu există evaluări

- DMOS11Document1 paginăDMOS11sakina laabidÎncă nu există evaluări

- ControleDocument4 paginiControleOlss BbzoÎncă nu există evaluări

- CEWAC QMOS ExplicationDocument2 paginiCEWAC QMOS ExplicationAmi Roslane100% (1)

- Cours Guide en 15614-1Document33 paginiCours Guide en 15614-1laz_kÎncă nu există evaluări

- Vademecum Pour Inspecteur - Type de Défauts - CopieDocument86 paginiVademecum Pour Inspecteur - Type de Défauts - CopieIbrahima BIBANG0% (1)

- API 1104 Illustrations D'imperfections de SouduresDocument2 paginiAPI 1104 Illustrations D'imperfections de SouduresFethi BELOUISÎncă nu există evaluări

- ASME IX Variables WPS - SMAWDocument1 paginăASME IX Variables WPS - SMAWFethi BELOUISÎncă nu există evaluări

- Rediger Et Verifier Un Cahier de SoudageDocument2 paginiRediger Et Verifier Un Cahier de SoudageTeam QuestIn100% (2)

- Dmos Ato 5755 32Document4 paginiDmos Ato 5755 32Patrick BaridonÎncă nu există evaluări

- Procedure DP Lala Abdia 8x40 GZ1Document17 paginiProcedure DP Lala Abdia 8x40 GZ1Tayyeb Ouis100% (1)

- EssaisDocument24 paginiEssaisNaceri Mohamed RedhaÎncă nu există evaluări

- Comment Bien Choisir Son Gaz de Protection de Soudage Selon Le Procédé ENBAGDocument14 paginiComment Bien Choisir Son Gaz de Protection de Soudage Selon Le Procédé ENBAGdaemsalÎncă nu există evaluări

- SEANCE-45 - Lire Et Interpréter La Norme de Qualification de Soudage ISO 9606-1Document21 paginiSEANCE-45 - Lire Et Interpréter La Norme de Qualification de Soudage ISO 9606-1Julian EmpraÎncă nu există evaluări

- Catalogue de Formation Du CETIME ©2019 (2ème Édition)Document4 paginiCatalogue de Formation Du CETIME ©2019 (2ème Édition)Le CETIME - Centre Technique des Industries Mécaniques et ÉlectriquesÎncă nu există evaluări

- Grue 1Document2 paginiGrue 1alex mackaghaÎncă nu există evaluări

- 07-19 Oil Libya Mesure D'épaisseurDocument6 pagini07-19 Oil Libya Mesure D'épaisseurZarai MaherÎncă nu există evaluări

- Iso 4063Document1 paginăIso 4063Vivien EmeraldoÎncă nu există evaluări

- Procèdes de Soudage SAWDocument7 paginiProcèdes de Soudage SAWFethi BELOUISÎncă nu există evaluări

- Rédaction Dmos WPS de Soudage Eswl 01 2019Document2 paginiRédaction Dmos WPS de Soudage Eswl 01 2019saxhorn100% (2)

- Achat Sur Stock Clapets Anti Retour 8''Document32 paginiAchat Sur Stock Clapets Anti Retour 8''SaidÎncă nu există evaluări

- Contrôle Soudage 2Document28 paginiContrôle Soudage 2rbibouh100% (1)

- 7 - Catalogue2007SoudageTig Inertage94 114Document20 pagini7 - Catalogue2007SoudageTig Inertage94 114daemsalÎncă nu există evaluări

- Aquaprox PC7300-Fiche TechDocument2 paginiAquaprox PC7300-Fiche TechRedhouane OudjidaÎncă nu există evaluări

- Problèmes Et Défauts de Soudage - Causes Et Remèdes PDFDocument1 paginăProblèmes Et Défauts de Soudage - Causes Et Remèdes PDFmail_younes6592100% (1)

- Liste Des Taches de L'inspecteur en SoudageDocument9 paginiListe Des Taches de L'inspecteur en SoudageFethi BELOUISÎncă nu există evaluări

- IWIPDocument87 paginiIWIPg33k59Încă nu există evaluări

- Tableau Des Couples de Serrage de BrideDocument3 paginiTableau Des Couples de Serrage de Bridedi piazzaÎncă nu există evaluări

- Provincial Registration: MS WPDocument2 paginiProvincial Registration: MS WPazertyÎncă nu există evaluări

- Specification de de Soudage Partie Local Technique Z21: Type D'enrobageDocument2 paginiSpecification de de Soudage Partie Local Technique Z21: Type D'enrobagesifaouiÎncă nu există evaluări

- 316L-GTSM-002 R.00Document3 pagini316L-GTSM-002 R.00Massimo FumarolaÎncă nu există evaluări

- CS-GT-009 R.00Document2 paginiCS-GT-009 R.00Massimo FumarolaÎncă nu există evaluări

- 1 PDFDocument41 pagini1 PDFKhalidMoutarajiÎncă nu există evaluări

- Welding Procedure Specification Descript de Mode Opératoire de SoudageDocument2 paginiWelding Procedure Specification Descript de Mode Opératoire de SoudageMassimo FumarolaÎncă nu există evaluări

- 133-WPS Blondin2170Document1 pagină133-WPS Blondin2170sakina laabidÎncă nu există evaluări

- Modele DMOS2022-03-0003-1Document7 paginiModele DMOS2022-03-0003-1maazouz radouaneÎncă nu există evaluări

- Img 004Document1 paginăImg 004Aïdara SowÎncă nu există evaluări

- WPS BoumerdesDocument13 paginiWPS BoumerdesBensmatÎncă nu există evaluări

- 5025 Soco MT 1364 16Document1 pagină5025 Soco MT 1364 16Zouhair BenmabroukÎncă nu există evaluări

- 5025 Soco PT 421 16Document1 pagină5025 Soco PT 421 16Zouhair BenmabroukÎncă nu există evaluări

- 5025 Soco MT 412 16Document1 pagină5025 Soco MT 412 16Zouhair Benmabrouk100% (1)

- 5025 Soco PT 413 16Document2 pagini5025 Soco PT 413 16Zouhair BenmabroukÎncă nu există evaluări

- 5025 Soco PT 421 16Document1 pagină5025 Soco PT 421 16Zouhair BenmabroukÎncă nu există evaluări

- 5025 Soco MT 423 16Document1 pagină5025 Soco MT 423 16Zouhair BenmabroukÎncă nu există evaluări

- 5025 Soco PT 421 16Document1 pagină5025 Soco PT 421 16Zouhair BenmabroukÎncă nu există evaluări

- 5025 Soco PT 421 16Document1 pagină5025 Soco PT 421 16Zouhair BenmabroukÎncă nu există evaluări

- Rapport Inspection Echangeur: Caracteristiques TechniquesDocument5 paginiRapport Inspection Echangeur: Caracteristiques TechniquesZouhair BenmabroukÎncă nu există evaluări

- 5025 Soco PT 421 16Document1 pagină5025 Soco PT 421 16Zouhair BenmabroukÎncă nu există evaluări

- Welder LOG 2017Document2 paginiWelder LOG 2017Zouhair BenmabroukÎncă nu există evaluări

- 8.34C306 Iv-Ta-2014Document6 pagini8.34C306 Iv-Ta-2014Zouhair BenmabroukÎncă nu există evaluări

- Rapport Inspection Echangeur: RAPPORT N°:0315-436-IV 36-E-123 BDocument7 paginiRapport Inspection Echangeur: RAPPORT N°:0315-436-IV 36-E-123 BZouhair BenmabroukÎncă nu există evaluări

- 3.34H101 Iv-Ta-2014Document10 pagini3.34H101 Iv-Ta-2014Zouhair BenmabroukÎncă nu există evaluări

- 1.36H101 Iv-Ta-2014Document22 pagini1.36H101 Iv-Ta-2014Zouhair BenmabroukÎncă nu există evaluări

- 6.34C201 Iv-Ta-2014Document12 pagini6.34C201 Iv-Ta-2014Zouhair BenmabroukÎncă nu există evaluări

- Assistant de Soudage Et ASME PDFDocument11 paginiAssistant de Soudage Et ASME PDFKamel BousninaÎncă nu există evaluări

- 3040guide Qualitesoudage-2010Document46 pagini3040guide Qualitesoudage-2010YahyaMoummouÎncă nu există evaluări

- 2.34H201 Iv-Ta-2014Document14 pagini2.34H201 Iv-Ta-2014Zouhair BenmabroukÎncă nu există evaluări

- WPS Et PQR-193Document18 paginiWPS Et PQR-193Zouhair Benmabrouk100% (1)

- Repertoire Des Memoires 2014Document121 paginiRepertoire Des Memoires 2014Prince TendjonÎncă nu există evaluări

- Mini Projet SprayDocument9 paginiMini Projet Sprayanass benhassi100% (1)

- LEVOTHYROX - Sommation Interpellative Extraits Sans Nom 02112017Document5 paginiLEVOTHYROX - Sommation Interpellative Extraits Sans Nom 02112017Christophe LèguevaquesÎncă nu există evaluări

- 3 MSPMChap 3Document26 pagini3 MSPMChap 3soumia bouÎncă nu există evaluări

- STG C120Document14 paginiSTG C120bouabdallah laref100% (1)

- GazochimieDocument9 paginiGazochimieHadjer zitÎncă nu există evaluări

- NotcompDocument37 paginiNotcompxxxÎncă nu există evaluări

- UranuimDocument40 paginiUranuimOussama DhahriÎncă nu există evaluări

- ENAP CHLORIC CC Blanc F C Ref 218103901Document1 paginăENAP CHLORIC CC Blanc F C Ref 218103901massiÎncă nu există evaluări

- 47K - Operating Manual - 10052472 - 09 - FRDocument39 pagini47K - Operating Manual - 10052472 - 09 - FRAhmed HarratÎncă nu există evaluări

- Chapitre I: Formes Des Médicaments SolidesDocument22 paginiChapitre I: Formes Des Médicaments SolidesDjellal Zahariya mohammadÎncă nu există evaluări

- Copie de Annale Finalisée - A4 VF ProfsDocument83 paginiCopie de Annale Finalisée - A4 VF Profsfalilou loÎncă nu există evaluări

- Ca CL 2Document1 paginăCa CL 2Fatima VessaliusÎncă nu există evaluări

- Solutions Ozone Eau Potable WedecoDocument8 paginiSolutions Ozone Eau Potable WedecoalainÎncă nu există evaluări

- Arrêté2008 885 PDFDocument14 paginiArrêté2008 885 PDFkhouloudÎncă nu există evaluări

- Ec AntoineDocument28 paginiEc AntoineAlicia ZÎncă nu există evaluări

- 17-Techniques de Biologie MoléculaireDocument76 pagini17-Techniques de Biologie MoléculaireInsafÎncă nu există evaluări

- Dosage de L'acide Citrique Dans Un Détartrant Commercial (Corrigé)Document4 paginiDosage de L'acide Citrique Dans Un Détartrant Commercial (Corrigé)theobromine100% (5)

- Determination A Sec Du Coefficient Micro-DevalDocument3 paginiDetermination A Sec Du Coefficient Micro-DevalL'acteur VictimeÎncă nu există evaluări

- Revisions 2nd Atomes Et Molecules PDFDocument2 paginiRevisions 2nd Atomes Et Molecules PDFSaad MabchourÎncă nu există evaluări

- MSDS HelichryseDocument26 paginiMSDS HelichryseOnjaÎncă nu există evaluări

- Exercices Diversite Usage MatiereDocument2 paginiExercices Diversite Usage Matierem.cadartÎncă nu există evaluări

- Fiche Métier - Employé de Station ServiceDocument11 paginiFiche Métier - Employé de Station ServiceCHEIKH ALIOU SOUANEÎncă nu există evaluări