Documente Academic

Documente Profesional

Documente Cultură

Friction Belt Drive Problems

Încărcat de

Kenta HirohataDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Friction Belt Drive Problems

Încărcat de

Kenta HirohataDrepturi de autor:

Formate disponibile

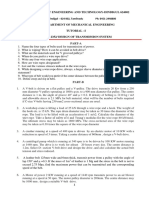

FME 212: Belt Drive Problems

1. Figure Q1 illustrates an open flat belt drive. Identify all the links and kinematic

pairs in the drive.

O1 O2

Fig. Q1

In the flat-belt drive of Fig. Q1, the angle of wrap on the smaller pulley is 1600, the

speed ratio is 5 to 1, and the nominal diameter of the smaller pulley is 100 mm.

Calculate the centre distance and the length of the belt.

Suppose that the belt is linearly elastic and that, after assembly, it retains a constant

length whether it transmits power or not. If the mass per unit length of the

assembled belt is 0.2 kg/m, the limiting coefficient of friction between the belt and

either pulley is 0.25, and the linear speed of the belt is limited to 20 m/s, determine

the initial tension for maximum power transmission without slip, and the

corresponding transmitted power.

2. Name the three most common mechanisms for the transmission of mechanical

power between two parallel shafts.

A flat belt drive has a centre distance of 1.55 m. The smaller pulley, which is the

driver, has an effective diameter of 0.2 m, and is driven at 1000 rpm. The angle of

wrap on the smaller pulley is 150 degrees. Neglecting the mass of the belt and

assuming the free lengths of the belt to be straight,

Determine the linear belt speed and the angular velocity ratio of the drive,

assuming there is no slip between the belt and either pulley

Determine the tensions in the free lengths of the belt and the direction and

magnitude of the total load on the bearings of the driving shaft.

Friction Belt Drives 1 of 4

An open V-belt drive transmits 12 kW from a 255 mm pitch diameter sheave,

operating at 1800 rpm, to a 637.5 mm pitch diameter sheave. The centre distance

between the input and output shaft axes is 1000 mm. The sheave groove angles are

40o each. The coefficient of friction between the belt and each sheave is 0.2. The

mass per unit length of the belt is 0.78 kg/m. The maximum allowable tension in the

belt is 900 N. How many belts are necessary on this drive?

3. The belt in an open V-belt drive is 2230 mm long, and operates on sheaves whose

pitch diameters are 300 mm and 400 mm, respectively. The length of the belt may

be estimated by use of the following equation:

( D2 D1 ) 2

L = 2C + 1.57( D1 + D2 ) +

4C

where: L is the length of the belt

C is the drives centre distance

D1, D2 are the pitch diameters of the smaller and larger sheaves,

respectively.

Determine the angle of wrap on the smaller sheave.

4. In an open flat-belt drive, the belt has a unit mass of 0.2 kg/m. When the drive is

operated such that maximum power is transmitted, with just no slip between belt and

either pulley, the tensions in the tight and slack sides of the belt are 450 N and 260

N, respectively. Given that the two pulleys are made of the same material, that the

belt is linearly elastic and retains a constant overall length under all operating

conditions, that the smaller pulley diameter is 150 mm, that the larger pulley

diameter is 420 mm, and that the centre distance is 480 mm, determine:

The linear speed of the belt

The power transmitted

The limiting coefficient of friction

The approximate length of the belt

5. Explain why a belt drive can provide some overload protection to driven machines

and contrast this phenomenon with the case of a chain drive.

The smaller sheave in a V-belt drive has a pitch diameter of 200 mm and a V-groove

of 400 included angle. The angle of wrap on this sheave is 1500. If the maximum

running belt tension is to be 1000 N, and the coefficient of friction is 0.25, determine

the number of belts that will be required in order to transmit 40 kW at 1200 rpm.

You may neglect the mass of the belts.

Friction Belt Drives 2 of 4

6. The data give pertain to the belt drive illustrated in Fig. Q6.

Pulley 1

Pulley 2

O1 O2

Fig. Q6

Centre distance O1O2 = C = 480 mm Tight side tension, Ft = 450 N

Radius of larger pulley, R1 = 210 mm Slack side tension, Fs = 260 N

Radius of smaller pulley, R2 = 75 mm

What are the values of the torques on the two shafts? What is the accurate length of

the belt? What is the combined reaction on the bearing supporting the shaft whose

axis is at O1.

7. Compare the V-belt drive, the chain drive and the gear drive in the contexts of:

Power transmission capacity

Speed of operation

Compactness

Noise levels

A V-belt drive has a groove angle of 380. The linear speed of the belt is to be 10.5

m/s and the smaller pulley, which is to be the driver, is to be driven at 1 000 rpm. If

the speed ratio is to be 5:1, the angle of wrap on the smaller pulley is to be 1500 and

the coefficient of static friction between the belt and the pulleys is 0.27, determine:

(i) The centre distance of the drive

(ii) The length of the belt

(iii) The power transmitted by the drive, if the tension in the slack side of the belt is

to be 285 N. You may neglect the mass of the belt.

Friction Belt Drives 3 of 4

8. A shaft is to be driven at 480 rpm, from a driving shaft that rotates at 200 rpm,

through an open flat belt drive. The centre distance of the drive is 1000 mm and the

diameter of the driving pulley, is 240 mm. The coefficient of friction between the

belt and the pulleys is = 0.3 . If the drive can transmit a maximum power of 3 kW

without slipping of the belt relative to the pulleys, determine the necessary belt

width if the safe permissible belt tension is 15 N per mm of belt width.

Neglect any centrifugal effects.

4.0 Resources

BUDYNAS, RICHARD G. and J. KEITH NISBETT. Shigleys Mechanical

Engineering Design, 8th Edition, Chapter 17 Flexible Mechanical Elements.

McGraw-Hill International, 2008.

DIMAROGONAS, ANDREW D. Machine Design. A CAD Approach, Chapter

10 Design of Dry Friction Elements. Wiley Interscience, 2001.

WILSON, CHARLES E. Computer Integrated Machine Design, Chapter 10

Belt Drives. Prentice Hall International, 1997.

BURR, ARTHUR H. and JOHN B. CHEATHAM. Mechanical Analysis and

Design, Second Edition, Chapter 3 Friction Theory and Applications. Prentice

Hall, 1995.

SPOTTS, M. F. Design of Machine Elements, 6th Edition, Chapter 6 Belts,

Clutches, Brakes, and Chains. Prentice Hall, 1991.

JUVINALL, ROBERT C. Fundamentals of Machine Component Design,

Chapter 19 Miscellaneous Power Transmission Components. John Wiley and

Sons, 1983.

BLACK, PAUL H. and O. EUGENE ADAMS Jr. Machine Design, 3rd Edition,

Chapter 14 Belt Drives and Hoists. McGraw-Hill International, 1981.

http://school.mech.uwa.edu.au/~dwright/DANotes/V-belts/intro/intro.html#top

Many standard texts on engineering mechanics include chapters on friction, which

may deal with belt friction and clutch theory.

Many standard texts on the theory of machines include chapters dealing with belt

drive theory.

Other Internet Resources.

Friction Belt Drives 4 of 4

S-ar putea să vă placă și

- Electronic Control Module (Power Train) ... 120H, 12H, 135H, 140H, 143H, 160H and 163H Motor Graders Caterpillar - Spare Parts PDFDocument11 paginiElectronic Control Module (Power Train) ... 120H, 12H, 135H, 140H, 143H, 160H and 163H Motor Graders Caterpillar - Spare Parts PDFbrahimÎncă nu există evaluări

- Electrical Load Calculations for Building ConstructionDocument16 paginiElectrical Load Calculations for Building ConstructionKitz DerechoÎncă nu există evaluări

- Erv CatalogueDocument12 paginiErv CatalogueSaahil KhaanÎncă nu există evaluări

- BELTS,ROPES & CHAIN DRIVE SYSTEMSDocument54 paginiBELTS,ROPES & CHAIN DRIVE SYSTEMSIshank Singh SandhuÎncă nu există evaluări

- Reduce Evaporative Emissions with the Prius EVAP SystemDocument18 paginiReduce Evaporative Emissions with the Prius EVAP Systemlongtrandang5867100% (1)

- Caterpillar Cat GC20K HP Forklift Lift Trucks Service Repair Manual SN AT82E-90011 and Up PDFDocument30 paginiCaterpillar Cat GC20K HP Forklift Lift Trucks Service Repair Manual SN AT82E-90011 and Up PDFfjkskekmdmme0% (1)

- Machine Design Chapter SummaryDocument254 paginiMachine Design Chapter SummaryErAniketKokateÎncă nu există evaluări

- Motivation and Background: Simple and Effective Solution For Organic WasteDocument1 paginăMotivation and Background: Simple and Effective Solution For Organic WasteRadu GeorgescuÎncă nu există evaluări

- CD Deluxe New PDFDocument109 paginiCD Deluxe New PDFSANTOSH KUMAR100% (3)

- 1200 Bunker and Field Rake TM1525Document476 pagini1200 Bunker and Field Rake TM1525ZeeÎncă nu există evaluări

- NSR Nab-1000 (Ais Transponder (B) ) User's ManualDocument25 paginiNSR Nab-1000 (Ais Transponder (B) ) User's ManualPalaKhartikeyan50% (4)

- Mechatronic Component ofDocument2 paginiMechatronic Component ofdljbÎncă nu există evaluări

- Class Exercise 1 - OttoDocument1 paginăClass Exercise 1 - OttoHaziq MansorÎncă nu există evaluări

- Sumande - Field Work No.10 - Laying of Simple Curve Using Theodolite and TapeDocument8 paginiSumande - Field Work No.10 - Laying of Simple Curve Using Theodolite and TapeCedrix SumandeÎncă nu există evaluări

- Bend Test Determines Ductility of Reinforcing Steel BarsDocument14 paginiBend Test Determines Ductility of Reinforcing Steel BarsJohn Henry SalvadoÎncă nu există evaluări

- Hydraulic Similitude and Dimensional Analysis, RL. Acol, Cajipe, Goles CE-5CDocument5 paginiHydraulic Similitude and Dimensional Analysis, RL. Acol, Cajipe, Goles CE-5CRalph Lobederio AcolÎncă nu există evaluări

- Ria SiduheADocument3 paginiRia SiduheAshimic32000Încă nu există evaluări

- Mechanical Laboratory 2 OrientationDocument17 paginiMechanical Laboratory 2 OrientationRustom Janno S. GersinÎncă nu există evaluări

- Sheet 2 VibrationDocument1 paginăSheet 2 VibrationEngAbdallahMohamedÎncă nu există evaluări

- Dynamics LectureDocument220 paginiDynamics LectureShiro Emiya0% (2)

- Theory of Machinary-1 PDFDocument258 paginiTheory of Machinary-1 PDFPriya KumarÎncă nu există evaluări

- Velocity in MechanismsDocument41 paginiVelocity in MechanismsMohamed MostafaÎncă nu există evaluări

- Tme 11303 CHP1Document26 paginiTme 11303 CHP1Tuisyen Al FatehÎncă nu există evaluări

- 1617 Iemecon Handouts PDFDocument82 pagini1617 Iemecon Handouts PDFJose Lorenz Gerard CutaranÎncă nu există evaluări

- Generations of Microprocessors: From 4004 to Core i7Document23 paginiGenerations of Microprocessors: From 4004 to Core i7AnasÎncă nu există evaluări

- Friction ScrewsDocument51 paginiFriction ScrewsMewnEProwt100% (1)

- Technological Institute of The Philippines: Data and ResultsDocument6 paginiTechnological Institute of The Philippines: Data and Resultsjec_tanez100% (3)

- DTS Question BankDocument21 paginiDTS Question BankSam TirshathÎncă nu există evaluări

- Dme-II Question BankDocument4 paginiDme-II Question BankenggsantuÎncă nu există evaluări

- St. Joseph's College Design of Transmission Systems DocumentDocument14 paginiSt. Joseph's College Design of Transmission Systems DocumentAravinthan VijayanÎncă nu există evaluări

- Me1036 Dts Tutorial Note BookDocument176 paginiMe1036 Dts Tutorial Note BookSachi DhanandamÎncă nu există evaluări

- Design and Selection of Belt, Rope and Chain DrivesDocument7 paginiDesign and Selection of Belt, Rope and Chain DrivesenggsantuÎncă nu există evaluări

- ME-311 Belt 2018Document2 paginiME-311 Belt 2018VishnuÎncă nu există evaluări

- Topics - Clutches, Belts and Ropes: Part - ADocument3 paginiTopics - Clutches, Belts and Ropes: Part - AramÎncă nu există evaluări

- Belt Design AssngmntDocument1 paginăBelt Design AssngmntMohammedAminShaikhÎncă nu există evaluări

- Design of Transmission Systems Question Bank 1Document27 paginiDesign of Transmission Systems Question Bank 1shivesh rockesÎncă nu există evaluări

- Unit-I Design of Transmission Systems For Flexible Elements - Part-A Belt DrivesDocument15 paginiUnit-I Design of Transmission Systems For Flexible Elements - Part-A Belt DrivesM Rasyid RidhoÎncă nu există evaluări

- Simple Mechanisms: (2 Marks) 1. What Are The Materials Used For Making Ropes?Document3 paginiSimple Mechanisms: (2 Marks) 1. What Are The Materials Used For Making Ropes?RahulÎncă nu există evaluări

- Group B3Document24 paginiGroup B3Atalelew ZeruÎncă nu există evaluări

- ME6601 Transmission Design QuestionsDocument11 paginiME6601 Transmission Design QuestionsMURUGANÎncă nu există evaluări

- Chapter Wise Questions Bank MD-iiDocument6 paginiChapter Wise Questions Bank MD-iiinderpreet singhÎncă nu există evaluări

- DTSDocument26 paginiDTSvijayakumarÎncă nu există evaluări

- ME2352-DTS Question BankDocument8 paginiME2352-DTS Question BankNaresh015Încă nu există evaluări

- Possible Exercise On Machine Element Two Flat BeltDocument4 paginiPossible Exercise On Machine Element Two Flat BeltAbebaw AyeleÎncă nu există evaluări

- Design of Transmission Systems-Question BankDocument28 paginiDesign of Transmission Systems-Question BankAlfred Franklin V100% (1)

- Design of Transmission Systems Question BankDocument26 paginiDesign of Transmission Systems Question BankJennifer WilsonÎncă nu există evaluări

- 7 Dts Question Bank-1Document22 pagini7 Dts Question Bank-1Placements DhaanishÎncă nu există evaluări

- SSM Institute Design of Transmission System TutorialDocument1 paginăSSM Institute Design of Transmission System TutorialRama SamyÎncă nu există evaluări

- Belt Drives ExamplesDocument3 paginiBelt Drives ExamplesMuhd Afiq AzmirÎncă nu există evaluări

- Belt Drive Assignment Problems SolvedDocument2 paginiBelt Drive Assignment Problems SolvedNevil ModiÎncă nu există evaluări

- 3.1.belt and Belt DrivesDocument17 pagini3.1.belt and Belt DrivesVignesh ShenoyÎncă nu există evaluări

- Belt Drive Module 1 ProblemsDocument3 paginiBelt Drive Module 1 ProblemsKerr GenebraldoÎncă nu există evaluări

- Tutorial 3 (Kom)Document2 paginiTutorial 3 (Kom)patelsandip1990Încă nu există evaluări

- Belt DriveDocument12 paginiBelt DriveBISHAL AdhikariÎncă nu există evaluări

- Assignment 3 MEC 302Document2 paginiAssignment 3 MEC 302naseemahmadkhan_123Încă nu există evaluări

- Design of Transmission System Question BankDocument18 paginiDesign of Transmission System Question BankAravind50% (2)

- Tutorial 8Document1 paginăTutorial 8PARTEEK SINGLAÎncă nu există evaluări

- Machine Design I TutorialDocument3 paginiMachine Design I TutorialbngelotrÎncă nu există evaluări

- Mechanism ComponentsDocument21 paginiMechanism ComponentsRocsÎncă nu există evaluări

- Design of Transmission Systems Question BankDocument27 paginiDesign of Transmission Systems Question BankbalajimetturÎncă nu există evaluări

- Belt DrivesDocument40 paginiBelt DrivesKhairil Ashraf Ahmad MalikiÎncă nu există evaluări

- Design of Transmission Systems Question BankDocument15 paginiDesign of Transmission Systems Question Bankpremgmech762Încă nu există evaluări

- Macdes BoardsDocument6 paginiMacdes BoardsJerdÎncă nu există evaluări

- Belt (Autosaved)Document59 paginiBelt (Autosaved)Khánh NguyễnÎncă nu există evaluări

- Me-1352 Design of Transmission SystemDocument7 paginiMe-1352 Design of Transmission Systemshujai cruise100% (1)

- Design of Transmission System - 2 Marks - All 5 UnitsDocument20 paginiDesign of Transmission System - 2 Marks - All 5 UnitsMohan Prasad.M80% (15)

- Design of Machine Elements - II: Assignment 5Document2 paginiDesign of Machine Elements - II: Assignment 5Abhishek KulkarniÎncă nu există evaluări

- Unit IDocument3 paginiUnit Imahendra babu mekalaÎncă nu există evaluări

- Assignment MS55301-20 WIJ001 2021A 4 BDocument1 paginăAssignment MS55301-20 WIJ001 2021A 4 BIqbal HabibÎncă nu există evaluări

- Sheet Pile WallDocument6 paginiSheet Pile Wallully amaliaÎncă nu există evaluări

- Biochar and Sustainable AgricultureDocument12 paginiBiochar and Sustainable AgricultureSusanThorntonHuÎncă nu există evaluări

- DS 7200hqhi K2Document4 paginiDS 7200hqhi K2tago_704714561Încă nu există evaluări

- Enhancing Student Interest in The Agricultural Sciences Through AquaponicsDocument4 paginiEnhancing Student Interest in The Agricultural Sciences Through AquaponicsAquaponicsÎncă nu există evaluări

- History-TAPP Quiz No. 001Document5 paginiHistory-TAPP Quiz No. 001Ranier PablicoÎncă nu există evaluări

- Tks RP Retrieval Tool: Installation, Operation & Maintenance InstructionsDocument30 paginiTks RP Retrieval Tool: Installation, Operation & Maintenance Instructionssaiful anwarÎncă nu există evaluări

- RPS Modrobs PDFDocument3 paginiRPS Modrobs PDFHarsha NÎncă nu există evaluări

- DCS Black Shark Ka-50 Keyboard MinilistDocument1 paginăDCS Black Shark Ka-50 Keyboard MinilistMichiel ErasmusÎncă nu există evaluări

- Quickly Overcome Obstacles: LukasDocument2 paginiQuickly Overcome Obstacles: LukasArrum FirdaÎncă nu există evaluări

- Sae Technical Paper Series: Pierre LabelleDocument14 paginiSae Technical Paper Series: Pierre LabelleClaireÎncă nu există evaluări

- Guide To Construction Projects 2006-Publication IssueDocument43 paginiGuide To Construction Projects 2006-Publication IssueAiswarya RajeevÎncă nu există evaluări

- UPV SoTech ChE Study PlanDocument4 paginiUPV SoTech ChE Study PlanBoodjieh So ImbaÎncă nu există evaluări

- Enhanced Oil Recovery Using PolymerDocument12 paginiEnhanced Oil Recovery Using Polymerkalpak jadhavÎncă nu există evaluări

- Advantages, Disadvantages AND ApplicationsDocument7 paginiAdvantages, Disadvantages AND ApplicationsEngineers GalleryÎncă nu există evaluări

- Is.9523.2000 0 PDFDocument38 paginiIs.9523.2000 0 PDFVijay Rama RajuÎncă nu există evaluări

- Brass PPTDocument41 paginiBrass PPTAbhiram shuklaÎncă nu există evaluări

- Ofna/Picco .26 Engine 51214 Pull Start 51213 Non-Pull Start: New Engine Break-InDocument3 paginiOfna/Picco .26 Engine 51214 Pull Start 51213 Non-Pull Start: New Engine Break-InClaude LerouxÎncă nu există evaluări

- Lathan Esei 5png TermoplastikDocument2 paginiLathan Esei 5png TermoplastikMell Honey MardenÎncă nu există evaluări

- Basic SWOT MatrixDocument1 paginăBasic SWOT MatrixTarenjeet SinghÎncă nu există evaluări

- Sa Akx92 PDFDocument157 paginiSa Akx92 PDFfjeroÎncă nu există evaluări

- 3ah3 PDFDocument44 pagini3ah3 PDFAndi GheorgheÎncă nu există evaluări