Documente Academic

Documente Profesional

Documente Cultură

Davit Arm Calculation

Încărcat de

joerijiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Davit Arm Calculation

Încărcat de

joerijiDrepturi de autor:

Formate disponibile

Page 188

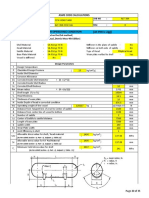

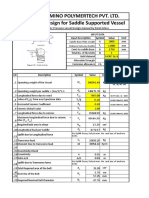

MANWAY DAVIT CALCULATION

(Ref. : Pressure Vessels Design Manual, Dennis R. Moss, 1989)

Job No. : Revision : REV A

Customer : Date : 08/12/10

Vessel Description : Prepared by : DMT

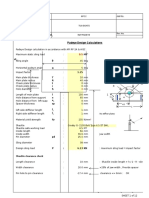

A Design Data

Weight of Blind Flange 56" NPS 300# w1 : 6,001 Lbs

Weight of Davit Arm w2 : 137 Lbs

Vertical Impact Factor Cv : 1.50

Horizontal Impact Factor Ch : 0.25

Size of Fillet Weld on Support tsup : 0.394 Inch

: 10 mm

Size of Fillet Weld on Stiffener tstiff : 0.394 Inch

: 10 mm

Size of Fillet Weld on Ring Pipe Plate tring : 1.417 Inch

: 36 mm

Allowable Stress of Fillet Weld f : 9,600 Lbs/square inch leg area

B Properties of Davit Arm

Mast (Round Bar)

Material of Mast Davit Arm : AH-36

Yield Stress of Mast Davit Arm Material Ysm : 51,488 psi

Outside Diameter of Round Bar Mast ODm : 6.30 Inch

Cross Sectional Area of Mast Davit Arm Apm : 31.16 Inch2

Moment Inertia of Mast Davit Arm Ipm : 77.29 Inch4

Section Modulus of Round Bar Zpm : 24.54 Inch3

Radius Gyration of Round Bar rgm : 1.57 Inch

Boom (Beam)

Material of Boom Davit Arm : AH-36

Yield Stress of Boom Davit Arm Material Ysm : 51,000 psi

Flange Depth db : 7.874 Inch

Web Thickness tb : 0.551 Inch

Web Height hb : 4.488 Inch

Flange Thickness tf : 0.551 Inch

Flange Width b : 7.874 Inch

Moment of Inertia Ib : 46.735 Inch4

Section Modulus of Boom Zb : 18.548 Inch3

Radius of Gyration rb : 2.075 Inch

Secttion Area Ab : 10.850 Inch2

C Properties of Eye Bolt

Material of Eye Bolt : SA-193 Gr B7

Allowable Stress of Eye Bolt Material Sb : 25,000 psi

Diameter of Eye Bolt d : 1.000 Inch

Page 189

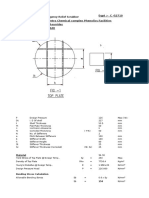

L L

5 6

L1 : 44.685 in 1135 mm

L2 : 37.598 in 955 mm

L3 : 18.898 in 480 mm

L4 : 36.339 in 923 mm

L5 : 15.748 in 400 mm

L6 : 19.685 in 500 mm

D Stress Coefficients

1. Load applied on davit arm

At vertical direction

fv = Cv * W1 = 1.5 x 6000.5 fv = 9000.750 Lbs

At horizontal direction

fh = Ch * W1 = 0.25 x 6000.5 fh = 1500.125 Lbs

2. Bending moment applied on davit arm at top guide or support

M1 = fv * L1 + 0.5 * W2 * L1 + fh * L2

= 9000.75 x 44.685 + 0.5 x 137.498291315 x 44.685 + 1500.125 x 37.598

M1 = 461673.264 Lbs.Inch

3. Axial load applied on davit arm

P = f v + W2 = 9000.75 + 137.498291315 P = 9138.248 Lbs

4. Allowable axial stress of mast & boom

at Boom (beam)

Fab = 0.7*Ys = 0.7 x 51000 Fab = 35700.000 psi

at Mast

Fam = 0.7 * Ysm = 0.7 x 51488.3835 Fam = 36041.868 psi

5. Allowable bending stress of mast & boom

at Boom (beam)

Fbb = 0.7*Ys = 0.7 x 51000 Fbb = 35700.000 psi

at Mast

Fbm = 0.7 * Ysm = 0.7 x 51488.3835 Fbm = 36041.868 psi

6. Axial stress of mast

fa = P / Apm = 9138.248291315 / 31.165 fa = 293.225 psi

7. Bending stress on mast

At M1

fb1 = M1 / Zpm = 461673.264 / 24.5391 fb1 = 18813.779 psi

8. Combined stress on mast

At M1 = [fa / Fam] + [fb1 / Fbm]

= [293.225 / 36041.868] + [18813.779 / 36041.868] = 0.530

9. Judgement

Since combined stress value at M1 less than 1.0 ADEQUATE

10. Bending stress on boom (beam)

fb2 = fv L5 / Zb = 9000.75 x 15.748 / 18.548 fb2 = 7642.051 psi

11. Judgement (Beam Boom strength)

[fb2 / Fbb] < 1

0.2 < 1 ADEQUATE

E Eye Bolt Calculation

1. Area available of eye bolt

Arb = / 4 d2 = 3.142/4 *1^2 Arb = 0.785 Inch2

2. Minimum area required of eye bolt

Ar1 = P / Sb = 9138.248291315 / 25000 Ar1 = 0.366 Inch2

3. Judgement

Since Arb more than Ar1 ADEQUATE

Page 190

Page 191

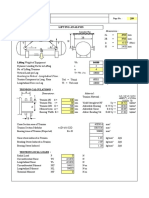

F Weld Strength Calculation

1. Section modulus of weld lines

a. At Support

Sw1 = L32 / 3 = 18.898^2 / 3 Sw1 = 119.040 Inch2

b. At Stiffener

Sw2 = L62 / 3 = 19.685^2/3 Sw2 = 129.167 Inch2

c. At Ring Davit Arm

Sw3 = d2 / 4 = 3.14 * 6.299^2 /4 Sw3 = 31.165 Inch2

2. Bending moment

a. At Support & Stiffener

Mb = P * L4 = 9138.248291315 x 36.339 Mb = 332070.991 Lbs.Inch

b. At Ring Davit Arm

Mb3 = P * L1 = 38.33 x 44.685 Mb3 = 408342.985 Lbs.Inch

3. Bending force applied on fillet weld

a. At Support

Wb1 = Mb / Sw1 = 332070.991 / 119.04 Wb1 = 2789.569 Lbs/Inch

b. At Stiffener

Wb2 = Mb / Sw2 = 332070.991 / 129.167 Wb2 = 2570.867 Lbs/Inch

c. At Ring Davit Arm

Wb3 = Mb3 / Sw3 = 408342.985 / 31.165 Wb3 = 13102.757 Lbs/Inch

4. Average vertical shear force applied on fillet weld

a. At Support

Ws1 = P / 2 L3 = 9138.248291315 / 2 x 18.898 Ws1 = 241.783 Lbs/Inch

b. At Stiffener

Ws2 = P / 2 L6 = 9138.248291315 / 2 x 19.685 Ws2 = 232.112 Lbs/Inch

c. At Ring Davit Arm

Ws3 = P / ( d) = 9138.248291315 /( 3.14* 1.417Ws3 = 438.998 Lbs/Inch

5. Resultante force applied on fillet weld

a. At Support

Rw1 = Sqrt (Wb12 + Ws12)

= Sqrt (2789.569^2 + 241.783^2) Rw1 = 2800.028 Lbs/Inch

b. At Stiffener

Rw2 = Sqrt (Wb22 + Ws22)

= Sqrt (2570.867^2 + 232.112^2) Rw2 = 2581.324 Lbs/Inch

c. At Ring Davit Arm

Rw3 = Sqrt (Wb32 + Ws32)

= Sqrt (13102.757^2 + 438.998^2) Rw3 = 13110.109 Lbs/Inch

6. Minimum required fillet weld leg size

tc1 = Rw1 / f = 2800.028 / 9600 tc1 = 0.292 Inch

= 7.408 mm

tc2 = Rw2 / f = 2581.324 / 9600 tc2 = 0.269 Inch

= 6.830 mm

tc3 = Rw3 / f = 13110.109 / 9600 tc3 = 1.366 Inch

= 34.687 mm

7. Judgement

Since tc1 = 0.292'' (7.408mm) less than tsupp = 0.394'' (10mm) ADEQUATE

Since tc2 = 0.269'' (6.83mm) less than tstiff = 0.394'' (10mm) ADEQUATE

Since tc3 = 1.366'' (34.687mm) less than tring = 1.417'' (36mm) ADEQUATE

S-ar putea să vă placă și

- Davit CalcDocument4 paginiDavit CalcrustamriyadiÎncă nu există evaluări

- Input Rev. NO: L + (c1 + c2) TWDocument6 paginiInput Rev. NO: L + (c1 + c2) TWMudasir MughalÎncă nu există evaluări

- Padeye .5MT CHKDocument12 paginiPadeye .5MT CHKDhanraj VasanthÎncă nu există evaluări

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document30 paginiMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)fsijest50% (4)

- Davit Cal 2251B (Davit Arm Calculation)Document4 paginiDavit Cal 2251B (Davit Arm Calculation)Prajwal Shetty100% (4)

- Davit Arm Support Plate CheckDocument56 paginiDavit Arm Support Plate CheckHafizi HZnumismatic100% (5)

- Saddle Road Transportation Analysis 1Document2 paginiSaddle Road Transportation Analysis 1vpjagannaathÎncă nu există evaluări

- 2 A Davit CalculationDocument30 pagini2 A Davit CalculationKarina RoquelÎncă nu există evaluări

- Manhole Davit ArmDocument1 paginăManhole Davit ArmgaratetaÎncă nu există evaluări

- Saddle Stresses On Shell During Transportation: Equipment NoDocument5 paginiSaddle Stresses On Shell During Transportation: Equipment NoshazanÎncă nu există evaluări

- Davit CalcDocument6 paginiDavit Calcrustamriyadi100% (1)

- Davit Cal 2251B Davit Arm CalculationDocument4 paginiDavit Cal 2251B Davit Arm Calculationnitin400Încă nu există evaluări

- Vessel Davit Design (Based On Pressure Vessel Design Manual by Dennis R Moss)Document8 paginiVessel Davit Design (Based On Pressure Vessel Design Manual by Dennis R Moss)pandiangv100% (1)

- LIFTING LUG Weld Check KGDocument4 paginiLIFTING LUG Weld Check KGjoerijiÎncă nu există evaluări

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 paginiBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiÎncă nu există evaluări

- Davit With ElbowDocument2 paginiDavit With ElbowSajal Kulshrestha100% (4)

- Design of Flat Head For HydrotestDocument12 paginiDesign of Flat Head For HydrotestSAGARÎncă nu există evaluări

- Davit Design Calculation: L 1 D V H V H V DDocument2 paginiDavit Design Calculation: L 1 D V H V H V DSiva baalanÎncă nu există evaluări

- Design of Pad Eye Using Check PlatesDocument3 paginiDesign of Pad Eye Using Check Plateshyoung65Încă nu există evaluări

- Lifting Trunnion AnalysisDocument1 paginăLifting Trunnion Analysisprajwal86Încă nu există evaluări

- Davit Design and Support CalculationDocument22 paginiDavit Design and Support CalculationShan50% (2)

- Crossover Area Calc For Floating HeadDocument2 paginiCrossover Area Calc For Floating HeadRitesh VishambhariÎncă nu există evaluări

- Sample design calculation for skirt support of vertical columnDocument8 paginiSample design calculation for skirt support of vertical columnimrancenakk100% (2)

- PPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationDocument4 paginiPPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationNadya Askar100% (1)

- Round Attachment Cylindrical Shell AnalysisDocument9 paginiRound Attachment Cylindrical Shell AnalysisakisdassasÎncă nu există evaluări

- Swing Bolt CalculationDocument2 paginiSwing Bolt CalculationNicolaSavili100% (2)

- Lifting analysis of vessel equipmentDocument1 paginăLifting analysis of vessel equipmentshaishav100% (2)

- Tailing LugDocument3 paginiTailing LugSajad AbdulÎncă nu există evaluări

- PT TECHNICs SPREADER BEAM CALCULATION TITLEDocument5 paginiPT TECHNICs SPREADER BEAM CALCULATION TITLEmramico100% (1)

- Rectangular Tank Calculation Roarks FormulasDocument39 paginiRectangular Tank Calculation Roarks FormulasInamullah Khan100% (3)

- Flange Pad CalcsDocument4 paginiFlange Pad CalcstomÎncă nu există evaluări

- 2.a) Davit CalculationDocument11 pagini2.a) Davit CalculationneelÎncă nu există evaluări

- Lifting Lug Calculation RefDocument2 paginiLifting Lug Calculation Refmarc_albertoÎncă nu există evaluări

- Sendai Project Lifting Lug DesignDocument6 paginiSendai Project Lifting Lug DesignkalpanaadhiÎncă nu există evaluări

- Lug Support DesignDocument11 paginiLug Support Designimrancenakk100% (6)

- Rectangular Tank SizingDocument8 paginiRectangular Tank Sizingvofaith100% (16)

- Saddle design calculationsDocument9 paginiSaddle design calculationsduf fuÎncă nu există evaluări

- Lifting LugDocument39 paginiLifting LugSasikumar JothiÎncă nu există evaluări

- Calculation of left and right saddle supports for offshore tankerDocument12 paginiCalculation of left and right saddle supports for offshore tankerrustamriyadiÎncă nu există evaluări

- Baffle Thickness CalculationDocument22 paginiBaffle Thickness CalculationAdrian Stoicescu100% (1)

- Davit Cal 2251B Davit Arm CalculationDocument4 paginiDavit Cal 2251B Davit Arm CalculationKarina RoquelÎncă nu există evaluări

- Design of Leg & Skirt Per EN 13445-3 - 2009 PDFDocument17 paginiDesign of Leg & Skirt Per EN 13445-3 - 2009 PDFtranhonghakd5533100% (1)

- Saddle-Design-Operating - FinalDocument17 paginiSaddle-Design-Operating - FinalSiva baalan75% (4)

- Flange Pad CalcsDocument4 paginiFlange Pad CalcstomÎncă nu există evaluări

- Jn1399 - 71t Lifting LugDocument5 paginiJn1399 - 71t Lifting LugRiyan EsapermanaÎncă nu există evaluări

- Calculation of Davit ArmDocument1 paginăCalculation of Davit ArmpiziyuÎncă nu există evaluări

- Calculating saddle dimensions for pipesDocument2 paginiCalculating saddle dimensions for pipesrinabiswas50% (2)

- TrunnionDocument7 paginiTrunnionRUDHRA DHANASEKAR100% (1)

- Calculation of DavitDocument2 paginiCalculation of DavitpiziyuÎncă nu există evaluări

- 28 Roark Flat PlatesDocument4 pagini28 Roark Flat PlatesJorge Silva100% (1)

- PFS FWKO Tank EvaluationDocument12 paginiPFS FWKO Tank EvaluationkoyahassanÎncă nu există evaluări

- Skirt Bracing Calc For Vertical Pressure VesselsDocument4 paginiSkirt Bracing Calc For Vertical Pressure Vesselsnagtummala100% (1)

- Unreinforced Bellows Design Calculation Sheet: (Ejma Nineth Edition)Document1 paginăUnreinforced Bellows Design Calculation Sheet: (Ejma Nineth Edition)TriadBellowsÎncă nu există evaluări

- JASMINO POLYMERTECH PVT. LTD. Anchor Bolt DesignDocument6 paginiJASMINO POLYMERTECH PVT. LTD. Anchor Bolt DesignPankajDhobleÎncă nu există evaluări

- Expansion Bellows Design CalculationDocument1 paginăExpansion Bellows Design CalculationvvpvarunÎncă nu există evaluări

- "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Document4 pagini"Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriÎncă nu există evaluări

- Beam To Beam Pinned SH-300Document2 paginiBeam To Beam Pinned SH-300Tri Aditha NugrahaÎncă nu există evaluări

- Bollard Column Base Plate (Fixed Type)Document15 paginiBollard Column Base Plate (Fixed Type)GANESHÎncă nu există evaluări

- Column Base Plate (Fixed Type)Document13 paginiColumn Base Plate (Fixed Type)KM YapÎncă nu există evaluări

- Hays Pressure Drop Calculator ChartsDocument7 paginiHays Pressure Drop Calculator Chartsjoeriji0% (1)

- IFC FabStrainers - CatDocument40 paginiIFC FabStrainers - CatSpoonful BurnsideÎncă nu există evaluări

- Packed Bed Pressure Drop vs. Char SizeDocument11 paginiPacked Bed Pressure Drop vs. Char SizejoerijiÎncă nu există evaluări

- Pressure DropDocument19 paginiPressure DropGigis Kintan MyarthalunaÎncă nu există evaluări

- Hays Pressure Drop Calculator ChartsDocument7 paginiHays Pressure Drop Calculator Chartsjoeriji0% (1)

- BC Lifting Arrangement ULDocument3 paginiBC Lifting Arrangement ULjoerijiÎncă nu există evaluări

- Barge Stability GuidelinesDocument10 paginiBarge Stability Guidelinesnautilus73100% (2)

- Packed Bed Pressure Drop vs. Char Size v3Document12 paginiPacked Bed Pressure Drop vs. Char Size v3joerijiÎncă nu există evaluări

- P4 Design SummaryDocument1 paginăP4 Design SummaryjoerijiÎncă nu există evaluări

- Caison Buckling CheckDocument3 paginiCaison Buckling CheckjoerijiÎncă nu există evaluări

- Base Plate CheckDocument6 paginiBase Plate CheckjoerijiÎncă nu există evaluări

- Buckling CheckDocument1 paginăBuckling CheckjoerijiÎncă nu există evaluări

- BC Lifting Arrangement ULDocument3 paginiBC Lifting Arrangement ULjoerijiÎncă nu există evaluări

- Concrete Rail Block CalcDocument2 paginiConcrete Rail Block CalcjoerijiÎncă nu există evaluări

- Square Blind Flange With Stiffener ULDocument5 paginiSquare Blind Flange With Stiffener ULjoeriji100% (1)

- LIFTING LUG Weld Check KGDocument4 paginiLIFTING LUG Weld Check KGjoerijiÎncă nu există evaluări

- Sample - Weight & COG Estimation FormatDocument4 paginiSample - Weight & COG Estimation FormatjoerijiÎncă nu există evaluări

- Concrete Design - IIT KGPDocument603 paginiConcrete Design - IIT KGPanil97232Încă nu există evaluări

- Prediction of Ground Movement Due To TunnelingDocument6 paginiPrediction of Ground Movement Due To Tunnelingsandip0002100% (1)

- Beam TheoryDocument61 paginiBeam Theorysaleemm_2Încă nu există evaluări

- Bounding Surface Plasticity Model For The Seismic Liquefaction Analysis of GeostructuresDocument17 paginiBounding Surface Plasticity Model For The Seismic Liquefaction Analysis of GeostructuressharikaÎncă nu există evaluări

- Simulation of Masonry in ANSYS and LS-DYNA: Features and ChallengesDocument15 paginiSimulation of Masonry in ANSYS and LS-DYNA: Features and ChallengesaminÎncă nu există evaluări

- The Clamp BoltsDocument2 paginiThe Clamp BoltsНемања Караклајић100% (1)

- Design of Concrete CorbelDocument2 paginiDesign of Concrete CorbelUttam Kumar GhoshÎncă nu există evaluări

- Hot Working & Cold WorkingDocument34 paginiHot Working & Cold Workingavutu_kunduruÎncă nu există evaluări

- HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudDocument16 paginiHKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudRajesh GangwalÎncă nu există evaluări

- CE 6121 Advanced Structural Steel Design Syllabus SummaryDocument10 paginiCE 6121 Advanced Structural Steel Design Syllabus SummaryMasudÎncă nu există evaluări

- Slope Stability Analysis: Wedge FailureDocument22 paginiSlope Stability Analysis: Wedge Failurechaymaa MRHAR100% (1)

- Foundation-Ch 7 PDFDocument19 paginiFoundation-Ch 7 PDFAlbanÎncă nu există evaluări

- 23 - PCA MethodDocument63 pagini23 - PCA MethodEkala XuhalxÎncă nu există evaluări

- AISC DG11 ExamplesDocument7 paginiAISC DG11 ExamplesMarcel Toruño MendezÎncă nu există evaluări

- Understanding Earthquakes in the PhilippinesDocument10 paginiUnderstanding Earthquakes in the PhilippinesReina BenguaÎncă nu există evaluări

- Slope Stability Analysis Analiza Interna Input DataDocument22 paginiSlope Stability Analysis Analiza Interna Input DatananesculÎncă nu există evaluări

- MEC424 Content TorsionDocument12 paginiMEC424 Content TorsionHaFiy HaZimÎncă nu există evaluări

- OUT OF PLANE ANALYSIS FOR COMPOSITE STRUCTURESDocument17 paginiOUT OF PLANE ANALYSIS FOR COMPOSITE STRUCTURESKubilayÎncă nu există evaluări

- Consolidation Test ParametersDocument11 paginiConsolidation Test ParametersAbdul WahabÎncă nu există evaluări

- Ground-Motion Simulations For ZimbabweDocument16 paginiGround-Motion Simulations For ZimbabweAneleÎncă nu există evaluări

- Engineering Structures: C.X. Dong, A.K.H. Kwan, J.C.M. HoDocument14 paginiEngineering Structures: C.X. Dong, A.K.H. Kwan, J.C.M. HoElieser SinagaÎncă nu există evaluări

- Performance of Reinforced Soil Wall on Stone ColumnsDocument9 paginiPerformance of Reinforced Soil Wall on Stone ColumnsMuhammad RoslanÎncă nu există evaluări

- Draft Amendments in SP 114Document45 paginiDraft Amendments in SP 114Neeraj SharmaÎncă nu există evaluări

- Characterization of Models For Time-Dependent Behavior of SoilsDocument21 paginiCharacterization of Models For Time-Dependent Behavior of SoilsrkÎncă nu există evaluări

- XJTLU - Steelwork CW - Portal Frame 2021 (v02)Document3 paginiXJTLU - Steelwork CW - Portal Frame 2021 (v02)FanisÎncă nu există evaluări

- T650 - Engineering Science N4 April Memo 2021Document11 paginiT650 - Engineering Science N4 April Memo 2021Logan JesseÎncă nu există evaluări

- Short AnswerDocument10 paginiShort AnswerNarendra Singh Shekhawat100% (1)

- Earthquakes and Faults PowerpointDocument30 paginiEarthquakes and Faults PowerpointCassiopeia DimatulacÎncă nu există evaluări

- Practical Approximate Analysis of Beams and FramesDocument4 paginiPractical Approximate Analysis of Beams and Framessami_bangash_1100% (1)

- Fillet Weld Research Paper - For UndercuttingDocument7 paginiFillet Weld Research Paper - For UndercuttingHemantÎncă nu există evaluări