Documente Academic

Documente Profesional

Documente Cultură

MARUMA Undercarriage

Încărcat de

aafloresh0 evaluări0% au considerat acest document util (0 voturi)

171 vizualizări4 paginiMantenimiento de carrileria

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMantenimiento de carrileria

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

171 vizualizări4 paginiMARUMA Undercarriage

Încărcat de

aafloreshMantenimiento de carrileria

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

THE WORLDS MOST EFFICIENT

UNDERCARRIAGE REBUILDING EQUIPMENT

The undercarriage of machines wear out sooner, because inside of the

track link, rollers and idler wear against each other and the track shoe

is in contact with the ground when machine is running. The life of

worn undercarriage parts can be extended by special welding methods

and repositioning of the parts.

Think before throwing

away your valuable parts.

Undercarriage parts such as

Track link, Roller, Shoe, etc.

can easily be rebuilt with

appropriate rebuilding equipment.

We are pleased to introduce the

most efficient rebuilding equipment.

Rebuilding of Track Rollers

( Idlers can also be rebuilt in the same manner )

Worn Roller

(Still within rebuilding

limits)

Actual worn area

Rebuilding Roller

Rebuilding with submerged

hard facing welding method

by Model MRW-F

Rebuilt Rollers

The rollers are rebuilt

to their original size,

extending their life span.

Rebuilding of Track Links

Worn Track Links

(Still within rebuilding

limits)

Actual worn area

This area can be rebuilt

by means of the Track Link

Welder (Model MTW)

Disassembling

Track Links

Actual worn side

By turning over the

bushings and pins,

the non-worn surface

can be used to extend

the life of the track

links.

Assembling Track Link

When track links are assembled,

bushes and pins are turned over

from the original position to utilize

the non-worn side.

Special Tools for Undercarriage

Sprocket Remover

& Installer

Proper undercarriage

special tools bring you

quick and safe service.

Hook Wrench

Master Pin Remover

& Installer

MARUMA TECHNICA CO., LTD.

6-2-1 Ohnodai, Minami-ku, SagamiharaCity,

KanagawaPref. 252-0331, Japan

Tel: 81-42-751-3024 Fax: 81-42-751-9065

S-ar putea să vă placă și

- PDS390S-4B1, Hal 15Document4 paginiPDS390S-4B1, Hal 15AkmalÎncă nu există evaluări

- R220LC-9S (B137) Jeticoconstruction McuadditionaltroubleshootingDocument10 paginiR220LC-9S (B137) Jeticoconstruction McuadditionaltroubleshootingJet acostaÎncă nu există evaluări

- History Card EquipmentDocument1 paginăHistory Card EquipmentEngineering WhÎncă nu există evaluări

- Harvester Head for ExcavatorsDocument3 paginiHarvester Head for ExcavatorsdongÎncă nu există evaluări

- Amtiss - Saldo - Inventory 28-01-2020Document224 paginiAmtiss - Saldo - Inventory 28-01-2020Asido PurbaÎncă nu există evaluări

- Belt Inspect Adjust Replace PDFDocument4 paginiBelt Inspect Adjust Replace PDFnay hlaing SoeÎncă nu există evaluări

- Boom Cylinder Remove and InstallDocument8 paginiBoom Cylinder Remove and InstallEDSON JONATHAN SALINAS AYALAÎncă nu există evaluări

- BD50 Crawler Dozer 67kW Engine Spur Gear TransmissionDocument4 paginiBD50 Crawler Dozer 67kW Engine Spur Gear TransmissionAnsh MishraÎncă nu există evaluări

- Dynapac Vibro CA250Document2 paginiDynapac Vibro CA250Rachmat ArifÎncă nu există evaluări

- PC1250Document106 paginiPC1250yonathan yonathan100% (1)

- SY35 Vs Competition - V2Document4 paginiSY35 Vs Competition - V2Raj Kumar V RÎncă nu există evaluări

- HM400 3M0 PDFDocument20 paginiHM400 3M0 PDFFakhrur RizkyÎncă nu există evaluări

- Service Manual OverviewDocument23 paginiService Manual Overviewbasem elhosanyÎncă nu există evaluări

- RS8140 Single Drum CompactorDocument4 paginiRS8140 Single Drum CompactorMartin Lee100% (2)

- Sunward Intelligent Equipment Co.,LtdDocument16 paginiSunward Intelligent Equipment Co.,Ltdconcrete engineeringÎncă nu există evaluări

- Zaxis 110 Zaxis 125usDocument41 paginiZaxis 110 Zaxis 125ushs1766370Încă nu există evaluări

- Zaxis 50uDocument7 paginiZaxis 50uashokrawat010% (1)

- Komatsu PC400-8 Hydraulic Excavator SpecsDocument24 paginiKomatsu PC400-8 Hydraulic Excavator Specshendra hardyÎncă nu există evaluări

- Martillo Duraegon ManualDocument46 paginiMartillo Duraegon ManualJavier ChavezÎncă nu există evaluări

- PC350 8 - PC350LC 8 - Cen00222 03 PDFDocument8 paginiPC350 8 - PC350LC 8 - Cen00222 03 PDFLU YOÎncă nu există evaluări

- SY500H Excavator Warranty GuideDocument12 paginiSY500H Excavator Warranty GuideGuillermo Herrera100% (2)

- Catalouge Bucket Wearplate & AccessoriesDocument18 paginiCatalouge Bucket Wearplate & Accessoriesaribawayuni16Încă nu există evaluări

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorDocument18 paginiHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesÎncă nu există evaluări

- SY500H lifting specifications chartDocument4 paginiSY500H lifting specifications chartAzmi MaulanaÎncă nu există evaluări

- Pc200 8m0 Swing Yarder Zessp208m0sy-01Document3 paginiPc200 8m0 Swing Yarder Zessp208m0sy-01ekoryantekoÎncă nu există evaluări

- Engine 125 2Document392 paginiEngine 125 2Augusto OliveiraÎncă nu există evaluări

- TT216E-00 CircitDocument412 paginiTT216E-00 Circitthuan100% (1)

- 0573Document1 pagină0573Lily VyÎncă nu există evaluări

- DAWSON CONSTRUCTION EMV EXCAVATOR VIBRATORSDocument4 paginiDAWSON CONSTRUCTION EMV EXCAVATOR VIBRATORSGabriel AmorimÎncă nu există evaluări

- r994b GB Us TB ArcticDocument12 paginir994b GB Us TB Arcticwalk01Încă nu există evaluări

- Operación y MantenimientoDocument299 paginiOperación y MantenimientoJose A. Basanta H.Încă nu există evaluări

- SG16 3Document2 paginiSG16 3ERMIANUS SAMALEIÎncă nu există evaluări

- Operational PrincipleDocument257 paginiOperational PrinciplemahmudiÎncă nu există evaluări

- Improve Safety and Efficiency of Tyre MaintenanceDocument4 paginiImprove Safety and Efficiency of Tyre MaintenanceRui FerreiraÎncă nu există evaluări

- HM400-3R Leaflet Cen00510-01 - 86997 PDFDocument9 paginiHM400-3R Leaflet Cen00510-01 - 86997 PDFKevin Andrian0% (1)

- GTBZ40-42 Parts ManualDocument66 paginiGTBZ40-42 Parts ManualTesla EcÎncă nu există evaluări

- (SM Eng) PC340 LC (NLC) - 6K (EEAM008007)Document323 pagini(SM Eng) PC340 LC (NLC) - 6K (EEAM008007)НиколайÎncă nu există evaluări

- Ex450lc 5Document7 paginiEx450lc 5anon_485665212100% (1)

- 12H Frein TestDocument13 pagini12H Frein TestaniriÎncă nu există evaluări

- XS85 To XS145 Specs - March 2011-4Document8 paginiXS85 To XS145 Specs - March 2011-4lucioleo1975Încă nu există evaluări

- JFE HitenDocument19 paginiJFE HitenPandu PhintaruÎncă nu există evaluări

- QRF HB205+HB215Document2 paginiQRF HB205+HB215Ralf MaurerÎncă nu există evaluări

- 14M ExcerptDocument70 pagini14M ExcerptHassan ZAFFA CISNEROSÎncă nu există evaluări

- 835 III Wheel Loader Specs & FeaturesDocument2 pagini835 III Wheel Loader Specs & FeaturesRuben Eduardo Meilicke Gould100% (3)

- Brieser Construction Excavator & Backhoe Hand Signals ManualDocument4 paginiBrieser Construction Excavator & Backhoe Hand Signals ManualBry ManÎncă nu există evaluări

- Cat Hydo 10wDocument4 paginiCat Hydo 10wWilbort Encomenderos RuizÎncă nu există evaluări

- Sany Wheel-Loader SpecSheet 6-10-19Document2 paginiSany Wheel-Loader SpecSheet 6-10-19Akhmad SebehÎncă nu există evaluări

- Sem 636DDocument2 paginiSem 636DVinoth KumarÎncă nu există evaluări

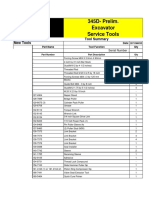

- 345D-Prelim. Excavator Service Tools: Tool Summary New ToolsDocument6 pagini345D-Prelim. Excavator Service Tools: Tool Summary New ToolsNova kurniawan 34Încă nu există evaluări

- Operation & Maintenance SEAM02080502 Manual: Hydraulic ExcavatorDocument267 paginiOperation & Maintenance SEAM02080502 Manual: Hydraulic ExcavatorSarno MukriÎncă nu există evaluări

- Cs - Cp-533e Specalog (Qehq9995)Document16 paginiCs - Cp-533e Specalog (Qehq9995)Sanggalangi LatinroÎncă nu există evaluări

- Full Air Brake SystemDocument81 paginiFull Air Brake SystemMuhamad RifkyÎncă nu există evaluări

- BY - PY120M Motor GraderDocument2 paginiBY - PY120M Motor GraderHush Pips100% (1)

- Crawler Crane-Hitachi Sumitomo SCX550E 55t SpecificationsDocument28 paginiCrawler Crane-Hitachi Sumitomo SCX550E 55t SpecificationsAnonymous hRWwL7pZnCÎncă nu există evaluări

- Mini Hydraulic ExcavatorDocument8 paginiMini Hydraulic ExcavatorYaroslava YatsukÎncă nu există evaluări

- XE215C ExcavatorDocument2 paginiXE215C Excavatorasme acehÎncă nu există evaluări

- DX300LCA excavator specificationsDocument21 paginiDX300LCA excavator specificationsKeron Trotz100% (1)

- Tubing and Casing Roller PDFDocument12 paginiTubing and Casing Roller PDFnasr yassinÎncă nu există evaluări

- BearingDocument423 paginiBearingaubd100% (2)

- Robust technology with low running costsDocument12 paginiRobust technology with low running costsm arif pÎncă nu există evaluări

- Thesis Zhou NanotubesDocument191 paginiThesis Zhou NanotubesaafloreshÎncă nu există evaluări

- Catalogo Bombas Hidraulica White House Products CatalogueDocument348 paginiCatalogo Bombas Hidraulica White House Products Catalogueaafloresh50% (2)

- BiomechanicDocument45 paginiBiomechanicaafloreshÎncă nu există evaluări

- Engineering CompositesDocument193 paginiEngineering CompositesMelih AltıntaşÎncă nu există evaluări

- Caterpillar Custom Track Service HandbookDocument826 paginiCaterpillar Custom Track Service HandbookGyimesi András96% (45)

- Soft Lithography: Presented By: Summayya ShafiqueDocument22 paginiSoft Lithography: Presented By: Summayya ShafiqueSummayya ShafiqueÎncă nu există evaluări

- Construction Careers - Steel FixerDocument2 paginiConstruction Careers - Steel Fixeryrdgcgf5664Încă nu există evaluări

- JIT Production: Eliminating Waste for EfficiencyDocument13 paginiJIT Production: Eliminating Waste for Efficiencymery dollÎncă nu există evaluări

- SKF SpindleDocument6 paginiSKF SpindlebhadriptÎncă nu există evaluări

- Hot Metal FormingDocument12 paginiHot Metal FormingKiran DuggarajuÎncă nu există evaluări

- CNC PLC STUDY OF MACHINESDocument22 paginiCNC PLC STUDY OF MACHINESChaitanya Prasad100% (3)

- RemelterDocument4 paginiRemelterAntonio PerezÎncă nu există evaluări

- Lincoln Pulse On PulseDocument4 paginiLincoln Pulse On PulseEdison MalacaraÎncă nu există evaluări

- Report in Technical Analysis CEMENTDocument26 paginiReport in Technical Analysis CEMENTNatrium KirchhoffÎncă nu există evaluări

- Nitrogen PSA GeneratorsDocument8 paginiNitrogen PSA GeneratorsMilos Bajic100% (1)

- Inbound Opus 08Document33 paginiInbound Opus 08Dhez RoblesÎncă nu există evaluări

- Philips Pole GuideDocument36 paginiPhilips Pole GuideDragan VuckovicÎncă nu există evaluări

- Aluminium: Particularly Suitable For Large SeriesDocument1 paginăAluminium: Particularly Suitable For Large SeriesmarijaÎncă nu există evaluări

- Industrial Tour On Youth GroupDocument17 paginiIndustrial Tour On Youth GroupNahid HasanÎncă nu există evaluări

- Mbmonthly20170601 PDFDocument72 paginiMbmonthly20170601 PDFAnonymous g5l9spl1Încă nu există evaluări

- JIS (Japanese) Standards For Steel MaterialsDocument2 paginiJIS (Japanese) Standards For Steel MaterialsLG Nguyen100% (1)

- DPTDocument12 paginiDPTAMIT SHAH100% (2)

- Process CostingDocument4 paginiProcess CostingVidia ProjÎncă nu există evaluări

- Tan Thuan Industrial ParkDocument10 paginiTan Thuan Industrial ParkNguyen Tran AnhÎncă nu există evaluări

- Solids Storage and TransportationDocument51 paginiSolids Storage and Transportationebuy100% (1)

- P&G & Godrej Supply ChainDocument6 paginiP&G & Godrej Supply ChainNitin BighaneÎncă nu există evaluări

- PMP Full Process MapDocument14 paginiPMP Full Process MapSIBINÎncă nu există evaluări

- Research challenges and technologies for floating LNGDocument16 paginiResearch challenges and technologies for floating LNGPasquale Cutri100% (1)

- KEL Industrial Visit ReportDocument18 paginiKEL Industrial Visit ReportAnoopAsokan0% (1)

- DF M1Document2 paginiDF M1plj0001Încă nu există evaluări

- PP QuizDocument7 paginiPP QuizBurke TagneyÎncă nu există evaluări

- JK Paper PresentationDocument27 paginiJK Paper PresentationnilomadhabaÎncă nu există evaluări

- Principles of Supply Chain Management: A Balanced Approach: Prepared by Daniel A. Glaser-Segura, PHDDocument29 paginiPrinciples of Supply Chain Management: A Balanced Approach: Prepared by Daniel A. Glaser-Segura, PHDWasif MuhammadÎncă nu există evaluări

- Inventory ManagementDocument24 paginiInventory ManagementBhanushekhar YadavÎncă nu există evaluări

- The Toyota WayDocument45 paginiThe Toyota WayRishi Kesavaram100% (3)