Documente Academic

Documente Profesional

Documente Cultură

Out Standing Items

Încărcat de

eng20072007Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

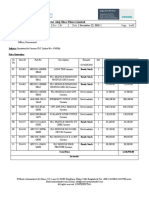

Out Standing Items

Încărcat de

eng20072007Drepturi de autor:

Formate disponibile

Out Standing Items

Package Out Standing

Item Position Status Hazard

1'-Lead to manual operation 2-lead to errosion and passing of manual valves

SLUG CATCHER LCV-5012 water outlet from slug catcher - needs to be replaced with another sand resistance type . 3- affeect on daily condensate and water production rate evaluation and

V-5001 monitroring

LTS LIC5032A /B 1- lead to manual operation 2-affect on retention time and seperation efficiency

V-5003A/B LI5031 A /B MEG level Transmitters - no actual reading for the MEG level lead to operating in manual mode . 3-increase glycol losses 4- lead to condensate escaping with MEG

5-over load at charcol filter

N-5601A/B MEG filters - no filter element inside the filter (N-5601A ) and there is only two 1-affect on filtration efficiency to remove all particles 2-Erosion of pumps

elements at filter (N-5601B) due to shortage of spare parts . 3-Deposit on still packing 4-Valves plugging

MEG 1- Lead to manual dipping to measure tank level

REGENRATION 2- may lead to glycol oxidation as Oxygen can enter the glycol system via the

UNIT LI5610 MEG tank level transimeter - not working and need to be replaced as IMS recommendation

vapour space of an un-blanketed storage tank and form corrosive organic acids

3- diffuclty to monitor glycol losses

CTP FQI5610A/B/C MEG pump flow rate - not work propably from day one and needs to be replaced 1- diffuclty to define MEG injection rate

P-4401A 2nd stage condensate stablizer - there is a crack in the metallic disc element between the spacer and

the hub . Waitting coupling spare parts supply 1- lead to over load at stand by pump (P-4401B)

P-4002 condensate recycling pump - no oil level inside the pump tank . 1- lead to offespc condensate samples 2- more load on open drain vessel

CONDENSATE 3- drain water level from tank manually by externl pump and connections

Tanks & pumps

P-4001A Condensate loading pump - waitting seal oil supply 1- more load on other two pumps

2-more time during loading if there is problem of two other pumps

PSV 4001B/C Condensate loading pumps PSV - there is leak of PSV and need to be recalibrated. 1- unsafe operation 2- more condensate leakage

Gas Metering Gas Chromatograph Sales gas metering skid - waiting for inert gas bottel material supplay . 1- there is no gas analysis data 2- depend on gasco BTU value which always less

than GC value and reduce sales gas price .

- driving motor is not compatable with pump impelers and problem 1- unsafe operation 3- drain vessel manually to open drain system

Flare K.O.D P-5101A/B Liquid pumps to closed drain still under investigation . 2- very hazard incase of ESD as all BDV open at flare and incase of pigging with

more liquid recovery as it will lead liquid carry over

Inlet Seperator D water and condensate inlet seperator water and - all controllers and level control valves have malufunction and need to 1- lead to manual opertaion 2- vessel operate as two phase flow not three phase

-101 level control loops condensate outlets be calibrated , also all manual valves is passing and need to be replaced 3- more load on cond stablizer unit and cond PD tanks 4- poor seperation

efficency

Filter Sep filter internal element Inside the filter - need to check filter internal element but there is no spare parts 1- liquid escaping with gas to glycol contactor tower

F-101 avilable with sigma and filter package is now by passed from along time 2- this rental package is by passes and must disconted from sigma contract

GLYCOL 1- unsafe operation 2- diffuclty to control reboiler temp within optimum range

RPF REGENRATION

UNIT

Burner mangment

system (BMS) Glycol reboiler

- there is no BMS and sigma control reboiler temp by manual needle

valve 3- some times reach to glycol degrdation temp and some times operate at low

temp and decrease lean TEG concentration

1- manual operation 2- diffuclty to adjust inlet seperator prerssure

Joule Thomson valve Inlet to LTS vessel - valve operated manually with very bad response and there is no any 3- may lead to back pressure at NWK flow lines and HIPPS S/D

LTS PACKAGE (JT) spare parts or stand by valve. 4- offspec sales gas with a high HC dew point

D-102

condensate level LTS vessel cond outlet line - level controller and level control valve has a malufunctioun and need 1- unaccepted manual operation 2- passing of manual valves

control loop to be calibrated and checked

Flare System Automatic ignation Fare header - flare ignation system is operated manually with high unsafe conditions 1- unsafe operation 2- if flare pilot is off it require more time to be intiated

system again

-there is amalufunction at WHCP also, all sigma WHCP with one output

NWK 1-2 Well head Well site signal to both actuator wing valve and SCSSV , also no spare parts for 1- unsafe operation as actuator wing valve is isolated

control panel panel components 2- lead to actuator damage 3- manual mode operation

RPF NWK Wells

Sigma chemical Well sites - there is no any spare parts for pumps and also , there is no stand by 1- if there is malufunction of any pump it will be stop without repairing by sigma

corrosion pumps ones which may increase corrosion rate at flow lines

WELLS

FIT 2003 Wells flow line flow rate transmiters - flow transmiter give error readings and need to be corrected and 1- cannot monitor and evaluate wells flow rates from DCS diplay

reallocted

CTP WELLS

SSG wells fiber optics pipe route - there is cutting at well fiber optics cables

cables 1- cannot monitor wells data from DCS diplay and control room

S-ar putea să vă placă și

- R101 To R801 Start Up PlanDocument21 paginiR101 To R801 Start Up Planbikas_sahaÎncă nu există evaluări

- Monocellular Centrifugal Electro-Pumps: Installation and MaintenanceDocument12 paginiMonocellular Centrifugal Electro-Pumps: Installation and MaintenanceBasem TamÎncă nu există evaluări

- Datasheet Gasmultibloc MB Zrdle 415 420 b01Document6 paginiDatasheet Gasmultibloc MB Zrdle 415 420 b01Oussama ChemiÎncă nu există evaluări

- 000 5Document185 pagini000 5fahad jamilÎncă nu există evaluări

- UF System Instrument and Control PhilosophyDocument79 paginiUF System Instrument and Control PhilosophyJayraj Dayma100% (1)

- Risk Assessment Checklist - Use of Vlsfo Without Lab Analysis Report - 2022-12-20 - 16-29-43Document2 paginiRisk Assessment Checklist - Use of Vlsfo Without Lab Analysis Report - 2022-12-20 - 16-29-43ARUN100% (1)

- LPG SOP Rev6Document26 paginiLPG SOP Rev6Kuldeepsingh Chandel100% (1)

- CSC IOM Manual BombaDocument18 paginiCSC IOM Manual BombaLuis Sánchez RoblesÎncă nu există evaluări

- Rocsan-Lix NT Eng 50hzDocument10 paginiRocsan-Lix NT Eng 50hzAntonio StrahijaÎncă nu există evaluări

- Start Up of Alkylation Reactor R101Document4 paginiStart Up of Alkylation Reactor R101bikas_sahaÎncă nu există evaluări

- Sop STPDocument45 paginiSop STPB.r. SharmaÎncă nu există evaluări

- Jaguatirica Deviations PDFDocument24 paginiJaguatirica Deviations PDFAnonymous wCDPbgMLJÎncă nu există evaluări

- Daily Commissioning Progress Report18.01.10Document1 paginăDaily Commissioning Progress Report18.01.10Prudhvi RajÎncă nu există evaluări

- Presentation - Ruby II - Fso Bd01 - Fpso Lam SonDocument127 paginiPresentation - Ruby II - Fso Bd01 - Fpso Lam SonRubyÎncă nu există evaluări

- Unit-Iii Boiler Drum Level Control System Drum Level Control ObjectivesDocument22 paginiUnit-Iii Boiler Drum Level Control System Drum Level Control ObjectivesBigg Boss ReviewÎncă nu există evaluări

- 3443-SZ-RT-101 - 04 Attachment 15Document8 pagini3443-SZ-RT-101 - 04 Attachment 15tak-1963Încă nu există evaluări

- Sump PumpDocument5 paginiSump PumpTanvir ChowdhuryÎncă nu există evaluări

- Daily Commissioning Progress Report14.01.10Document1 paginăDaily Commissioning Progress Report14.01.10Prudhvi RajÎncă nu există evaluări

- Qatar Petroleum Ngl-1 Operating Manual: 1. GeneralDocument49 paginiQatar Petroleum Ngl-1 Operating Manual: 1. Generalvaratharajan g rÎncă nu există evaluări

- GB088 2013 200 HS RP 003 - 1 PDFDocument225 paginiGB088 2013 200 HS RP 003 - 1 PDFMohammed AbdallaÎncă nu există evaluări

- PSMR TechnicalDocument7 paginiPSMR Technicalrinashah1203Încă nu există evaluări

- GCP Sect5RB RB LineDocument25 paginiGCP Sect5RB RB Linelevanvui161Încă nu există evaluări

- Devex-2018-Base-Management-workshopDocument27 paginiDevex-2018-Base-Management-workshopQaiser HafeezÎncă nu există evaluări

- Water Valve Update On Wheeled Loaders JCBDocument2 paginiWater Valve Update On Wheeled Loaders JCBJunaid RehmanÎncă nu există evaluări

- MOM of WTPDocument12 paginiMOM of WTPMohamed IbrahimÎncă nu există evaluări

- Qatar Petroleum Ngl-1 Operating ManualDocument66 paginiQatar Petroleum Ngl-1 Operating Manualvaratharajan g rÎncă nu există evaluări

- Step by Step RMC Analysis of Centrifugal PumpDocument1 paginăStep by Step RMC Analysis of Centrifugal Pumpnathanael tayorÎncă nu există evaluări

- Process Measurement & Control Solutions: Dewatering of Storage Tanks, Automatic Draw Water Control, & Manual Tank GaugingDocument3 paginiProcess Measurement & Control Solutions: Dewatering of Storage Tanks, Automatic Draw Water Control, & Manual Tank GaugingT. LimÎncă nu există evaluări

- TPCK Series Immersible Pump: Instruction ManualDocument8 paginiTPCK Series Immersible Pump: Instruction ManualThiago Teixeira PiresÎncă nu există evaluări

- Kiln Shutdown Maintenance Schedule Area No. Issues Date PIC Support Inspector Remarks Completion DateDocument1 paginăKiln Shutdown Maintenance Schedule Area No. Issues Date PIC Support Inspector Remarks Completion DateKunÎncă nu există evaluări

- Tanker Project 2Document4 paginiTanker Project 2SACHIN SINGH CHAUHANÎncă nu există evaluări

- Checklist For Catalyst UnloadingDocument1 paginăChecklist For Catalyst UnloadingJahanzeb khanÎncă nu există evaluări

- Work Requests / Concerns: Area EquipmentDocument8 paginiWork Requests / Concerns: Area EquipmentHerwin NavarreteÎncă nu există evaluări

- 21 PDFDocument22 pagini21 PDFMaltin SelmanllariÎncă nu există evaluări

- Daily Commissioning Progress Report16-17.01.10Document1 paginăDaily Commissioning Progress Report16-17.01.10Prudhvi RajÎncă nu există evaluări

- V5032Y Balans Vanaları Kombi IIDocument12 paginiV5032Y Balans Vanaları Kombi IIYalcin DogrulÎncă nu există evaluări

- Walk Down Punch ListDocument7 paginiWalk Down Punch ListGomathyselviÎncă nu există evaluări

- E39 Ahsop 03Document3 paginiE39 Ahsop 03Sanjit SinghÎncă nu există evaluări

- PSP 21 - PSP 22 - PSP 23: ElectropumpsDocument8 paginiPSP 21 - PSP 22 - PSP 23: ElectropumpsSamira 1986Încă nu există evaluări

- Crosshead Bearing InspectionDocument7 paginiCrosshead Bearing InspectionShaif uddin rifatÎncă nu există evaluări

- Calgonpump Catalogue (BSN Shah Alam)Document13 paginiCalgonpump Catalogue (BSN Shah Alam)Zul HafizzÎncă nu există evaluări

- Weekly Report 46Document7 paginiWeekly Report 46TarekÎncă nu există evaluări

- Installation and Maintenance Manual (Ebara Non-Submersible Pump)Document36 paginiInstallation and Maintenance Manual (Ebara Non-Submersible Pump)tm_2075% (8)

- Commissioning of Phenolic Sour Water Storage Tank 142-D-0022 (2) Latest - Docx NewDocument13 paginiCommissioning of Phenolic Sour Water Storage Tank 142-D-0022 (2) Latest - Docx NewyoganandamÎncă nu există evaluări

- Service Letter RTA-12 - 02 Water Drain From Water Separator After Scavenge Air CoolerDocument11 paginiService Letter RTA-12 - 02 Water Drain From Water Separator After Scavenge Air CoolerCatalin CataÎncă nu există evaluări

- Bilge System in ERDocument34 paginiBilge System in ERCua TranÎncă nu există evaluări

- Manual Rubineti ElektrikDocument12 paginiManual Rubineti ElektrikLucian CiolanÎncă nu există evaluări

- SET2 F1-C1 - Maintain Safe Engineering WatchDocument4 paginiSET2 F1-C1 - Maintain Safe Engineering WatchRamon Carlo AlmiranezÎncă nu există evaluări

- Water Softener 223100Document7 paginiWater Softener 223100ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥÎncă nu există evaluări

- Manual Lavaloza Blankelee D-18Document66 paginiManual Lavaloza Blankelee D-18christopher menesesÎncă nu există evaluări

- Planning Your Autoclave Installation V11 1Document20 paginiPlanning Your Autoclave Installation V11 1asankandessÎncă nu există evaluări

- Morning Meeting Discussion PointsDocument1 paginăMorning Meeting Discussion PointsJawad AslamÎncă nu există evaluări

- Series: Oil Sampling ValveDocument2 paginiSeries: Oil Sampling Valvemarran almarranyÎncă nu există evaluări

- Gasmultibloc Combined Regulator and Safety Shut-Off Valves Single-Stage Function Integrated Bypass Valve MB-D (Le) 405 - 412 B07Document6 paginiGasmultibloc Combined Regulator and Safety Shut-Off Valves Single-Stage Function Integrated Bypass Valve MB-D (Le) 405 - 412 B07TobiasAngererÎncă nu există evaluări

- Site Date Sr. No. M/C Detail Dir. No Particuler Cause Photos RemarksDocument6 paginiSite Date Sr. No. M/C Detail Dir. No Particuler Cause Photos RemarksddhruvalpÎncă nu există evaluări

- KSB KWP: Non-Clogging Centrifugal PumpsDocument12 paginiKSB KWP: Non-Clogging Centrifugal PumpsalfredÎncă nu există evaluări

- HAZOP Workbook-Distillation Column 101-102Document4 paginiHAZOP Workbook-Distillation Column 101-102Ibrahim Nick DibalÎncă nu există evaluări

- CCPP Plant Operating Procedures PDFDocument123 paginiCCPP Plant Operating Procedures PDFReda Nari100% (1)

- Factory PidDocument1 paginăFactory Pideng20072007Încă nu există evaluări

- Water Treatment PidDocument1 paginăWater Treatment Pideng20072007Încă nu există evaluări

- City Director of Public Works Organizational Chart: Description/DateDocument2 paginiCity Director of Public Works Organizational Chart: Description/Dateeng20072007Încă nu există evaluări

- City Director of Public Works Organizational Chart: Description/DateDocument2 paginiCity Director of Public Works Organizational Chart: Description/Dateeng20072007Încă nu există evaluări

- Factory PidDocument1 paginăFactory Pideng20072007Încă nu există evaluări

- Adding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017Document1 paginăAdding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017eng20072007Încă nu există evaluări

- Ngdiploma EnglishDocument2 paginiNgdiploma Englisheng20072007Încă nu există evaluări

- Oklahoma Corporation Commission: Packer Setting ReportDocument2 paginiOklahoma Corporation Commission: Packer Setting Reporteng20072007Încă nu există evaluări

- BlocksDrilling Line Rev-Peview PDFDocument11 paginiBlocksDrilling Line Rev-Peview PDFLa Ode Hadi AugustmanÎncă nu există evaluări

- 1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3Document1 pagină1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3eng20072007Încă nu există evaluări

- El Sayed Amer Last UpdatedDocument3 paginiEl Sayed Amer Last Updatedeng20072007Încă nu există evaluări

- 1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers SpecificationDocument18 pagini1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers Specificationeng20072007Încă nu există evaluări

- Envelope Envelope-11Document1 paginăEnvelope Envelope-11eng20072007Încă nu există evaluări

- Reliability and Risk Assessment: Ace 4 ApDocument1 paginăReliability and Risk Assessment: Ace 4 Apeng20072007Încă nu există evaluări

- Previous Well Open Hole Section For Well W5-8 Al-Wafa FieldDocument4 paginiPrevious Well Open Hole Section For Well W5-8 Al-Wafa Fieldeng20072007Încă nu există evaluări

- DareDocument11 paginiDareeng20072007Încă nu există evaluări

- Block ProposalDocument11 paginiBlock Proposaleng20072007Încă nu există evaluări

- Gad SeparatorDocument3 paginiGad Separatoreng20072007Încă nu există evaluări

- Duplicate Cleaner LogDocument1 paginăDuplicate Cleaner LogMuhammad Hafizuddin Bin JumadinÎncă nu există evaluări

- SuperbizDocument11 paginiSuperbizeng20072007Încă nu există evaluări

- احدث CVDocument4 paginiاحدث CVeng20072007Încă nu există evaluări

- 5-1 13 3/8" Surface Casing DesignDocument10 pagini5-1 13 3/8" Surface Casing Designeng20072007Încă nu există evaluări

- 5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)Document6 pagini5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)eng20072007Încă nu există evaluări

- Warna Three: What Is Marketing?Document11 paginiWarna Three: What Is Marketing?eng20072007Încă nu există evaluări

- 0 - Cources IntroductionDocument5 pagini0 - Cources Introductioneng20072007Încă nu există evaluări

- 1007-Disq-0-L-ss-39154 Rev 2 Supplementary Purchasing Requirements For ValvesDocument14 pagini1007-Disq-0-L-ss-39154 Rev 2 Supplementary Purchasing Requirements For Valveseng20072007Încă nu există evaluări

- 1007 DISQ 0 J SS 33030 Control Valve SpecificationDocument18 pagini1007 DISQ 0 J SS 33030 Control Valve Specificationeng20072007Încă nu există evaluări

- 1007 Disq 0 G Ae 30033 Rev 5 Equipment ListDocument22 pagini1007 Disq 0 G Ae 30033 Rev 5 Equipment Listeng20072007100% (1)

- 1007-Disq-0-L-ss-39151 Rev 2 Spec For Chemical Cleaning of PipingDocument10 pagini1007-Disq-0-L-ss-39151 Rev 2 Spec For Chemical Cleaning of Pipingeng20072007Încă nu există evaluări

- 1007-DISQ-0-M-SS-42026-Rev.3 ValvesDocument13 pagini1007-DISQ-0-M-SS-42026-Rev.3 Valveseng20072007Încă nu există evaluări

- EPW, Vol.58, Issue No.44, 04 Nov 2023Document66 paginiEPW, Vol.58, Issue No.44, 04 Nov 2023akashupscmadeeaseÎncă nu există evaluări

- Sony x300 ManualDocument8 paginiSony x300 ManualMarcosCanforaÎncă nu există evaluări

- Construction Project - Life Cycle PhasesDocument4 paginiConstruction Project - Life Cycle Phasesaymanmomani2111Încă nu există evaluări

- Audi A4-7Document532 paginiAudi A4-7Anonymous QRVqOsa5Încă nu există evaluări

- L GSR ChartsDocument16 paginiL GSR ChartsEmerald GrÎncă nu există evaluări

- National Interest Waiver Software EngineerDocument15 paginiNational Interest Waiver Software EngineerFaha JavedÎncă nu există evaluări

- MPI Unit 4Document155 paginiMPI Unit 4Dishant RathiÎncă nu există evaluări

- Atoma Amd Mol&Us CCTK) : 2Nd ErmDocument4 paginiAtoma Amd Mol&Us CCTK) : 2Nd ErmjanviÎncă nu există evaluări

- Maximum and Minimum PDFDocument3 paginiMaximum and Minimum PDFChai Usajai UsajaiÎncă nu există evaluări

- L 11Document3 paginiL 11trangÎncă nu există evaluări

- D E S C R I P T I O N: Acknowledgement Receipt For EquipmentDocument2 paginiD E S C R I P T I O N: Acknowledgement Receipt For EquipmentTindusNiobetoÎncă nu există evaluări

- Pam8610 PDFDocument15 paginiPam8610 PDFRaka Satria PradanaÎncă nu există evaluări

- Static Electrification: Standard Test Method ForDocument10 paginiStatic Electrification: Standard Test Method Forastewayb_964354182Încă nu există evaluări

- Blackberry: Terms of Use Find Out MoreDocument21 paginiBlackberry: Terms of Use Find Out MoreSonu SarswatÎncă nu există evaluări

- Chapter 01 What Is Statistics?Document18 paginiChapter 01 What Is Statistics?windyuriÎncă nu există evaluări

- Pitch DeckDocument21 paginiPitch DeckIAÎncă nu există evaluări

- Hitachi Vehicle CardDocument44 paginiHitachi Vehicle CardKieran RyanÎncă nu există evaluări

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDocument9 paginiDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaÎncă nu există evaluări

- TTDM - JithinDocument24 paginiTTDM - JithinAditya jainÎncă nu există evaluări

- Waves and Ocean Structures Journal of Marine Science and EngineeringDocument292 paginiWaves and Ocean Structures Journal of Marine Science and Engineeringheinz billÎncă nu există evaluări

- Six Sigma PresentationDocument17 paginiSix Sigma PresentationDhular HassanÎncă nu există evaluări

- Acoustic Glass - ENDocument2 paginiAcoustic Glass - ENpeterandreaÎncă nu există evaluări

- Installing Surge Protective Devices With NEC Article 240 and Feeder Tap RuleDocument2 paginiInstalling Surge Protective Devices With NEC Article 240 and Feeder Tap RuleJonathan Valverde RojasÎncă nu există evaluări

- Object Oriented ParadigmDocument2 paginiObject Oriented ParadigmDickson JohnÎncă nu există evaluări

- Diverging Lenses - Object-Image Relations: Previously in Lesson 5 Double Concave LensesDocument2 paginiDiverging Lenses - Object-Image Relations: Previously in Lesson 5 Double Concave LensesleonÎncă nu există evaluări

- Polysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Document1 paginăPolysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Carlos JiménezÎncă nu există evaluări

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 paginiLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulÎncă nu există evaluări

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Document2 paginiSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhÎncă nu există evaluări

- FIR FliterDocument10 paginiFIR FliterasfsfsafsafasÎncă nu există evaluări

- Meta100 AP Brochure WebDocument15 paginiMeta100 AP Brochure WebFirman RamdhaniÎncă nu există evaluări