Documente Academic

Documente Profesional

Documente Cultură

Blend Content Uniformity Process Flow Diagram Design Validation PDF

Încărcat de

marwaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Blend Content Uniformity Process Flow Diagram Design Validation PDF

Încărcat de

marwaDrepturi de autor:

Formate disponibile

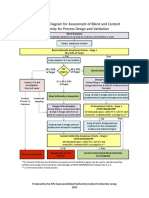

Process Flow Diagram for Assessment of Blend and Content Uniformity

for Process Design and Process Qualification Batches

Published in: J Pharm Innov, 2014, (DOI) 10.1007/s12247-014-9207-0

Blend (Samples): Sample at least 3 replicate samples from at least 10 locations in the blender or drum

Assay 1 sample per location

Blend Uniformity Acceptance Criteria Stage 1: SD 3.0% of target

Fail Pass

Assay samples 2 & 3 per location

SD > 5.0% of Target SD 3.0% of Target

BU Stage 2 Blend Uniformity is Acceptable

3.1 SD 5.0%

Conduct VCA and of Target Dosage Units (Samples): During filling or

investigation. compression, take at least 3 samples from at

Was root cause: least 40 locations across the batch

Product / Analytical/ Blend Uniformity Assay at least 3 dosage units from at least 20

Process Sampling is Acceptable predetermined locations throughout the batch

Dosage Units (Samples): During Acceptance Criteria Stage 1

filling or compression, take at All individual values within 75.0-125.0% and,

least 3 samples from at least 40 Complies with statistical test to provide an

locations across the batch appropriate level of assurance to comply with

USP <905> for n*

Assay at least 3 dosage units from Fail Pass

at least 40 predetermined Assay at least 3 dosage units from the re-

locations throughout the batch maining 20 locations not tested in Stage 1.

Acceptance Criteria Stage 2

All individual values within 75.0-125.0% and,

Complies with statistical test to provide an appropriate level of assurance to

comply with USP <905> for n*

Fail Pass

Blend is not uniform Dosage Units are not uniform Blend & content uniformity are acceptable

*n is the total number of assay results.

S-ar putea să vă placă și

- Blend Content Uniformity Process Flow Diagram Design ValidationDocument1 paginăBlend Content Uniformity Process Flow Diagram Design Validationhicham1963Încă nu există evaluări

- A Guide To Blend Uniformity: Overview of Blending Process and EquipmentDocument6 paginiA Guide To Blend Uniformity: Overview of Blending Process and Equipmentmailtorubal2573100% (1)

- Content UniformityDocument9 paginiContent UniformitySiri KalyanÎncă nu există evaluări

- Basic Aspects of Process Validation of Solid Oral Dosage FormsDocument15 paginiBasic Aspects of Process Validation of Solid Oral Dosage FormsAbeer TamimiÎncă nu există evaluări

- ProtocolDevelopment 01Document8 paginiProtocolDevelopment 01mgvtertvÎncă nu există evaluări

- Semi Solid Dosage Forms Manufacturing Tools Critical Process Parameters Strategies Optimization and ValidationDocument9 paginiSemi Solid Dosage Forms Manufacturing Tools Critical Process Parameters Strategies Optimization and ValidationGeotamÎncă nu există evaluări

- Annex 4 WHO Guidelines 4 Sampling of Pharmaceutical ProductsDocument23 paginiAnnex 4 WHO Guidelines 4 Sampling of Pharmaceutical ProductsJakobus Benny SalimÎncă nu există evaluări

- Q C of Sterile ProductsDocument103 paginiQ C of Sterile ProductsMuhammad TaimurÎncă nu există evaluări

- Hold Time Study Protocol OF Cleaned Manufacturing Equipment Awaiting For UseDocument11 paginiHold Time Study Protocol OF Cleaned Manufacturing Equipment Awaiting For UseMarwa AhmedÎncă nu există evaluări

- Canada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1Document34 paginiCanada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1atulbsÎncă nu există evaluări

- Techniques of Tablet Coating Concepts and Advancements A Comprehensive Review 1 6Document6 paginiTechniques of Tablet Coating Concepts and Advancements A Comprehensive Review 1 6Stefany Luke0% (1)

- Basic Aspects of Process Validation of Solid Oral Dosage FormsDocument33 paginiBasic Aspects of Process Validation of Solid Oral Dosage FormsMahendra SinghÎncă nu există evaluări

- QBD AnalyticalDocument17 paginiQBD Analyticalqbdresearch labÎncă nu există evaluări

- Omgoing Stability Testing - Innovations - in - Pharmaceutical - TechnologyDocument3 paginiOmgoing Stability Testing - Innovations - in - Pharmaceutical - TechnologyJuan RojasÎncă nu există evaluări

- Aerosol Part21Document39 paginiAerosol Part21Kiki MegasariÎncă nu există evaluări

- Microbiological Pharmaceutical Quality Control LabsDocument7 paginiMicrobiological Pharmaceutical Quality Control LabsDede Kizzy Black100% (1)

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Document8 paginiHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104iloveit52252Încă nu există evaluări

- QBD Approach To Dissolution Through Understanding of The Release Mechanisms and Critical in Vivo ParametersDocument61 paginiQBD Approach To Dissolution Through Understanding of The Release Mechanisms and Critical in Vivo Parametersvg_vvgÎncă nu există evaluări

- 1.2 Pharmaceutical Dosage FormsDocument41 pagini1.2 Pharmaceutical Dosage FormsHumanic GenesÎncă nu există evaluări

- Stability Studies Assessment ExperienceDocument61 paginiStability Studies Assessment ExperienceDANIBATAÎncă nu există evaluări

- Validacion Con TOCDocument4 paginiValidacion Con TOCdatinjacabÎncă nu există evaluări

- Blend UniformityDocument10 paginiBlend Uniformityitung23Încă nu există evaluări

- Cleaning and Cleaning Validation PDFDocument6 paginiCleaning and Cleaning Validation PDFedgar palominoÎncă nu există evaluări

- GS Coating Equipment enDocument8 paginiGS Coating Equipment enAkber LakhaniÎncă nu există evaluări

- No. of Cumulative Units No. of Units USP Tested Tested All UnitsDocument19 paginiNo. of Cumulative Units No. of Units USP Tested Tested All UnitsalnoorphÎncă nu există evaluări

- Quality by Design in Pharmaceutical Industry: Ruchi Singh NeekhraDocument43 paginiQuality by Design in Pharmaceutical Industry: Ruchi Singh NeekhraRuchi Cerelia NutritechÎncă nu există evaluări

- Analytical Control Strategies of VaccineDocument20 paginiAnalytical Control Strategies of VaccineDimitris PapamatthaiakisÎncă nu există evaluări

- 2013-09-18 USP Stability 1 RegulationsDocument68 pagini2013-09-18 USP Stability 1 RegulationssreekanthsharmaÎncă nu există evaluări

- Membrane FiltrationDocument30 paginiMembrane FiltrationsupravietuireÎncă nu există evaluări

- Process Validation Article 1Document12 paginiProcess Validation Article 1baluchakpÎncă nu există evaluări

- Tablets Quality ControlDocument18 paginiTablets Quality ControlThangabalan Than100% (2)

- 5 Parenteral Preparations Formulation and PackagingDocument29 pagini5 Parenteral Preparations Formulation and PackagingSukhwinder SinghÎncă nu există evaluări

- Annex4-TRS992 Hold Time Study GuidelineDocument8 paginiAnnex4-TRS992 Hold Time Study Guidelinensk79in@gmail.com100% (1)

- Annex10a - Asean Guideline On Process Validation - Presentation (1 - July - 2003) - AdoptedDocument22 paginiAnnex10a - Asean Guideline On Process Validation - Presentation (1 - July - 2003) - AdoptedBrian WilliamsÎncă nu există evaluări

- Validating Dissolution MethodsDocument51 paginiValidating Dissolution MethodshenryÎncă nu există evaluări

- Validation-An Important Tool of GMP: About Authors: Karmveer TomarDocument4 paginiValidation-An Important Tool of GMP: About Authors: Karmveer TomarShiv KumarÎncă nu există evaluări

- Validation of MicrobiologicalDocument26 paginiValidation of MicrobiologicalOsman AitaÎncă nu există evaluări

- 10.dissolution Comparison As Per IpbpuspepDocument5 pagini10.dissolution Comparison As Per IpbpuspepNitinPrachiJainÎncă nu există evaluări

- Hold Time Study SOP Indian Pharma 1Document3 paginiHold Time Study SOP Indian Pharma 1ziadddÎncă nu există evaluări

- Cleaning Validation AlconoxDocument8 paginiCleaning Validation AlconoxEDGARÎncă nu există evaluări

- Ophthalmic Dosage Forms Types and Characteristics 1) Liquid ...Document6 paginiOphthalmic Dosage Forms Types and Characteristics 1) Liquid ...Kiran VemaÎncă nu există evaluări

- Jabed Process ValidationDocument8 paginiJabed Process Validationjabed sarkarÎncă nu există evaluări

- Blend Astm Final Dosage Units Calculations Version 10-14-16Document21 paginiBlend Astm Final Dosage Units Calculations Version 10-14-16ruben orozcoÎncă nu există evaluări

- GMPs Workshop - Analytical Method Validation (Regulatory Perspective - Linda NG, FDA)Document31 paginiGMPs Workshop - Analytical Method Validation (Regulatory Perspective - Linda NG, FDA)Helena DordioÎncă nu există evaluări

- Ongoing Stability Testing Requirements, Solutions and Potential PitfallsDocument3 paginiOngoing Stability Testing Requirements, Solutions and Potential PitfallssamxuÎncă nu există evaluări

- Water For Pharmaceutical Use: Commissioning, Qualification and ValidationDocument16 paginiWater For Pharmaceutical Use: Commissioning, Qualification and ValidationAndy RojasÎncă nu există evaluări

- Biopharmaceutical Considerations in Drug Product Design and in Vitro Introduction (Biopharm)Document22 paginiBiopharmaceutical Considerations in Drug Product Design and in Vitro Introduction (Biopharm)vipinkv99Încă nu există evaluări

- Documentation Required For Periodic GMP Compliance Inspection Annex 1 JPDocument5 paginiDocumentation Required For Periodic GMP Compliance Inspection Annex 1 JPspam_discardÎncă nu există evaluări

- Liquid Dosage FormDocument29 paginiLiquid Dosage FormALIMAH MOSARWAÎncă nu există evaluări

- TRS961 - Annex7 WHO Tech TransferDocument25 paginiTRS961 - Annex7 WHO Tech TransferkrasataÎncă nu există evaluări

- Compressed Air Testing ProcedureDocument5 paginiCompressed Air Testing ProcedureroopadharÎncă nu există evaluări

- Systems-Based Inspections For Cleaning Validation: ObjectivesDocument11 paginiSystems-Based Inspections For Cleaning Validation: ObjectivesPrashansa Shrestha100% (1)

- HPLC Verification - Pic Added &shortendDocument40 paginiHPLC Verification - Pic Added &shortendMD Fahad MiajiÎncă nu există evaluări

- Forced Degradation Studies-DDT June2010-Rd3Document4 paginiForced Degradation Studies-DDT June2010-Rd3Prem GoelÎncă nu există evaluări

- Guide To Inspections of Pharmaceutical Quality Control LaboratoriesDocument16 paginiGuide To Inspections of Pharmaceutical Quality Control Laboratoriessubrata1Încă nu există evaluări

- ICH Quality Guidelines: An Implementation GuideDe la EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleÎncă nu există evaluări

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersDe la EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersÎncă nu există evaluări

- Validation of Dry Powder Mixer MalibaDocument21 paginiValidation of Dry Powder Mixer MalibamarwaÎncă nu există evaluări

- 01-How-to-identify-CQA-CPP-CMA-Final Imp PDFDocument40 pagini01-How-to-identify-CQA-CPP-CMA-Final Imp PDFmarwa100% (1)

- 15 1 Morvai Slides PDFDocument24 pagini15 1 Morvai Slides PDFmarwaÎncă nu există evaluări

- Internal Auditing of Laboratory Quality Management SystemsDocument66 paginiInternal Auditing of Laboratory Quality Management Systemsmarwa100% (4)

- Blend Content Uniformity Process Flow Diagram Design ValidationDocument1 paginăBlend Content Uniformity Process Flow Diagram Design ValidationmarwaÎncă nu există evaluări

- FDA Stratified SamplingDocument18 paginiFDA Stratified SamplingAnkit Sitoke100% (5)

- 01-How-to-identify-CQA-CPP-CMA-Final Imp PDFDocument40 pagini01-How-to-identify-CQA-CPP-CMA-Final Imp PDFmarwa100% (1)

- Oiml R76-1Document144 paginiOiml R76-1Andrés Pacompía100% (1)

- IVT Network - The FDA CGMP Inspection Is Coming - Make The Best of It - 2016-02-05Document18 paginiIVT Network - The FDA CGMP Inspection Is Coming - Make The Best of It - 2016-02-05marwaÎncă nu există evaluări

- Journal of Greenhouse Gas Control 19 (2013) 576-583Document9 paginiJournal of Greenhouse Gas Control 19 (2013) 576-583marwaÎncă nu există evaluări

- E03 Singhai-Potent Product Process and Facility DesignDocument29 paginiE03 Singhai-Potent Product Process and Facility DesignmarwaÎncă nu există evaluări

- Quality Risk ManagementDocument20 paginiQuality Risk Managementmarwa100% (1)

- Annex 2: WHO Good Practices For Pharmaceutical Microbiology Laboratories BackgroundDocument24 paginiAnnex 2: WHO Good Practices For Pharmaceutical Microbiology Laboratories Backgroundanandhra2010Încă nu există evaluări

- Annex 2: WHO Good Practices For Pharmaceutical Microbiology Laboratories BackgroundDocument24 paginiAnnex 2: WHO Good Practices For Pharmaceutical Microbiology Laboratories Backgroundanandhra2010Încă nu există evaluări

- ISO 14644 2015 - Pharmig XDocument36 paginiISO 14644 2015 - Pharmig Xmarwa100% (8)

- Iso14644 3Document31 paginiIso14644 3Justin Southerland100% (1)

- 1-3 HvacDocument65 pagini1-3 HvacDonig FermanianÎncă nu există evaluări

- 1-3 HvacDocument65 pagini1-3 HvacDonig FermanianÎncă nu există evaluări

- Compilation of Key GMP Requirements in Us and Japan For Tablet ManufacturingDocument10 paginiCompilation of Key GMP Requirements in Us and Japan For Tablet ManufacturingmarwaÎncă nu există evaluări

- 1-7 Manufacturing BasicsDocument29 pagini1-7 Manufacturing Basicssadiq455Încă nu există evaluări

- 1-5 Equipment QualificationDocument47 pagini1-5 Equipment QualificationSandip NajanÎncă nu există evaluări

- 1 4d - Qualiy Risk ManagementDocument22 pagini1 4d - Qualiy Risk Managementelektron2010Încă nu există evaluări

- Ansi Aga B109 1 2000Document43 paginiAnsi Aga B109 1 2000Ihab El-SaftawiÎncă nu există evaluări

- Degassed Cation Conductivity MeasurementDocument11 paginiDegassed Cation Conductivity MeasurementPhạm Nhật MinhÎncă nu există evaluări

- BulldogDocument20 paginiBulldogFlorinÎncă nu există evaluări

- Rattan Pole BendingDocument21 paginiRattan Pole Bendingcintamore_jos355Încă nu există evaluări

- Gmail - CAMPUS DRIVE NOTIFICATION - Himadri Speciality Chemical LTDDocument2 paginiGmail - CAMPUS DRIVE NOTIFICATION - Himadri Speciality Chemical LTDShresth SanskarÎncă nu există evaluări

- TwistedBrush Pro Studio VideosDocument63 paginiTwistedBrush Pro Studio VideosPraveen KumarÎncă nu există evaluări

- Ducon Construction Chemicals Industries LTD - Concrete Admixtures in BangladeshDocument3 paginiDucon Construction Chemicals Industries LTD - Concrete Admixtures in BangladeshFounTech612Încă nu există evaluări

- 78-00583 Profo Metpoint Ocv Compact 8p Int DisplayDocument8 pagini78-00583 Profo Metpoint Ocv Compact 8p Int DisplayLinh NgoÎncă nu există evaluări

- NISSOS NIKOURIA - KYKLADES MARITIME - SpecsDocument2 paginiNISSOS NIKOURIA - KYKLADES MARITIME - SpecsEkvazis TarsachÎncă nu există evaluări

- As 3638-1993 Test Sieving ProceduresDocument7 paginiAs 3638-1993 Test Sieving ProceduresSAI Global - APACÎncă nu există evaluări

- 13.2.2.13 Lab - Incident HandlingDocument3 pagini13.2.2.13 Lab - Incident Handlingc583706Încă nu există evaluări

- CIS Kubernetes Benchmark v1.4.1Document254 paginiCIS Kubernetes Benchmark v1.4.1Anonymous 4uxmV5Z4oÎncă nu există evaluări

- The Business Analyst and The SDLCDocument8 paginiThe Business Analyst and The SDLCErlet ShaqeÎncă nu există evaluări

- Installation, Use and Maintenance Manual: Translation of The Original InstructionsDocument148 paginiInstallation, Use and Maintenance Manual: Translation of The Original InstructionsCTHÎncă nu există evaluări

- Fpga Viva QuestionDocument4 paginiFpga Viva QuestionManila MathurÎncă nu există evaluări

- Id Based Multicast Secret-Key Management Scheme (SKMS) in ManetsDocument10 paginiId Based Multicast Secret-Key Management Scheme (SKMS) in ManetsSandhya RaniÎncă nu există evaluări

- CHE463 Heat TransferDocument1 paginăCHE463 Heat TransferEitrah Tasnim Mohamat KasimÎncă nu există evaluări

- 5400 Replace BBU BlockDocument15 pagini5400 Replace BBU BlockAhmed HaggarÎncă nu există evaluări

- M180: Data Structure and Algorithms in Java Arab Open UniversityDocument18 paginiM180: Data Structure and Algorithms in Java Arab Open Universityamr201020Încă nu există evaluări

- Chapter 1 FinalDocument13 paginiChapter 1 FinalThahzeen KazifÎncă nu există evaluări

- Nob - Data Center - DammamDocument1 paginăNob - Data Center - DammamImthiyazAliAhamedHÎncă nu există evaluări

- 3CP.1.3 PaperDocument4 pagini3CP.1.3 PaperAlexander ChekalinÎncă nu există evaluări

- GSECL - Daily Progress Report 11.9.21Document2 paginiGSECL - Daily Progress Report 11.9.21krishna mohanÎncă nu există evaluări

- Thermal Modeling and Design Considerations of Lithium-Ion BatteriesDocument8 paginiThermal Modeling and Design Considerations of Lithium-Ion BatteriesVarun Gupta100% (1)

- Huawei OLT MA5600T 10G GPON H801XGBD Board Hardware DescriptionDocument6 paginiHuawei OLT MA5600T 10G GPON H801XGBD Board Hardware DescriptionHuawei GPON Networks100% (1)

- Erection Procedures of Earthing Arrangements TNC TNS TNCS and TTDocument7 paginiErection Procedures of Earthing Arrangements TNC TNS TNCS and TTPierre Enrique Carrasco Fuentes0% (1)

- w170 w190 w230c - 30644gb 123bbDocument20 paginiw170 w190 w230c - 30644gb 123bbJIMISINGÎncă nu există evaluări

- Kapil Sharma ResumeDocument4 paginiKapil Sharma ResumeKapil SharmaÎncă nu există evaluări

- Nissan in EuropeDocument24 paginiNissan in Europeonlyur44Încă nu există evaluări

- Fluorescence Activated Cell SortingDocument6 paginiFluorescence Activated Cell SortingAjit YadavÎncă nu există evaluări