Documente Academic

Documente Profesional

Documente Cultură

Smart PV Plant Solution Description 01 PDF

Încărcat de

bacuoc.nguyen356Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Smart PV Plant Solution Description 01 PDF

Încărcat de

bacuoc.nguyen356Drepturi de autor:

Formate disponibile

Smart PV Power Plant Solution

Descritpion

Issue 01

Date 2015-06-30

HUAWEI TECHNOLOGIES CO., LTD.

Copyright Huawei Technologies Co., Ltd. 2015. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Huawei Proprietary and Confidential i

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion Change History

Change History

Date Version Description Author

2015-06-30 01 Initial draft. Li Junyong (employee ID: 00311268)

Shu Zhenhuan (employee ID: 00192146)

Huawei Proprietary and Confidential ii

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion Contents

Contents

Change History ........................................................................................................................... ii

1 About This Document ............................................................................................................. 1

2 Solution Overview ................................................................................................................... 2

2.1 Solution Architecture ............................................................................................................................................. 2

2.2 Solution Scenarios ................................................................................................................................................. 2

2.3 Solution Features ................................................................................................................................................... 3

3 Solution Devices ...................................................................................................................... 5

3.1 Devices Overview ................................................................................................................................................. 5

3.2 Device Description ...............................................................................................................................................10

3.2.1 PV Module ........................................................................................................................................................10

3.2.2 Inverter.............................................................................................................................................................. 11

3.2.3 AC Combiner Box/AC PDC...............................................................................................................................18

3.2.4 Transformer .......................................................................................................................................................21

3.2.5 Power Cable ......................................................................................................................................................22

3.2.6 Smart Communications Cabinet .........................................................................................................................25

3.2.7 Data Collector ...................................................................................................................................................29

3.2.8 PID Module .......................................................................................................................................................31

3.2.9 Ring Network Switch.........................................................................................................................................32

3.2.10 Other Monitoring and Communication Devices ................................................................................................33

4 Solution Scenarios ................................................................................................................. 34

4.1 Overview .............................................................................................................................................................34

4.2 Low-Voltage Grid-tied Scenario............................................................................................................................34

4.3 Medium-Voltage Grid-tied Scenario ......................................................................................................................35

4.4 Smart PV Power Plant Monitoring Networking Solutions ......................................................................................37

4.4.1 RS485+Fiber Ring Network Solution .................................................................................................................37

4.4.2 RS485+4G LTE Dedicated Network Solution .....................................................................................................39

4.4.3 PLC+4G LTE Dedicated Network Solution ........................................................................................................41

4.4.4 PLC+Fiber Ring Network Solution ....................................................................................................................43

4.4.5 RS485+3G Solution ...........................................................................................................................................45

4.4.6 PLC+3G Solution ..............................................................................................................................................47

4.5 4G LTE Dedicated Network Solution ....................................................................................................................49

Huawei Proprietary and Confidential iii

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion Contents

4.5.1 Frequency Band.................................................................................................................................................49

4.5.2 Frequency Band Application ..............................................................................................................................49

4.5.3 Performance ......................................................................................................................................................50

4.5.4 Distributed Architecture and Coverage Distance .................................................................................................50

4.5.5 Site Types ..........................................................................................................................................................51

4.5.6 4G LTE Dedicated Network Base Station Devices ..............................................................................................52

5 FusionSolar Smart PV Management System ...................................................................... 58

5.1 FusionSolar Smart PV Management System..........................................................................................................58

5.1.1 Introduction .......................................................................................................................................................58

5.1.2 FusionSolar Devices ..........................................................................................................................................60

5.2 NetEco 1000S Smart PV Power Plant Management System...................................................................................60

5.2.1 Introduction .......................................................................................................................................................60

5.2.2 MOQ for NetEco 1000S Devices .......................................................................................................................61

6 Reference ................................................................................................................................. 62

Huawei Proprietary and Confidential iv

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 1 About This Document

1 About This Document

Purpose

This document describes the following aspects of the smart photovoltaic (PV) power plant

solution:

System composition

Networking in various scenarios

Third-party device access

Device list

Major services

The smart PV power plant solution applies to low-voltage and medium-voltage grid-tied

scenarios. Various solution portfolios are available in these scenarios to meet customers'

requirements.

Intended Audience

This document is intended for:

Installation and commissioning engineers

Site maintenance engineers

Product delivery engineers

System maintenance engineers

Huawei Proprietary and Confidential 1

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 2 Solution Overview

2 Solution Overview

2.1 Solution Architecture

Figure 2-1 Smart PV power plant solution architecture

Smart O&M cloud center

Smart O&M mgmt system Centralized dispatching system

Multi-plant

centralized

mgmt system

FusionSolar app Server

Mgmt system interface

Electrical

Internet/ private line

dedicated line

Remote mgmt unit

Booster Optical power Climate

Interworking station forecast host server

devices AGC/AVC

monitoring

Production Area III Area I PV monitoring system

mgmt system

Plant-level

mgmt system

eLTE Mod bus IEC104

PV terminal and

Comm. Comm. Area I Area II Area III

O&M app

mgmt unit mgmt unit

Data collector

Secondary Relay protection Centralized

EMI Transformer control Relay protection device Meter Meter DCD

equipment device oscillograph

Data collection and comm

EMI

Data stream

Primary Grid

Electrical power cable

equipment

PV panel Smart PV Box-type Switch cabinet Step-up Switch cabinet SVG

transformer Load

controller Array area transformer Pooling station Booster station

The smart PV power plant solution mainly consists of the power system (primary and

secondary equipment) and the monitoring and management system (plant-level management

system and multi-plant centralized management system).

2.2 Solution Scenarios

The smart PV power plant solution applies to low-voltage (three-phase, line voltage 380/400

V AC) and medium-voltage (three-phase, line voltage: 635 kV AC) grid-tied scenarios.

Huawei Proprietary and Confidential 2

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 2 Solution Overview

Table 2-1 Smart PV power plant solution scenarios

No. Scenario Grid Inverter Array Plant

Voltage Communication Communication

Solution Solution

1 Low-voltage 380/400 SUN2000-8 RS485 Fiber ring network

grid-tied V AC /10/12/15/1

7/20/23/33K 3G or 4G router

TL

4G LTE dedicated

network

SUN2000-3 PLC Fiber ring network

3KTL

3G or 4G router

4G LTE dedicated

network

2 Medium-vol 635 kV SUN2000-2 RS485 Fiber ring network

tage AC 4.5/28/33/40

grid-tied KTL 3G or 4G router

4G LTE dedicated

network

SUN2000-3 PLC Fiber ring network

3/40KTL

3G or 4G router

4G LTE dedicated

network

The low-voltage grid-tied scenario is targeted mainly for direct connection to the

380/400 V AC grid. In this scenario, use the SUN2000-8/10/12/15/17/20/23/33KTL as

the inverter. The SUN2000-8/10/12/15/17/20/23KTL inverter provides the RS485

communication function but not the PLC communication function. The

SUN2000-33KTL inverter provides the RS485 communication function (mandatory) and

PLC communication function (optional).

The medium-voltage grid-tied scenario is targeted mainly for connection to the 635 kV

AC (after conversion by a step-up transformer) grid. It is recommended that the

SUN2000-28/40KTL be used as the inverter. The SUN2000-28/40KTL provides a 480 V

AC output voltage and the RS485 communication function. The PLC communication

function is optional for the SUN2000-40KTL.

In low-voltage grid-tied scenarios such as in Japan or other areas, if the voltage is 200 V,

the SUN2000-24.5/28KTL inverter output voltage (480 V AC) needs to be converted to

200 V AC by a transformer before grid connection.

A power plant can use the fiber ring network, 3G router, or 4G LTE dedicated network

solution for communication.

2.3 Solution Features

The smart PV power plant solution is smart, efficient, safe, and reliable.

Huawei Proprietary and Confidential 3

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 2 Solution Overview

The smart PV inverter is protected to IP65 and uses the design involving no fuses. It can

also collect high-precision information about each PV string, such as the current and

voltage, to precisely locate component faults and other electrical faults.

The solution does not require a large number of DC combiner boxes. Only a small

number of AC combiner boxes that use components not easily damaged, such as fuses,

need to be configured. The AC combiner boxes do not require regular replacement,

facilitating maintenance.

The solution uses 4G mobile communication technologies, enabling wireless

transmission of data inside PV arrays. No cable or communication device maintenance is

involved.

The smart network management system (NMS) performs monitoring, operation and

maintenance (O&M), management, and alarm functions from various aspects, analyzes

power plant operating problems, and provides comprehensive data and services to O&M

personnel, achieving smart O&M.

Huawei Proprietary and Confidential 4

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

3 Solution Devices

3.1 Devices Overview

The smart PV power plant solution consists of the power system and the monitoring and

management system. Table 3-1 lists the main devices involved in the solution. For the

monitoring and management system, Table 3-1 lists only the devices required for the power

plant arrays. For details about the devices in the plant-level monitoring system and

FusionSolar smart PV management system, see chapter 5 "FusionSolar Smart PV

Management System."

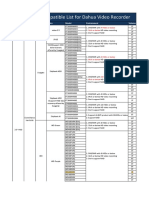

Table 3-1 Main devices in the smart PV power plant solution

No. Scenario Grid Power System Monitoring and Management System

Voltage

Inverter Other Array Plant Devices

Devices Communication Communication

Solution Solution

1 Low-volt 380/400 SUN200 PV RS485 Fiber ring network Smart

age V AC 0-8/10/12 module, communica

grid-tied /15/17/20 AC tion cabinet

/23/33KT combiner (optional),

L box (power data

distribution collector,

cabinet, ring

that is, network

PDC), switch,

power optical

cable fiber,

outdoor

shielded

network

cable

3G or 4G router Smart

communica

tion cabinet

(optional),

data

collector,

3G router,

3G router

power

Huawei Proprietary and Confidential 5

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

No. Scenario Grid Power System Monitoring and Management System

Voltage

Inverter Other Array Plant Devices

Devices Communication Communication

Solution Solution

source,

outdoor

shielded

network

cable, 3G

data card

4G LTE dedicated Smart

network communica

tion cabinet

(optional),

data

collector,

power over

Ethernet

(PoE)

power

source,

customer

premises

equipment

(CPE)

terminal,

4G LTE

dedicated

base station

devices

SUN200 PV PLC Fiber ring network Smart

0-33KTL module, communica

AC tion cabinet

combiner (optional),

box (PDC), data

power collector,

cable ring

network

switch,

optical

fiber,

outdoor

shielded

network

cable, PLC

CCO

module

3G or 4G router Smart

communica

tion cabinet

(optional),

Huawei Proprietary and Confidential 6

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

No. Scenario Grid Power System Monitoring and Management System

Voltage

Inverter Other Array Plant Devices

Devices Communication Communication

Solution Solution

data

collector,

3G router,

3G router

power

source,

outdoor

shielded

network

cable, 3G

data card,

PLC CCO

module

4G LTE dedicated Smart

network communica

tion cabinet

(optional),

data

collector,

PoE power

source,

CPE

terminal,

PLC CCO

module, 4G

LTE

dedicated

base station

devices

2 Medium- 635 kV SUN200 PV RS485 Fiber ring network Smart

voltage AC 0-24.5/28 module, communica

grid-tied /40KTL AC tion cabinet

combiner (optional),

box (PDC), data

power collector,

cable, PID ring

module network

(optional), switch,

transforme optical

r fiber,

outdoor

shielded

network

cable

3G or 4G router Smart

communica

tion cabinet

Huawei Proprietary and Confidential 7

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

No. Scenario Grid Power System Monitoring and Management System

Voltage

Inverter Other Array Plant Devices

Devices Communication Communication

Solution Solution

(optional),

data

collector,

3G router,

3G router

power

source,

outdoor

shielded

network

cable, 3G

data card

4G LTE dedicated Smart

network communica

tion cabinet

(optional),

data

collector,

PoE power

source,

CPE

terminal,

4G LTE

dedicated

base station

devices

SUN200 PLC Fiber ring network Smart

0-40KTL communica

tion cabinet

(optional),

data

collector,

ring

network

switch,

optical

fiber,

outdoor

shielded

network

cable, PLC

CCO

module

3G or 4G router Smart

communica

tion cabinet

(optional),

Huawei Proprietary and Confidential 8

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

No. Scenario Grid Power System Monitoring and Management System

Voltage

Inverter Other Array Plant Devices

Devices Communication Communication

Solution Solution

data

collector,

3G router,

3G router

power

source,

outdoor

shielded

network

cable, 3G

data card,

PLC CCO

module

4G LTE dedicated Smart

network communica

tion cabinet

(optional),

data

collector,

PoE power

source,

CPE

terminal,

PLC CCO

module, 4G

LTE

dedicated

base station

devices

Remarks:

Inverters for Japan: SUN2000-24.5/28KTL; inverters for Europe and other regions:

SUN2000-823, 28, 33KTL

Table 3-1 does not cover devices in the plant-level monitoring system and FusionSolar smart

PV management system. For details about these devices, see chapter 5 "FusionSolar Smart PV

Management System."

Huawei Proprietary and Confidential 9

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

3.2 Device Description

3.2.1 PV Module

Mainstream PV power plants use monocrystalline silicon or polycrystalline silicon solar cells.

Table 3-2 describes the specifications of monocrystalline silicon and polycrystalline silicon

PV modules.

Table 3-2 Specifications of mainstream crystalline silicon PV modules

Specifications/ Polycrystalline Polycrystalline Monocrystalline Monocrystalline

Type Silicon Solar Silicon Solar Silicon Solar Silicon Solar

Cell-60-260Wp Cell-72-305Wp Cell-60-265Wp Cell-72-310Wp

Number of 60 72 60 72

wafers

Peak power 260 Wp 305 Wp 260 Wp 310 Wp

Open-circuit 37.7 V 45.4 V 38.3 V 45.57 V

voltage

Short-circuit 9.09 A 8.93 A 9.37 A 8.85 A

current

Peak voltage 30.3 V 36.1 V 30.1 V 37.04 V

Peak current 8.59 A 8.45 A 8.79 A 8.37 A

Weight 18.5 kg 25.5 kg 18.5 kg 30 kg

Dimensions 1650 mm x 992 1935 mm x 991 mm 1650 mm x 992 mm 1935 mm x 991 mm x

mm x 50 mm x 45 mm x 40 mm 45 mm

Similar specifications

Max. endured 1000 V DC

voltage

Power error + 3%

Wind and 60 m/s (200 kg/sq.m)

pressure resistant

performance

Temperature 0.06/C

coefficient of the

short-circuit

current

Temperature 0.33/C

coefficient of the

open-circuit

voltage

Peak power 0.42/C

temperature

coefficient

Huawei Proprietary and Confidential 10

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Specifications/ Polycrystalline Polycrystalline Monocrystalline Monocrystalline

Type Silicon Solar Silicon Solar Silicon Solar Silicon Solar

Cell-60-260Wp Cell-72-305Wp Cell-60-265Wp Cell-72-310Wp

Standard test Solar irradiance: 1000 W/m2

conditions

Panel surface temperature: 25C

3.2.2 Inverter

The Huawei SUN2000 string smart inverter functions as the controller in a smart PV power

plant. It efficiently converts DC power into AC power, monitors the power plant, and controls

the active/reactive power output of the power plant.

The working principles of the SUN2000 are described as follows:

The input current detection circuit detects the current of each string, analyzes the

operating status of each string, and generates an alarm to inform users in the case of a

string exception so that they can perform maintenance.

The DC switch disconnects internal circuits from the DC input to facilitate manual

operations.

The class II DC surge protective device (SPD) protects the SUN2000 internal circuits

from DC overvoltage.

The input/output environmental monitoring instrument (EMI) filter filters out

high-frequency interference in the output current, ensuring that the output current meets

the power grid requirements.

The maximum power point tracking (MPPT) circuits ensure optimal output power by

monitoring the voltages and currents of PV strings and tracking the MPP.

The DC-to-AC converter converts the DC power into AC power, which is then fed to the

power grid with an output frequency and voltage matching the power grid.

The LC filter filters out electromagnetic interference inside the SUN2000 to ensure that

the SUN2000 meets electromagnetic compatibility requirements.

The output isolation relay isolates the inverter from the power grid if either of them is

faulty.

The class II AC SPD protects the SUN2000 internal circuits from AC overvoltage.

Figure 3-1 shows the SUN2000-33/40KTL inverter.

Huawei Proprietary and Confidential 11

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Figure 3-1 SUN2000-33/40KTL inverter

Table 3-3 describes the electrical specifications of the SUN2000-33/40KTL.

Table 3-3 Electrical specifications of the SUN2000-33/40KTL

Specifications SUN2000-33KTL SUN2000-40KTL

Efficiency

Max. efficiency 98.60% 98.80%

European efficiency 98.30% 98.40%

Input

Max. input power (cos = 1) 33,800 W 40,800 W

Max. input voltage 1000 V

Max. input current (per MPPT) 23 A

Max. short-circuit current (per MPPT) 32 A

Max. input current (three MPPTs) 69 A

Min. operating voltage 200 V

Full load MPPT voltage range 480800 V 580800 V

Max. inputs 6 6

Number of MPPTs 3 3

Huawei Proprietary and Confidential 12

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Output

Rated power 30,000 W 36,000 W

Rated output voltage 220230 V/380400 V, 277/480 V, 3W+PE

3W+N+PE

Output voltage frequency 50/60 Hz

Max. output current 48 A

Power factor 0.8 overexcited ... 0.8 underexcited

Total harmonic distortion (THD) < 3%

Protection

Input DC switch Supported

Anti-islanding protection Supported

Output overcurrent protection Supported

Input reverse connection protection Supported

Fault detection for PV strings Supported

DC surge protection Class II

AC surge protection Class II

Insulation resistance detection Supported

Residual current device (RCD) detection Supported

Display and Communication

Display LED

RS485 Supported

USB Supported

PLC Supported

Common Parameters

Dimensions (W x H x D) 550 mm x 770 mm x 255 mm

Weight 49 kg

Operating temperature 25C to +60C

Cooling mode Natural convection

Altitude 4000 m

Relative humidity (non-condensing) 0100%

Input terminal Amphenol H4

Output terminal Waterproof PG connector + OT terminal

Huawei Proprietary and Confidential 13

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Protection level IP65

Power consumption at night <1W

Topology No transformer

Noise 29 dB

Warranty period 5 years

Standards Compliance

Safety/EMC EN61000-6-2, EN61000-6-3, EN61000-3-2,

EN61000-3-3, EN61000-3-11, EN61000-3-12,

EN/IEC62109-1, EN/IEC62109-2

Power grid connection standard VDE-AR-N4105, VDE0126-1-1, BDEW 2008,

Enel-Guideline, CEI 0-21, G59/2, G83/1-1,

AS4777, CGC/GF004:2011, IEC61727,

IEC62116, RD1669

Figure 3-2 shows the electrical diagram of the SUN2000-33/40KTL inverter.

Figure 3-2 Electrical diagram of the SUN2000-33/40KTL

MPPT circuit 1

Output EMI

Input EMI filter

filter

MPPT circuit 2

DC-AC Output

inverter circuit isolation relay

AC SPD

MPPT circuit 3 LCL filter

Input

DC

current

switch

detection

DC SPD

SUN2000-40KTL

Figure 3-3 shows the SUN2000-828KTL inverter.

Huawei Proprietary and Confidential 14

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Figure 3-3 SUN2000-828KTL inverter

Table 3-4 describes the specifications of the SUN2000-828KTL.

Table 3-4 Specifications of the SUN2000-828KTL

Specifications SUN SUN2 SUN2 SUN2 SUN2 SUN2 SUN2 SUN2 SUN2

2000- 000-10 000-12 000-1 000-17 000-20 000-2 000-24 000-28

8KTL KTL KTL 5KTL KTL KTL 3KTL .5KTL KTL

Effici Max. efficiency 98.50% 98.60% 98.70%

ency

European 98.00% 98.30% 98.40%

efficiency

Input Max. input 9100 11400 13700 17100 19200 22500 23600 - 28200

power (cos = W W W W W W W W

1)

Max. input 1000 V

voltage

Max. input 18 A

current (per

MPPT)

Min. startup 200 V

voltage

Full load MPPT 320800 V 3808 400800 V 480800 V

voltage range 00 V

Rated input 620 V 680 V

voltage

Number of 4 6

inputs

Huawei Proprietary and Confidential 15

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Specifications SUN SUN2 SUN2 SUN2 SUN2 SUN2 SUN2 SUN2 SUN2

2000- 000-10 000-12 000-1 000-17 000-20 000-2 000-24 000-28

8KTL KTL KTL 5KTL KTL KTL 3KTL .5KTL KTL

Number of 2 3

MPPTs

Outp Rated power 8000 10000 12000 15000 17000 20000 23000 24500 27500

ut VA VA VA VA VA VA VA VA VA

Max. AC output 8800 11000 13200 16500 18700 22000 - - -

power (cos=1) W W W W W W

Rated output 220230 V/380400 V, 3W+N+PE 277/48 277/48

voltage 0 V, 0 V,

3W+P 3W+P

E E

Output voltage 50/60 Hz

frequency

Max. output 12.8 16 A 19.2 A 24 A 27.2 A 32 A 33.5 A

current A

Power factor 0.8 overexcited ... 0.8 underexcited

THD < 3%

AC grid 33 A/2 ms

connection

impulse current

(peak

current/duration

)

Output max. 400 A/110 ms

short-current

current (peak

current/duration

)

Prote Input DC Supported

ction switch

Anti-islanding Supported

protection

Output Supported

overcurrent

protection

Input reverse Supported

connection

protection

Fault detection Supported

for PV strings

DC surge Class II

Huawei Proprietary and Confidential 16

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Specifications SUN SUN2 SUN2 SUN2 SUN2 SUN2 SUN2 SUN2 SUN2

2000- 000-10 000-12 000-1 000-17 000-20 000-2 000-24 000-28

8KTL KTL KTL 5KTL KTL KTL 3KTL .5KTL KTL

protection

AC surge Class II

protection

Insulation Supported

resistance

detection

RCD detection Supported

Displ Display Liquid crystal display (LCD)

ay

and RS485 Supported

com

USB Supported

muni

catio

n

Com Dimensions (W 520 mm x 610 mm x 255 mm

mon x H x D)

para

meter Weight 40 kg 48 kg

s

Operating 25C to +60C

temperature

Cooling mode Natural convection

Altitude 3000 m

Relative 0100%

humidity

(non-condensin

g)

Input terminal

Output terminal Amphenol C16/3

Protection level IP65

Class of Class I

protection

Pollution III

degree

Power <1W

consumption at

night

Topology No transformer

Noise 29 dB

Huawei Proprietary and Confidential 17

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Specifications SUN SUN2 SUN2 SUN2 SUN2 SUN2 SUN2 SUN2 SUN2

2000- 000-10 000-12 000-1 000-17 000-20 000-2 000-24 000-28

8KTL KTL KTL 5KTL KTL KTL 3KTL .5KTL KTL

Warranty 5 years

period

Stand Safety/EMC EN/IEC62109-1, EN/IEC62109-2, EN61000-6-2, EN61000-6-3, EN61000-3-2,

ards EN61000-3-3, EN61000-3-11, EN61000-3-12

comp

lianc Power grid VDE-AR-N4105, VDE0126-1-1, BDEW 2008, Enel-Guideline, CEI 0-21, CEI

e connection 0-16, G59/2, G83/2, AS4777, CGC/GF004:2011, IEC61727, IEC62116, RD1669,

standard EN50438, MEA 2013, PEA 2013

For details about other parameters, see the SUN2000 (8KTL-28KTL) Product Description and

Smart PV Power Plant Solution Product Catalog - Japanese Version.

3.2.3 AC Combiner Box/AC PDC

The SUN2000 AC combiner box (PDC) combines the output currents of multiple inverters or

AC combiner boxes and provides the currents to the low-voltage power grid or the

low-voltage input side of a box-type transformer. The SUN2000 AC combiner box (PDC)

applies to scenarios in which the power of the Huawei inverter is lower than 40 kW,

low-voltage (400 V AC) scenarios, or medium-voltage (480 V DC) scenarios.

Figure 3-4 AC combiner box appearance

Table 3-5 lists the SUN2000 AC PDC technical specifications.

Table 3-5 SUN2000 AC PDC technical specifications

Item Specifications

Engineering features Dimensions (H x W x D) Unpacked: 660 mm x 900 mm x 275 mm

Packed: 845 mm x 1095 mm x 420 mm

Weight Without miniature circuit breakers (MCBs): 46.2 kg

With MCBs: 54.4 kg

Huawei Proprietary and Confidential 18

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Item Specifications

Without MCBs: 48 kg

With MCBs: 56.2 kg

Temperature 25C to +55C (full load at 25C to +50C; linear

derating at more than 50C)

Humidity 595% RH (non-condensing)

Altitude 03000 m (derating when the altitude exceeds 3000 m)

Transport/storage 40C to +70C

temperature

Enclosure protection level IP55

Cabling Routed in and out from the bottom

Maintenance mode Maintained from the front; circuit breaker with a

protective cover

Installation mode Support-mounted or wall-mounted

Electrical Max. input voltage MCB: 400 V AC

specifications Molded case circuit breaker (MCCB): 480 V AC

Rated insulation voltage MCB: 500 V AC

MCCB: 690 V AC

Max. branch input current MCB: 34 A

MCCB: 45 A

Max. output current 270 A

Power frequency withstand 2500 V

voltage

Bus rated operating current 270 A

Rated frequency 50 Hz

Number of inputs MCB: eight

MCCB: six

Numbers of outputs One

Surge protection level Level C

PDCs of the same dimensions may differ slightly in weight due to capacity differences.

Figure 3-5 shows the location of the AC PDC in the entire power supply and distribution

system. Use MCBs in low-voltage grid-tied scenarios and use MCCBs in medium-voltage

grid-tied scenarios.

Huawei Proprietary and Confidential 19

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Figure 3-5 Location of the AC PDC in the power supply and distribution system

The SUN2000 AC PDC combines the output currents of multiple upstream SUN2000s

through the corresponding MCBs or MCCBs and level-C SPD and provides the currents to

the low-voltage input side of the box-type transformer.

Figure 3-6 and Figure 3-7 show the AC PDC power distribution principles.

Figure 3-6 Power distribution conceptual diagram (MCB)

Huawei Proprietary and Confidential 20

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Figure 3-7 Power distribution conceptual diagram (MCCB)

3.2.4 Transformer

The grid-tied transformer applies mainly to medium-voltage grid-tied scenarios. It converts

the 480 V AC output voltage of the inverter to 635 kV voltage and then connects to the

booster station in the power distribution grid or substation in the power supply grid. In most

cases, a double-column transformer integrated with the low-voltage AC power distribution

unit is used and a communications port is reserved, reducing the system cost. Mainstream

step-up transformers used in PV power plants have a rated capacity of 800, 1000, 1250, 1600,

or 2000 kVA, a voltage of 480 V AC on the low-voltage side, and a voltage of 635 kV on the

high-voltage side. The low-voltage side uses delta connection and the high-voltage side uses

star connection.

In certain scenarios such as the low-voltage grid-tied scenarios in Japan, the transformer

reduces the 480 V AC output voltage of the inverter to 200 V AC before grid connection. The

step-down transformer has the same structure as the step-up transformer.

Figure 3-8 Step-up transformer appearance and conceptual diagram

Huawei Proprietary and Confidential 21

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Table 3-6 Specifications of mainstream box-type transformers (1600 kVA, 480 V to 35 kV)

Item Recommended Specifications

Rated capacity 1600 kVA

Rated voltage Double-column, (36.75 kV2) x 2.5%/0.48 kV

Rated frequency 50 Hz

Vector group number Dy11 (with low-voltage side unearthed)

Impedance voltage 6.5% (at least 6%)

Max. efficiency > 99%

European efficiency > 98.5%

System and surge protection Three-phase three-wire IT system, 3+1

pressure-sensitive modules (three 385 V and one 510

V pressure-sensitive modules)

General circuit breaker One three-pole 2500 A/690 V circuit breaker

Branch MCCB Eight three-pole 400 A/690 V MCCBs

Enclosure material Stainless steel or aluminum

Communications protocol Modbus-RTU

Communications port RS485

Others Power port reserved for the communications cabinet:

load switch and fuses (see the following table for the

specifications)

Table 3-7 Box-type transformer ports reserved for the communications cabinet

Communications Specifications Quantity Manufacturer

Power Port

Fuse box CHM3DIU/690 V/32 A 1 PCS Bussmann

Fuse FWC-6A/600 V/6 A/50 kA 3 PCS Bussmann

Disconnector OT16F3/690 V/16 A 1 PCS ABB

Some low-voltage grid-tied scenarios require the use of the isolation transformer. The isolation

transformer has the similar structure as the step-up transformer. The isolation transformer isolates the

upstream device from the downstream device without boosting or reducing voltages.

3.2.5 Power Cable

Cable selection rules:

Huawei Proprietary and Confidential 22

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Factors to consider: cable type, soil thermal resistance coefficient, routing efficient,

PV running system features

Basic rule: The cable must meet the current-carrying capacity, cable loss, and voltage

drop requirements.

Main constraints: current-carrying capacity, cable loss, voltage drop

The selected cable must at least meet current-carrying capacity requirements. If the

system efficiency needs to be considered, the cable must also meet the cable loss

requirements.

Current-carrying capacity

Different design institutes may refer to different specifications:

GB 50217-2007 Code for design of cables of electric engineering: China standard

reference for cable selection

Electrical cable current-carrying capacity written by Ma Guodong: supplementary

reference that describes more scenarios

Industrial and civil power distribution design manual: referred to by many design

institutes. The manual provides many cable current-carrying capacity cables that

cover most scenarios.

Cable loss

Generally, the allowed ratio of total cable power loss to the total transmitted power is

less than 2%. The total cable power loss is the sum of power loss of all cables with

various diameters.

Voltage drop

Generally, the voltage drop from the inverter output to the box-type transformer

low-voltage busbar (from inverter to combiner box, from combiner box to box-type

transformer low-voltage PDC) must not exceed 5% of 400/480 V AC.

Cable model

Table 3-8 Cable models

Environment Type Cable to Select in Cable to Select in Damp, High

Common Ground Water Level, or Chemical

Conditions Corrosion Conditions

Direct bury ZC-YJV22-0.6/1kV- ZC-YJV23-0.6/1kV-x*xxmm2

x*xxmm2

Direct bury (soil ZC-YJV32-0.6/1kV- ZC-YJV33-0.6/1kV-x*xxmm2

displacement may x*xxmm2

occur)

Cable tray, cable ZC-YJV-0.6/1kV-x* ZC-YJY-0.6/1kV-x*xxmm3

trough, tube xxmm3

Rooftop (WDZC WDZC-YJV-0.6/1kV

recommended) -x*xxmm3

PV dedicated PV1-F-1*xxmm2

Huawei Proprietary and Confidential 23

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Table 3-9 Cable model description

Model Description Remarks

YJV Copper-core cross linked polyethylene (XLPE)

insulated polyvinyl chloride (PVC) sheath power

cable

YJY Copper-core cross linked polyethylene (XLPE) Polyethylene offers

insulated polyethylene sheath power cable better waterproof

performance than PVC.

ZC Flame-resistant level C

WDZC Low-smoke, halogen free, flame-resistant level C No toxic gas is emitted

during burning.

YJV22 Copper-core XLPE insulated steel belt armored The cable can withstand

PVC sheath power cable some mechanical stress.

YJV23 Copper-core XLPE insulated steel belt armored

polyethylene sheath power cable

YJV32 Copper-core XLPE insulated fine steel wire The cable can withstand

armored PVC sheath power cable some mechanical stress

and pulling force.

YJV33 Copper-core XLPE insulated fine steel wire

armored polyethylene sheath power cable

AC/DC power cable specifications (for the 1.6 MW PV array and 40KTL inverter)

Table 3-10 Recommended cable specifications

No. Cable Specifications Remarks

1 DC cable from a module to 600V/1000V-PV1-F DC cable dedicated for PV

the inverter -1*4mm2-34A, PV scenarios and should not be

power cable buried

2 Cable from the inverter to ZC-YJV22-0.6/1kV Multi-core hard cable

the combiner box -316mm2

3 AC cable from the combiner ZC-YJV22-0.6/1kV Applies to the combiner box

box to the box-type -3150mm2 that combines six inputs and

transformer provides one output

4 Cable from the ZC-YJV22-0.6/1kV Power cable

communications cabinet to -34mm2

the box-type transformer

5 Communications cable from ZC-DJYP2VP2-22- RS485 cable

the box-type transformer to 2*2*1.0mm2

the communications cabinet

Huawei Proprietary and Confidential 24

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

No. Cable Specifications Remarks

6 Communications cable from CAT5e-SFTP4PR CPE power cable and

the communications cabinet 24AWG Ethernet communications

to the CPE cable

3.2.6 Smart Communications Cabinet

The smart communications cabinet is the communication core in the PV array unit. It collects

data from PV array devices (including the inverter, AC combiner box, box-type transformer,

and EMI), and reports the data to the power plant monitoring background through the fiber

ring network, the LTE network, or other network. This provides reliable guarantee for the

communication between the smart power plant monitoring background and array devices.

The smart communications cabinet can be equipped with the data collector, PLC

communications module, PID module, fiber ring network switch, Access Terminal Box (ATB),

PoE power source, communication management unit, and corresponding wiring terminals and

power distribution switches.

The smart communications cabinet can be wall-mounted or support-mounted. It is equipped

with front and rear doors and can be maintained from the front or rear, facilitating cable

connection and maintenance.

Table 3-11 Smart communications cabinet specifications

Category Item Specifications

Basic Cabling Routed in and out from the bottom

Maintenance mode Maintained from the front

Natural environment Outdoor

Altitude 3000 m

Installation mode Support-mounted or wall-mounted

Dimensions (W x H x D) Not greater than (600 x 1100 x 600),

including the base. The dimensions

should be as small as possible.

Quality and Certification requirements /

reliability

Enclosure protection level Above IP55

Fire-resistance rating UL790 Class C

Service life 20

Environmental Operating ambient temperature 25C to +50C

adaptability

Temperature rise inside the 10 K

chassis

Operating relative humidity Not greater than 95%

(non-condensing)

Huawei Proprietary and Confidential 25

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Category Item Specifications

Environmental Huawei environmental Compliant

protection protection requirements (ROSH

and REACH)

Figure 3-9 Internal layout diagram of the communications cabinet

Table 3-12 Equipped components before delivery

No. Component Specifications Quantity Silk Screen Description

1 Three-pin 220 V/3 pins, 3 XS1, XS2, A two-prong

power socket multi-purpose XS3 or three-prong

plug can be

inserted.

2 SPD 480 V/20 kA/3P 1 FS -

3 Input MCB 480 V/32 A/3P 1 AC INPUT -

4 MCB 480 V/6 A/3P 1 PID INPUT

5 Input terminal 480 V/32 1 X1 Labels: L1,

A/3-pin L2, L3, and N

Huawei Proprietary and Confidential 26

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

No. Component Specifications Quantity Silk Screen Description

6 Power transfer 480 V/32 1 X1 Labels: A1,

terminal block A/8-pin A2, A3, B1,

B2, B3, C1,

C2, C3, N1,

and N2

7 Output power 480 V/32 1 X1 Labels: L, L,

terminal block A/4-pin N, and N

8 Output fuse 220 V/2 A/2P 2 FU1, FU2 -

9 Signal 12 V/5 A/8-pin 1 X2 Labels: A4,

terminal block B4, A5, B5,

A6, B6, A7,

and B7

10 PID module - 1 - -

Figure 3-10 shows the appearance and dimensions of the communications cabinet.

Figure 3-10 Communications cabinet appearance and dimensions

Figure 3-11 shows the top view of the communications cabinet bottom.

Huawei Proprietary and Confidential 27

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Figure 3-11 Top view of the communications cabinet bottom

(1) General power input port (2) PE input port (3) Fiber input port

(4) RS485 input port for connecting the data collector (5) Antenna input port

The communications cabinet can be equipped with or without the PID module before

delivery.

Figure 3-12 shows the conceptual diagram of the communications cabinet equipped with the

PID module before delivery. The diagram is the same for the communications cabinet without

the PID module except that the PID module is absent.

Figure 3-12 Conceptual diagram of the communications cabinet before delivery

Figure 3-13 shows the conceptual diagram of the communications cabinet equipped with the

internal devices.

Huawei Proprietary and Confidential 28

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Figure 3-13 Conceptual diagram of the communications cabinet equipped with the internal

devices

Remarks:

If there is no smart communications cabinet, devices such as the data collector and PLC

communications module are installed in the box-type transformer in most cases.

The box-type transformer must reserve guide rails for installing devices so that other optional

devices including the data collector can be installed. The box-type transformer needs to

reserve two to three 220 V three-pin power sockets (also support two-prong plugs) to function

as the power access point for the data collector, PoE power source, and PLC module. If the

reserved three-pin power sockets are insufficient, add a 220 V three-pin power strip to provide

more three-pin power sockets.

During the product solution design phase, the installation position, mounting method, and

layout scheme need to be finalized and the corresponding hole dimensions (see the user

manual for details) requirements need to be sent to the design institute as a reference for

figure design.

3.2.7 Data Collector

The SmartLogger data collector is dedicated for monitoring and managing the PV power

system. It converges all ports, converts protocols, collects and stores data, and centrally

monitors and maintains the PV power system.

A maximum of 30 devices can be connected over an RS485 route in series and a maximum of 80

devices can be connected in total.

If the EMI is required, connect it to the end terminal and set the EMI address to 1.

Huawei Proprietary and Confidential 29

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Figure 3-14 Front view of the data collector

Table 3-13 Data collector specifications

Specifications SmartLogger1000

Device Maximum number of 80

management devices that can be

managed

Communication mode 3 x RS485

Maximum communications RS485: 1000 m; Ethernet: 100 m

distance

Display LCD 3.5-inch LCD screen

LED Three LED indicators

Web WebUI

Common Power source 90270 V AC, 50/60 Hz

parameters

Power consumption Normal: 3 W; maximum: 7 W

Storage capacity 70 MB flash, can be expanded to 16 GB by

configuring an SD card.

Language English, Chinese, German, Italian

Dimensions 255 mm x 140 mm x 50 mm

Weight 500 g

Operating temperature 25C to +60C

Relative humidity 095% (non-condensing)

Protection level IP20

Installation mode Installed on a wall, desk, or along a guide

rail.

Ports Ethernet 10/100M, Modbus-TCP

Huawei Proprietary and Confidential 30

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Specifications SmartLogger1000

RS485 Three Modbus-RTU ports

Digital input (DI) 4

Analog input (AI) 2

Relay output 3

3.2.8 PID Module

PID means potential induced performance degradation in PV modules. During the running of

power plant modules, as the modules are grounded, some modules in the string are running

with a negative voltage to the ground. Due to the negative voltage, PID occurs in PV modules.

PID is likely to occur in a damp environment and the PID is accelerated by high humidity.

The PID effect is also related to the electrical conductivity, acidity, and alkalinity of PV

module surfaces and presence of objects with ions on the PV module surfaces. The PID effect

reduces the electric energy yield of the power plant, affecting revenues. The Huawei PID

module is installed in the communications cabinet to control the injection of AC voltage to the

ground. The PID module automatically adjusts the output voltage based on the inverter

voltage so that the voltage of all PV modules to the ground is positive. In this way, the PID

effect is prevented.

Working Principles

The PID module is installed in the communications cabinet and used with the cabinet. It

cannot be used independently. The PID module controls the injection of AC voltage to the

ground. It automatically adjusts the output voltage based on the inverter voltage so that the

voltage of all PV modules to the ground is positive.

Figure 3-15 Conceptual diagram for PID module installation

Communications

cabinet

Data

RS485 collector

Power

source

N

A/B/C

PID PE

1 Medium-voltage

power grid

Inverter 1 AC combiner box

Inverter n

Huawei Proprietary and Confidential 31

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

Appearance

The PID module dimensions (L x W x H) are 350 mm x 225 mm x 81.5 mm.

Figure 3-16 PID module appearance

Cable Installation

The PID module is installed in the communications cabinet, as shown in Figure 3-15. The

following table describes the cables to be installed. The three-phase AC power cable needs to

be connected to wiring terminals A, B, and C from the cabinet bottom. The PE terminal of the

PID module needs to be connected to the terminal block in the communications cabinet. The

data collector is connected to inverters using an RS485 cable, and connected to the PID

module inside the communications cabinet. For details about the communications cabinet, see

section 3.2.6 "Smart Communications Cabinet."

No. Signal Source

1 Three-phase AC power Combiner box or the low-voltage side of

the step-up transformer

2 PE PGND bar

3 RS485 communication Data collector

3.2.9 Ring Network Switch

A ring network switch is required when the fiber ring network is used for networking. The

Huawei AR550-series industrial switching routers are dedicated for harsh environments. They

can meet the network communication requirements in environments with harsh temperatures,

humidities, and electromagnetic interference. The Huawei AR550-series switching routers

integrate functions such as routing, switching, and IPSec VPN. They have strong application

expansion capabilities.

Huawei Proprietary and Confidential 32

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 3 Solution Devices

The AR550-series have two models: AR550-8FE-D-H and AR550-24FE-D-H.

Model Specifications

Fixed ports: 4 x GE combo, 8 x FE RJ45, 1 x USB2.0, 1 x Do

Operating temperature: 40C to +70C

Dimensions (W x D x H): 97 mm x 133 mm x 150 mm

Redundant power supply (RPS): 9.660 V DC

AR550-8FE-D-H

Fixed ports: 4 x GE combo, 24 x FE RJ45, 1 x USB2.0, 1 x Do

Operating temperature: 40C to +70C

Dimensions (W x D x H): 133 mm x 133 mm x 150 mm

RPS: 9.660 V DC

AR550-24FE-D-H

For details about the AR550-series devices, see the Huawei AR550-Series Industrial

Switching Router Brochure.

3.2.10 Other Monitoring and Communication Devices

See chapters 4 "Solution Scenarios" and 5 "FusionSolar Smart PV Management System".

Huawei Proprietary and Confidential 33

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

4 Solution Scenarios

4.1 Overview

The smart PV power plant solution applies mainly to low- and medium-voltage grid-tied

scenarios. This chapter describes the networking in the two scenarios. The low-voltage or

medium-voltage grid-tied scenario consists of the smart PV power plant monitoring

networking (illustrated in sections 4.4 "Smart PV Power Plant Monitoring Networking

Solutions" and 4.5 "4G LTE Dedicated Network Solution") and the FusionSolar smart PV

management system (described in chapter 5 "FusionSolar Smart PV Management System").

4.2 Low-Voltage Grid-tied Scenario

System composition

Figure 4-1 Low-voltage grid-tied scenario

Huawei Proprietary and Confidential 34

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

In the low-voltage grid-tied scenario:

Capacity: In some cases, the power grid capacity is required to be no greater than

25%30% of that of the distribution transformer. If the power grid capacity exceeds

the 25%30% of that of the distribution transformer, the PV energy needs to be

delivered to a power grid with a higher capacity.

Distribution transformer: The transformer already exists. According to the power

distribution specifications, the N cable is connected to the PE cable on the

transformer side. There is voltage between the DC cable and the PE cable. If the PV

to the ground is short-circuited, short-circuit may occur inside the inverter.

Output power cable: The N cable must be used. All low-voltage grid-tied standards

are based on the N cable. If the N cable is not used, it will be difficult to meet the

single-phase islanding requirements.

Communication: Use RS485 or PLC for communication based on the actual situation.

RCD protection: As the N cable and PE cable are connected, if the impedance of the

input to the PE cable becomes lower, residual current will exist. According to the

requirements in standards, the RCD is used to protect against personal injuries and

fire.

PID protection: If the PID module is required in a low-voltage grid-tied scenario, an

isolation transformer must be installed before the grid-feeding point.

Devices in the low-voltage grid-tied scenario

Table 4-1 Devices in the low-voltage grid-tied scenario

Input PV panel

Output Three-phase low-voltage power grid (phase voltage: 220/230 V AC)

Configurations Inverter: SUN2000-820/33KTL

AC PDC (An AC switch is required for each inverter output, and the

switch is generally provided by the system integrator.)

(Optional) EMI, which is provided by the system integrator.

Distribution transformer (local power distribution grid)

Monitoring See sections 4.4 "Smart PV Power Plant Monitoring Networking

Solutions" and 4.5 "4G LTE Dedicated Network Solution") and

chapter 5 "FusionSolar Smart PV Management System".

4.3 Medium-Voltage Grid-tied Scenario

System composition

Huawei Proprietary and Confidential 35

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Figure 4-2 Medium-voltage grid-tied scenario

In the medium-voltage grid-tied scenario:

On-grid unit: Generally, 12 MW PV panels form an on-grid unit. The transformer

high-voltage side voltage is generally 10 kV or 35 kV. Communication data needs to

be connected to the central monitoring room through the monitoring network (fiber

ring network, 3G/4G router, 4G LTE dedicated network).

Booster power station: In most cases, large-sized PV power plants require a booster

station that boosts 35 kV to 110 kV or 220 kV.

Step-up transformer: In most cases, the N cable is not connected to the PE cable and

there is no residual current circuit. There is no voltage between the DC side and the

PE cable. Therefore, a discharge current will not be formed through the inverter.

Output power cable: The AC side mostly uses the delta connection without the N

cable.

Communication: PLC is recommended for communication.

Devices in the medium-voltage grid-tied scenario

Table 4-2 Devices in the medium-voltage grid-tied scenario

Input PV panel

Output Medium-voltage power grid (635 kV)

Configurations Inverter: SUN2000-28/40KTL (low-voltage side: 480 V AC)

AC PDC

(Optional) EMI, which is provided by the system integrator.

(Optional) PID module

(Optional) Communications cabinet

Huawei Proprietary and Confidential 36

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Input PV panel

Step-up transformer (provided by the system integrator)

Pooling station devices, including the switch station and AGC/SVG

(provided by the system integrator)

Monitoring See sections 4.4 "Smart PV Power Plant Monitoring Networking

Solutions" and 4.5 "4G LTE Dedicated Network Solution") and chapter

5 "FusionSolar Smart PV Management System".

4.4 Smart PV Power Plant Monitoring Networking

Solutions

Inverters inside the power plant arrays can use RS485 (applies to all SUN2000 inverter

models) or PLC (applies to SUN2000-33/40KTL) for communication. A power plant mostly

uses the fiber ring network, 3G router, or 4G LTE dedicated network for communication. Six

solutions are available for power plant-level monitoring networking. For large-sized power

plants, the PLC+4G LTE dedicated network solution is recommended for better

cost-effectiveness and reliability. For scenarios in unsuitable for routing optical fiber, the 4G

LTE dedicated network solution is recommended.

4.4.1 RS485+Fiber Ring Network Solution

Solution topology

Huawei Proprietary and Confidential 37

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Figure 4-3 Topology of the RS485+fiber ring network solution

If the box-type transformer supports the Modbus protocol, the SmartLogger can connect to the box-type

transformer over RS485. The box-type transformer with the inverter or the transformer alone can be

connected to one RS485 port of the SmartLogger. If the box-type transformer supports the IEC103

protocol, it can connect to the RS485 or RS232 port of the SmartLogger. It is recommended that the

box-type transformer alone be connected to the RS485 port.

Application scenarios

Applies to all SUN2000 PV inverters.

Applies to large-sized ground power plants, a few mountain power plants suitable for

routing optical fiber, and industrial base rooftop power plant projects for which

optical fibers are planned or cable trenches are available.

Solution features

Broad optical fiber frequency and large communication capacity

Long communication distance of the selected single-mode fiber (SMF): 120 km

High communication reliability and superb anti-electromagnetic interference

capability offered by optical fiber. The raw materials of optical fiber consist of

insulator materials made of quartz, which are difficult to corrode and provide good

Huawei Proprietary and Confidential 38

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

insulation. An important feature related to optical fiber is that optical wavefiber is

immune to electromagnetic interference. Optical fiber is not affected by thunder,

ionosphere change, or sunspot activities in the natural environment or manual

electromagnetic interference.

Minimum Order Quantity (MOQ) for devices

Table 4-3 MOQ for devices in the RS485+fiber ring network solution

No. Device

1* Communications cabinet

2 Data collector

3 Huawei ring network switch

4 ATB

5 Pigtail

* If there is no communications cabinet in a project, other devices listed in the MOQ are

installed in the box-type transformer in most cases.

4.4.2 RS485+4G LTE Dedicated Network Solution

Solution topology

Huawei Proprietary and Confidential 39

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Figure 4-4 RS485+4G LTE solution topology

If the box-type transformer supports the Modbus protocol, the SmartLogger can connect to the box-type

transformer over RS485. The box-type transformer with the inverter or the transformer alone can be

connected to one RS485 port of the SmartLogger. If the box-type transformer supports the IEC103

protocol, it can connect to the RS485 or RS232 port of the SmartLogger. It is recommended that the

box-type transformer alone be connected to the RS485 port.

Application scenarios

A 4G LTE dedicated network in standard configuration applies to a power plant with

a distance less than 10 km. If the distance is longer, signals cannot cover the power

plant and additional devices are required.

The solution applies to power plants in mountainous areas, which are unsuitable for

routing optical fiber or power plants in the industrial base where multiple factory

rooftops are unsuitable for routing optical fiber.

Solution features

Quick deployment, a coverage of 10 km by a single power plant, 60 Mbit/s

bandwidth provided by each base station (three sectors), no trench required for

burying optical cables

Huawei Proprietary and Confidential 40

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Low delay, high security, wireless end-to-end transmission delay less than 50 ms,

safety and reliability of carrier-class devices reaching up to 99.999%

Easy O&M (flat network), channels that support maintenance, reducing

communication interruption caused by device faults

MOQ for devices

Table 4-4 MOQ for devices in the RS485+LTE network solution

No. Device

1 Communications cabinet

2 Data collector

3 PoE power source

4 CPE terminal

5 4G LTE devices (see xxx for details)

* If there is no communications cabinet in a project, other devices listed in the MOQ are

installed in the box-type transformer in most cases.

4.4.3 PLC+4G LTE Dedicated Network Solution

Solution topology

Huawei Proprietary and Confidential 41

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Figure 4-5 PLC+4G LTE solution topology

If the box-type transformer supports the Modbus protocol, the SmartLogger can connect to the box-type

transformer over RS485. The box-type transformer with the inverter or the transformer alone can be

connected to one RS485 port of the SmartLogger. If the box-type transformer supports the IEC103

protocol, it can connect to the RS485 or RS232 port of the SmartLogger. It is recommended that the

box-type transformer alone be connected to the RS485 port.

Application scenarios

The PLC networking applies only to the SUN2000-33KTL and SUN2000-40KTL.

A 4G LTE dedicated network in standard configuration applies to a power plant with

a distance less than 10 km. If the distance is longer, signals cannot cover the power

plant and additional devices are required.

Huawei Proprietary and Confidential 42

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

The solution applies to power plants in mountainous areas, which are unsuitable for

routing optical fiber or power plants in which multiple factory rooftops are unsuitable

for routing optical fiber.

Solution features

No RS485 communications cables required, improving communication reliability and

efficiency

Quick deployment, a coverage of 10 km by a single 4G LTE network, 60 Mbit/s

bandwidth provided by each base station (three sectors), no trench required for

burying optical cables

Low delay, high security, wireless end-to-end transmission delay less than 50 ms,

safety and reliability of carrier-class devices reaching up to 99.999%

Easy O&M (flat network), channels that support maintenance, reducing

communication interruption caused by device faults

MOQ for devices

Table 4-5 MOQ for devices in the PLC+LTE network solution

No. Device

1* Communications cabinet

2 Data collector

3 PLC module

4 PoE power source

5 CPE terminal

6 4G LTE devices (see xxx for details)

* If there is no communications cabinet in a project, other devices listed in the MOQ are

mostly installed in the box-type transformer.

4.4.4 PLC+Fiber Ring Network Solution

Solution topology

Huawei Proprietary and Confidential 43

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Figure 4-6 Topology of the PLC+fiber ring network solution

If the box-type transformer supports the Modbus protocol, the SmartLogger can connect to the box-type

transformer over RS485. The box-type transformer with the inverter or the transformer alone can be

connected to one RS485 port of the SmartLogger. If the box-type transformer supports the IEC103

protocol, it can connect to the RS485 or RS232 port of the SmartLogger. It is recommended that the

box-type transformer alone be connected to the RS485 port.

Application scenarios

The PLC networking applies only to the SUN2000-33KTL and SUN2000-40KTL.

The maximum Ethernet communication distance between the power plant monitoring

room and the data collector exceeds 100 m.

Huawei Proprietary and Confidential 44

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Solution features

PLC used for communication and therefore no RS485 communications cables

required, improving communication reliability and efficiency

Broad optical fiber frequency and large communication capacity. The optical fiber

provides much higher transmission bandwidth than copper or electrical cables

Long communication distance of the selected SMF: 120 km

High communication reliability and superb anti-electromagnetic interference

capability offered by optical fiber. The raw materials of optical fiber consist of

insulator materials made of quartz, which are difficult to corrode and provide good

insulation. An important feature related to optical fiber is that optical wavefiber is

immune to electromagnetic interference. Optical fiber is not affected by thunder,

ionosphere change, or sunspot activities in the natural environment or manual

electromagnetic interference.

MOQ for devices

Table 4-6 MOQ for devices in the PLC+fiber ring network solution

No. Device

1* Communications cabinet

2 Data collector

3 Ring network switch

4 ATB

5 Pigtail

6 PLC module

* If there is no communications cabinet in a project, other devices listed in the MOQ are

mostly installed in the box-type transformer.

4.4.5 RS485+3G Solution

Solution topology

Huawei Proprietary and Confidential 45

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Figure 4-7 RS485+3G solution topology

Application scenarios

The 3G network signal (such as by China Mobile, China Unicom, or China Telecom)

is available.

Wireless communication is available in places where wired communication such as

Ethernet is unavailable.

The monitoring sites are dispersed and away from each other or on factory or

residential block rooftops that are unsuitable for routing optical fiber.

Solution features

There is no limit on the communications distance.

Data traffic fees need to be paid to 3G operators (such as China Mobile, China

Unicom, or China Telecom) by month or by year.

The monitoring background system can be the Huawei NetEco or a third-party

electrical supervisory control and data acquisition (SCADA) system. If a third-party

electrical SCADA system is used, data between the SmartLogger and the SCADA

system is transmitted using plaintext and SSL encryption is not supported.

The server or PC on which the monitoring background system is to be installed must

have a fixed public network IP address.

MOQ for devices

Huawei Proprietary and Confidential 46

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Table 4-7 MOQ for devices in the RS485+3G network solution

No. Device

1* Communications cabinet

2 Data collector

3 3G router power supply

4 (choose one from three) 3G router (China Unicom) **

3G router (China Mobile)

3G router (China Telecom)

5 (choose one from three) 3G data card (China Unicom)

3G data card (China Mobile)

3G data card (China Telecom)

* If there is no communications cabinet in a project, other devices listed in the MOQ are

mostly installed in the box-type transformer.

** The China Unicom 3G router is recommended.

4.4.6 PLC+3G Solution

Solution topology

Huawei Proprietary and Confidential 47

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

Figure 4-8 PLC+3G solution topology

Application scenarios

The 3G network signal (such as by China Mobile, China Unicom, or China Telecom)

is available.

Wireless communication is available in places where wired communication such as

Ethernet is unavailable.

The monitoring sites are dispersed and away from each other or on factory or

residential block rooftops that are unsuitable for routing optical fiber.

The PLC networking applies only to the SUN2000-33KTL and SUN2000-40KTL.

Solution features

There is no limit on the communications distance.

Data traffic fees need to be paid to 3G operators (such as China Mobile, China

Unicom, or China Telecom) by month or by year.

Huawei Proprietary and Confidential 48

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

The monitoring background system can be the Huawei NetEco or a third-party

electrical SCADA system. If a third-party electrical SCADA system is used, data

between the SmartLogger and the SCADA system is transmitted using plaintext and

SSL encryption is not supported.

The server or PC on which the monitoring background system is to be installed must

have a fixed public network IP address.

MOQ for devices

Table 4-8 MOQ for devices in the PLC+3G network solution

No. Device

1* Communications cabinet

2 Data collector

3 PLC module

4 3G router power supply

5 (choose one from three) 3G router (China Unicom)

3G router (China Mobile)

3G router (China Telecom)

6 (choose one from three) 3G data card (China Unicom)

3G data card (China Mobile)

3G data card (China Telecom)

* If there is no communications cabinet in a project, other devices listed in the MOQ are

mostly installed in the box-type transformer.

4.5 4G LTE Dedicated Network Solution

Refer to this section only when the 4G LTE dedicated network solution is selected.

4.5.1 Frequency Band

The 1.8 GHz frequency band (17851805 MHz) is supported, and the frequency bandwidth

can be 5 MHz, 10 MHz, or 20 MHz (recommended).

4.5.2 Frequency Band Application

The LTE dedicated frequency band needs to be applied for from the wireless management

committee in the project area before it can be used. In most cases, lease fees are required for

the frequency band use. According to the notice on the charge for frequency band usage for

new wireless services released by China's National Development and Reform Commission,

the frequency band usage fee required for each base station is 150 RMB. The process for

applying for a frequency band is as follows:

Huawei Proprietary and Confidential 49

Copyright Huawei Technologies Co., Ltd.

Smart PV Power Plant Solution

Descritpion 4 Solution Scenarios

4.5.3 Performance

When the frequency bandwidth is 20 MHz, the maximum downlink rate per cell is 100 Mbps;

and the maximum uplink rate is 50 Mbps, and the average uplink rate is 18 Mbps.

4.5.4 Distributed Architecture and Coverage Distance

A distributed base station separates the remote radio unit (RRU) from the baseband unit

(BBU). The RRU and BBU are connected using optical fiber. This minimizes the feeder loss

and helps improve the coverage area of the base station. The base station can cover a radius of