Documente Academic

Documente Profesional

Documente Cultură

Pages From ACI-224R-90 Control of Cracking in Concrete Structures

Încărcat de

Omar MokhtarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pages From ACI-224R-90 Control of Cracking in Concrete Structures

Încărcat de

Omar MokhtarDrepturi de autor:

Formate disponibile

I A C 1 224R 90 m Obb2949 002LBb2 5

~~ ~

m

CONTROL F-CRACKING 224R-19

-

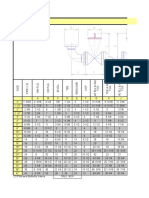

TABLE 4.1 Tolerable crack widths, prestressed member to account for the differences in

reinforced concrete bond properties.

The difficulty with this approach is the complexity

Tolerable

Exposure condition crack width, in. (mm)

of calculations. The determination of the decompres-

"___ - ~~

sion moment and, especially, the stress in th' steel

Dry air or protective membrane 0.016 (0.41)

is complicated and unreliable unless elaborate meth-

Humidity, moist airi soil 0.012 (0.30)

Deicing chemicals 0.007 (0.181

ods are For this reason,

approximate meth-

Seawater and seawater spray: ods for crack width prediction are attractive. These

wetting and drying 0.006 (0.151 arenotmuchlessaccuratethanthemore com-

Water retaining structures* 0.004 (0.101 plicated methods, and the lack of sufficient data, cov-

eringlargevariations in the variables,precludes

'Excluding nonpressure Pipes further refinements a t this date.

The CEB Model Code has the same equation for

the prediction of the crack width in prestressed

members as in nonprestressed members (see Section

not always a reliable indication of the corrosion and 4.2.2). The increase in steel strain is calculated from

deterioration to be expected. In particular, a larger the decompression stage. Several other equations

cover,even if itleadstoalargersurfacecrack have been pr~posed.~."-~.~'

width,maysometimesbepreferableforcorrosion

Limited evidence seems to indicate that unbonded

control in certainenvironments.Thus,thedesigner membersdeveloplargercracksthanbondedmem-

must exercise engineering judgment on the extent of

bers. Nonprestressed deformed bars may be used to

crackcontrol to beused.Whenused in conjuncion

reduce the width of the cracks to acceptable levels,

with the recommendations presented in Sections

Thecracks in bondedpost-tensionedmembersare

4.2.1 and 4.2.3 to limit crack width, it should be ex- not

much differentfromcracks in pretensioned

pected that a portion of the cracks in the structure

beams.

will exceed these values by a significant amount.

4.6.2 Allowable crack widths - Some authors state

thatcorrosion is a greater problem in prestressed

-

4.5 Flexural cracking in prestressed concrete

concretemembersbecause of the smallerarea of

Partiallyprestressedmembers, in whichcracks

steel used. However, recent research resuls4." indi-

may appearunderworkingloads,areusedexten-

c a t e that there is no general relationship between

sively. Cracks form in these members when the ten- crackingandcorrosion in mostcircumstances.Fur-

sile stress exceedsthemodulus of rupture of the

thermore, cracks close upon removal of the load, and

concrete ( S c to 9 a under short-term conditions).

the use of crackwidthlimitsshoulddepend on the

The control of these cracks is necessarymainlyfor fluctuation and magnitude of the live load.

esthetic reasons. The residual crack width, after re-

moval of the major portion of the live load, is small

[about 0.001 in. to 0.003 in. (0.03to 0.08 mm)]and

therefore,crackcontrol is usuallynotnecessary if -

4.6 Anchorage zone cracking in prestressed con.

the live load is transitory. Crete

The prediction of crack widths in- prestressed con- Longitudinal cracks frequently occur in the ancho-

cretemembershasreceivedfar less attention than rage zones of prestressed concrete members due to

in reinforced concretemembers. The availableex- transversetensilestresses set upby the concen-

perimentaldataarelimitedand,at the sametime, trated force^.*^^^* 423 Such cracks maylead to (or in

the number of variables is greater in prestressed certain cases are equivalent to) the failure of t h e

members. member. Transverse reinforcement (stirrups) must

be designed to restrict these cracks.

4.6.1 Crack prediction equations - One approach o Two types of cracks may develop: spalling cracks

crack

prediction,

which

relates it tothe non- which begin attheend face(loadedsurface)and

prestressedcase,hastwosteps.First the decom- propagateparalleltotheprestressing force,and

pression moment is calculated, a t which the stress a t bursting cracks which develop along the line of the

the tension face is zero. Then the member is treated force or forces, but away from the end face.

as a reinforced concrete member and the increase in For manyyearsstirrupsweredesignedtotake

stress in the steel is calculatedfortheadditional the entire calculated tensile force based on the anal-

loading. Theexpressionsgivenforcrackprediction ysis of the uncracked section. Classical and finite-ele-

in nonprestressedbeamsmaybeusedtoestimate mentanalysesshowsimilar stress distributions for

thecracksfor the load increaseabovethedecom- which thestirrupsaretobeprovided.However,

pressionmoment. A multiplicationfactor of about since

experimental

evidenceshows that

higher

1.5 is neededwhenstrands,ratherthandeformed . ' ~ indicated by these an-

stresses c a n r e s ~ l t . ~than

bars,are used nearesttothebeamsurface in the alyses, and the consequences of under-reinforcement

COPYRIGHT American Concrete Institute

Licensed by Information Handling Services

S-ar putea să vă placă și

- Jean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Document209 paginiJean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Mi na100% (1)

- Petroleum Regeneration and Processing Facility - Phase Ii: Employer'S RequirementsDocument72 paginiPetroleum Regeneration and Processing Facility - Phase Ii: Employer'S RequirementsChitradeep FalguniyaÎncă nu există evaluări

- Technical Specification For Site Preparation Earthworks - Roads & FencingDocument62 paginiTechnical Specification For Site Preparation Earthworks - Roads & FencingAhmed Samir Salim100% (1)

- Pages From ACI-224R-90 Control of Cracking in Concrete StructuresDocument1 paginăPages From ACI-224R-90 Control of Cracking in Concrete StructuresOmar MokhtarÎncă nu există evaluări

- 1635 The Papal Stakes - Eric FlintDocument1.813 pagini1635 The Papal Stakes - Eric Flintwon100% (2)

- Vendor Security ChecklistDocument11 paginiVendor Security ChecklistHarisÎncă nu există evaluări

- Financial Risk Management (Zain Ullah)Document12 paginiFinancial Risk Management (Zain Ullah)Afaq AhmadÎncă nu există evaluări

- Ws - Mea Millennium Ecosystem AssessmentDocument3 paginiWs - Mea Millennium Ecosystem Assessmentapi-305791685Încă nu există evaluări

- Worksheet 2 - TLC - Updated Summer 2021Document4 paginiWorksheet 2 - TLC - Updated Summer 2021Bria PopeÎncă nu există evaluări

- Nursing Care of A Family With An InfantDocument26 paginiNursing Care of A Family With An InfantJc GarciaÎncă nu există evaluări

- Attachment #1 Stilling Well Design Concept PDFDocument1 paginăAttachment #1 Stilling Well Design Concept PDFUrdian SyahÎncă nu există evaluări

- E-Engineering Services - Dubai C.DDocument62 paginiE-Engineering Services - Dubai C.DWaseem AsifÎncă nu există evaluări

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Document12 paginiInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)uki12345Încă nu există evaluări

- Hazards and Risk Assessment: Appendix BDocument60 paginiHazards and Risk Assessment: Appendix BGILBERTO YOSHIDAÎncă nu există evaluări

- MBAOGSem3 5Document226 paginiMBAOGSem3 5ShammimBegumÎncă nu există evaluări

- Define Your PetrochemicalProject Execution PlanDocument9 paginiDefine Your PetrochemicalProject Execution PlanLiu Yangtze100% (1)

- CCPP Operating BehaviorDocument32 paginiCCPP Operating BehaviorphamquanghieuÎncă nu există evaluări

- 10040-2563 Payment Certificate 05Document5 pagini10040-2563 Payment Certificate 05Deepak DevÎncă nu există evaluări

- Progress Payment FormDocument5 paginiProgress Payment FormriskhaÎncă nu există evaluări

- UAE - Requirements For Cladding - Peremeter Wall ContractorsDocument1 paginăUAE - Requirements For Cladding - Peremeter Wall Contractorsclarkie_bdÎncă nu există evaluări

- Combined Cycle ConversionDocument61 paginiCombined Cycle ConversionDomingo PintoÎncă nu există evaluări

- Engineered Packaging Center A Global ProviderDocument6 paginiEngineered Packaging Center A Global ProviderLTE002Încă nu există evaluări

- Piping Valve Flange DimensionsDocument252 paginiPiping Valve Flange DimensionschadÎncă nu există evaluări

- Demolition Environmental Management Plan PDFDocument73 paginiDemolition Environmental Management Plan PDFjamsheedÎncă nu există evaluări

- SNO-I-DS-005 - C Instrument Data Sheet For Radar Level TransmitterDocument95 paginiSNO-I-DS-005 - C Instrument Data Sheet For Radar Level Transmitterono_czeÎncă nu există evaluări

- 2011 Samsung Engineering SR Eng1Document44 pagini2011 Samsung Engineering SR Eng1Sangeet BhandariÎncă nu există evaluări

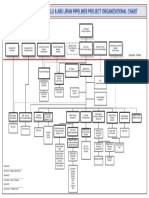

- Saudi KAD Contracting Company Contract No. 6600034300 SK-POC-01 Rev 4 - Project Organization Chart Dated: February 13, 2017Document1 paginăSaudi KAD Contracting Company Contract No. 6600034300 SK-POC-01 Rev 4 - Project Organization Chart Dated: February 13, 2017Saudi KadÎncă nu există evaluări

- D2 Dinesh Pant Biomass Technology and ImplementationDocument57 paginiD2 Dinesh Pant Biomass Technology and ImplementationBuddhi Raj SharmaÎncă nu există evaluări

- AMEC Preset at Ion On CCSDocument33 paginiAMEC Preset at Ion On CCSPete_EvelogenÎncă nu există evaluări

- GHBJDocument48 paginiGHBJईन्द्रनील रायÎncă nu există evaluări

- FEA Study On LPG BulletsDocument8 paginiFEA Study On LPG BulletsSpyros DimakisÎncă nu există evaluări

- Modular Design PDFDocument5 paginiModular Design PDFherysyam1980100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 paginiNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobÎncă nu există evaluări

- HRSG Tender8228 PDFDocument222 paginiHRSG Tender8228 PDFnefoussiÎncă nu există evaluări

- Maamoura and Baraka Development ProjectDocument12 paginiMaamoura and Baraka Development ProjectAHMED AMIRAÎncă nu există evaluări

- 10 Beach Well Intakes For Small Seawater Reverse Osmosis PlantsDocument239 pagini10 Beach Well Intakes For Small Seawater Reverse Osmosis PlantsAnonymous tqG0TJSAap100% (1)

- LMB2-E-FC-PIP-OCS-MS1-0015 Stress & Flexibility Analysis Report For Steam Separator LMB-ADocument30 paginiLMB2-E-FC-PIP-OCS-MS1-0015 Stress & Flexibility Analysis Report For Steam Separator LMB-AAzhar BudimanÎncă nu există evaluări

- Biomethanation of Biomass Feeds - Dr. H. N. Chanakya, IIScDocument57 paginiBiomethanation of Biomass Feeds - Dr. H. N. Chanakya, IIScDhruv SinghÎncă nu există evaluări

- Plot Plan PDFDocument1 paginăPlot Plan PDFBadredine FarahÎncă nu există evaluări

- MC20005-WHP-WI-P-0117 Chemical Injection Datasheet WI - Rev D1Document10 paginiMC20005-WHP-WI-P-0117 Chemical Injection Datasheet WI - Rev D1nguyenmainamÎncă nu există evaluări

- Saudi Arabian Oil Company: NotesDocument1 paginăSaudi Arabian Oil Company: NotesAbu Anas M.SalaheldinÎncă nu există evaluări

- V754749001XC (241 242) PDFDocument5 paginiV754749001XC (241 242) PDFErin JohnsonÎncă nu există evaluări

- SBC Energy Institute - Hydrogen-Based Energy Conversion - AbstractDocument17 paginiSBC Energy Institute - Hydrogen-Based Energy Conversion - AbstractJuan Jose SossaÎncă nu există evaluări

- Matindok Gas Development Project Master Deliverable List: Pt. Pertamina EpDocument10 paginiMatindok Gas Development Project Master Deliverable List: Pt. Pertamina Epsaiful anwar0% (1)

- PSEC Standard Rev 02 (DRAFT) 16-09-2020Document156 paginiPSEC Standard Rev 02 (DRAFT) 16-09-2020Irf NavaneethÎncă nu există evaluări

- Consultancy Services (Lump Sum Assignment)Document44 paginiConsultancy Services (Lump Sum Assignment)Natasha AdvaniÎncă nu există evaluări

- Biodiesel & Green BiodieselDocument38 paginiBiodiesel & Green BiodieselVATCHARI A/P AISEN MKK201042Încă nu există evaluări

- P116-MGS P3 Org ChartDocument1 paginăP116-MGS P3 Org ChartSaudi KadÎncă nu există evaluări

- ES Petroleum Energy GuideDocument122 paginiES Petroleum Energy GuideRizkina Ika AryanaÎncă nu există evaluări

- 007-Stand Post Type Fire HydrantDocument6 pagini007-Stand Post Type Fire HydrantshabahatÎncă nu există evaluări

- Annexure 2 - Requisition For Pipe 4inch & AboveDocument11 paginiAnnexure 2 - Requisition For Pipe 4inch & Abovefrankz89Încă nu există evaluări

- Engineering Services Related To Process Study: SRU RevampDocument16 paginiEngineering Services Related To Process Study: SRU RevampSiddiqui Muhammad AshfaqueÎncă nu există evaluări

- Itb Part I - Instruction To BiddersDocument16 paginiItb Part I - Instruction To BiddersilsaÎncă nu există evaluări

- Copper Extraction From The 60s. Into The 21st CenturyDocument25 paginiCopper Extraction From The 60s. Into The 21st CenturyPatricia FuenzalidaÎncă nu există evaluări

- Petronas Pressol: Premium Grade Air Compressor OilsDocument1 paginăPetronas Pressol: Premium Grade Air Compressor OilsMujeeb SiddiqueÎncă nu există evaluări

- TA-143-D00-G-TD005 - 0 - Employer's Requirements PDFDocument78 paginiTA-143-D00-G-TD005 - 0 - Employer's Requirements PDFshareyhouÎncă nu există evaluări

- A8ij 300 25 BD 0006 - 1Document34 paginiA8ij 300 25 BD 0006 - 1becpavanÎncă nu există evaluări

- Use Caution When Specifying "Seal Welds": Design FileDocument4 paginiUse Caution When Specifying "Seal Welds": Design FilePrabhat K KarnaÎncă nu există evaluări

- CoP SUC2013e (Concrete) 7.2Document1 paginăCoP SUC2013e (Concrete) 7.2P CÎncă nu există evaluări

- Standard Test Method For Vickers Indentation Hardness of Advanced CeramicsDocument8 paginiStandard Test Method For Vickers Indentation Hardness of Advanced CeramicsJosué Licona MármolÎncă nu există evaluări

- Offshore Fatigue Crack Repair by Grinding and Wet WeldingDocument11 paginiOffshore Fatigue Crack Repair by Grinding and Wet WeldingBipin KumarÎncă nu există evaluări

- Shear Tests of Extruded Hollow-Core Slabs: Roger J. BeckerDocument15 paginiShear Tests of Extruded Hollow-Core Slabs: Roger J. BeckerSheila StravateÎncă nu există evaluări

- Code Commentary: R21.5 - Flexural Members of Special Moment Frames 21.5 - Flexural Members of Special Moment FramesDocument1 paginăCode Commentary: R21.5 - Flexural Members of Special Moment Frames 21.5 - Flexural Members of Special Moment Framesminhthanha6Încă nu există evaluări

- Spe 526 MS PDFDocument5 paginiSpe 526 MS PDFAliÎncă nu există evaluări

- Ship in Operation Renewal CriteriaDocument8 paginiShip in Operation Renewal CriteriaThe MatrixÎncă nu există evaluări

- 1985-Review of Cracking of Partially Prestressed Concrete Member Canadian Journal of Civil EngineeringDocument8 pagini1985-Review of Cracking of Partially Prestressed Concrete Member Canadian Journal of Civil EngineeringChan Dara KoemÎncă nu există evaluări

- Addendum IRC 112Document8 paginiAddendum IRC 112suphal.ghoshÎncă nu există evaluări

- Guide Specification For Architectural Precast Concrete: This DocumentDocument37 paginiGuide Specification For Architectural Precast Concrete: This DocumentOmar Mokhtar100% (1)

- Ref. Calculations Output: The Capacity of The Slab Basic MeshDocument3 paginiRef. Calculations Output: The Capacity of The Slab Basic MeshOmar MokhtarÎncă nu există evaluări

- Gratings CatalogDocument33 paginiGratings CatalogLupul50Încă nu există evaluări

- Structural Precast ConcreteDocument39 paginiStructural Precast ConcreteMherlieÎncă nu există evaluări

- 13 2904Document15 pagini13 2904Omar MokhtarÎncă nu există evaluări

- A842 Pde 81 41 06701 PDFDocument1 paginăA842 Pde 81 41 06701 PDFOmar MokhtarÎncă nu există evaluări

- GratingDocument1 paginăGratingOmar MokhtarÎncă nu există evaluări

- Calculation Methods For Structural Fire PDFDocument12 paginiCalculation Methods For Structural Fire PDFOmar Mokhtar100% (1)

- Unistrut UK Mini 090214 WebDocument76 paginiUnistrut UK Mini 090214 WebOmar MokhtarÎncă nu există evaluări

- 13 2904Document15 pagini13 2904Omar MokhtarÎncă nu există evaluări

- BS5950 Load CasesDocument46 paginiBS5950 Load CasesthespecifierÎncă nu există evaluări

- Unistrut UK Mini 090214 WebDocument76 paginiUnistrut UK Mini 090214 WebOmar MokhtarÎncă nu există evaluări

- CFSD - Pub - S 220-11 - Standard For Nonstructural Mbrs Final PDFDocument33 paginiCFSD - Pub - S 220-11 - Standard For Nonstructural Mbrs Final PDFOmar MokhtarÎncă nu există evaluări

- 13 2904Document15 pagini13 2904Omar MokhtarÎncă nu există evaluări

- 13 2904 PDFDocument15 pagini13 2904 PDFOmar MokhtarÎncă nu există evaluări

- Radiation Hazards & Radiation ProtectionDocument62 paginiRadiation Hazards & Radiation ProtectionGurupada JanaÎncă nu există evaluări

- Matriculation Chemistry Amino Acids-Part-1Document24 paginiMatriculation Chemistry Amino Acids-Part-1iki292Încă nu există evaluări

- Pia AlgebraDocument12 paginiPia AlgebraCarvajal EdithÎncă nu există evaluări

- A Novel Procedure For Transient CFD Modeling of Basin Solar Stills, Coupling of Species and Energy EquationsDocument16 paginiA Novel Procedure For Transient CFD Modeling of Basin Solar Stills, Coupling of Species and Energy EquationsAverroesÎncă nu există evaluări

- MCQDocument5 paginiMCQJagdishVankar100% (1)

- (Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldDocument12 pagini(Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldHf CreationÎncă nu există evaluări

- Dna Recombinant TechnologyDocument20 paginiDna Recombinant TechnologyJuliet Ileto Villaruel - AlmonacidÎncă nu există evaluări

- Application of Different Fruit Peels FormulationsDocument3 paginiApplication of Different Fruit Peels FormulationsYvette GarciaÎncă nu există evaluări

- Future Proofing Cities Toolkit by Craig Applegath 2012-03-01sm PDFDocument20 paginiFuture Proofing Cities Toolkit by Craig Applegath 2012-03-01sm PDFJorge Fernández BaluarteÎncă nu există evaluări

- Les Essences D'amelie BrochureDocument8 paginiLes Essences D'amelie BrochuresayonarasÎncă nu există evaluări

- Tom Kenyon - ImmunityDocument9 paginiTom Kenyon - ImmunityDren Hoti100% (2)

- Assessment in The Affective DomainDocument19 paginiAssessment in The Affective DomainChano MorenoÎncă nu există evaluări

- (VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006Document4 pagini(VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006Carlos AntonioÎncă nu există evaluări

- Jan Precious Mille BDocument1 paginăJan Precious Mille BJebjeb C. BrañaÎncă nu există evaluări

- HMPE1 (Catering MGT.)Document17 paginiHMPE1 (Catering MGT.)Rysyl Mae MoquerioÎncă nu există evaluări

- A - S-2W & B - S-2W Series: 2W, Fixed Input, Isolated & Unregulated Dual/Single Output DC-DC ConverterDocument5 paginiA - S-2W & B - S-2W Series: 2W, Fixed Input, Isolated & Unregulated Dual/Single Output DC-DC ConverteranonbeatÎncă nu există evaluări

- LabExercise2 PoriferaDocument13 paginiLabExercise2 PoriferaMarvin I. Delos SantosÎncă nu există evaluări

- Channels of DistributionDocument101 paginiChannels of DistributionlakshmanlakhsÎncă nu există evaluări

- 8291 w13 Ms 22Document8 pagini8291 w13 Ms 22Caterina De LucaÎncă nu există evaluări

- Affidavit: IN WITNESS WHEREOF, I Have Hereunto Affixed MyDocument2 paginiAffidavit: IN WITNESS WHEREOF, I Have Hereunto Affixed Myceleste LorenzanaÎncă nu există evaluări

- Fan Adta-En-50hz-March-2018 - 20180315Document52 paginiFan Adta-En-50hz-March-2018 - 20180315Andi JatmikoÎncă nu există evaluări

- HooksDocument7 paginiHooksapi-233765416Încă nu există evaluări

- Neurology and Special Senses: High-Yield SystemsDocument72 paginiNeurology and Special Senses: High-Yield SystemsMahmoud Abu MayalehÎncă nu există evaluări