Documente Academic

Documente Profesional

Documente Cultură

Droplet Entrainment From A Shear-Driven Liquid Wall Film in Inclined Ducts: Experimental Study and Correlation Comparison

Încărcat de

D DTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Droplet Entrainment From A Shear-Driven Liquid Wall Film in Inclined Ducts: Experimental Study and Correlation Comparison

Încărcat de

D DDrepturi de autor:

Formate disponibile

Droplet Entrainment From a

Shear-Driven Liquid Wall Film

in Inclined Ducts: Experimental

J. Ebner

e-mail: Joachim.Ebner@its.uni-karlsruhe.de

Study and Correlation

M. Gerendas Comparison

O. Schafer The primary objective of the present study is to clarify the droplet disintegration mecha-

nism and the film properties of liquid oil films driven by shear stress, which is induced by

S. Wittig a co-current gas flow. This work focuses on the flow behavior within the starting length of

the complex two-phase flow and the effect of inclination on the entrainment rate. Many

Lehrstuhl und Institut fur Thermische investigations have been performed in the past to determine the droplet entrainment in the

Stromungsmaschinen, gas core for fully developed flow conditions with respect to their relevance in pipes of

Universitat Karlsruhe (T.H.), power plants and various chemical engineering systems. In more recent work the effect of

Kaiserstrasse 12, inclination has been studied in detail. Nevertheless, a lack of knowledge can be realized

76128 Karlsruhe, Germany for droplet entrainment within the starting length of this complex flow type. Thus, funda-

mental experiments have been carried out to provide a data base for droplet entrainment

of liquid disintegrated from an oil film within its starting length at several inclination

angles of the flow. The experimental results have been compared with correlations from

literature. Additionally, the wall film thickness has been measured to allow a fully coupled

modeling of entrainment and liquid film properties depending on global flow parameters.

Based on film Reynolds number, Weber number, a dimensionless film flow length, and a

modified Froude number, taking into account the angle of inclination, correlations have

been developed, where those from literature are not applicable.

DOI: 10.1115/1.1476926

Introduction thickness have been conducted for various air velocities, oil flow

rates, test section slopes, and film flow lengths. Thus, the major

A proper characterization of the air/oil flow in bearing compart-

parameters to describe the heat transfer and the propagation of the

ments and many other cavities of the so-called secondary air sys- liquid wall film are available for the air/oil flow under

tem of modern aeroengines requires reliable models for droplet investigation.

entrainment from shear-driven oil films. In particular the develop-

ment of CFD-based design tools computational fluid dynamics

to simulate this complex type of flow requires detailed informa- Experimental Setup and Operating Conditions

tion as shown by Glahn et al. 1. The pressure drop of the two- The measurements presented in this paper have been performed

phase flow as well as the heat transfer from the wall to the gas using an unheated rectangular duct (30 mm50 mm) with only

core is strongly affected by the distribution of oil as wall film and the bottom wall wetted and a length of up to l30H900 mm.

as droplets within the gas core 2,3. Thus, the thickness of the The air pressure is p3 bar absolute and the oil has a kinematic

liquid film becomes a vitally important parameter for a proper viscosity of f 5.2 mm2 /s DOW: DC 200 Fluid 5 cs. Thereby,

description of the overall flow field. the film flows only on a width of b40 mm to minimize effects

A profound modeling of the droplet generation mechanism at due to a three-dimensional air flow in the duct. It flows in a height

the gas-liquid interface, caused by the co-current air stream is adjustable groove such that it can be lowered a little bit more than

very demanding. For that reason, this type of flow is still under its film thickness with respect to the bottom wall of the duct. By

research. Extensive investigations have been performed in the past this method, the film remains in the restricted area and further-

for fully developed two-phase flow with respect to their signifi- more no point of discontinuity of the gas phase occurs at the start

cance, e.g., for air/water flow in pipe systems of nuclear power of the film.

plants or evaporators 4 8. In more recent work the effect of A schematic diagram of the test section is given in Fig. 1. The

inclination has been studied in detail 911. The present work air is supplied by a compressor at a constant pressure. A settling

focuses on developing film flow, because the typical pipe lengths chamber with a nozzle is placed upstream of the rectangular duct

within the secondary air system of aeroengines and many other to generate a constant velocity profile at the entrance. The oil film

applications are by far too short to expect fully developed flow is formed by a device consisting of a small slit, through which the

conditions. Thus, the film flow length has to be taken into account. liquid flows into the test section at a shallow angle with respect to

Measurements of the entrainment fraction and the oil film the main stream direction. Therewith, a point of discontinuity is

avoided at the start of the film. For the same reason, the film flows

Contributed by the International Gas Turbine Institute IGTI of THE AMERICAN on a plate, which can be adjusted in its height. Thus, the cross

SOCIETY OF MECHANICAL ENGINEERS for publication in the ASME JOURNAL OF section of the gas flow remains constant changing the film load-

ENGINEERING FOR GAS TURBINES AND POWER. Paper presented at the Interna-

tional Gas Turbine and Aeroengine Congress and Exhibition, New Orleans, LA, June

ing. Three different film flow lengths can be installed (l10

4 7, 2001; Paper 01-GT-115. Manuscript received by IGTI, December 2000, final 30H). The film draining is realized via a variable slit to adjust

revision, March 2001. Associate Editor: R. Natole. it according to the present flow conditions. This procedure ensures

874 Vol. 124, OCTOBER 2002 Copyright 2002 by ASME Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jetpez/26816/ on 06/19/2017 Terms of Use: http://www.asme.org/ab

Fig. 1 Schematic of rectangular test section

the complete removal of the wall film with minimal air content for Measurement Techniques

all test conditions. The performance of the device can be observed

In the following a brief description of the measurement systems

through a window.

Extensive measurements have been performed over a wide used to analyze the complex two-phase flow will be given. First of

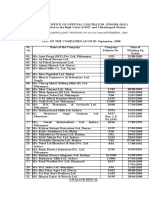

range of air and oil flow rates. Table 1 gives a detailed overview all, the mass flow rate measurement of the droplets in the gas core

of the operating conditions and the fluid properties. and the liquid wall film to determine the entrainment fraction with

a high level of accuracy is described. The liquid flows in a closed

circuit. It is supplied to the test rig by a pump out of a reservoir

and is continuously drained by an adjustable slot. The functional-

Table 1 Operating conditions of entrainment fraction and film ity of the device can be observed optically. Thus, the slot can be

thickness measurements adjusted according to the working conditions such that an addi-

tional drainage of droplets from the gas core can be avoided.

Between the outlet of the filter system downstream and the inlet of

the oil tank the liquid can be redirected by computer-controlled

valves onto a high-accuracy scale resolution: m0.1 g for a

well defined period of time. By this procedure the oil flow rate of

both, the droplets and the wall film can be determined with an

accuracy of m0.05 g/s.

The measurement of film thickness is very demanding. In the

past, several capacitive and inductive techniques have been ap-

plied e.g., Hewitt 12. A major restriction in the use of these

sensors are their large dimensions. In order to obtain a better

spatial resolution optical approaches have been suggested. An ad-

vanced system based on the absorption of infrared light is de-

scribed by Samenfink et al. 13. This technique is suitable for

water and alcohols due to the strong absorption within the fluid.

Unfortunately, nearly no absorption occurs for the oil under inves-

Fig. 2 Optical setup and the modified data acquisition of the nonintrusive

laser-based film thickness measurement technique

Journal of Engineering for Gas Turbines and Power OCTOBER 2002, Vol. 124 875

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jetpez/26816/ on 06/19/2017 Terms of Use: http://www.asme.org/ab

tigation. Due to the closed circuit of the liquid including several Table 2 Dimensionless groups used to characterize the two-

filter systems the use of dye to increase absorption is not appro- phase flow field

priate, because its concentration would not remain constant. Thus,

a laser-based system, a so-called laser focus displacement meter,

according to Takamasa et al. 14 is applied. The optical and elec-

tronic setup of the system is illustrated in Fig. 2.

The measurement principle is based on focusing the light cone

of a laser diode wavelength 670 nm onto the phase interface.

One of the focusing lenses oscillates due to electric attenuation,

shifting the spatial position of the focal point of the laser beam. At

the gas-liquid interface the beam is reflected to a great extent back

into the emitting optics. The reflected light is redirected through a

pinhole onto a photo detector by a half-transparent mirror. For one

cycle of oscillation the photo detector receives the maximum

amount of light in the time instant, when the focal point is directly

located on the phase interface as illustrated in Fig. 2. The relation

of the spatial position of the objective lens and the peak in light the film flow is not always dominated by shear stress at the phase

intensity allows one to determine the distance of the film surface interface. Thus, gravity F G has to be taken into consideration

from the sensor. Since the spacing of the sensor and the glass Spedding et al. 8.

window on which the film flows is known and remains constant, Based on this system, four dimensionless groups can be de-

the film thickness can be determined. The sample frequency of the duced for the purpose to describe the film disintegration mecha-

LFD sensor Keyence: model LT-8110 is f 1.5 kHz and the nism: the film Reynolds number Re f , the Weber number We , the

range of the sensor is 0h2.1 mm in air. A spatial resolution of Ohnesorge number On, and a modified Froude number Fr f . The

h0.2 m is specified by the manufacturer. This resolution can Froude number accounts for the inclination angle of the test sec-

be obtained using the sensor with standard options, i.e., averaging tion, i.e., the gravitational force acting in film flow direction. The

two or even more samples, thereby taking into account a decrease superficial velocity u *f of the film is used in its definition, since no

in the data rate. In order to reach the maximal temporal resolution information of the film velocity is available yet. The behavior of

to perform detailed measurements of the film structure, the analog the flow in the developing region is taken into consideration by a

output of the LFD system has to be used. For this purpose, an dimensionless film length depending on the hydraulic diameter

external trigger unit was built to generate a suitable pulse for the of the duct D h 4A/ P. An overview of the definitions of all

analogue-to-digital conversion board of the data acquisition com- groups to characterize the flow is given in Table 2.

puter. Due to this method the spatial resolution decreases to a Especially the studies of Ishii and co-workers are used quite

value of h2 m, which is very accurate for the measurement often for the prediction of the entrainment fraction. Those authors

of liquid films in the range of 0.1 mmh f 2 mm. summarized a large amount of droplet entrainment measurements

The refraction of the light at the glass/liquid interface as well as performed in the past. Based on these experimental data sets cor-

the reflection of the light at the wavy surface of the film has to be relations have been developed, to predict the droplet entrainment

taken into account. According to Eq. 1 the measurement range of fraction EF depending on the operating conditions. Those corre-

the sensor increases by a factor of c(n,n f )1.404 due to the lations mainly focus on fully developed flow. Nevertheless, an

refraction index of n f 1.390 of the oil under investigation. On approach to describe the starting of the entrainment has been sug-

the other hand the half-angle of the aperture is reduced from a gested. Thus, the experimental results of the present study are

value of /211.5 deg in air to f /28.25 deg in the liquid film. compared to the prediction according to Ishii and Mishima 19.

h f h

tan /2

tan f /2

hc n,n f with f /2arcsinn

nf

sin /2 .

The prediction of the entrainment fraction EF according to Eq.

2 is done assuming that all liquid above the stability limit of the

film is disintegrated. Two different entrainment mechanisms are

(1) introduced. The so-called wave undercut and shear off roll waves

Thus, the film structure can be detected as long as the surface depending on the flow conditions. This contemplation leads to a

angle of the film remains lower than f /28.0 deg. Previous in- equilibrium entrainment fraction EF cp. Eq. 3 of droplets in

vestigations on film flows at the Institute of Thermal Turboma- the gas core and liquid at the wall for a fully developed flow. It

chinery Samenfink et al. 13,15 revealed that the surface angles should be mentioned that the definition of both, the film Reynolds

of shear-driven liquid films are mostly smaller. Therefore, the number Re*f as well as the Weber number We* , differ from the

LFD technique can be applied in order to perform spatial resolved definitions used in this paper as shown in Eqs. 45. Thus,

measurements of the film structure 16,17. In the case that the these modified parameters are superscripted by an asterisk.

maximal angle is exceeded and no measurement can be performed The following correlations have been introduced by Ishii and

the sensor gives a specific signal. This allows to discriminate Mishima 19:

those cases from valid measurements. Since such strong reflec-

tions are rare the wave structure can be reconstructed easily by V dr V dr

interpolating the missing data points. EF (2)

V f V dr V tot

EF tanh 7.25107 We* 1.25 Re*f 0.25 (3)

Theoretical Background

In this section dimensionless groups and fundamental equations f u *f D h

are provided to characterize the overall flow field. They are all Re*f (4)

f

based on the forces acting in two-phase flows. In the following, a

brief description of the forces dominating the interaction of liquid

film and co-flowing air stream is given. Inertia F I , friction F F ,

and surface tension F S can be identified as vitally important pa-

We*

g u 2g D h

g

1/3

with u *f

V f

A bH

V f

and f g .

(5)

rameters to characterize the droplet generation from shear-driven

liquid films Kataoka et al. 18. Due to the variation of the in- In order to describe the entrainment in the developing region an

clination of the flow and the large span of air velocities conducted, exponential function has been suggested. A dimensionless length

876 Vol. 124, OCTOBER 2002 Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jetpez/26816/ on 06/19/2017 Terms of Use: http://www.asme.org/ab

Fig. 3 Comparison of measured entrainment fraction with cor- Fig. 4 Comparison of measured entrainment fraction with cor-

relation according to Ishii and Mishima 19 film length l relation in entrance region Ishii and Mishima 19

30H

depending on film Reynolds number Re*f and a gas phase velocity separation of the parameters controlling the droplet disintegration

mechanism has been performed to derive singular relationships

u g* corrected for the droplet content are used. An overview of the for each. Thus, Figs. 6 8 give an overview of measured data sets

entrance correlation are given in Eq. 5. separating the parameters film loading Reynolds number, shear

EF 1e 10

5 2

EF stress Weber number, film length, and inclination. The angle

in Fig. 8 is defined positive for upwards directed flow according to

with

1

Re*f

and u g*

ug a force balance, which can be derived for a fluid element in the

film.

(6)

Dh u g* 4 g g 2/3

2g

The value of the constant in the relation has been derived based on

experimental data sets of Cousins et al. 20. A comparison of the

measured entrainment fraction of the present study and the half-

empirical approach is presented in the following.

Experimental Results

Entrainment Fraction. A comparison of measured and cal-

culated entrainment fraction is plotted in Fig. 3 in terms of the

dimensionless numbers described above. The diagram shows mea-

surements of entrainment fraction for horizontal flow. It displays

some shortcomings in the accuracy of the prediction for the

present application, especially taking into account the double-

logarithmic scaling. The calculated values according to the en-

trance correlation cp. Eq. 6 do not match the measured data.

On the other hand the comparison to fully developed flow condi-

tions appears reasonable. Thus, it can be assumed that the devia- Fig. 5 Entrainment function in entrance region Ishii and

tions occur due to an incorrect characterization of the entrance Mishima 19

effect.

In order to find out the origin of the discrepancies the entrance

effect is analyzed in detail. Therefore, the experimental results are

compared to data according to the exponential entrance function

cp. Eq. 6. A comparison of measured entrainment fractions and

data obtained by the correlation according to Ishii is given in Fig.

4. It can be seen clearly, that the run of the predicted curve does

not match the measured data.

Figure 5 presents a plot of the exponential function defined by

Eq. 6. The effect of the Reynolds number in the dimensionless

length is not described properly for the air/oil flow under inves-

tigation as evident in the diagram. The shape of the curve also

differs from the trend given by the measured entrainment frac-

tions. Thus, an adjustment of the model constants is not appropri-

ate in order to improve the predicting quality significantly.

Therefore, a new correlation to characterize the entrainment of

the developing air/oil flow has to be deduced. In order to obtain a

model with a high accuracy, a correlation based on the dimension- Fig. 6 Effect of Reynolds and Weber number on entrainment

less groups defined in Table 2 is presented in the following. A fraction film length l 30H ; inclination 0 deg

Journal of Engineering for Gas Turbines and Power OCTOBER 2002, Vol. 124 877

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jetpez/26816/ on 06/19/2017 Terms of Use: http://www.asme.org/ab

Fig. 7 Effect of film flow length on entrainment fraction Fig. 9 Comparison of measured entrainment fraction and cor-

relation film length l 20H ; inclination 0 deg

The correlation derived for the entrainment fraction by the

least-squares method reads as follows: Table 2, the experimental results are presented depending on film

loading, air flow rate, and film flow length. Figure 11 shows that

Re2f 2.25

the film thickness decreases with higher air velocities Weber

EF1.042107 We1.2 Re0.4

f 12.06110

0.8 4

. (7)

WeFr f number due to the rising shear stress at the gas/liquid interface.

The increase of shear accelerates the film and additionally in-

It has to be pointed out that the correlation has been derived from creases the droplet generation cp. Fig. 6. On the other hand no

all data sets performed within this study see Table 1. The calcu- significant effect of the film length can be observed at first sight.

lated values of the entrainment fraction according to Eq. 7 are This behavior can be explained with respect to the various inter-

also plotted in the diagrams. In order to give a measure for the locking effects. On the one hand the film loading decreases due to

overall prediction accuracy a mean relative error of EF/EF film disintegration. On the other hand the loss of momentum of

20% of the measured data and the entrainment fraction corre- the gas boundary layer leads to a decrease of the shear force. By

lation can be determined. Since no variation of the Ohnesorge this, the negligible influence of the length scale becomes evident.

number has been applied it should be mentioned that the applica-

bility of the formula is restricted to two-phase flows under com-

parable operating conditions.

The overall accuracy in predicting the entrainment fraction with

the newly developed correlation is also confirmed by the results

presented in Figs. 9 and 10. The tests have been performed over a

wide range of flow conditions which are typical for the secondary

air system of modern aero engines. Even though minor deviations

occur in some cases the correlation leads to a significant increase

of accuracy in predicting the entrainment of the air/oil flow under

investigation.

Film Thickness. Film thickness measurements have been

conducted for all operating conditions see Table 1. As mentioned

above, time-resolved film thickness measurements can be per-

formed with the LFD technique. Since modeling of liquid films is

usually done by an analysis based on mean values only time-

averaged film thickness are presented here. In order to deduce a

correlation depending on the dimensionless groups according to

Fig. 10 Comparison of measured entrainment fraction and

correlation film length l 30H ; inclination 20 deg

Fig. 11 Comparison of measured film thickness and correla-

Fig. 8 Effect of inclination angle on entrainment fraction tion for different film flow lengths

878 Vol. 124, OCTOBER 2002 Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jetpez/26816/ on 06/19/2017 Terms of Use: http://www.asme.org/ab

correlation has to be verified for other liquids if the properties

differ significantly from the oil used in the present study.

A global description of the air/oil flow requires not only de-

tailed information of the droplet phase. The heat transfer as well

as the pressure drop is also affected by the properties of the liquid

wall film. Thus, based on experimental data a correlation for the

mean film thickness is presented.

Acknowledgment

This work was supported by grant from the United Technology

Research Center UTRC, East Hartford U.S. which is gratefully

acknowledged. Special thanks are due to A. Glahn for the valuable

discussions on the subject and the excellent collaboration during

the investigation.

Nomenclature

Fig. 12 Comparison of measured film thickness and correla-

tion for different inclination angles AbH cross-section area m

b width of filmm

c conversion factor

D diameter m

The impact of the inclination on the film thickness is displayed f sample frequency 1/s

in Fig. 12. The effect is rather small as long as the slope of the EF entrainment fraction

duct is in the range of 20 deg 20 deg. Nevertheless, the F force N

inclination is taken into account in the correlation presented in the Fr Froude number

following. The film thickness decreases for a positive as well as h thickness, distance m

for a negative inclination angle. An explanation can be derived by H height of duct m

analyzing the gravity effect on the film propagation and the drop- l length m

let generation. In upwards directed flow the force of gravity de- LFD laser focus displacement meter

celerates the film. On the one hand, the film thickness rises up due m mass flow rate kg/s

to the conservation of mass. On the other hand, a thicker film n refraction index

exhibits a higher roughness, thereby leading to a higher interfacial On Ohnesorge number

shear stress. This results in an increase of film disintegration ac- P perimeter of duct m

cording to Fig. 8. Since both effects are of same magnitude, the p pressure Pa

dependence of the film thickness on the inclination angle becomes Re Reynolds number

clear. A similar contemplation can be conducted for downwards u velocity m/s

directed flow, respectively. u *f V f /A superficial velocity m/s

With respect to the findings presented above, the following cor- T temperature K

relation of the mean film thickness can be obtained:

V volume flow rate m3/s

h f 1.714We0.36 Re0.457

f

11.0961014

Re4f

Fr2f

0.375

mm . (8)

We

Greek Symbols

Weber number

The fraction term in the formula, taking into account the incli- aperture angle, angle of inclination deg

nation angle, confirms the considerations discussed above. The wavelength m

effect of the inclination is controlled both by the stability of the , dimensionless film length

film via the Reynolds number and by the gravity force via the kinematic viscosity mm2/s

Froude number. The predicted film thickness according to Eq. 8 surface tension N/m

are also presented in Figs. 11 and 12. The calculated curves match Indices

the measured values very well. A relative error lower than

dr droplet

h f /h f 10% of measured and predicted film thickness can be

f film

stated for all operating conditions.

F friction

g gas

Summary and Conclusions G gravity

h hydraulic

This paper supplies detailed information on the complex two- l inertia

phase flow. Extensive experimental work has been performed un- S surface tension

der operating conditions typical for the secondary air system of tot total

modern aero engines. Based on this experimental data and ad- fully developed

dressing the underlying physical relationships in terms of nondi- * modified parameter

mensional parameters, correlations for the entrained liquid and the

film thickness for air/oil flows have been developed with special References

emphasis to the starting length of the flow.

1 Glahn, A., Busam, S., Blair, M. F., Allard, K. L., and Wittig, S., 2000, Drop-

The study reveals that entrainment correlations from literature let Generation by Disintegration of Oil Films at the Rim of a Rotating Disk,

are not suitable for the present air/oil flow due to a lack in pre- 45th ASME Paper 2000-GT-279.

diction accuracy. In order to develop detailed models for CFD- 2 Glahn, A., Busam, S., and Wittig, S., 1997, Local and Mean Heat Transfer

based design tools a relationship based on dimensionless groups is Coefficients along the Internal Housing Walls of Aero Engine Bearing Cham-

bers, ASME Paper 97-GT-261.

provided. The accuracy of the correlation is excellent for all test 3 Busam, S., Glahn, A., and Wittig, S., 1999, Internal Bearing Chamber Wall

conditions performed. Due to its nondimensional form it can be Heat Transfer as a Function of Operating Conditions and Chamber Geometry,

scaled easily to similar applications. Nevertheless, the entrainment ASME J. Eng. Gas Turbines Power, 122, pp. 314 320.

Journal of Engineering for Gas Turbines and Power OCTOBER 2002, Vol. 124 879

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jetpez/26816/ on 06/19/2017 Terms of Use: http://www.asme.org/ab

4 Hewitt, G. F., and Taylor, N. S., 1970, Annular Two-Phase Flow, Pergamon Transport Mechanisms of Shear-Driven Liquid Films, Proceedings of the

Press, Oxford, UK. Eighth International Symposium on Applications of Laser Techniques to Fluid

5 van Rossum, J. J., 1959, Experimental Investigation of Horizontal Film Mechanics, Lisbon, Portugal, July 8 11.

Flow, Chem. Eng. Sci., 11, pp. 3552. 14 Takamasa, T., Tamura, S., and Kobayashi, K., 1998, Interfacial Waves on a

6 Ishii, M., and Grolmes, M. A., 1975, Inception Criteria for Droplet Entrain- Film Flowing Down Plate Wall in an Entry Region Measured With Laser

ment in Two-Phase Concurrent Film Flow, AIChE J., 212, pp. 308 318. Focus Displacement Meters, 3rd International Conference on Multiphase

7 Woodmansee, D. E., and Hanratty, T. J., 1969, Mechanism for the Removal Flow, Lyon, France, June 8 12.

of Droplets from a Liquid Surface by a Parallel Air Flow, Chem. Eng. Sci., 15 Samenfink, W., 1997, Fundamental Study of the Interaction of Droplets and

24, pp. 299307. Shear-Driven Liquid Films, Ph.D. thesis, Institute of Thermal Turbomachin-

8 Spedding, P. L., Watterson, J. K., Raghuanthan, S. R., and Ferguson, M. E. G.,

ery, University Karlsruhe, Germany.

1998, Two-Phase Co-Current Flow in Inclined Pipe, Int. J. Heat Mass

16 Fujii, T., Asano, H., Takenaka, N., and Yamada, H., 1998, The Liquid Film

Transf., 41, pp. 4205 4228.

Structure in a Two-Phase Gas-Liquid Annular Flow, 3rd International Con-

9 Lee, C. K., and Mjani, A. M., 1995, Enhancement of Droplet Entrainment

From Liquid Film Flowing Over Horizontal Ribbed Surfaces, Proceedings ference on Multiphase Flow, Lyon, France, June 8 12.

1st Int. Symp. on Two-Phase Modelling and Experimentation, G.-P. Celata and 17 Busam, S., Ebner, J., and Wittig, S., 2001, An Experimental Study of Liquid

R. K. Shah, eds, Edizione ETS, Pisa, 1, pp. 143148. Film Thickness in Annular Air/Oil Flow in a Vertical Pipe Using a Laser Focus

10 Azzopardi, B. J., 1997, Drops in Annular Two-Phase Flow, Int. J. Multi- Displacement Meter, 46th ASME Paper 2001-GT-116.

phase Flow, 23, pp. 153. 18 Kataoka, I., Ishii, M., and Mishima, K., 1983, Generation and Size Distribu-

11 Azzopardi, B. J., Zaidi, S. H., and Jepson, D. M., 1997, Entrained Fraction in tion of Droplet in Annular Two-Phase Flow, Trans. ASME, 105, pp. 230238.

Inclined Annular Gas/Liquid Flow, Proceedings of the ASME Fluid Eng Di- 19 Ishii, M., and Mishima, K., 1989, Droplet Entrainment Correlation in Annu-

vision, ASME, New York, 244, pp. 6976. lar Two-Phase Flow, Int. J. Heat Mass Transf., 3210, pp. 18351845.

12 Hewitt, G. F., 1978, Measurement of Two Phase Flow Parameters, Academic 20 Cousins, L. B., Denton, W. H., and Hewitt, G. F., 1965, Liquid Mass Transfer

Press, London. in Annular Two-Phase Flow, Symposium on Two-Phase Flow, Exeter, U.K., 1

13 Samenfink, W., Elsaer, A., Wittig, S., and Dullenkopf, K., 1996, Internal Paper C4.

880 Vol. 124, OCTOBER 2002 Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jetpez/26816/ on 06/19/2017 Terms of Use: http://www.asme.org/ab

S-ar putea să vă placă și

- Schramm 2002Document7 paginiSchramm 2002ahmeterenbacakÎncă nu există evaluări

- Dimensional Analysis of Droplet Size and Ligament Length During High-Speed Rotary Bell AtomizationDocument7 paginiDimensional Analysis of Droplet Size and Ligament Length During High-Speed Rotary Bell AtomizationEmilio HipolaÎncă nu există evaluări

- Numerical Model of An Air-Jet Loom Main Nozzle For Drag Forces EvaluationDocument6 paginiNumerical Model of An Air-Jet Loom Main Nozzle For Drag Forces EvaluationAnuj ShandilyaÎncă nu există evaluări

- 2003 HMTJ Azzi JubranDocument9 pagini2003 HMTJ Azzi JubranNeymar DasilvaÎncă nu există evaluări

- Computers & Fluids: Lanchang Xing, Hoi Yeung, Yanfeng Geng, Yi Cao, Joseph ShenDocument12 paginiComputers & Fluids: Lanchang Xing, Hoi Yeung, Yanfeng Geng, Yi Cao, Joseph Shenbedhief ahmedÎncă nu există evaluări

- Modeling of Transient Cuttings TransportDocument11 paginiModeling of Transient Cuttings Transportmohamadi42Încă nu există evaluări

- Air Density Effect On The Atomization of Liquid Jets in CrossflowDocument25 paginiAir Density Effect On The Atomization of Liquid Jets in CrossflowJosephat KalanziÎncă nu există evaluări

- SPE 94901 A Methodology To Evaluate The Gas Migration in Cement SlurriesDocument9 paginiSPE 94901 A Methodology To Evaluate The Gas Migration in Cement SlurriespaimanÎncă nu există evaluări

- Effects of A Parametric Variation of The Rim Seal Geometry On The Interaction Between Hub Leakage and Mainstream Flows in High Pressure TurbinesDocument11 paginiEffects of A Parametric Variation of The Rim Seal Geometry On The Interaction Between Hub Leakage and Mainstream Flows in High Pressure TurbinesIvan MagriniÎncă nu există evaluări

- A Study of Fan-Distortion Interaction Within The NASA Rotor 67 Transonic StageDocument12 paginiA Study of Fan-Distortion Interaction Within The NASA Rotor 67 Transonic StageNavdeep SinghÎncă nu există evaluări

- Primary Breakup of A Non-Newtonian Liquid Using A High-Speed Rotary Bell Atomizer For Spray-Painting ProcessesDocument16 paginiPrimary Breakup of A Non-Newtonian Liquid Using A High-Speed Rotary Bell Atomizer For Spray-Painting ProcessesmachadrsÎncă nu există evaluări

- Calculo de Potencia para Evaporadores de Pelicula Agitada Mckenna 1995Document15 paginiCalculo de Potencia para Evaporadores de Pelicula Agitada Mckenna 1995Sebastian PinzonÎncă nu există evaluări

- 13.IJAEST Vol No 5 Issue No 1 A Parametric Study On Ambient Pressure Effects On Super Circulation Over A Simple Ramp 094 104Document11 pagini13.IJAEST Vol No 5 Issue No 1 A Parametric Study On Ambient Pressure Effects On Super Circulation Over A Simple Ramp 094 104iserpÎncă nu există evaluări

- Fluid Dynamics Research TopicsDocument6 paginiFluid Dynamics Research TopicsJohn Rhey Almojallas BenedictoÎncă nu există evaluări

- FEDSM-ICNMM2010-30775: Gas Liquid Vane Separators in High Pressure ApplicationsDocument5 paginiFEDSM-ICNMM2010-30775: Gas Liquid Vane Separators in High Pressure ApplicationsAmine BennouriÎncă nu există evaluări

- Cavitao2016cincia Experimental de Fluidos e TrmicosDocument11 paginiCavitao2016cincia Experimental de Fluidos e TrmicosPaulinho JuniorÎncă nu există evaluări

- 2017 Ijts Cavitating-Flow PDFDocument12 pagini2017 Ijts Cavitating-Flow PDFAdam AnugrahesaÎncă nu există evaluări

- Fluids: A Computational Simulation Study of Fluid Mechanics of Low-Speed Wind Tunnel ContractionsDocument12 paginiFluids: A Computational Simulation Study of Fluid Mechanics of Low-Speed Wind Tunnel ContractionsJAIR DIEGO VIDAURRE QUISPEÎncă nu există evaluări

- Numerical Simulation of The Dynamic Effects Due To Impeller-Volute Interaction in A Centrifugal PumpDocument8 paginiNumerical Simulation of The Dynamic Effects Due To Impeller-Volute Interaction in A Centrifugal PumpMichaelÎncă nu există evaluări

- An Experimental Study of Heat Transfer and Film Cooling On Low Aspect Ratio Turbine NozzlesDocument9 paginiAn Experimental Study of Heat Transfer and Film Cooling On Low Aspect Ratio Turbine NozzlesDivyansh RathiÎncă nu există evaluări

- Spe 90038 MSDocument12 paginiSpe 90038 MSMejbahul SarkerÎncă nu există evaluări

- SPE/DOE 11638 A Method For Evaluation of Formation Damage Due To Fracturing FluidsDocument10 paginiSPE/DOE 11638 A Method For Evaluation of Formation Damage Due To Fracturing FluidsYeferson TrujilloÎncă nu există evaluări

- Effect of Release Coefficient on Water Flow SystemsDocument12 paginiEffect of Release Coefficient on Water Flow Systemschristian.canaleÎncă nu există evaluări

- Hagedorn and Brown 1965Document10 paginiHagedorn and Brown 1965LIDIA PUGLIESSAÎncă nu există evaluări

- Pressure Loss CharacteristicsDocument6 paginiPressure Loss CharacteristicsMarilucia CopqueÎncă nu există evaluări

- Numerical Simulation of Multiphase Flow Inside Hydrocyclone Based On CFDDocument6 paginiNumerical Simulation of Multiphase Flow Inside Hydrocyclone Based On CFD89prasantaÎncă nu există evaluări

- 1 s2.0 S0142727X99000405 MainDocument7 pagini1 s2.0 S0142727X99000405 MainMarcos Noboru ArimaÎncă nu există evaluări

- SPE 77942 Smart Well Solutions For Thin Oil Rims: Inflow Switching and The Smart Stinger CompletionDocument10 paginiSPE 77942 Smart Well Solutions For Thin Oil Rims: Inflow Switching and The Smart Stinger CompletionJuan Manuel ReinaÎncă nu există evaluări

- Zhang 2003Document10 paginiZhang 2003Luiz EliasÎncă nu există evaluări

- A Case Study of Gas-Condensate Reservoir Performance Under Bottom Water Drive MechanismDocument19 paginiA Case Study of Gas-Condensate Reservoir Performance Under Bottom Water Drive MechanismhaimuoiÎncă nu există evaluări

- Processes: Numerical Simulation of Performance of An Air-Water Separator With Corrugated Plates For Marine Diesel EnginesDocument11 paginiProcesses: Numerical Simulation of Performance of An Air-Water Separator With Corrugated Plates For Marine Diesel EnginesLa Ode AdhanÎncă nu există evaluări

- AA AO DP: Liquid Film Characteristics Inside A Pressure-Swirl AtomizerDocument1 paginăAA AO DP: Liquid Film Characteristics Inside A Pressure-Swirl AtomizerKumbamÎncă nu există evaluări

- Bayazit Et Al. (2014)Document8 paginiBayazit Et Al. (2014)Marilucia CopqueÎncă nu există evaluări

- Simulating Slug Flow Regime in Air-Water Pipes Using CFDDocument13 paginiSimulating Slug Flow Regime in Air-Water Pipes Using CFDDr Mohammed AzharÎncă nu există evaluări

- Effect of Bent Inlet Pipe On The Ow Instability Behavior of Centrifugal CompressorsDocument11 paginiEffect of Bent Inlet Pipe On The Ow Instability Behavior of Centrifugal CompressorsAnbarasan RaviÎncă nu există evaluări

- Numerical Analysis of Suppression of Laminar Bubble at Low Reynolds Number Using Different ProtrusionsDocument8 paginiNumerical Analysis of Suppression of Laminar Bubble at Low Reynolds Number Using Different ProtrusionsKarthikÎncă nu există evaluări

- Hydrodynamics of Laminar Flow Through Dimpled PipeDocument5 paginiHydrodynamics of Laminar Flow Through Dimpled PipeAndre RochaÎncă nu există evaluări

- On The Use of Air-Bubble Screens As Oil BarriersDocument8 paginiOn The Use of Air-Bubble Screens As Oil BarriersmynameisjohnÎncă nu există evaluări

- AIAA-1999-3402 Riblets On Airfoils and Wings-A ReviewDocument20 paginiAIAA-1999-3402 Riblets On Airfoils and Wings-A Reviewsseale_79157309Încă nu există evaluări

- Walter2003 UnlockedDocument13 paginiWalter2003 UnlockedLorena CamposÎncă nu există evaluări

- Owusu Et Al-2019-Steel Research InternationalDocument14 paginiOwusu Et Al-2019-Steel Research InternationalMau MarÎncă nu există evaluări

- Investigation of Steady Compressible Flow Through Thick OrificesDocument13 paginiInvestigation of Steady Compressible Flow Through Thick OrificesmsreerajvarmaÎncă nu există evaluări

- Arc RM 2523Document21 paginiArc RM 2523naimukhan7Încă nu există evaluări

- BaheriIslami-Jubran2012 Article TheEffectOfTurbulenceIntensityDocument10 paginiBaheriIslami-Jubran2012 Article TheEffectOfTurbulenceIntensityLilou MGKÎncă nu există evaluări

- Chemical Engineering Science: E. Pagan, W.C. Williams, S. Kam, P.J. WaltrichDocument13 paginiChemical Engineering Science: E. Pagan, W.C. Williams, S. Kam, P.J. WaltrichJohn DoeÎncă nu există evaluări

- The Design of Wind Tunnels and Wind Tunnel PropellersDocument26 paginiThe Design of Wind Tunnels and Wind Tunnel PropellersfrgonzalezÎncă nu există evaluări

- Experimental Measurements of Bubble Convection Models in Two-PhaseDocument9 paginiExperimental Measurements of Bubble Convection Models in Two-PhaseStephany CamacaroÎncă nu există evaluări

- 2008 - Lister Et Al. - Shape and Stability of Axisymmetric Levitated Viscous Drops - Journal of Fluid MechanicsDocument19 pagini2008 - Lister Et Al. - Shape and Stability of Axisymmetric Levitated Viscous Drops - Journal of Fluid MechanicsClaudio BiaginiÎncă nu există evaluări

- Pipe Flow With Radial Inflow Experimentaland Modeling WorkDocument7 paginiPipe Flow With Radial Inflow Experimentaland Modeling WorkRodrigo LimaÎncă nu există evaluări

- Surface & Coatings Technology: Jianzhong Lin, Lijuan Qian, Hongbin Xiong, Tat Leung ChanDocument8 paginiSurface & Coatings Technology: Jianzhong Lin, Lijuan Qian, Hongbin Xiong, Tat Leung ChanEmilio HipolaÎncă nu există evaluări

- Comparison of Vertical, Slanted, and Horizontal Wells Productivity in Layered Gas-Condensate ReservoirDocument6 paginiComparison of Vertical, Slanted, and Horizontal Wells Productivity in Layered Gas-Condensate ReservoirJesus Ponce GÎncă nu există evaluări

- Effect_of_bent_inlet_pipe_on_the_flow_instability_Document11 paginiEffect_of_bent_inlet_pipe_on_the_flow_instability_MaximilianoÎncă nu există evaluări

- Air Lift PumpDocument23 paginiAir Lift PumpFrancisco OppsÎncă nu există evaluări

- Improve Air Diffuser Efficiency with Plume Spacing and FlowrateDocument14 paginiImprove Air Diffuser Efficiency with Plume Spacing and FlowrateStephany CamacaroÎncă nu există evaluări

- Effect of Temperature On The In-Plane Permeability in The Gas Diffusion Layer of A PEM Fuel CellDocument10 paginiEffect of Temperature On The In-Plane Permeability in The Gas Diffusion Layer of A PEM Fuel CellminliÎncă nu există evaluări

- Performance of A Two-Phase Gas/liquid Flow Model in VerticalDocument17 paginiPerformance of A Two-Phase Gas/liquid Flow Model in VerticalDarryan DhanpatÎncă nu există evaluări

- Watted Wall TowerDocument13 paginiWatted Wall TowerRajdeep MallickÎncă nu există evaluări

- Rufer Et Kezios - 1966 - Analysis of Two-Phase, One-Component Stratified FLDocument8 paginiRufer Et Kezios - 1966 - Analysis of Two-Phase, One-Component Stratified FLMartinÎncă nu există evaluări

- 1Document14 pagini1Umair MunirÎncă nu există evaluări

- CantarellDocument4 paginiCantarellD DÎncă nu există evaluări

- Leak Detection Methods For PipelinesDocument6 paginiLeak Detection Methods For PipelinesD DÎncă nu există evaluări

- Fugaz y TomasDocument11 paginiFugaz y TomasD DÎncă nu există evaluări

- AGA 7 Measurement of Gas by Turbine MetersDocument11 paginiAGA 7 Measurement of Gas by Turbine MetersD DÎncă nu există evaluări

- Folleto InstrumetDocument16 paginiFolleto InstrumetD DÎncă nu există evaluări

- Hamiltonian Discretization of Boundary Control Systems PDFDocument14 paginiHamiltonian Discretization of Boundary Control Systems PDFD DÎncă nu există evaluări

- AGA 7 Measurement of Gas by Turbine MetersDocument11 paginiAGA 7 Measurement of Gas by Turbine MetersD DÎncă nu există evaluări

- Ahmed Tarek - Hydrocarbon Phase BehaviorDocument216 paginiAhmed Tarek - Hydrocarbon Phase BehaviorD DÎncă nu există evaluări

- ASGMT2004 Overviewof AGA TechWhitepaperDocument9 paginiASGMT2004 Overviewof AGA TechWhitepaperAbdelrhman MamdouhÎncă nu există evaluări

- Dictionary For The Petroleum Industry.Document242 paginiDictionary For The Petroleum Industry.Clarissa100% (5)

- Diccionario Ingles-Espanol PDFDocument295 paginiDiccionario Ingles-Espanol PDFJose Daniel ChamorroÎncă nu există evaluări

- Diccionario Ingles-Espanol PDFDocument295 paginiDiccionario Ingles-Espanol PDFJose Daniel ChamorroÎncă nu există evaluări

- Which Fair-Market Value Method Should You Use?Document12 paginiWhich Fair-Market Value Method Should You Use?German RodriguezÎncă nu există evaluări

- Petroleum Resources Management System 2007Document49 paginiPetroleum Resources Management System 2007Mujtaba SaleemÎncă nu există evaluări

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Document4 paginiStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20Încă nu există evaluări

- Restructuring Egypt's Railways - Augst 05 PDFDocument28 paginiRestructuring Egypt's Railways - Augst 05 PDFMahmoud Abo-hashemÎncă nu există evaluări

- Product CycleDocument2 paginiProduct CycleoldinaÎncă nu există evaluări

- Living Nonliving DeadDocument11 paginiLiving Nonliving DeadArun AcharyaÎncă nu există evaluări

- Control SystemsDocument269 paginiControl SystemsAntonis SiderisÎncă nu există evaluări

- Symmetry (Planes Of)Document37 paginiSymmetry (Planes Of)carolinethami13Încă nu există evaluări

- Miami Police File The O'Nell Case - Clemen Gina D. BDocument30 paginiMiami Police File The O'Nell Case - Clemen Gina D. Barda15biceÎncă nu există evaluări

- Material Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008Document6 paginiMaterial Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008suckrindjink100% (1)

- Amul ReportDocument48 paginiAmul ReportUjwal JaiswalÎncă nu există evaluări

- Piping MaterialDocument45 paginiPiping MaterialLcm TnlÎncă nu există evaluări

- Postnatal Assessment: Name Date: Age: D.O.A: Sex: Hospital: Marital Status: IP .NoDocument11 paginiPostnatal Assessment: Name Date: Age: D.O.A: Sex: Hospital: Marital Status: IP .NoRadha SriÎncă nu există evaluări

- Driving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorsDocument10 paginiDriving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorskellendadÎncă nu există evaluări

- Rheology of Polymer BlendsDocument10 paginiRheology of Polymer Blendsalireza198Încă nu există evaluări

- Chicago Electric Inverter Plasma Cutter - 35A Model 45949Document12 paginiChicago Electric Inverter Plasma Cutter - 35A Model 45949trollforgeÎncă nu există evaluări

- Environment ManagerDocument234 paginiEnvironment ManagerAbhishek kumarÎncă nu există evaluări

- PharmacologyAnesthesiology RevalidaDocument166 paginiPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- Honors Biology Unit 2 - Energy Study GuideDocument2 paginiHonors Biology Unit 2 - Energy Study GuideMark RandolphÎncă nu există evaluări

- Antiquity: Middle AgesDocument6 paginiAntiquity: Middle AgesPABLO DIAZÎncă nu există evaluări

- NetsimDocument18 paginiNetsimArpitha HsÎncă nu există evaluări

- Ecole Polytechnique Federale de LausanneDocument44 paginiEcole Polytechnique Federale de LausanneSyed Yahya HussainÎncă nu există evaluări

- Bandung Colonial City Revisited Diversity in Housing NeighborhoodDocument6 paginiBandung Colonial City Revisited Diversity in Housing NeighborhoodJimmy IllustratorÎncă nu există evaluări

- Digital Communication Quantization OverviewDocument5 paginiDigital Communication Quantization OverviewNiharika KorukondaÎncă nu există evaluări

- Waves and Thermodynamics, PDFDocument464 paginiWaves and Thermodynamics, PDFamitÎncă nu există evaluări

- The Product Development and Commercialization ProcDocument2 paginiThe Product Development and Commercialization ProcAlexandra LicaÎncă nu există evaluări

- Understanding Oscilloscope BasicsDocument29 paginiUnderstanding Oscilloscope BasicsRidima AhmedÎncă nu există evaluări

- Application D2 WS2023Document11 paginiApplication D2 WS2023María Camila AlvaradoÎncă nu există evaluări

- Newcomers Guide To The Canadian Job MarketDocument47 paginiNewcomers Guide To The Canadian Job MarketSS NairÎncă nu există evaluări

- 5 Important Methods Used For Studying Comparative EducationDocument35 pagini5 Important Methods Used For Studying Comparative EducationPatrick Joseph63% (8)

- Emerson Park Master Plan 2015 DraftDocument93 paginiEmerson Park Master Plan 2015 DraftRyan DeffenbaughÎncă nu există evaluări

- Test Bank For Core Concepts of Accounting Information Systems 14th by SimkinDocument36 paginiTest Bank For Core Concepts of Accounting Information Systems 14th by Simkinpufffalcated25x9ld100% (46)