Documente Academic

Documente Profesional

Documente Cultură

Tangki

Încărcat de

Reza FadhilaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tangki

Încărcat de

Reza FadhilaDrepturi de autor:

Formate disponibile

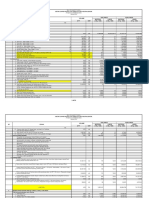

PROJECT : STORAGE TANK DEVELOPMENT PHASE - 1, TOTAL CAP. 100.

000 MT

SUPPORTING FACILITIES & INFRASTRUCTURE

SCOPE PEKERJAAN : PACKAGE 2 - STORAGE TANK, TANK FARM & BUND WALL

LOCATION : KAWASAN PELABUHAN PELINDO 1, KUALA TANJUNG, BATUBARA, SUMUT

OWNER : PT. PRIMA TANGKI INDONESIA

CONSULTANT : PT. LYDUMA INTERMAS CONSULTANT - INDONESIA

YEAR : JANUARY 2017

Bill of Quantity

1 2 3 4 5 6 7 43 45

NO. ITEM OF WORKS UNIT TOTAL AMOUNT (Rp.)

A. PREPARATION WORKS

1 Mobilization of all personnel,plants,crane and any other required ls 1.00

equipment and materials to carry out the work and to maintain

them till job completion.

2 Provide two Insurance as follows : ls 1.00

- Conctractor's all Risks Insurance Policy

- Workman's compensation

3 Provide and maintain for the use of the contractor of works andlsclient & consultant

1.00 kind of safety helmets

and pairs of safety boots, safety glass, welding gloves, masker, full body harness of the assorted sizes as required,

scaffolding standard, safety net, fire blanket, fire extinguisher

4 To provide Medical facilities (First Aid) throughout the construction

ls period. 1.00

5 Establish and maintain during the entire period of stay at site ls 1.00

Contractors' all temporary facilities such us office,workshop,

fabrication area,store,sanitary facilities,etc.

6 Project Management, Progress Report, Work Programme ls 1.00

Prepare, maintain, modify as and when required and submit to the

Engineer for approval a detailed time schedule and progress chart as specified

7 Provide Permits that use along Construction Works ls 1.00

8 Provide Project security ls 1.00

9 To Provide Power Supply, Lighting and others, during construction ls 1.00

10 To Provide Water Supply during the construction ls 1.00

11 House Keeping during Construction and On completion of the works, ls the Contactor

1.00 shall clean up

entire site, remove and cart away all building rubbish and leave everything clean and tidy

to the Engineer's satisfaction and Authority's approval

12 Shop Drawing and as built drawing ls 1.00

13 Material Preparation ls 1.00

14 Bouwplank ls 1.00

B. TANK WORKS

B.1. EARTH WORKS

1 Excavation Works m3 6,969.92 348,495,757

2 Back Filling Works m3 6,969.92 209,097,454

3 Compacted Sand m3 305.61 9,168,201

4 Supply and Install 2" PVC Pipe Class D unit 88.00

B.2. CONCRETE WORKS

1 Cutting 450 mm Spun Pile ttk 1,404.00

2 Pile Head Works

- Concrete K-300 (include Test Cube) m3 178.64 157,200,772

- Fabrication and Install Rebar kg 22,562.73 406,129,220

- Plate 2 mm for Support m2 3,505.76 1,064,172,192

3 Lean Concrete K-100 m3 305.61 213,924,700

4 Pile Head Foundation Works

- Concrete K-300 (include Test Cube) m3 3,985.09 3,506,881,226

Prepared by : PT. Lyduma Intermas Consultant - Indonesia

- Fabrication and Install Rebar kg 434,862.18 7,827,519,224

- Form Work m2 849.89 201,229,497

5 Ring Foundation Works

- Concrete K-300 (include Test Cube) m3 225.17 198,148,613

- Fabrication and Install Rebar kg 24,744.36 445,398,482

- Form Work m2 1,340.32 317,348,528

6 Ring Sump Works

- Concrete K-300 (include Test Cube) m3 7.10 6,247,999

- Fabrication and Install Rebar kg 692.50 12,465,038

- Form Work m2 63.08 14,936,205

7 Pad of Sand Works m3 2,680.87

8 Supply and Spread Asphalt as Protective/Waterproof Bottom Tank

m3 254.32

with Specified Asphalt MACADAM

9 Filler Board. 10mm - 200 mm height m' 1,224.98

B.3. GROUNDING LOOP

1 BC Grounding Cable 50 Sq mm, include Sparing Steel Pipe 1/2"unitfor Tank 8000MT

4.00 203,200

2 BC Grounding Cable 50 Sq mm, include Sparing Steel Pipe 1/2"unitfor Tank 5000MT

8.00 406,400

3 BC Grounding Cable 50 Sq mm, include Sparing Steel Pipe 1/2"unitfor Tank 3000MT

8.00 406,400

4 BC Grounding Cable 50 Sq mm, include Sparing Steel Pipe 1/2"unitfor Tank 2000MT

2.00 101,600

5 Box Control 400 x 400 x 400 mm, with Cover, Campacted Sand unit

and lean Concrete

6.00 and Bus Bar as specified2,574,000

and drawing

6 Earth Clamp, Stick Cooper dia 1" & 2" c/w Clamp and bolt, Max.

unit2 Ohm 6.00

7 BC Grounding Cable 120 sq mm unit 6.00

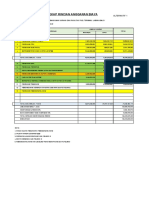

B.4. STEEL WORKS FOR TANK

Fabricating, Assembling and Erecting Welded Cone Roof Tanks, with API 650 Standard for Condstruction and Designing

Carbon and Stainless Steel Standard SNI including all necessary test

1 Bottom dan Annular Plate (ASTM A 36) Harga @rp. 18000/Kg

- MS plate 20 mm x 6' x 20' kg 170,128.51 3,062,313,111

- MS plate 18 mm x 6' x 20' kg 42,007.04 756,126,694

- MS plate 16 mm x 6' x 20' kg 56,009.38 1,008,168,926

- MS plate 14 mm x 6' x 20' kg 215,636.13 3,881,450,364

- MS plate 12 mm x 6' x 20' kg 92,415.48 1,663,478,727

- MS plate 10 mm x 6' x 20' kg 7,001.17 126,021,116

- MS plate 8 mm x 6' x 20' kg 15,402.58 277,246,455

- MS Plate 12 mm, Sumpit Bottom kg 3,711.06 66,799,132

- SS 304 L Plate 10 mm x 5' x 20' sheet - 23,200,000

- SS 304 L Plate 8 mm x 5' x 20' sheet - 18,200,000

- SS 304 L Plate 12 mm, Sumpit Bottom

( 5 x 20) sheet - 28,000,000

2 Shell Tanks

- MS Plate 20 mm x 6 x 20' kg 154,025.81 2,772,464,545

- MS Plate 18 mm x 6 x 20' kg 138,623.23 2,495,218,091

- MS Plate 16 mm x 6' x 20' kg 324,854.43 5,847,379,768

- MS Plate 14 mm x 6' x 20' kg 352,859.12 6,351,464,231

- MS Plate 12 mm x 6' x 20' kg 495,683.06 8,922,294,992

- MS Plate 10 mm x 6' x 20' kg 374,562.76 6,742,129,690

- MS Plate 8 mm x 6' x 20' kg 408,868.51 7,359,633,157

- MS Plate 6 mm x 6' x 20' kg 292,999.09 5,273,983,692

- MS Plate 5 mm x 6' x 20' kg 30,630.13 551,342,381

Prepared by : PT. Lyduma Intermas Consultant - Indonesia

- SS 304 L Plate 10 mm x 5' x 20' sheet - 23,200,000

- SS 304 L Plate 8 mm x 5' x 20' sheet - 18,200,000

- SS 304 L Plate 6 mm x 5' x 20' sheet - 15,000,000

- SS 304 L Plate 5 mm x 5' x 20' sheet - 13,000,000

- Angle Ring siku 100x100x10 kg 18,835.37 339,036,701

- Channel Stiff Ring UNP 200x80x6x7.5 kg 7,260.18 130,683,232

- Channel Stiff Ring UNP 150x75x6.5 kg 17,790.90 320,236,161

- Channel Stiff Wind Girder MS Plate 8 mm thk kg 20,714.78 372,865,993

- 10mm thk MS Channel Stiff Plate, Ring kg 734.76 13,225,680

- Angle Ring SS L 100x100x10 kg -

- Channel Stiff Ring SS UNP 150x80x6x7.5 kg -

'- 10mm thk SS Channel Stiff Plate, Ring kg -

3 Roof Plate & Frame

- MS plate 5 mm x 6' x 20' kg 201,283.73 3,623,107,076

- SS 304 L Plate 5 mm x 5' x 20' sheet - 13,000,000

UNP 250.90.9 kg 51,484.80 926,726,400

UNP 150.75.6,5 kg 11,946.67 215,040,000

UNP 100.50.5 kg 60,557.28 1,090,031,040

UNP 75.40.5 kg 21,019.20 378,345,600

L 50.50.5 kg 2,939.33 52,907,904

MS Plate 16 mm 4x8 kg 4,616.63 83,099,398

MS Plate 14 mm 4x8 kg 12,231.51 220,167,166

MS Plate 12 mm 4x8 kg 1,154.16 20,774,850

MS Plate 10 mm 4x8 kg 1,786.80 32,162,380

MS Plate 8 mm 4x8 kg 16,302.68 293,448,223

SS UNP 250.90.9 kg -

SS UNP 100.50.5 kg -

SS L 50.50.5 kg -

SS 304 L Plate 16 mm 4x8 sheet - 14,000,000

SS 304 L Plate 14 mm 4x8 sheet -

SS 304 L Plate 10 mm 4x8 sheet - 8,000,000

SS 304 L Plate 8 mm 4x8 sheet - 6,000,000

4 Handrail, Cat Walk & Vertical Gutter

Pipa Hitam Medium Dia. 1,5" m' 2,086.13 87,617,567

Pipa Hitam Medium Dia. 1" m' 2,250.27 63,007,422

Pipa Galvanized Dia. 1,5", Vertical Gutter m' 2,471.57 113,692,128

Elbow LR 90, Galvanized, Vertical Gutter Pcs 264.00

Plat Support Pipe for Gutter Vertical @3000 c/c on both sides

Pcs 808.00

Expanded Metal, Cat Walk m2 762.32

Plate 18 mm, Plate Support kg 2,650.79 47,714,184

L 50.50.5, Plate Support kg 3,288.60 59,194,800

Plate 6 mm for Kick Plate kg 13,148.97 236,681,469

5 Level Indicator, Incl. Numbering of Level

Sling, 65x12mm thk Pulley, Pulley Cover, S.S Float, etc Set

and all accessories

22.00 complete

6 Drain Pipe

CS Pipe Seamless dia. 3" sch. 40, Class 150 m' 208.00 125,000

Elbow LR 90 dia. 3" CS. Sch. 40 Pcs 22.00

UNP 100.50.5 Kg 1,045.20 18,813,600

Plate 10 mm Kg 535.76 9,643,725

U-Bolt w/ 2 nuts dia. 8mm Unit 130.00

Compensating Plate Welded Pcs 22.00

Stub End c/w Slip On Flange Class 150, dia. 3" Pcs 22.00

SS Pipe Seamless dia. 3" sch. 10 m' -

SS Elbow LR 90 dia. 3" SS 304 L Sch. 10 Pcs -

SS UNP 100.50.5 Kg -

SS 304 L Plate 10 mm Kg -

U-Bolt w/ 2 nuts dia. 8mm Unit -

Compensating Plate Welded Pcs -

Prepared by : PT. Lyduma Intermas Consultant - Indonesia

Stub End c/w Slip On Flange Class 150, dia. 3" Pcs -

7 Discharge Pipe

CS Pipe Seamless dia. 8" sch. 40 Class 150 m' 208.00 500,000

Elbow dia. 8" LR 90 CS. Sch. 40 Pcs 22.00

UNP 100.50.5 Kg 2,961.40 53,305,200

Plate 10 mm Kg 306.15 5,510,700

U-Bolt w/ 2 nuts dia. 12mm Unit 130.00

Compensating Plate Welded Pcs 22.00

Stub End c/w Slip On Flange Class 150, dia. 8" Pcs 22.00

SS 304 L Pipe Seamless dia. 8" sch. 10 m' -

Elbow dia. 8" LR 90 SS. 304 Sch. 10 Pcs -

SS UNP 100.50.5 Kg -

SS 304 L Plate 10 mm Kg -

U-Bolt w/ 2 nuts dia. 12mm Unit -

Compensating Plate Welded Pcs -

Stub End c/w Slip On Flange Class 150, dia. 8" Pcs -

8 Heating Coil

CS Pipe Seamless dia. 2" sch. 40, Class 150 m' 6,872.00 68,000

Pipe Shoe 1/2-dia. 2" Sch. 40, Class 150 Unit 4,016.00

L 65.65.6, Support Kg 30,938.85 556,899,300

U-Bolt w/ 2 nuts dia. 8mm Set 4,016.00

Compensating Plate Welded Pcs 184.00

Stub End c/w Slip On Flange Class 150, dia. 2" Pcs 184.00

SS Pipe Seamless dia. 2" sch. 10 m' -

Pipe Shoe 1/2-dia. 2" SS Sch. 10 Unit -

SS L 65.65.6, Support Kg -

U-Bolt w/ 2 nuts dia. 8mm Set -

Compensating Plate Welded Pcs -

Stub End c/w Slip On Flange Class 150, dia. 2" Pcs -

9 Sounding Pipe

Standard Cap Screw, Incl. 9 MS Rod Unit 22.00

CS Pipe Seamless dia. 4" sch. 40, Class 150 m' 638.00 178,000

L 75.75.6 Kg 3,309.97 59,579,388

U-Bolt & nuts dia. 8mm unit 66.00

Plate 8 mm kg 221.06 3,979,008

Plate 6 mm kg 302.16 5,438,807

Standard Cap Screw, Incl. 9 MS Rod Unit -

SS Pipe Seamless dia. 4" sch. 10 m' -

SS L 75.75.6 Kg -

U-Bolt & nuts dia. 8mm unit -

SS Plate 8 mm kg -

SS Plate 6 mm kg -

10 Product Inlet Pipe

CS Pipe Seamless dia. 8" sch. 40, Class 150, Perforated Hole

m' dia. 20

1,232.00

mm

L 75.75.6 kg 6,347.88 114,261,840

Plate 18 mm kg 420.73 7,573,086

Plate 10 mm kg 1,934.24 34,816,320

Plate 8 mm Kg 442.11 7,958,016

U-Bolt & nuts dia. 16mm Set 616.00

Stub End c/w Slip On Flange Class 150, dia. 8" Pcs 44.00

SS Pipe Seamless dia. 8" sch. 10, Perforated Hole dia. 20m'

mm -

SS L 75.75.6 kg -

SS Plate 18 mm kg -

SS Plate 10 mm kg -

SS Plate 8 mm Kg -

U-Bolt & nuts dia. 16mm Set -

Stub End c/w Slip On Flange Class 150, dia. 8" Pcs -

11 Top Cover and Vent

Prepared by : PT. Lyduma Intermas Consultant - Indonesia

CS. Wire Mesh Cover w/ 6mm SQ. Hole Welded to 6mm Unit

thk MS Flange

22.00

CS Pipe Seamless dia. 12" sch. 40, Class 150 m' 66.00

Elbow dia. 12" LR 90 CS. Sch. 40 Pcs 44.00

SS. Wire Mesh Cover w/ 6mm SQ. Hole Welded to 6mm Unit

thk MS Flange -

SS Pipe Seamless dia. 12" sch. 10 m' -

Elbow dia. 12" LR 90 SS. Sch. 10 Pcs -

12 Mixer Agitator

Mixer Agitator LSS-400, ex. Lightnin Mixer Unit 36.00

Mixer Agitator LSS-220, ex. Lightnin Mixer Unit 2.00

13 Temperature Indicator

Temperature Gauge ex. Wika Unit 22.00

12 Spiral Staircase

Chequered Plate 4.5 mm Thk Kg 27,912.50 502,425,000

UNP 100.50.5 Kg 1,500.80 27,014,400

L 75.75.6 Kg 769.44 13,849,920

L 60.60.6 Kg 1,244.43 22,399,776

Plate 6 mm Kg 1,002.29 18,041,184

Round Bar 19mm Kg 3,547.55 63,855,911

Pipa Hitam Medium Dia. 1,5" m' 400.00 16,800,000

13 Nozzle Orientation

Roof Area (Complete with compensating plate welded and all accessories)

- Radar Nozzle 4", ANSI 150 B16.5 Set -

- Level Indicator Nozzle (Manual) 2", ANSI 150 B16.5 Set 22.00

- Nitrogen Inlet 2", ANSI 150 B16.5 Set -

- Line Sensing for BV 1", ANSI 150 B16.5 Set -

- Pressure Indicator (PI) 1/2", ANSI 150 B16.5 Set -

- Breather Valve / Ventilation 12", ANSI 150 B16.5 Set -

- Product Inlet 10", ANSI 150 B16.5 Set -

- Product Inlet 8", ANSI 150 B16.5 Set 44.00

- Manhole dia. 600 mm, Complete with all Accessories Set 22.00

- Transfer Line / Circulation Line / Return Line 6", ANSI 150

Set B16.5 -

- Steam/Condensate Nozzle 2" ANSI 150 B16.5 Set -

- Transfer Line / Circulation Line / Return Line 10", ANSISet

150 B16.5 -

- Spare 6", ANSI 150 B16.5 Set 22.00

Shell Area (Complete with compensating plate welded and all accessories)

- Temp. Indicator, ANSI 150 B16.5 Set 22.00

- Manhole dia. 800 mm, ANSI 150 B16.5, complete with All Set

Accessories22.00

- Agitator 8", ANSI 150 B16.5 Set 64.00

- Temp. Element w/ Condom, ANSI 150 B16.5 Set 22.00

- Steam/Condensate Nozzle 2" ANSI 150 B16.5 Set 184.00

14 Test Works

a. Vaccum Test for joints of bottom plate 100 % unit 22.00

b. Hydro Test for Plat Shell (Pengadaan Pompa, Genset, air dan

unit Chemical22.00

ditanggung oleh Kontraktor)

c. Dye Penetran for Nozzle, Ventilasi dan Manhole 100 % unit 22.00

d. Dye Penetran for T-Joint Shell 10% unit 22.00

e. Vaccum Test for Roof plate 10 % unit 22.00

f. Callibration Test By Metrologi (Pemerintah) unit 22.00

15 Testing for Heating Coil

a. Dye Penetran for Heating coil 100 % unit 22.00

b. Hydro Test unit 22.00

B.5. PAINTING WORKS

Sandblasting and Painting resistant to temperature 200 C

1 - External Coating, Sandblasting to SA 2 (SSPC SP 10 m2 45,707.55

2 - Sandblasting to SA 2 (SSPC SP 10 near white metal m2 79,947.13

Prepared by : PT. Lyduma Intermas Consultant - Indonesia

C. STAIR SND CONNECTING BRIDGE WORKS

C.1. CONNECTING BRIDGE

1 UNP 200.80.7,5 kg 2,190.70 39,432,528

2 L 50.50.5 kg 416.18 7,491,204

3 Plate 12 mm kg 2,314.49 41,660,892

4 Plate 8 mm kg 344.21 6,195,722

5 Bolt & Nuts M18x50 mm set 84.00

6 Expanded Metal m2 44.40 1,054,000

7 Pipa Hitam Medium Dia. 1,5" m' 132.00 5,544,000

8 Pipa Hitam Medium Dia. 1" m' 353.00 9,884,000

9 Plate 6 mm, for Kick Plate kg 627.37 11,292,696

C.2. BUNDWALL/PIPE RACK BRIDGE WORKS

1 Pondasi Concrete K-250 m3 0.09 72,576

2 Plate 10 mm kg 271.30 4,883,328

3 Anchor bar dia. 10 mm kg 35.51 639,187

4 UNP 150.75.6,5 kg 3,886.40 69,955,200

5 Chequered Plate 4.5 mm Thk kg 2,247.34 40,452,030

6 Pipa Hitam Medium Dia. 1,5" m' 337.00 14,154,000

7 Pipa Hitam Medium Dia. 1" m' 437.00 12,236,000

C.3. PAINTING WORKS

Cleaning w/ wirebrush and Painting resistant to temperature 200 C

1 - External Coating, Wirebrush, Painting Total thickness m2 595.36

D. TANK FARM AREA

D.1. PIPE RACK FOUNDATION WORKS

1 Excavation Works m3 168.73 8,436,525

2 Back filling Works m3 168.73 5,061,915

3 Compacted Sand m3 13.05 391,526

4 Lean Concrete m3 13.05 567,713

5 Pile Cap

Concrete K-300 m3 32.99 29,028,780

Fabrication and Install Rebar kg 2,854.72 51,384,969

Form Work m2 87.21 20,648,712

6 Beam 300 x 500 mm

Concrete K-300 m3 68.46 60,244,800

Fabrication and Install Rebar kg 7,945.11 143,011,904

Form Work m2 456.40 108,061,828

7 Pedestal

Concrete K-300 m3 1.87 1,647,360

Fabrication and Install Rebar kg 1,130.78 20,354,080

Form Work m2 31.20 7,387,224

Anchor Bolt unit 208.00 4,160,000

D.2. SLAB TANK FARM & BUNDWALL

1 Stripping, Cutting, Filling and Compacting Tank farm area to reached

m2 design

2,584.00

Level

2 Compacted Sand m3 129.20 3,876,000

3 Lean Concrete m3 129.20 5,620,200

4 Tank Farm Slab, 100 mm thk

Concrete K-300 m3 258.40 227,392,000

Wiremesh M6-150 m2 2,713.20

5 Kolom 150 x 150 mm

Concrete K-300 m3 2.97 2,613,600

Fabrication and Install Rebar kg 3,421.78 61,592,079

Form Work m2 79.20 18,752,184

6 Beam 150x150 mm

Prepared by : PT. Lyduma Intermas Consultant - Indonesia

Concrete K-300 m3 8.89 7,821,000

Fabrication and Install Rebar kg 1,458.64 26,255,538

Form Work m2 118.50 28,057,245

7 110 mm thick Cement and Sand Brickwall Works in Cement Mortar

m2 (1:4) and

217.20

cement Reinder for Surface finished

8 15 mm Thick Plaster for Brickwall in Cement Mortar (1:4) m2 434.40

9 Finishing Topping Bundwall m' 395.00

10 Construct 20 cm width of Drainage inside Tank Farm area m' 1,873.40

D.3. FAT TRAP TANK FARM AREA

1 Excavation Works m3 27.95 1,397,550

2 Back filling Works m3 27.95 838,530

3 Compacted Sand m3 0.77 22,995

4 Lean Concrete m3 0.77 33,343

5 Construct Slab & Wall Fat Trap

Concrete K-300 m3 10.21 8,983,040

Fabrication and Install Rebar kg 2,017.92 36,322,612

Form Work m2 107.36 25,419,627

Water Stop m' 23.20 1,600,800

6 Supply, Fabrication and Install Folding Gate, c/w all accessories

unit 1.00

83,724,104,375

Prepared by : PT. Lyduma Intermas Consultant - Indonesia

S-ar putea să vă placă și

- King Conan - Crown of Iron (P. 14)Document167 paginiKing Conan - Crown of Iron (P. 14)Rafa Eyesman100% (2)

- 3.2 Example of Cost EstimateDocument35 pagini3.2 Example of Cost EstimateMuhammad Abdurrokhim AÎncă nu există evaluări

- Data Sheet FOR HSD STORAGE TANK 5000 KL (01-T-002) : Client ReviewDocument6 paginiData Sheet FOR HSD STORAGE TANK 5000 KL (01-T-002) : Client ReviewWardhana Zolli100% (1)

- Boq of 100kl Storage TankDocument6 paginiBoq of 100kl Storage TankMauliÎncă nu există evaluări

- Ak Barnett Hart ThesisDocument8 paginiAk Barnett Hart ThesisWhereCanIFindSomeoneToWriteMyCollegePaperUK100% (2)

- BOQ Tanjung Uban MekanikalDocument21 paginiBOQ Tanjung Uban MekanikalRemmo S ArdiansyahÎncă nu există evaluări

- Teknikal Proposal Tangki Sambu T-32 LengkapDocument17 paginiTeknikal Proposal Tangki Sambu T-32 Lengkapveva santiÎncă nu există evaluări

- Jms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0013Document11 paginiJms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0013amir hakimÎncă nu există evaluări

- Brosur Reckat 2017 PDFDocument12 paginiBrosur Reckat 2017 PDFRidwanda HimawanÎncă nu există evaluări

- BOOK IV-small SizeDocument488 paginiBOOK IV-small SizeBahtiar AfandiÎncă nu există evaluări

- BARQI BROTHERS Company Profile - 2022Document25 paginiBARQI BROTHERS Company Profile - 2022Muljono MolÎncă nu există evaluări

- Pipe Stands BrochureDocument11 paginiPipe Stands BrochureSonhaji11Încă nu există evaluări

- 130 - S-HZL Storage tankBOQ - 20.12.19Document4 pagini130 - S-HZL Storage tankBOQ - 20.12.19ananthu.uÎncă nu există evaluări

- Truck HaulDocument36 paginiTruck HaulantogsÎncă nu există evaluări

- Tracon IndustriDocument20 paginiTracon IndustriSlamet Purwadi S.T100% (1)

- 26071-100-VSC-MAH0-40023 - Method Statement For Installation Fire Fighting System (Equipment Safety and Fire Suppression System) - 001Document27 pagini26071-100-VSC-MAH0-40023 - Method Statement For Installation Fire Fighting System (Equipment Safety and Fire Suppression System) - 001ogyrisky100% (1)

- Quotation For Industrial Pipling MaterialsDocument6 paginiQuotation For Industrial Pipling MaterialsKingsley MÎncă nu există evaluări

- GFS Tank Quotation C20210514Document4 paginiGFS Tank Quotation C20210514Francisco ManriquezÎncă nu există evaluări

- Mangalore Refinery and Petrochemicals Limited Mangalore Karnataka 2632018104557516Document76 paginiMangalore Refinery and Petrochemicals Limited Mangalore Karnataka 2632018104557516Veena NageshÎncă nu există evaluări

- PT Rapid Infrastruktur Indonesia Compro General 20220210Document52 paginiPT Rapid Infrastruktur Indonesia Compro General 20220210Andhika Permana SutantoÎncă nu există evaluări

- EPC For ASAB Phase-II Stage-2-LatestDocument2 paginiEPC For ASAB Phase-II Stage-2-LatestGokulprabhuÎncă nu există evaluări

- PT Poeser IndonesiaDocument13 paginiPT Poeser Indonesiaqdod_waffiÎncă nu există evaluări

- COOEC Fluor Workflow PDFDocument1 paginăCOOEC Fluor Workflow PDFwahyu santosoÎncă nu există evaluări

- Thummapala Pipe Line EstimateDocument39 paginiThummapala Pipe Line EstimateRavi IvarÎncă nu există evaluări

- TechnipDocument36 paginiTechnipShashwat Nigam0% (1)

- DOW Ultrafiltration SFD 2660Document2 paginiDOW Ultrafiltration SFD 2660juliancardonaÎncă nu există evaluări

- D2 Dinesh Pant Biomass Technology and ImplementationDocument57 paginiD2 Dinesh Pant Biomass Technology and ImplementationBuddhi Raj SharmaÎncă nu există evaluări

- Failure Analysis Report: SIMS InformationDocument13 paginiFailure Analysis Report: SIMS InformationHasby PotterÎncă nu există evaluări

- MJC Reverse Jet Cartridge FilterDocument6 paginiMJC Reverse Jet Cartridge FilterJuan Karlos Alberca AlfaroÎncă nu există evaluări

- BOQ Fire SystemDocument90 paginiBOQ Fire SystemDSAKÎncă nu există evaluări

- QMS System References PDFDocument2 paginiQMS System References PDFAbdhel X-Meta100% (1)

- Tender Document-Biodiesel Supply Manning KIOSK Field Refueling 2019 01Document34 paginiTender Document-Biodiesel Supply Manning KIOSK Field Refueling 2019 01Boy Frahmana SiradÎncă nu există evaluări

- PO Monitoring Sheet Ver 1Document141 paginiPO Monitoring Sheet Ver 1api-3700469100% (3)

- Columns Internals - PRICE-SHEET (U-114, 127, 214) - New FormatDocument12 paginiColumns Internals - PRICE-SHEET (U-114, 127, 214) - New FormatErin JohnsonÎncă nu există evaluări

- Monorail & RGVs PDFDocument19 paginiMonorail & RGVs PDFVern Jasmine AlferezÎncă nu există evaluări

- Calculation Precom&Comm GGCP - PoDocument20 paginiCalculation Precom&Comm GGCP - PoHANIF AKBARÎncă nu există evaluări

- Load Chart-Wire RopeDocument2 paginiLoad Chart-Wire RopeRajmohan Babu100% (1)

- Interview EnglishDocument4 paginiInterview EnglishThomas ChristianÎncă nu există evaluări

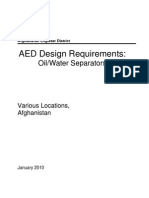

- Oil Water Sep Design ArmyDocument9 paginiOil Water Sep Design ArmyJose A. Marti100% (1)

- Sub-Vendor List: Doc. No.: 26071-203-V1A-MPPM-00006 Job No.: 26071Document3 paginiSub-Vendor List: Doc. No.: 26071-203-V1A-MPPM-00006 Job No.: 26071Arif HakimÎncă nu există evaluări

- Pump TemplateDocument2 paginiPump TemplateamitkrayÎncă nu există evaluări

- Daftar Harga Fire Hydrant AppronDocument2 paginiDaftar Harga Fire Hydrant AppronWeri IsvebriantiÎncă nu există evaluări

- JIEYUAN Project Execution Plan of Chemical Cleaning and Oil Flushing For Cooling Medium SystemDocument12 paginiJIEYUAN Project Execution Plan of Chemical Cleaning and Oil Flushing For Cooling Medium SystemTao QuÎncă nu există evaluări

- ZEECO Boiler Burner Data SheetDocument11 paginiZEECO Boiler Burner Data SheetValiÎncă nu există evaluări

- Iffco ReportDocument22 paginiIffco ReportNEHAÎncă nu există evaluări

- Term of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4Document7 paginiTerm of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4tiantaufik100% (1)

- T2364 BOQ - Closed Sampling SystemDocument1 paginăT2364 BOQ - Closed Sampling SystemvuongÎncă nu există evaluări

- Torri FactionDocument16 paginiTorri FactionhedayatinluvÎncă nu există evaluări

- Procedure Welding Consumible ProcedureDocument11 paginiProcedure Welding Consumible ProcedureCilobong Kubuk KubingÎncă nu există evaluări

- Proposal 4034 ADocument20 paginiProposal 4034 AAbdul AlimÎncă nu există evaluări

- Scope of Inspection For Ammonia TankDocument3 paginiScope of Inspection For Ammonia TankHamid MansouriÎncă nu există evaluări

- S-Curve & Progress TableDocument4 paginiS-Curve & Progress TableShinta TheresiaÎncă nu există evaluări

- S-Curve Maret W1 2021Document9 paginiS-Curve Maret W1 2021adiÎncă nu există evaluări

- Approved Vendor List-20110729Document3 paginiApproved Vendor List-20110729임동섭Încă nu există evaluări

- Struktur Organisasi Office & ProyekDocument17 paginiStruktur Organisasi Office & ProyekfitraÎncă nu există evaluări

- NG01023000 - Technical IttDocument52 paginiNG01023000 - Technical IttendyÎncă nu există evaluări

- Project: Tapis Eor Brownfield Modifications & RetrofitsDocument8 paginiProject: Tapis Eor Brownfield Modifications & RetrofitsMohamad Azizi AzizÎncă nu există evaluări

- STF HRSGDocument20 paginiSTF HRSGDaniellzhangÎncă nu există evaluări

- Gasification and PyrolysisDocument12 paginiGasification and Pyrolysismani kantaÎncă nu există evaluări

- Offer For Kiln Tyre Crack Repair - DroliaDocument5 paginiOffer For Kiln Tyre Crack Repair - DroliaNapoleon Das100% (1)

- Coastal Ocean Observing SystemsDe la EverandCoastal Ocean Observing SystemsYonggang LiuÎncă nu există evaluări

- 01 Civ Ce 001Document2 pagini01 Civ Ce 001jorah246Încă nu există evaluări

- Img 20170714 Wa0001 PDFDocument1 paginăImg 20170714 Wa0001 PDFReza FadhilaÎncă nu există evaluări

- Untitled Scanned 04 Doa 3Document1 paginăUntitled Scanned 04 Doa 3Reza FadhilaÎncă nu există evaluări

- Untitled Scanned 03 Doa1Document1 paginăUntitled Scanned 03 Doa1Reza FadhilaÎncă nu există evaluări

- Untitled Scanned 07 Doa2Document1 paginăUntitled Scanned 07 Doa2Reza FadhilaÎncă nu există evaluări

- Img 20170714 Wa0003Document1 paginăImg 20170714 Wa0003Reza FadhilaÎncă nu există evaluări

- Img 20170714 Wa0001 PDFDocument1 paginăImg 20170714 Wa0001 PDFReza FadhilaÎncă nu există evaluări

- Img 20170714 Wa0000Document1 paginăImg 20170714 Wa0000Reza FadhilaÎncă nu există evaluări

- Img 20170714 Wa0002Document1 paginăImg 20170714 Wa0002Reza FadhilaÎncă nu există evaluări

- Img 20170714 Wa0003 PDFDocument1 paginăImg 20170714 Wa0003 PDFReza FadhilaÎncă nu există evaluări

- Img 20170714 Wa0001Document1 paginăImg 20170714 Wa0001Reza FadhilaÎncă nu există evaluări

- Img 20170714 Wa0001Document1 paginăImg 20170714 Wa0001Reza FadhilaÎncă nu există evaluări

- Blacklisted Journal Publishers and Their Respective JournalsDocument4 paginiBlacklisted Journal Publishers and Their Respective JournalsReza FadhilaÎncă nu există evaluări

- Take Me or Leave MeDocument1 paginăTake Me or Leave MeReza FadhilaÎncă nu există evaluări

- Denomination Denomination Denomination Denomination Denomination Denomination Denomination Denomination DenominationDocument1 paginăDenomination Denomination Denomination Denomination Denomination Denomination Denomination Denomination DenominationReza FadhilaÎncă nu există evaluări

- Best Practice Guidelines On Publishing Ethics 2ed PDFDocument56 paginiBest Practice Guidelines On Publishing Ethics 2ed PDFReza FadhilaÎncă nu există evaluări

- SS304 304L Data SheetDocument2 paginiSS304 304L Data SheetPrakash KumarÎncă nu există evaluări

- Take Me or Leave MeDocument1 paginăTake Me or Leave MeReza FadhilaÎncă nu există evaluări

- Best Practice Guidelines On Publishing Ethics 2ed PDFDocument56 paginiBest Practice Guidelines On Publishing Ethics 2ed PDFReza FadhilaÎncă nu există evaluări

- Electric Analysis Balance Gas 6% Intrest in USD 400 MW - / MW Amount 2.5 Million USDDocument1 paginăElectric Analysis Balance Gas 6% Intrest in USD 400 MW - / MW Amount 2.5 Million USDReza FadhilaÎncă nu există evaluări

- Test Problems Material StructureDocument10 paginiTest Problems Material StructureReza FadhilaÎncă nu există evaluări

- Kunci Latihan Bahasa Inggris Smup 2010Document1 paginăKunci Latihan Bahasa Inggris Smup 2010Reza FadhilaÎncă nu există evaluări

- FDDocument17 paginiFDYash BhatnagarÎncă nu există evaluări

- General Sir Arthur Cotton R E His Life and Work Lady Hope 1000598480Document656 paginiGeneral Sir Arthur Cotton R E His Life and Work Lady Hope 1000598480rajk_onlineÎncă nu există evaluări

- User Guide: How To Register & Verify Your Free Paxum Personal AccountDocument17 paginiUser Guide: How To Register & Verify Your Free Paxum Personal AccountJose Manuel Piña BarriosÎncă nu există evaluări

- Journey of BhaavaDocument5 paginiJourney of BhaavaRavi GoyalÎncă nu există evaluări

- APLN - Audit Report 2018Document133 paginiAPLN - Audit Report 2018Dini DesvarhozaÎncă nu există evaluări

- Dharma DuraiDocument3 paginiDharma Duraivsection managerÎncă nu există evaluări

- Republic V Encelan GR No 170022 January 9, 2013Document20 paginiRepublic V Encelan GR No 170022 January 9, 2013ultra gayÎncă nu există evaluări

- NYS OPRHP Letter Re IccDocument3 paginiNYS OPRHP Letter Re IccDaily FreemanÎncă nu există evaluări

- Experience Certificate For English TeacherDocument2 paginiExperience Certificate For English TeacherShaher Alburaihy86% (7)

- Grupo NovEnergia, El Referente Internacional de Energía Renovable Dirigido Por Albert Mitjà Sarvisé - Dec2012Document23 paginiGrupo NovEnergia, El Referente Internacional de Energía Renovable Dirigido Por Albert Mitjà Sarvisé - Dec2012IsabelÎncă nu există evaluări

- Is.8910.2010 General Technical Delivery Requirements For Steel and Steel ProductsDocument19 paginiIs.8910.2010 General Technical Delivery Requirements For Steel and Steel ProductsledaswanÎncă nu există evaluări

- An Introduction To The "Mantra Śãstra": By: S.E. Gop ĀlāchārluDocument25 paginiAn Introduction To The "Mantra Śãstra": By: S.E. Gop ĀlāchārluKuldeep SharmaÎncă nu există evaluări

- Radical Feminism Enters The 21st Century - Radfem HubDocument53 paginiRadical Feminism Enters The 21st Century - Radfem HubFidelbogen CfÎncă nu există evaluări

- Barnacus: City in Peril: BackgroundDocument11 paginiBarnacus: City in Peril: BackgroundEtienne LÎncă nu există evaluări

- PolinationDocument22 paginiPolinationBala SivaÎncă nu există evaluări

- 3.19 Passive VoiceDocument10 pagini3.19 Passive VoiceRetno RistianiÎncă nu există evaluări

- Marathi 3218Document11 paginiMarathi 3218Nuvishta RammaÎncă nu există evaluări

- Managing Transaction ExposureDocument34 paginiManaging Transaction Exposureg00028007Încă nu există evaluări

- IJN Minekaze, Kamikaze and Mutsuki Class DestroyersDocument11 paginiIJN Minekaze, Kamikaze and Mutsuki Class DestroyersPeterD'Rock WithJason D'Argonaut100% (2)

- Tallado V. ComelecDocument3 paginiTallado V. ComelecLorelain ImperialÎncă nu există evaluări

- Name Position Time of ArrivalDocument5 paginiName Position Time of ArrivalRoseanne MateoÎncă nu există evaluări

- State of Cyber-Security in IndonesiaDocument32 paginiState of Cyber-Security in IndonesiaharisÎncă nu există evaluări

- Marilena Murariu, DESPRE ELENA ÎN GENERAL at Galeria SimezaDocument19 paginiMarilena Murariu, DESPRE ELENA ÎN GENERAL at Galeria SimezaModernismÎncă nu există evaluări

- Ancient History Dot Point SummaryDocument16 paginiAncient History Dot Point SummaryBert HaplinÎncă nu există evaluări

- Fashion OrientationDocument7 paginiFashion OrientationRAHUL16398Încă nu există evaluări

- Climate ChangeDocument3 paginiClimate ChangeBeverly TalaugonÎncă nu există evaluări

- Listening Test 2Document5 paginiListening Test 2teju patneediÎncă nu există evaluări

- The City Bride (1696) or The Merry Cuckold by Harris, JosephDocument66 paginiThe City Bride (1696) or The Merry Cuckold by Harris, JosephGutenberg.org100% (2)