Documente Academic

Documente Profesional

Documente Cultură

Super Critical Power - Part41

Încărcat de

Dhiraj SatyamTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Super Critical Power - Part41

Încărcat de

Dhiraj SatyamDrepturi de autor:

Formate disponibile

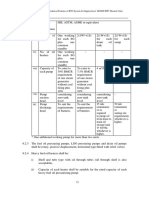

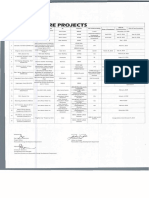

Standard Technical Features of BTG System for Supercritical 660/800 MW Thermal Units

ii) The enclosure integral with boiler (except air heaters) shall be formed by

water/steam cooled tubes on all the four sides, roof and bottom. The

furnace water walls shall be formed using either spiral (helical) wound

tubes or vertical plain/rifled tubes. The roof of single pass/tower type

boilers could be formed by gas tight metal sheeting of appropriate

material.

iii) The enclosure shall be formed using welded wall construction only.

Where use of refractory is unavoidable, 4mm thick steel plate behind

refractory shall be provided to form enclosure.

iv) Any penetration(s) into the steam generator enclosure shall be sealed for

gas tight integrity.

v) The Steam generator enclosure shall be provided with:

a) Air cooled observation ports for each oil/coal burner and at various

platform levels on all the walls.

b) Openings with hinged doors (air/gas tight) in all areas needing access

for internal observation/maintenance. Minimum two openings for

each area shall be provided.

c) Approach platform for each observation port/opening alongwith

ladders from nearest platform level.

d) Seal plates of stainless steel (type 430) or better corrosion and

erosion resistant steel material of minimum 6 mm thickness, all

round the furnace bottom, to prevent ingress of air.

vi) Dissimilar metal welds (DMW) between martensitic and austenitic

steels, martensitic and ferrite steel shall be avoided inside the boiler

enclosure for the pressure parts, which are exposed to hot flue gases.

However, if such DMW are unavoidable, same can be permitted at shop

provided manufacturer has previous experience of such DMW and

appropriate heat treatment is done after welding.

vii) In the steam generator enclosure, minimum 1.5 m cavity height shall be

provided in between the horizontal banks/ sections of economizer,

superheater and reheaters for maintenance purpose.

viii) No ingress of air from any opening like bottom hopper, soot blower, any

manhole or peep hole, ducts etc. shall be considered for sizing of

secondary and primary air fans while the same shall be considered for

performance predictions.

ix) Steam generator casing/pent house (as applicable) shall be provided. The

casing/pent house design shall ensure:

a) Complete enclosure of steam generator including superheater,

reheater & economizer headers.

30

S-ar putea să vă placă și

- Checklist Hvac p1Document16 paginiChecklist Hvac p1Aditya ChourasiaÎncă nu există evaluări

- Super Critical Power - Part46Document1 paginăSuper Critical Power - Part46Dhiraj SatyamÎncă nu există evaluări

- Part 1: General: Engineering Specifications For CXVB Evaporative CondensersDocument5 paginiPart 1: General: Engineering Specifications For CXVB Evaporative CondensersMARIVEL BASAÎncă nu există evaluări

- Air Cooled Heat ExchangerDocument24 paginiAir Cooled Heat Exchangeriaft100% (2)

- 88 Series 2 Boiler: Suggested SpecificationsDocument4 pagini88 Series 2 Boiler: Suggested SpecificationsAdam Bin Abu BakarÎncă nu există evaluări

- Stack Economizer Specification For Section VIII-Model CREDocument1 paginăStack Economizer Specification For Section VIII-Model CRELinggar Setiawan NÎncă nu există evaluări

- 2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)Document22 pagini2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)sabrila wandaÎncă nu există evaluări

- Mesan MXR-KM (F-K) Guide Specs r2Document4 paginiMesan MXR-KM (F-K) Guide Specs r2Renu TekumudiÎncă nu există evaluări

- Technical Specifications CanopyDocument5 paginiTechnical Specifications CanopyNaman SharmaÎncă nu există evaluări

- CS3 Air HandlersDocument35 paginiCS3 Air HandlersAhmed SofaÎncă nu există evaluări

- TanksDocument24 paginiTanksShaji Hakeem91% (23)

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-27Document5 paginiBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-27speedo3076Încă nu există evaluări

- Babcox BoilerDocument14 paginiBabcox BoilertoanbtdÎncă nu există evaluări

- GS 50PG 4PDDocument8 paginiGS 50PG 4PDSalvador Loyola TreviñoÎncă nu există evaluări

- 23 82 16 - Heating and Cooling CoilsDocument12 pagini23 82 16 - Heating and Cooling Coilssopan saÎncă nu există evaluări

- Air Cooled Heat ExchangerDocument15 paginiAir Cooled Heat Exchangerros56Încă nu există evaluări

- Section 3-1 - Installation - Steam BoilersDocument65 paginiSection 3-1 - Installation - Steam BoilersWissam Jarmak100% (1)

- Kencana Square Air Cooled Split Unit System Section Ac-750Document4 paginiKencana Square Air Cooled Split Unit System Section Ac-750james_chan2178Încă nu există evaluări

- Particular & General Specification-FRPDocument9 paginiParticular & General Specification-FRPmainur mechanical engineerÎncă nu există evaluări

- Basic API650-Training PDFDocument75 paginiBasic API650-Training PDFDivyesh PatelÎncă nu există evaluări

- Wms Acmv Duct WorksDocument8 paginiWms Acmv Duct Worksfahmi_majid_2Încă nu există evaluări

- Series 1500 Cooling Tower SpecificationDocument9 paginiSeries 1500 Cooling Tower SpecificationLorenaÎncă nu există evaluări

- Series V Cooling Towers SpecificationsDocument6 paginiSeries V Cooling Towers SpecificationsGeelissonÎncă nu există evaluări

- SSG App C Des Con Guide - pdf4Document7 paginiSSG App C Des Con Guide - pdf4Shohidul IslamÎncă nu există evaluări

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Document10 paginiES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsÎncă nu există evaluări

- Steam Coil Specification: Page 1 of 3Document3 paginiSteam Coil Specification: Page 1 of 3gaurav shindeÎncă nu există evaluări

- Fireguard I-4000 PDFDocument2 paginiFireguard I-4000 PDFjkhgvdj mnhsnjkhgÎncă nu există evaluări

- Va Nca 23 13 23Document6 paginiVa Nca 23 13 23Ali AlomyÎncă nu există evaluări

- Thermogain HeatPipesDocument2 paginiThermogain HeatPipesbhavin777Încă nu există evaluări

- KPR 53 2018 SpecDocument7 paginiKPR 53 2018 SpecABDELKADER BENABDALLAHÎncă nu există evaluări

- At/Ut/Uss: T F, A T !Document1 paginăAt/Ut/Uss: T F, A T !Jerico LlovidoÎncă nu există evaluări

- Basco - Type - Es-Heat Exchangers BrochureDocument8 paginiBasco - Type - Es-Heat Exchangers BrochureMarco Andrés Guevara LunaÎncă nu există evaluări

- Running Head: SECTION 1210-1215 and Rule 19Document10 paginiRunning Head: SECTION 1210-1215 and Rule 19Ken ChiaÎncă nu există evaluări

- Combi T Thermo enDocument6 paginiCombi T Thermo enadventure11111Încă nu există evaluări

- Commercial Kitchen Hood WorksheetDocument5 paginiCommercial Kitchen Hood Worksheetdavilla apizzasaÎncă nu există evaluări

- HVAC Ductwork SpecificationDocument4 paginiHVAC Ductwork SpecificationhvacwallyÎncă nu există evaluări

- Rowan University Design Guide 2013Document2 paginiRowan University Design Guide 2013zeliteÎncă nu există evaluări

- Design Air Cooler / Fin Fan Cooler: Pt. Encona Inti IndustriDocument23 paginiDesign Air Cooler / Fin Fan Cooler: Pt. Encona Inti IndustriTifano KhristiyantoÎncă nu există evaluări

- Bfit Model BFIT Condensing Hot Water Boiler SpecificationDocument8 paginiBfit Model BFIT Condensing Hot Water Boiler SpecificationjoeÎncă nu există evaluări

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Document9 paginiHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilÎncă nu există evaluări

- Chapter 7 - Mechanical Ventilation and Smoke Control SystemsDocument24 paginiChapter 7 - Mechanical Ventilation and Smoke Control Systemsyunying21Încă nu există evaluări

- Boiler OverhaulDocument9 paginiBoiler OverhaulHemant PatilÎncă nu există evaluări

- Section 4 Air Handling Units - Double Skin ScopeDocument4 paginiSection 4 Air Handling Units - Double Skin ScopematzoyekÎncă nu există evaluări

- SPEC D-Type TraducidoDocument16 paginiSPEC D-Type TraducidoOscar TapiaÎncă nu există evaluări

- PEB SpecificationDocument4 paginiPEB SpecificationRashmita SahuÎncă nu există evaluări

- Basement or CellarDocument4 paginiBasement or CellarSubadharshiniÎncă nu există evaluări

- Air Fin Cooler CatalougeDocument14 paginiAir Fin Cooler Catalougesammar_10Încă nu există evaluări

- TS-01 Air - Washer UnitsDocument27 paginiTS-01 Air - Washer UnitsPraveen KumarÎncă nu există evaluări

- Chap - 7-Ventilation and Smoke Purging SystemDocument21 paginiChap - 7-Ventilation and Smoke Purging SystemAbubacker Siddique SulthanÎncă nu există evaluări

- Packaged Steam Fired Water Heater: FeaturesDocument7 paginiPackaged Steam Fired Water Heater: Featuresjose arangoitiaÎncă nu există evaluări

- SECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsDocument4 paginiSECTION 15763 Fan Coils Units Part 1 - General 1.1 Related DocumentsMunir RasheedÎncă nu există evaluări

- Vha Program Guide Pg-18-3 April 2001Document1 paginăVha Program Guide Pg-18-3 April 2001Reza KhajeÎncă nu există evaluări

- BoilerDocument48 paginiBoilerSubramanian Ravishankar100% (1)

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocument18 paginieBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xÎncă nu există evaluări

- App027 Flue ApertureDocument5 paginiApp027 Flue Aperturechong pak limÎncă nu există evaluări

- Capitulo 4Document7 paginiCapitulo 4thanatitosÎncă nu există evaluări

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe la EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Steam Locomotive Construction and MaintenanceDe la EverandSteam Locomotive Construction and MaintenanceÎncă nu există evaluări

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 paginăChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part91Document1 paginăSuper Critical Power - Part91Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part92Document1 paginăSuper Critical Power - Part92Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part81Document1 paginăSuper Critical Power - Part81Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part83Document1 paginăSuper Critical Power - Part83Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part86Document1 paginăSuper Critical Power - Part86Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part88Document1 paginăSuper Critical Power - Part88Dhiraj SatyamÎncă nu există evaluări

- Suitable For Remote Manual OperationDocument1 paginăSuitable For Remote Manual OperationDhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part85Document1 paginăSuper Critical Power - Part85Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part76Document1 paginăSuper Critical Power - Part76Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part60Document1 paginăSuper Critical Power - Part60Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part77Document1 paginăSuper Critical Power - Part77Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part80Document1 paginăSuper Critical Power - Part80Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part62Document1 paginăSuper Critical Power - Part62Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part48Document1 paginăSuper Critical Power - Part48Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part57Document1 paginăSuper Critical Power - Part57Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part56Document1 paginăSuper Critical Power - Part56Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part59Document1 paginăSuper Critical Power - Part59Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part58Document1 paginăSuper Critical Power - Part58Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part35Document1 paginăSuper Critical Power - Part35Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part42Document1 paginăSuper Critical Power - Part42Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part37Document1 paginăSuper Critical Power - Part37Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part40Document1 paginăSuper Critical Power - Part40Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part47Document1 paginăSuper Critical Power - Part47Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part34Document1 paginăSuper Critical Power - Part34Dhiraj SatyamÎncă nu există evaluări

- Super Critical Power - Part38Document1 paginăSuper Critical Power - Part38Dhiraj SatyamÎncă nu există evaluări

- Combined Cycle Power Plant - Summary StudyDocument3 paginiCombined Cycle Power Plant - Summary StudydndudcÎncă nu există evaluări

- NEA Completed Renewable ProjectsDocument2 paginiNEA Completed Renewable ProjectsVic Rizenn Isidore BobilesÎncă nu există evaluări

- 9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏDocument80 pagini9 EÈ Ú ºÃ ÄÑ Ï°×ÊÁÏnabil160874100% (2)

- 1.2introduction To IC Engine Fundamentals PDFDocument57 pagini1.2introduction To IC Engine Fundamentals PDFSiraj MohammedÎncă nu există evaluări

- Steam Generation Calculations of BoilerDocument5 paginiSteam Generation Calculations of BoilerRaza Un Nabi100% (1)

- Internship Report: Authored By: Saumyajit SabuiDocument24 paginiInternship Report: Authored By: Saumyajit SabuiSAUMYAJIT SABUIÎncă nu există evaluări

- Fulton RB Horizontal Firetube Boilers: Product Data SubmittalDocument2 paginiFulton RB Horizontal Firetube Boilers: Product Data SubmittalCristhian MezaÎncă nu există evaluări

- OSK Catalog 2020 PDFDocument49 paginiOSK Catalog 2020 PDFWilo RomeroÎncă nu există evaluări

- Abbtc Bro1100 Our RangeDocument15 paginiAbbtc Bro1100 Our RangearesobscureÎncă nu există evaluări

- Posiflow Technology of Doosan Babcock For Supercritical BoilersDocument12 paginiPosiflow Technology of Doosan Babcock For Supercritical BoilersKarthick VelayuthamÎncă nu există evaluări

- Rooftop Solar Simulation Using PVsystDocument3 paginiRooftop Solar Simulation Using PVsystSourav NandiÎncă nu există evaluări

- Pik High Quality PV Modules SeriesDocument2 paginiPik High Quality PV Modules SeriesBujar DalipiÎncă nu există evaluări

- SolarDocument37 paginiSolarPrasannaÎncă nu există evaluări

- Boiler MaintenanceDocument144 paginiBoiler Maintenanceaziz100% (2)

- HydropowerDocument113 paginiHydropowerJames100% (1)

- STG FundamentalsDocument38 paginiSTG Fundamentalsbraulio90Încă nu există evaluări

- ImgDocument8 paginiImgAnonymous Qoz6rhj5yXÎncă nu există evaluări

- Datasheet Vertex DE19R en 2023Document2 paginiDatasheet Vertex DE19R en 2023Jhon AltamarÎncă nu există evaluări

- Pelton Turbine PDFDocument11 paginiPelton Turbine PDFabbas bilalÎncă nu există evaluări

- Indwell Constructions Private Limited Bhel/Nttps/U#8/Vijayawada Erection Programme For The Month of November'19Document6 paginiIndwell Constructions Private Limited Bhel/Nttps/U#8/Vijayawada Erection Programme For The Month of November'19Alanka PrasadÎncă nu există evaluări

- DSCLDocument14 paginiDSCLNazeeh Abdulrhman AlbokaryÎncă nu există evaluări

- Cylinder Block 26227236Document3 paginiCylinder Block 26227236dharmawan100% (1)

- Heat Technology: Chapter 10 Section 4Document23 paginiHeat Technology: Chapter 10 Section 4thegedusÎncă nu există evaluări

- Closed and Open Feed SystemDocument7 paginiClosed and Open Feed SystemRoneil BaculioÎncă nu există evaluări

- GRESIK GBU (PT. PJB - Generation Business Unit)Document4 paginiGRESIK GBU (PT. PJB - Generation Business Unit)Eliyanto E BudiartoÎncă nu există evaluări

- Gvu We' Yr K ' I Cwimsl VB: Solar Gas Hfo HSD Hydro Coal ImportDocument13 paginiGvu We' Yr K ' I Cwimsl VB: Solar Gas Hfo HSD Hydro Coal ImportWahed ImtiazÎncă nu există evaluări

- 4 Turbinat HidraulikeDocument24 pagini4 Turbinat HidraulikeAltin Dorri33% (3)

- Solar Main Catalogue Nov - 22 - V5Document24 paginiSolar Main Catalogue Nov - 22 - V5Kondameedi LgtvÎncă nu există evaluări

- Literature Review of Solar Power PlantDocument8 paginiLiterature Review of Solar Power Plantbav1dik0jal3100% (1)

- Sasconinfra Solar Solution 29062023 1Document19 paginiSasconinfra Solar Solution 29062023 1api-677650120Încă nu există evaluări