Documente Academic

Documente Profesional

Documente Cultură

Structure and Comparison: D27DT (EU IV) Engine - Front View

Încărcat de

Francisco Alejandro TelloTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Structure and Comparison: D27DT (EU IV) Engine - Front View

Încărcat de

Francisco Alejandro TelloDrepturi de autor:

Formate disponibile

0000-00 01-3

1. STRUCTURE AND COMPARISON

D27DT (EU IV) Engine - Front View

D27DT (EU IV) Engine - Top View

Downloaded from www.Manualslib.com manuals search engine

01-4

D27DT (EU IV) Engine - Side View

D27DT (EU IV) Engine - Left Side View

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-5

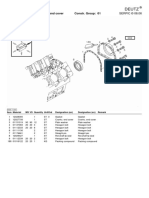

D27DT Engine (General) - Front View

D27DT Engine (General) - Top View

Downloaded from www.Manualslib.com manuals search engine

01-6

D27DT Engine (General) - Side View

D27DT Engine (General) - Left Side View

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-7

2. ENGINE SPECIFICATIONS AND PERFORMANCE CURVE

1) Specifications

Downloaded from www.Manualslib.com manuals search engine

01-8

2) D27DT Engine Performance Curve

(1) Output and Torque

(2) Oil Temperature/Pressure and Boost Pressure

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-9

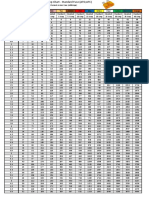

3. TIGHTENING TORQUE

This table shows the tightening torques for removal/mounting and disassembly/reassemly of the

engine.

Downloaded from www.Manualslib.com manuals search engine

01-10

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-11

Downloaded from www.Manualslib.com manuals search engine

01-12

4. MAJOR CHANGES IN D27DTP (POWER UP) ENGINE

(COMPARED TO D27DT)

The shape and size of D27DTP (POWER UP) are slightly different from those of D27DT engine

but the basic configuration of two systems is almost same.

1) Engine Assembly

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-13

2) Major Changes and Summary

Downloaded from www.Manualslib.com manuals search engine

01-14

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-15

Downloaded from www.Manualslib.com manuals search engine

01-16

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-17

Downloaded from www.Manualslib.com manuals search engine

01-18

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-19

Downloaded from www.Manualslib.com manuals search engine

01-20

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-21

5. GUIDELINES FOR SERVICE WORKS

1) For Safety

To perform the service works easily and safely, the service technicians must keep the proper

working procedures and rules.

This manual provides the useful instructions to the service technicians so that they can perform

the service works with standard working process, skills, tips in time.

Please read this manual and follow the instructions carefully.

Signal words such as CAUTION and NOTE have special meanings.

indicates information to assist maintenance and instructions.

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or property damage.

However, above references and cautions cannot be inclusive measures, so should have habits of

paying attentions and cautions based on common senses.

Downloaded from www.Manualslib.com manuals search engine

01-22

2) Cautions on Service Procedures

1. Before lifting up the vehicle with a lift, correctly support the lifting points.

2. When using a jack, park the vehicle on a level ground and place the wheel chocks under the

tires. Position the jack under the frame and lift up the vehicle and then support with chassis

stand before service work.

3. Make sure to disconnect the negative (-) cable from the battery to prevent any damage to

electric systems.

4. If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

5. Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

6. To improve the efficiency of service work, use only recommended and specified tools.

7. Use only Ssangyong genuine spare parts.

8. Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace

them with new ones. If reused, normal functions cannot be maintained.

9. Store the disassembled parts as a set based on disassembly order and unit.

10.Pay particular attention not to miss or mix the fasteners.

11.If necessary, especially for inspection, clean the removed parts completely.

12.Apply the oil or grease on the running and sliding surfaces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

13.Tighten the fasteners with the specified tightening torque.

14.As a final stage of service work, check if the serviced system is working properly and the

problem has been eliminated clearly.

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-23

3) Guidelines on Engine Service

To prevent personal injuries and vehicle damages that can be caused by mistakes during engine

and unit inspection/repair and to secure optimum engine performance and safety after service

works, basic cautions and service work guidelines that can be easily forgotten during engine

service works are described in.

Cautions before service works

- For safe and correct works, you must observe the working procedures and instructions in this

manual. And, use the designated tools as follow:

Engine stand / Heavy duty engine jack

- To prevent the engine from starting abruptly, do not allow anybody to get in the vehicle while

servicing in engine compartment.

- Before work on engine and electrical equipment, be sure to disconnect battery negative (-)

terminal.

- Before service works, be sure to prepare the works by cleaning and aligning work areas.

Do not allow the foreign material get into the fuel injection system.

- When removing the engine, use only the safety hook on engine and engine hanger. Do not

support the bottom of oil pan with a jack.

Engine and accessories

- Completely drain the engine oil, coolant and fuel from engine before removal.

- Before disassembling/assembling the engine components, carefully read the working

procedures in this manual.

- Make sure to keep the specified tightening torques during installation.

- Clean and properly lubricate the parts before reassembly.

- Carefully check that there is not any interference while servicing.

Downloaded from www.Manualslib.com manuals search engine

01-24

Fuel and lubrication system

- Do not allow the fluid and engine oil to make contact with the body paintwork and hoses.

- If work on the fluid system such as fuel and oil, working area should be well ventilated and

smoking should be prohibited.

- Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and

nuts should be tightened as specified.

- After removal/installation works, be sure to check whether there is leak on the connecting

section.

1. If fine dust or foreign material enters into DI engine's fuel system, there can be serious

damages between HP pump and injectors. So, be sure to cover removed fuel system

components with cap and protect removed parts not to be contaminated with dirt. (Refer to

cleanness in this manual while working on DI engine fuel system)

2. When working on the fuel line between priming pump and injector (including return line),

always plug the openings with caps to prevent foreign materials or dust from entering to the

openings and connections.

3. The HP fuel supply pipe (HP pump to fuel rail) and HP fuel pipe (Fuel rail to injector) should

be replaced with new ones when removed.

Electrical equipment

Electric devices should be handled more carefully.

Currently, the engine has a lot of electric devices. There could be poor engine performance,

incomplete combustion and other abnormal symptoms due to short circuit or poor contact.

- Before work on engine and electrical equipment, be sure to disconnect battery negative (-)

terminal.

- When replacing the electric device, use only genuine part and check the conditions of

connections and grounds. Loosened connection or ground makes cause a fire and personal

injury.

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-25

6. STANDARD BOLTS SPECIFICATIONS

1. Metric bolt strength is embossed on the head of each bolt. The strength of bolt can be

classified as 4T, 7T, 8.8T, 10.9T, 11T and 12.9T in general.

2. Observe standard tightening torque during bolt tightening works and can adjust torque to be

proper within 15 % if necessary. Try not to over max. allowable tightening torque if not

required to do so.

3. Determine extra proper tightening torque if tightens with washer or packing.

4. If tightens bolts on the below materials, be sure to determine the proper torque.

- Aluminum alloy: Tighten to 80 % of above torque table.

- Plastics: Tighten to 20 % of above torque table.

Downloaded from www.Manualslib.com manuals search engine

01-26

1. ENGINE COMPARTMENT

The major changes due to the newly adopted engine compared to D27DT engine are as follows:

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-27

Downloaded from www.Manualslib.com manuals search engine

01-28

Engine Compartment Layout

1. Engine assembly 14.FFH Assembly (Only for vehicle with FFH)

2. Engine oil dipstick 15.Power steering oil tank

3. Vacuum pump 16.Engine oil filler cap

4. Oil filter and cooler 17.Fan shroud

5. Fuel filter and priming pump 18.E-EGR Valve

6. Brake booster 19.High-capacity PCV oil separator

7. Brake oil tank 20.HFM sensor (6.0)

8. AQGS unit 21.VGT turbo charger

9. Washer fluid filler cap 22.Air cleaner housing

10.Engine compartment fuse box 23.2Coolant surge tank

11.PTC relay box 24.ABS/ESP HECU (Including TPMS function:

12.Battery optional)

13.Vacuum modulator (for VGT turbo charger) 25.Exhaust gas FRT Temp. sensor (T3)

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-29

Major Sensors and Components

Downloaded from www.Manualslib.com manuals search engine

01-30

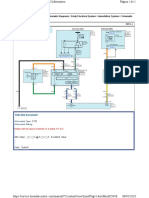

2. SYSTEMS IN ENGINE COMPARTMENT

1) Engine Accessories Related to ECU

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-31

Downloaded from www.Manualslib.com manuals search engine

01-32

2) Preheat System

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-33

3) Fuel System

Downloaded from www.Manualslib.com manuals search engine

01-34

Fuel Supply System

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-35

4) Lubrication System

Downloaded from www.Manualslib.com manuals search engine

01-36

5) Cooling System

Downloaded from www.Manualslib.com manuals search engine

0000-00 01-37

6) Intake System

Downloaded from www.Manualslib.com manuals search engine

01-38

7) Exhaust System

Downloaded from www.Manualslib.com manuals search engine

S-ar putea să vă placă și

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDe la EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideEvaluare: 4.5 din 5 stele4.5/5 (8)

- (Ssangyong) Manual de Taller Ssangyong Rexton 2004 2005Document1.991 pagini(Ssangyong) Manual de Taller Ssangyong Rexton 2004 2005Domingo Vasquez100% (2)

- HR MR Apr.06E A4Document7 paginiHR MR Apr.06E A4Prastyo TyoÎncă nu există evaluări

- Rexton - Service Manual - ENGINE PDFDocument587 paginiRexton - Service Manual - ENGINE PDFdanila99Încă nu există evaluări

- G3LA/G4LA: KAPPA 1.0L/1.2L MPI (W/O Button Start)Document1 paginăG3LA/G4LA: KAPPA 1.0L/1.2L MPI (W/O Button Start)Nelson TrujilloÎncă nu există evaluări

- Ssang Young Rex TonDocument14 paginiSsang Young Rex TonHri Vitalion100% (2)

- Service Training Manual: Engine Axle Transfer CaseDocument13 paginiService Training Manual: Engine Axle Transfer Casefrancisca19100% (1)

- Phun Xang Dien Tu p1 8097Document351 paginiPhun Xang Dien Tu p1 8097Đức Hòang100% (1)

- Rexton Owner ManualDocument210 paginiRexton Owner ManualAnushamalar Andiappan100% (2)

- Ranger 2018 Plano CompletoDocument477 paginiRanger 2018 Plano Completobanddido90Încă nu există evaluări

- Y290 WML 209.PDF Rexton SsangyongDocument6 paginiY290 WML 209.PDF Rexton SsangyongVelasquez JavierÎncă nu există evaluări

- ESPECIFICACIONES TECNICAS MOT Y TRANSMISION - PPTX 1Document15 paginiESPECIFICACIONES TECNICAS MOT Y TRANSMISION - PPTX 1Celeste PayneÎncă nu există evaluări

- Rexton - Service Manual - CHASSIS PDFDocument1.306 paginiRexton - Service Manual - CHASSIS PDFJuanes Nogueira100% (2)

- Security System Scorpio NCS90 07 2006 V0Document40 paginiSecurity System Scorpio NCS90 07 2006 V0luisxdÎncă nu există evaluări

- Tightening Torques: Dv4C, Dv6C, Dv6Dted, Dv6Eted, Dv6Uc, Dv6 Ue6 EnginesDocument24 paginiTightening Torques: Dv4C, Dv6C, Dv6Dted, Dv6Eted, Dv6Uc, Dv6 Ue6 EnginesKamen Kamenov100% (1)

- C210 WML 201Document13 paginiC210 WML 201Efrén SantínÎncă nu există evaluări

- C210 WML 211Document11 paginiC210 WML 211Efrén SantínÎncă nu există evaluări

- 362214Document59 pagini362214Anderson BombistaÎncă nu există evaluări

- Delphi HP Pump DiagnosisDocument38 paginiDelphi HP Pump DiagnosisИгорь Ясюк100% (1)

- DTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High InputDocument10 paginiDTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High InputOscar GonzálezÎncă nu există evaluări

- Engine Coolant Temperature (Ect) Sensor: 1F2-54 M161 Engine ControlsDocument4 paginiEngine Coolant Temperature (Ect) Sensor: 1F2-54 M161 Engine ControlsJulio Felipe Miranda MarzanÎncă nu există evaluări

- Crs Triton Common Rail System OkDocument78 paginiCrs Triton Common Rail System OkPps BubakanÎncă nu există evaluări

- C210 WML 206Document20 paginiC210 WML 206Efrén SantínÎncă nu există evaluări

- Air Conditioning: Service Manual: System Wiring DiagramsDocument124 paginiAir Conditioning: Service Manual: System Wiring DiagramsJonas Dos Santos AndradeÎncă nu există evaluări

- (Ssangyong) Manual de Taller Ssangyong Actyon 2001Document28 pagini(Ssangyong) Manual de Taller Ssangyong Actyon 2001serccons S.A.S100% (1)

- Cp3 Pump Installation InstructionsDocument16 paginiCp3 Pump Installation Instructionsvali_nedeleaÎncă nu există evaluări

- SsangyongDocument1.991 paginiSsangyongmichaeltiboche100% (2)

- Especificaciones Sssangyong Rexton 2.7 Xdi CRDocument2 paginiEspecificaciones Sssangyong Rexton 2.7 Xdi CRAmadeus De La Cruz0% (1)

- QQ3 S11 Manual de Reparacion Motor SQR372Document44 paginiQQ3 S11 Manual de Reparacion Motor SQR372Fernando Ortiz100% (1)

- 2005 Seadoo Rotax 1503 4 Tech Shop Manual - 26 50Document25 pagini2005 Seadoo Rotax 1503 4 Tech Shop Manual - 26 50Oscar Eduardo GomezÎncă nu există evaluări

- Nissan Almera P1251 Engine Trouble Code - Nissan Almera P1251 OBD-II Diagnostic Powertrain (P) Trouble Code For Nissan Almera PDFDocument2 paginiNissan Almera P1251 Engine Trouble Code - Nissan Almera P1251 OBD-II Diagnostic Powertrain (P) Trouble Code For Nissan Almera PDFJoaquin Enrique Rivas HungÎncă nu există evaluări

- Automatic Transmission A140Document1 paginăAutomatic Transmission A140Dang Tien PhucÎncă nu există evaluări

- M.I.L "ON" DTC P2195, P2197, P0138, P0158, P0171, P0174, P0031, or P0051Document4 paginiM.I.L "ON" DTC P2195, P2197, P0138, P0158, P0171, P0174, P0031, or P0051a8yssÎncă nu există evaluări

- Ssangyong Tempario Rexton Stavic KorandoDocument479 paginiSsangyong Tempario Rexton Stavic KorandoAnonymous 9eBG6PnN100% (2)

- RX290B PDFDocument1.855 paginiRX290B PDFleruri100% (2)

- Electronic Engine Controls TDV6 2.7Document10 paginiElectronic Engine Controls TDV6 2.7elisei sorinÎncă nu există evaluări

- DW10 FU (C/D/E) : EURO 6 Step 1 Diesel Engine L.C.V. Application VersionDocument2 paginiDW10 FU (C/D/E) : EURO 6 Step 1 Diesel Engine L.C.V. Application VersionArturHeiseÎncă nu există evaluări

- REXTON новыйDocument422 paginiREXTON новыйЮра РудикÎncă nu există evaluări

- The New 2 0 L and 2 2 L Four Cylinder Diesel Engine Family of Hyundai Kia PDFDocument6 paginiThe New 2 0 L and 2 2 L Four Cylinder Diesel Engine Family of Hyundai Kia PDFAhmed RamadanÎncă nu există evaluări

- Technical Service Bulletin: Hybrid Electric Oil Pump DTC P1774, P1775, P1776, P1777, P1784 & P1986Document6 paginiTechnical Service Bulletin: Hybrid Electric Oil Pump DTC P1774, P1775, P1776, P1777, P1784 & P1986Alex PAStranoÎncă nu există evaluări

- Supplemental Restraint System (SRS) Kia Picanto 1Document1 paginăSupplemental Restraint System (SRS) Kia Picanto 1Huy Trần QuốcÎncă nu există evaluări

- Toyota U140F Transmission Repair Manual RM772UDocument163 paginiToyota U140F Transmission Repair Manual RM772UOktavia IndrianiÎncă nu există evaluări

- Evoque 2011-13 - Engine Emission Control - TD4 2.2L DieselDocument32 paginiEvoque 2011-13 - Engine Emission Control - TD4 2.2L DieselAliÎncă nu există evaluări

- 2018 D 2.5 TCI-A2 Schematic Diagrams Engine Electrical System Engine Control System (With Euro6) Schematic DiagramsDocument1 pagină2018 D 2.5 TCI-A2 Schematic Diagrams Engine Electrical System Engine Control System (With Euro6) Schematic DiagramsANH LÊÎncă nu există evaluări

- Sprinter Turbo Vacuum Valve Circuito Valvula Control Turbo SprinterDocument1 paginăSprinter Turbo Vacuum Valve Circuito Valvula Control Turbo SprinterFacu BertoldoÎncă nu există evaluări

- Engine Cooling System: SectionDocument87 paginiEngine Cooling System: SectionLuis BarriosÎncă nu există evaluări

- Jac HFC4GB1Document70 paginiJac HFC4GB1Jeifred Espitia AraujoÎncă nu există evaluări

- D20Dtf Engine: 1. SpecificationDocument26 paginiD20Dtf Engine: 1. SpecificationKada Ben youcefÎncă nu există evaluări

- Auto Trans Overview Cooper SDocument25 paginiAuto Trans Overview Cooper SDiego Fuertes Forero100% (1)

- Korando C205 11-14 MT-SEDocument1.109 paginiKorando C205 11-14 MT-SEDaniel Tapia HenríquezÎncă nu există evaluări

- 2-3 Parts MINYI EFFADocument26 pagini2-3 Parts MINYI EFFARusonegroÎncă nu există evaluări

- Hyundai Santa Fé 2.7L 2008 - Cabeçote - Remoção Recolocação PDFDocument31 paginiHyundai Santa Fé 2.7L 2008 - Cabeçote - Remoção Recolocação PDFLeonardo Limberger0% (1)

- 2010-2012 Ssang Yong Actyon c146 SMDocument1.074 pagini2010-2012 Ssang Yong Actyon c146 SMcelyozÎncă nu există evaluări

- Manual Kyron - Completo WhatsDocument2.530 paginiManual Kyron - Completo WhatsHamilton ManféÎncă nu există evaluări

- AirBag ToyotaDocument7 paginiAirBag Toyotashadow_smdkÎncă nu există evaluări

- Motore d20dt d27dtDocument139 paginiMotore d20dt d27dtGONTONIÎncă nu există evaluări

- Manual de Taller de Motor Luv D-Max (6VE1) GasolinaDocument100 paginiManual de Taller de Motor Luv D-Max (6VE1) GasolinaAngel GarciaÎncă nu există evaluări

- Manuel de Diagnostico Rexton PDFDocument888 paginiManuel de Diagnostico Rexton PDFK_minosÎncă nu există evaluări

- Daewoo Mega250-V Shop ManualDocument584 paginiDaewoo Mega250-V Shop ManualIlkin Gedik100% (3)

- Cummins-K19-4021499-Service Manual PDFDocument2.048 paginiCummins-K19-4021499-Service Manual PDFDmitry91% (69)

- JF506E Supplement Part 1Document6 paginiJF506E Supplement Part 1Eban FloresÎncă nu există evaluări

- Plano Eléctrico 797B PDFDocument6 paginiPlano Eléctrico 797B PDFFrancisco Alejandro TelloÎncă nu există evaluări

- Codigos Invertex II.Document96 paginiCodigos Invertex II.HéctorHernándezDíaz100% (2)

- Drive Drawing 17KG535K1 - 84B522859AH Rev C 960E PDFDocument103 paginiDrive Drawing 17KG535K1 - 84B522859AH Rev C 960E PDFFrancisco Alejandro Tello100% (1)

- Datasheet Battery Balancer EN PDFDocument2 paginiDatasheet Battery Balancer EN PDFFrancisco Alejandro TelloÎncă nu există evaluări

- MussoDocument47 paginiMussoFrancisco Alejandro TelloÎncă nu există evaluări

- How To Use Electrical Wiring Diagram: Section 1Document1 paginăHow To Use Electrical Wiring Diagram: Section 1Francisco Alejandro TelloÎncă nu există evaluări

- Mazda Demio 2012 - User Manual PDFDocument344 paginiMazda Demio 2012 - User Manual PDFKeith zammit100% (2)

- Fuse Voltage Drop Chart - Standard Fuse PDFDocument2 paginiFuse Voltage Drop Chart - Standard Fuse PDFJosue Rodrigo Cruz Caballero85% (13)

- Section Index: (LHD) Electrical Wiring DiagramDocument5 paginiSection Index: (LHD) Electrical Wiring DiagramFrancisco Alejandro TelloÎncă nu există evaluări

- Service Manual MussoDocument1.465 paginiService Manual MussoBricolus95% (19)

- Here Is A List of ECU Error Codes For Those Who Have An Elgrand E50 With A Consult 14 Pin PlugDocument4 paginiHere Is A List of ECU Error Codes For Those Who Have An Elgrand E50 With A Consult 14 Pin PlugFrancisco Alejandro Tello50% (2)

- Propulsion Magnogravitodinamica 2-ModelDocument1 paginăPropulsion Magnogravitodinamica 2-ModelFrancisco Alejandro TelloÎncă nu există evaluări

- Esquema de Propulsion-ModelDocument1 paginăEsquema de Propulsion-ModelFrancisco Alejandro TelloÎncă nu există evaluări

- Automatic Transmisson Aw55-50 SN - Volvo XC 90 Opel VectraDocument16 paginiAutomatic Transmisson Aw55-50 SN - Volvo XC 90 Opel VectraNovacovici Dorel100% (1)

- AW55 50 Solenoid Adjustment Chart v2Document1 paginăAW55 50 Solenoid Adjustment Chart v2María Martz De García50% (2)

- D20Dtf Engine InformationDocument16 paginiD20Dtf Engine InformationFrancisco Alejandro TelloÎncă nu există evaluări

- Chevy 6.5 DieselDocument17 paginiChevy 6.5 DieselJerad Bixler75% (4)

- Periodic Maintenance: Tier 2 Emission EngineDocument58 paginiPeriodic Maintenance: Tier 2 Emission EnginehoiÎncă nu există evaluări

- Volvo EC140B LC, EC140B LCM Excavator Parts Catalogue Manual (SN 10001 - 15000)Document25 paginiVolvo EC140B LC, EC140B LCM Excavator Parts Catalogue Manual (SN 10001 - 15000)Jose Luis CastilloÎncă nu există evaluări

- Motor Cummins QSL9Document18 paginiMotor Cummins QSL9AndresPonceÎncă nu există evaluări

- Tabla de Mantenimiento e Inspección de Mitsubishi Outlander 1Document36 paginiTabla de Mantenimiento e Inspección de Mitsubishi Outlander 1CristianEdinsonAlbornozFuenzalidaÎncă nu există evaluări

- SSP 337 20l Fsi Engine With TurbochargerDocument28 paginiSSP 337 20l Fsi Engine With TurbochargerJose Ramón Orenes ClementeÎncă nu există evaluări

- 4le1da07 DGK25B 01Document46 pagini4le1da07 DGK25B 01Leo BurnsÎncă nu există evaluări

- 01.03 Intake ManifoldDocument12 pagini01.03 Intake ManifoldFrank Ch CcaicoÎncă nu există evaluări

- Camry FAQ P1of2Document45 paginiCamry FAQ P1of2Janet WertÎncă nu există evaluări

- NHTSA Safety Recall Report: PCV ValveDocument1 paginăNHTSA Safety Recall Report: PCV ValvePete Madden100% (1)

- Why Does My Engine Start But Then Stop - AxleAddict - A Community of Car Lovers, Enthusiasts, and Mechanics Sharing Our Auto AdviceDocument28 paginiWhy Does My Engine Start But Then Stop - AxleAddict - A Community of Car Lovers, Enthusiasts, and Mechanics Sharing Our Auto AdvicegrafpapÎncă nu există evaluări

- Daewoo Matiz 1 EngineDocument20 paginiDaewoo Matiz 1 Enginecharles100% (33)

- FDRB538UK SuperimpactorDocument12 paginiFDRB538UK SuperimpactordanieljcopleyÎncă nu există evaluări

- General MaintenanceDocument14 paginiGeneral MaintenanceJames HavocÎncă nu există evaluări

- Mechanical Interview Questions - V10Document231 paginiMechanical Interview Questions - V10JitheshÎncă nu există evaluări

- Toyota Code P0171Document3 paginiToyota Code P0171Bhanuka Srikantha100% (1)

- VW 1.4L TSI Engine - SSP - 359Document64 paginiVW 1.4L TSI Engine - SSP - 359freefly286% (7)

- Speccifications 1Document236 paginiSpeccifications 1garage ô tô CarmaxÎncă nu există evaluări

- MT GX670 PDFDocument274 paginiMT GX670 PDFEdar Jhon Montenegro RimarachinÎncă nu există evaluări

- H1 Service ManualDocument864 paginiH1 Service ManualFrank Ch Ccaico50% (2)

- EcDocument143 paginiEcTomas FleitasÎncă nu există evaluări

- Uuuuuuuuuuuuuuuuu: General Maintenance InformationDocument39 paginiUuuuuuuuuuuuuuuuu: General Maintenance InformationGuillermo A. Comba100% (1)

- Spare Parts Catalogue D2205963 43 SerieDocument204 paginiSpare Parts Catalogue D2205963 43 SerieRuwinda BandaraÎncă nu există evaluări

- VWvortex Forums - DIY - Oil Breather - Catch CanDocument34 paginiVWvortex Forums - DIY - Oil Breather - Catch Canapi-3739501100% (1)

- Alto JDM 660Document92 paginiAlto JDM 660Aatif_Saif_80Încă nu există evaluări

- VW Aircooled Engine1Document29 paginiVW Aircooled Engine1Antonio Daros90% (10)

- 99 9-5 2.3T Head Gasket Replacement - SaabCentral ForumsDocument3 pagini99 9-5 2.3T Head Gasket Replacement - SaabCentral ForumsDerrick ChongÎncă nu există evaluări

- Chapter 9Document18 paginiChapter 9broÎncă nu există evaluări

- Hego Obdii FordDocument17 paginiHego Obdii FordIchigo KurosakiiÎncă nu există evaluări

- Toyota NR Series EnginesDocument18 paginiToyota NR Series EnginesHortodoxocs50% (2)