Documente Academic

Documente Profesional

Documente Cultură

Nueva Vertical Multietapas

Încărcat de

Miick NuñeezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Nueva Vertical Multietapas

Încărcat de

Miick NuñeezDrepturi de autor:

Formate disponibile

e-SV

Nueva vertical multietapas.

Marketing: Training Kit for Level 1&2

Print Collaterals & PDFs Hardware Components

Commercial Brochure Impeller & Diffuser

Technical Catalogue Mechanical Seal

Flash drive Containing i-AlertTM

- Power Point presentation Selection Software CD

- Instructional video

- PDFs for additional print materials

2 Different Training Kits:

1 for EMEA & APR

1 for Americas

e-SV - Training 20-21/07/2010 2

Marketing: Launch

Web:

E-mail/Online Marketing: Video:

e-SV - Training 20-21/07/2010 3

Marketing: Launch

Advertising Campaign:

Media Plan:

Online and print publications targeting municipal, industrial and consulting engineers

Online and print publications targeting end-user, light-industry and vertical markets

Social media (YouTube, Google video, professional groups online, etc.)

Trade fair publications

e-SV - Training 20-21/07/2010 4

e-SV: Principales Caractersticas

e significa: energy-saving, eco-friendly y extra-efficiency

Mejoras clave:

Rango ms amplio: 11 modelos (1,3,5,10,15,22,33,46,66,92,125SV)

Mayor eficiencia: >10% Vs actual SV2-16

Menor NPSH

Nuevas versiones especiales: Bajo NPSH & Alta Temperatura

Sello mecnico fcil de reparar

Tiempos de entrega ms cortos : 3-5 das

Coincidencias con SV actual

Altura de flanges

Motores y sellos mecnicos estndar.

e-SV - Training 20-21/07/2010 5

e-SV: Lnea

1SV 3SV 5SV 10SV 15SV 22SV 33SV 46SV 66SV 92SV 125SV

Modelos existentes

e-SV - Training 20-21/07/2010 6

e-SV 1-22 Nomenclatura

Material / Conexin / Presin Nominal

F - AISI 304 Round Flanges PN 25

G - AISI 304 Cast Iron Pump Housing Round Flanges PN 25 (Standard for APR and US)

T - AISI 304 Oval Flanges PN 16

R - AISI 304 Round Flanges PN 25 Bottom Suction/Top Discharge

N - AISI 316 Round Flanges PN 25

V - AISI 316 Victaulic connections PN 25

P - AISI 316 Victaulic connections PN 40

Rango Familia C - AISI 316 Clamp DIN 32676 connections PN 25

S Stainless Steel K AISI 316 Threaded DIN 11851 (sanitary) connections PN 25

Global V-Vertical Multistage

22SV 02FL 05526T

Flujo m/h Numero de Impulsores Tipo Motor

Potencia Motor Phase Code

1

3 (kW x 10) 1 M

5 3 T

10

15 Opcional Motor Frequency

22 Configuraciones Especiales 50Hz

L Round Flanges PN 25 Low NPSH Available For F,N 6 60Hz

H Round Flanges PN 25 High Temperature Available for F,N

D Clean and Dry Available For F,N,V,C,K

E Passivated & Electro Polished Available For N,V,C,K Numero Polos

2 Poles

4 4 Poles

e-SV - Training 20-21/07/2010 7

e-SV 33-125 Nomenclatura

Material / Conexin

G - AISI 304 Cast Iron Pump Housing Round Flanges

Rango familia N - AISI 316 Round Flanges

S Stainless Steel P - AISI 316 Round Flanges PN40

Global V-Vertical Multistage

1 2 5 S V 4/4A G L 0 5 5 2 6 T

Flujo m/h Nmero de Impulsores Tipo Motor

Potencia Motor Phase Code

33

46 (kW x 10) 1 M

66 3 T

Numero de Impulsores Reducidos

92

125 Frecuencia Motor

Optional 50Hz

Configuraciones Especiales 6 60Hz

L Round Flanges Low NPSH Available For G,N

H Round Flanges High Temperature Available for G,N

D Clean and Dry Available For N

Nmero de Polos

2 Poles

E Passivated & Electro Polished Available For N

4 4 Poles

e-SV - Training 20-21/07/2010 8

Principales Beneficios: Mayor Eficiencia Hidrulica

Curvas de Eficiencia en 50Hz

Q [l/min]

0 100 200 300 400

80

e-SV

70

SV

60

h [%]

50

40

30

0 5 10 15 20 25

Q [m 3/h]

1 22

e-SV

2 16

SV

e-SV - Training 20-21/07/2010 9

Principales Beneficios: Mayor Eficiencia Hidrulica

Curvas de Eficiencia en 50Hz

Q [l/min]

0 500 1000 1500 2000 2500 3000

85

e-SV

75

65

h [%]

55

45

35

0 20 40 60 80 100 120 140 160 180

33 Q [m3/h] 125

e-SV

e-SV - Training 20-21/07/2010 10

Principales Beneficios: Menor NPSH

Curvas de NPSH en 50Hz

Q [m3/h]

0 5 10 15 20 25 30

7

22SV

6

1SV 10SV

5 3SV

15SV

NPSH [m]

4

SV16

SV4 SV8

3

5SV

SV2

2

0

0 100 200 300 400 500

Q [l/min]

e-SV - Training 20-21/07/2010 11

Principales Beneficios: Mejoras en Diseo

Diseo de Producto

1-3-5 SV 10-15-22 SV 125 SV

e-SV - Training 20-21/07/2010 12

Principales Beneficios: Mejoras en Diseo

Principales Diferencias en Diseo

Tapn de llenado superior con venteo

disponible.para todos los modelos.

Un 2do tapn se agrega a partir del

tamao 10SV

Es asiento del O-Ring es diseado

para facilitar desensamble de camisa

exterior (superior & inferior)

Anillos de desgaste en difusores

son flotantes para autoalineado

(Tecnopolmero PPS vidreado para

resistir lquidos qumicamente

corrosivos y mecnicamente agresivos,

as como altas temperaturas)

e-SV - Training 20-21/07/2010 13

Principales Beneficios: Mejoras en Diseo

Principales Diferencias en Diseo

Cojinete intermedio de material duro

(Carburo de Tungsteno) para mejorar

duracin y habilidad para resistir

aplicaciones pesadas, como

alimentacin de calderas.

Cuerpo de bomba en Fierro Fundido

disponible para las Americas.

e-SV - Training 20-21/07/2010 14

Principales Beneficios: Mejoras en Diseo

Principales Diferencias en Diseo

Sello mecnico EN 12756 reemplazable sin necesidad de desmontar el

motor ( para 10-22SV con motor 5.5kW o motor sobre 30kg)

e-SV - Training 20-21/07/2010 15

Principales Beneficios: Mejoras en Diseo

Diseo de Impulsor Balanceado: Patente en proceso Curvas de empuje axial en 50Hz

Q [m3/h]

0 5 10 15 20 25 30

350

300

Impulsor estndar SV16

250

Axial thrust [N]

200

SV8 15SV

150

10SV

100

SV4

F 50 SV2

5SV

Impulsor Balanceado 3SV

0

0 50 100 150 200 250 300 350 400 450 500

Q [l/min]

Menor empuje axial del impulsor, logrando mayor vida til

en cojinetes de motor estndar (17,500h)

0.6F

e-SV - Training 20-21/07/2010 16

Principales Beneficios: Mejoras en Diseo

Amplia gama en opciones de conexin: 1-22SV

Bridas circulares

Versin F & N

Conexiones Bridadas ms

comunes.

Kid de Contra-Bridas (EN 1092-1)

-AISI 304

-AISI 316L

disponibles como accesorio.

Versin R

Contra-bridas no estn

disponibles en el embalaje de

la bomba.

e-SV - Training 20-21/07/2010 17

Principales Beneficios: Mejoras en Diseo

Amplia gama en opciones de conexin: 1-22SV

T: Bridas ovaladas

Standard supply (included with the pump)

- AISI 304L stainless steel

C: Conexiones tipo abrazadera (clamp)

DN 32 en 1-3-5SV

DN 50 en 10-15-22SV

Kit de acoples tipo abrazadera disponible a pedido

Kit con 2 acoples tipo abrazadera con camisa en AISI 316L

soldada o roscada, ms empaquetadura de EPDM o FPM

Dimensiones y forma acople de acuerdo a DIN 32676

e-SV - Training 20-21/07/2010 18

Principales Beneficios: Mejoras en Diseo

Amplia gama en opciones de conexin: 1-22SV

V: Conexin tipo Victaulic

DN 32 en 1-3-5SV

DN 50 en 10-15-22SV

Kit de acople Victaulic desponible a pedido

Kit con 1 acople Victaulic con camisa en AISI316L

soldada o roscada, ms empaquetadura de EPDM o

FPM.

K: Conexiones roscadas DIN 11851

Disponible solo para bombas AISI 316L

DN 32 en 1-3-5SV

DN 50 en 10-15-22SV Nuevo

Diseada para uso en amplia gama de

aplicaciones industriales.

Kit the contra-bridas puede ser

desarrollado a pedido.

e-SV - Training 20-21/07/2010 19

Principales Beneficios: Mejoras en Diseo

Opciones de conexin : 125SV

Bridas circulares

Versin G & N

PN16 para 125SV desde 7,5kW a

45kW

PN25 para 125SV 55kW

Kit de contra-bridas (EN 1092-1)

conteniendo 2 contrabridas con

pernos y empaquetaduras.

-Versiones G: contra-bridas

soldadas, en acero

galvanizado.

-Versiones N: contra-bridas

soldadas en AISI 316L

disponibles como accesorio.

e-SV - Training 20-21/07/2010 20

Principales Beneficios : Motores de Mayor Eficiencia

Nivel de Eficiencia en 2 Polos Monofsico

85

80

SV 1~ 50 Hz 2 Poles

Efficincy [%]

75

70

e-SV 1~ 50 Hz 2 Poles

65

60

0 0,5 1 1,5 2 2,5

Motor Power [kW]

Todos los motores de e-SV han sido re-

testeados

Motores monofsicos no han sido rediseados

e-SV - Training 20-21/07/2010 21

Principales Beneficios : Motores de Mayor Eficiencia

Nivel de Eficiencia en 2 Polos Trifsico 50Hz

95

90

Motor fabricacin externa de Alta Eficiencia

85

SV 3~ 50 Hz 2 Poles

Efficincy [%]

80

75

e-SV 3~ 50 Hz 2 Poles

70

65

Motores Lowara

60

0 10 20 30 40 50 60

0,75 Motor Power [kW]

IE2

Todos los motores e-SV cumplen con IE2

Disponibles a pedido dos motores de Alta Eficiencia: 0,37kW & 0,55kW

Nuevos motores de Alta Eficiencia desde 0,75kW a 2,2kW

e-SV - Training 20-21/07/2010 22

Principales Beneficios: i-Alert

i-Alert Monitoreo de Condicin

Nuevo en el mercado

Todas lase-SV (1-3-5-10-15-22SV & 125SV) 7,5kW estn

equipadas con i-AlertTM

Para los otros modelos puede ser suministrado a pedido como

accesorio.

i-AlertTM sirve para reducir el Costo de Ciclo de Vida al

aumentar el tiempo medio entre fallas (MTBF)

Caractersticas

Continuamente mide vibracin observando respuestas del motor y la bomba durante la operacin.

Si se exceden lmites pre-seteados el dispositivo de monitoreo alerta al usuario final via un led rojo

parpadeante.

El i-Alert est equipado con un LED verde para indicar cuando est operacional y tiene suficiente batera.

Modo de Alarma

El monitor entra en modo de alarma cuando los lmites de vibracin son excedidos sobre dos lecturas

consecutivas, dentro de un perodo de diez minutos.

Lmite de Vibracin: Aumento de 100% sobre lnea base o max. nivel de vibracin de 12,7 mm/sec

Nivel mnino de vibracin para gatillar modo de alarma es de 3,175 mm/sec, para minimizar falsas seales.

e-SV - Training 20-21/07/2010 23

Principales Beneficios: i-Alert

i-Alert Monitoreo de Condicin

Seteo de Lnea Base

i-Alert esta listo para activarse cuando la bomba ha alcanzado un flujo, flujo,

presin y temperatura estable.

Coloque un pequeo magneto sobre el monitor frente al logo ITT y luego retirelo.

Cuando el monitor est activado el:

1. Despliega una serie de LEDs rojos, seguidos de un LED verde slido.

2. Colecta ocho registros espaciados en un segundo .

3. Promedia estas lecturas para establecer el nivel de vibracin base.

4. Parpadea un LED verde luego de aproximadamente doce segundos.

Mode de Monitoreo

Luego de que el proceso o condicin de la bomba que causa la alarma es corregido, el i-Alert retorna al

modo normal despus de un nivel de medicin normal.

e-SV - Training 20-21/07/2010 24

Principales Beneficios: i-Alert

i-Alert Monitoreo de Condicin

Vida de la Batera

La batera del i-ALERT no es reemplazable. Usted deber reemplazar la unidad completa una vez que

la batera se agote. La vida de la batera no est includa dentro de la garanta de la bomba.

Posibles causas de vibracin Estndares de Aprobacin del Producto

Air dentro del fludo de proceso. CSA certificacin

Flujo turbulento dentro del sistema. ATEX / IECEx:

Cojinetes gastados (bomba y/o motor) Grupo: IIC

Golpe de Ariete Categora: Ex ia

Anclajes sueltos Temperatura Clase: T4 (para ambiente hasta

100C)

Eje deformado o mal alineado

ATEX Marca: Ex II 1 G

Vibraciones Armnicas

Equipo rotatorio desbalanceado

e-SV - Training 20-21/07/2010 25

Principales Beneficios:Gran Posibilidad de Customizacin

Sellos Mecnicos:

1-3-5SV 10-15-22SV 5.5kW 125SV

10-15-22SV 4kW

Balanceados Balanceados

1 2 3 4 5

Rotating Face Stationary Face Elastomers Springs Other Temp.

Components Operations[C]

STANDARD Resin impregnated carbon

EPDM -30 +120

STANDARD OPTION 1 Silicon Carbide

STANDARD OPTION 2 Resin impregnated carbon

Silicon Carbide FPM AISI 316 AISI 316 -10 +120

STANDARD OPTION 3 Silicon Carbide

STANDARD OPTION 4* Special resin impregnated carbon

PTFE 0 +120

STANDARD OPTION 5* Silicon Carbide

* Versions with anti-rotation lockpin of the fixed part

Carburo de Tungsteno no es disponible

e-SV - Training 20-21/07/2010 26

Principales Beneficios:Gran Posibilidad de Customizacin

Motores:

Motor estndar de 4 polos:

til para tener bajo nivel de ruido

necesario cuando condiciones de succin son desventajosas

Motor con opcin de anti-condensacin para aplicaciones en condiciones de humedad.

Motor con proteccin de sobrecalentamiento, incorporando switches trmicos bimetlicos o

sensores PTC

Motor ATEX acoplado con bomba es parte de ZONA 2 CATEGORIA 3 y puede operar en

atmosferas explosivas (suministrado por distintos fabricantes de motores)

La direccin de la caja de conexiones del motor puedes ser ajustada.

Clase de encerramiento de motor alternativa (de acuerdo a IEC 60034-5): IP65

el motor es completamente a prueba de polvo

el motor es protegido contra agua proyectada por una boquilla desde cualquier direccin.

Voltajes especiales (ver proxima lmina)

e-SV - Training 20-21/07/2010 27

Principales Beneficios:Gran Posibilidad de Customizacin

Voltajes especiales disponibles a pedido:

50Hz 60Hz

/ Y / Y

110 / 190 110-115 / 190-200

200-208 / 346-360 200-208 / 346-360

230 / 400

220-240 / 380-415 Estndar 220-255 / 380-440

255-265 / 440-460 265-277 / 460-480

290-300 / 500-525 ----- / -----

----- / ----- 330-346 / 575-600

400 / 690

380-440 / 660

380 -415 / 660-690

440-460 / ----- 460-480 / -----

500 / ----- 575 / -----

e-SV - Training 20-21/07/2010 28

Principales Beneficios:Gran Posibilidad de Customizacin

Versin de Alta Presin:

Diseo de Doble camisa PN40 para 1-22SV &

125SV

Todos los modelos equipados con sellos

mecnicos balanceados

Aplicaciones:

Osmosis Inversa

Limpieza y Lavado

Alimentacin de Calderas

Filtracin

Las bombas e-SV de alta presin pueden usarse

como:

solucin de una bomba

solucin de 2 bombas

e-SV - Training 20-21/07/2010 29

Principales Beneficios:Gran Posibilidad de Customizacin

Versin Limpia & Seca (Clean & Dry Version):

Proceso de Produccin:

Todas las partes de la bomba son limpiadas en agua a 60-70C con un agente limpiante.

Todas las partes de la bomba son ejuagadas agua de-ionizada y secadas mediante aire.

La bomba es finalmente ensamblada y embalada en plstico libre de silicona.

Aplicaciones:

Todas las aplicaciones que requieren elevado nivel de higiene

La Performance y la presin de bomba versin limpia & seca no son testeadas.

Versin Electro pulida y Pasivada:

Proceso de produccin:

Este proceso remueve las rebabas y todas las inclusiones, proporcionando una superficie

limpia y resistente a la corrosin.

Aplicaciones:

Farmaceuticas

Bebidas y Alimentos

Cuando los materiales y calidad de superficie debe cumplir estrictos requerimientos de higiene

y/o resistencia a la corrosin.

e-SV - Training 20-21/07/2010 30

Principales Beneficios:Gran Posibilidad de Customizacin

Versin bajo NPSH:

3SV

Versin de bajo NPSH disponible

para 1-22SV

Impulsor 5SV

No disponible para 125SV

Estapa inicial 5SV Comparada con la versin

estndar, la etapa inicial y el primer

impulsor son distintos.

Aplicaciones:

Aplicaciones de alta temperatura (alimentacin de calderas)

Aplicaciones con baja presin en succin y/o aplicaciones de alto flujo.

Todas las aplicaciones con un elevado riesgo de cavitacin.

e-SV - Training 20-21/07/2010 31

Principales Beneficios:Gran Posibilidad de Customizacin

Versin de bajo NPSH:

Q [m3/h]

0 5 10 15 20 25 30

7

22SV

6

1SV 10SV

5 3SV

15SV

NPSH [m]

3 15-22SVL

5SV

2 10SVL

5SVL

3SVL

1

0 1SVL

0 100 200 300 400 500

Q [l/min]

e-SV - Training 20-21/07/2010 32

Principales Beneficios:Gran Posibilidad de Customizacin

Versin Horizontal:

Usada en aplicaciones por seguridad y/o requerimientos de ahorro de espacio.

- En zonas ssmicasIn earthquake areas the horizontal pumps dampen the oscillation of the pump

- In installation with limited access or space is recommended to improve installation and service

10-15-22SV

e-SV - Training 20-21/07/2010 33

Main Benefits: Wide Possibilities For Customization

High Temperature Version:

especially developed to operate with water at high temperatures (up to 150C)

Stainless Steel Base:

e-SV can be supplied with a stainless steel base for applications in aggressive areas

Elastomers:

as well as the EPDM elastomers used in the standard version, other materials are available to

satisfy specific customer requirements.

e-SV - Training 20-21/07/2010 34

Main Benefits: Wide Possibilities For Customization

Dry Run Sensor:

Is available as accessory

For the larger sizes (33 thru 125SV) a suitable adapter is

supplied with the product

is composed of a stainless steel body, a glass cap and a

connecting cable

can be mounted directly on filling plug of e-SV series pump

the sensor has been designed to be connected directly to

Hydrovar terminal block, X3

The sensor provides an electronic contact to be used for stopping the pump in case of lack of water in the

area of the mechanical seal

The contact opens after a factory set delay

Technical Data

Body: AISI 316L stainless steel. Liquids: Clean water, demineralized water Cable length = 2 meters

Optical Cap: Glass Power supply: 15-25 VDC Port: 38" ISO threads

Max pressure: 25 bar Output: NPN open collector Adapter: 38" "

Liquid temperature: 0-120C Alarm delay:10 s

e-SV - Training 20-21/07/2010 35

Spare Parts

e-SV - Training 20-21/07/2010 36

Forces And Moments On Flanges

e-SV - Training 20-21/07/2010 37

Proposicin de Creacin de Valor

Perspectiva Externa: Principal criterio de decisin de actores clave

Impacto Total

Principal criterio decisin OEM Distribuidor Instalador Diseador Usuario fin.

Alto Med Bajo

Precio de compra

Eficiencia/costo operativo

Ahorro energa

Confiabilidad

Mantencin/Garanta

Amistosa Medioambiente

Plazo entrega

Diagnsticos

Marca

Reduccin Costos Sistema

Soporte

Sistema compacto

Controles Alta Tecnologa

Muy Importante

No Importante

e-SV - Training 20-21/07/2010 38

Efficiency & Operating Cost

Best in class efficiency allows outstanding running cost savings for End-Users

End-User Running Cost Saving per Year

700

600

15SV Vs SV16

Assumptions

10SV Vs SV8

500 Running time: 6h per day

5SV Vs SV4 *365 days

400

Working point: BEP

[]

Cost of electricity:

300

0.15/kWh

3SV Vs SV2

200

100

0

1 3 5 7 9 11 13 15 17 19 21 23 25 27

N of Stages

e-SV - Training 20-21/07/2010 39

Efficiency & Operating Cost

Pay-back period for End-Users

Typical SV value chain

Players Suppliers Wholesale Installer End-user

High Medium High if smooth

Margins installation

Typical Application

110

15 125

Added value 10

100

SV () Assumptions

x

5% price premium for e-SV

WS margin is 10%

Installer Margin unchanged

e-SV value chain

Typical Application

110

15 130.5

Added value 10.5

105

e-SV ()

x

e-SV - Training 20-21/07/2010 40

Efficiency & Operating Cost

Pay-back period for End-Users

End-User Pay Back Period

1,6

1,4

15SV Vs SV16

1,2 Assumptions

Running time: 6h per day

1,0

*365 days

[Y]

0,8 Working point: BEP

Cost of electricity:

0,6

0.15/kWh

10SV Vs SV8

0,4

3SV Vs SV2

0,2

5SV Vs SV4

0,0

1 3 5 7 9 11 13 15 17 19 21 23 25 27

N of Stages

e-SV - Training 20-21/07/2010 41

Energy Saving & Environmental Friendliness

Key driver impacting our business: LEGISLATION

Hierarchy of Legal Frameworks Up-Coming EU Directives

Kyoto Protocol

1997 Reduction Of CO2 Emissions

UN By 5% (2012 Vs. 1990) Min. 20% Reduction Of GHG

Emissions By 2020 Compared To 1990

E 2007 EU Council Endorsed The Min. 20% Savings On EU Energy

U Energy Package Consumption By 2020

Min. 20% Of Share Of RE In The Overall

Creation Of EU Directives Energy Mix By 2020

EU +

country 2009 And Translation Into National

Law

e-SV contribute reducing EU Energy consumption and GHG Emissions

e-SV - Training 20-21/07/2010 42

Energy Saving & Environmental Friendliness

Assumptions for EU Energy flow

Energy generation Transport At the end-user location

GHG Primary Transfor- Useable Final Transfor- Energy

Emissions Energy mation Energy Energy mation Needed

g/kWh (6) (7) (4), (5) (3) (2) (1)

417

337

500 333 333

PE

428 =2,5

PE

(4)

367 =2,02

(5)

Exhaustible

Primary Power 167 167

250 167 Energy Plant 167

Year

2000 Year

2010 100

Electricity Electricity

Pump

efficiency

60%

0 0 0

(1) Eta=60%

(2) Final enrgy needed to run the pump

(3) Transpo rt impact is neglected but included in GHG emissio n ratio

(4) A ssumptio n is a P rimary Energy ratio o f 2,5 per the "Service Directive"

(5) A ssumptio n is the EU-28 (2010) P rimary Energy ratio (P E=2,02) fro m GEM IS database (ko Institute)

(6) B ased o n GEM IS versio n 4.42, dataset "El-kw-park-EU-28-2000" (428 g/kWh)

(7) B ased o n GEM IS versio n 4.42, dataset "El-kw-park-EU-28-2010" (367 g/kWh)

e-SV - Training 20-21/07/2010 43

Energy Saving & Environmental Friendliness

e-SV Vs SV: Primary Energy Saving

Primary Energy Saving per Year

45%

40%

35%

5SV Vs SV4 Assumptions

30%

Running time: 6h per day

25% *365 days

Working point: BEP

20%

Cost of electricity:

3SV Vs SV2

15% 0.15/kWh

10SV Vs SV8

Primary Energy Ratio: 2.5

10%

15SV Vs SV16

5%

0%

1 3 5 7 9 11 13 15 17 19 21 23 25 27

N of Stages

e-SV - Training 20-21/07/2010 44

Energy Saving & Environmental Friendliness

e-SV Vs SV: Reduction of GHG Emissions

Reduction of GHG Emissions per Year

45%

40%

35%

Assumptions

5SV Vs SV4

30% Running time: 6h per day

*365 Days

25%

Working point: BEP

20% Cost of electricity:

3SV Vs SV2 0.15/kWh

15%

Primary Energy Ratio: 2.5

10SV Vs SV8

10% El-kw-park-EU-28-2010:

15SV Vs SV16 367 g/kWh

5%

0%

1 3 5 7 9 11 13 15 17 19 21 23 25 27

N of Stages

e-SV - Training 20-21/07/2010 45

Reliability

Laser welding technology:

Less deformation of welded components, due to lower thermal energy needed for the welding

procedure

Reduced thickness of weld area, which means lower change of the material properties; the result is

a lower surface area exposed to the attack of chemical/aggressive agents

Better mechanical resistance (bending, torsion) in joints and flanges Milliseconds long pulses are

used to weld thin materials such as razor blades while continuous laser systems are employed for

deep welds

Small heat-affected zones

Cavitation stress tests:

e-SV withstands cavitation stress test resulting in outstanding reliability

600Hours @ 70Hz cavitation conditions

Reliability test with water & sand :

e-SV withstands this test without loosing any performance

.200 Hours @50Hz using water with 500g/mq of sand

e-SV - Training 20-21/07/2010 46

Maintenance

New design to replace mechanical seal:

The new design allow to save up to 50% of the

maintenance required time

New design to easily disassemble the pump:

The new design allow to considerably reduce the

disassemble required time

e-SV - Training 20-21/07/2010 47

Diagnostic

Dry-run Sensor: i-AlertTM:

Continuously measures vibration

Can be mounted directly on filling plug If pre-set limits are exceeded the monitoring

Has been designed to be connected directly to device alerts the end-user via blinking red LED

Hydrovar terminal block, X3 Single green LED indicate when it is

Stop the pump in case of lack of water in the operational and has sufficient battery life

area of the mechanical seal.

Dry-run Sensor and i-AlertTM

allow to reduce life cycle costs by increasing Mean Time Between Failures (MTBF)

e-SV - Training 20-21/07/2010 48

How To Replace Current SV With e-SV

Q [m 3/h]

0 1 2 3 4 5 6 7 8 9

250

SV 4 Vs 5SV 50Hz Operating Characteristic SV533-5.5kW - SV4 - 50Hz

- 5SV - 50Hz

SV424-4kW

Equivalent Pumps are not fully SV528-4kW

comparable in terms of performance

200

curves

The selection of the new e-SV pump

SV418-3kW

should be based on the duty point that can

not be known upfront SV521-3kW

150

H [m]

SV413-2.2kW

SV516-2.2kW

100

SV409-1.5kW

SV511-1.5kW

The following cross reference charts SV407-1.1kW

SV508-1.1kW

are based on the assumption that the 50

duty point is close to the BEP (Best SV505-0.75kW

SV404-0.75kW

Efficiency Point) SV504-0.55kW

SV403-0.55kW

SV503-0.37kW

SV402-0.37kW

0

0 20 40 60 80

BEP

Q [l/m in]

100 120 140 160

e-SV - Training 20-21/07/2010 49

How To Replace Current SV With e-SV

SV2 Vs 3SV 50Hz

Current SV Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

Model Power [m3/h] 3m3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 3m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

SV202 0,37 4,2 13 21,5 285 209 494 3SV03 0,37 4,4 17 22 278 209 487

SV203 0,37 4,2 19 32 310 209 519 3SV04 0,37 4,4 21 29 298 209 507

SV204 0,55 4,2 26 42,5 335 231 566 3SV05 0,55 4,4 30 38 318 231 549

SV205 0,75 4,2 32 53,5 370 226 596 3SV06 0,55 4,4 35 44 338 231 569

SV206 0,75 4,2 39 64 395 226 621 3SV07 0,75 4,4 42 52 368 263 631

SV207 1,1 4,2 45 75 420 263 683 3SV08 0,75 4,4 48 60 388 263 651

SV208 1,1 4,2 52 85,5 445 263 708 3SV09 1,1 4,4 55 68 408 263 671

SV209 1,1 4,2 58 96 470 263 733 3SV10 1,1 4,4 60 76 428 263 691

SV211 1,5 4,2 71 117 530 263 793 3SV12 1,1 4,4 71 90 468 263 731

SV212 1,5 4,2 78 128 555 263 818 3SV13 1,5 4,4 79 98 498 298 796

SV214 2,2 4,2 90 150 605 263 868 3SV16 1,5 4,4 96 120 558 298 856

SV216 2,2 4,2 103 171 655 263 918

3SV19 2,2 4,4 117 145 618 298 916

SV218 2,2 4,2 116 192 705 263 968

SV220 3 4,2 129 214 765 298 1063 3SV21 2,2 4,4 128 160 658 298 956

SV222 3 4,2 142 235 815 298 1113 3SV25 2,2 4,4 150 189 738 298 1036

SV224 3 4,2 155 256 865 298 1163 3SV27 3 4,4 163 205 788 298 1086

Note:

- L1 is the height of the pump without the motor

The new e-SVs have:

- L2 is the height of the Motor (~3)

Equal or Lower Nominal Power

Higher Q max

Lower L1+L2

e-SV - Training 20-21/07/2010 50

How To Replace Current SV With e-SV

SV4 Vs 5SV 50Hz

Current SV Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

Model Power [m3/h] 5,4m3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 5,4m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

SV402 0,37 8 12 20 285 209 494 5SV02 0,37 8,5 11 15 268 209 477

SV403 0,55 8 17 30 310 231 541 5SV03 0,55 8,5 18 22 293 231 524

SV404 0,75 8 23 40 345 226 571 5SV04 0,55 8,5 23 30 318 231 549

SV405 1,1 8 29 50 370 263 633 5SV05 0,75 8,5 30 38 353 263 616

SV406 1,1 8 36 60 395 263 658 5SV06 1,1 8,5 36 45 378 263 641

SV407 1,1 8 42 70 420 263 683 5SV07 1,1 8,5 42 53 403 263 666

SV408 1,5 8 47 80 455 263 718 5SV08 1,1 8,5 47 60 428 263 691

SV409 1,5 8 54 90 480 263 743 5SV09 1,5 8,5 54 68 463 298 761

SV411 2,2 8 66 111 530 263 793 5SV11 1,5 8,5 65 82 513 298 811

SV413 2,2 8 77 131 580 263 843 5SV13 2,2 8,5 77 98 563 298 861

SV414 3 8 83 141 615 298 913 5SV14 2,2 8,5 83 106 588 298 886

SV416 3 8 95 161 665 298 963 5SV16 2,2 8,5 95 120 638 298 936

SV418 3 8 107 181 715 298 1013 5SV18 3 8,5 108 136 698 298 996

SV420 4 8 118 201 765 319 1084 5SV21 3 8,5 123 158 773 298 1071

SV422 4 8 130 221 815 319 1134 5SV23 4 8,5 138 175 823 319 1142

SV424 4 8 142 241 865 319 1184 5SV25 4 8,5 149 190 873 319 1192

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3) The new e-SVs have:

Equal or Lower Nominal Power

Higher Q max

L1+L2 is almost equal

e-SV - Training 20-21/07/2010 51

How To Replace Current SV With e-SV

SV8 Vs 10SV 50Hz

Current SV Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

Model Power [m3/h] 10m3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 10m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

SV802 1,1 14 21 27 363 263 626 10SV03 1,1 14 27 37 389 263 652

SV803 1,5 14 31 41 411 263 674 10SV04 1,5 14 36 48 431 298 729

SV804 2,2 14 42 55 449 263 712 10SV05 2,2 14 46 60 463 298 761

SV805 2,2 14 52 68 487 263 750 10SV06 2,2 14 55 72 495 298 793

SV806 3 14 63 82 535 298 833 10SV07 3 14 64 83 537 298 835

SV808 4 14 83 110 611 319 930 10SV09 4 14 84 109 601 319 920

SV809 4 14 92 123 649 319 968 10SV10 4 14 92 120 633 319 952

SV811 5,5 14 112 150 745 375 1120 10SV13 5,5 14 119 157 796 375 1171

SV812 5,5 14 123 164 783 375 1158 10SV15 5,5 14 136 180 860 375 1235

SV814 7,5 14 144 192 859 367 1226 10SV17 7,5 14 159 205 924 367 1291

SV816 7,5 14 164 220 935 367 1302 10SV18 7,5 14 168 218 956 367 1323

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Equal Nominal Power

Equal Q max

Higher L1+L2 due to the new motor adaptor that allow to replace the

mechanical seal without disassembling the motor (for the models

>5.5kW)

e-SV - Training 20-21/07/2010 52

How To Replace Current SV With e-SV

SV16 Vs 15SV 50Hz

Current SV Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

Model Power [m3/h] 16m3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 16m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

SV1602 2,2 24 28 35 383 263 646 15SV03 3 24 35 43 467 298 765

SV1603 3 24 41 52 431 298 729 15SV04 4 24 47 58 515 319 834

SV1604 4 24 55 69 469 319 788 15SV05 4 24 58 72 563 319 882

SV1605 5,5 24 68 86 527 375 902 15SV06 5,5 24 73 90 678 375 1053

SV1606 5,5 24 83 104 565 375 940 15SV07 5,5 24 84 103 726 375 1101

SV1607 7,5 24 96 121 603 367 970 15SV08 7,5 24 98 120 774 367 1141

SV1608 7,5 24 109 138 641 367 1008 15SV09 7,5 24 110 135 822 367 1189

SV1610 11 24 137 173 749 428 1177 15SV11 11 24 137 165 948 428 1376

SV1612 11 24 165 207 825 428 1253 15SV13 11 24 161 195 1140 428 1568

SV1614 15 24 192 242 901 494 1395

15SV17 15 24 209 252 1236 494 1730

SV1615 15 24 205 260 939 494 1433

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Equal or Higher Nominal Power

Equal Q max

Higher L1+L2 due to the new motor adaptor that allow to replace the

mechanical seal without disassembling the motor (for the models

>5.5kW)

e-SV - Training 20-21/07/2010 53

How To Replace Grundfos CR With e-SV

Q [m3 /h]

0 1 2 3 4 5 6 7 8 9

CR5 Vs 5SV 50Hz Operating Characteristic 5SV-33-5.5kW

CR5-36 -5.5kW

- CR5 - 50Hz

- 5SV - 50Hz

250

5SV-28-4kW

Equivalent Pumps are comparable in CR5-29 -4kW

200

terms of performance curves

The selection of the new e-SV pump is

based on the Best Efficiency Point (BEP) 5SV-21-3kW

150

CR5-20 -3kW

H [m]

5SV-16-2.2kW

CR5-16 -2.2kW

100

5SV-11-1.5kW

CR5-10 -1.5kW

5SV-08-1.1kW

CR5-8 -1.1kW

50

5SV-05-0.75kW

CR5-5 -0.75kW

5SV-04-0.55kW

CR5-4 -0.55kW

CR5-2 -0.37kW

0

0 20 40 60 80

BEP

100 120 140 160

Q [l/min]

e-SV - Training 20-21/07/2010 54

How To Replace Grundfos CR With e-SV

CRN1 Vs 1SV 50Hz

Grundfos Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

CR Model Power [m 3/h] 1,7m 3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 1,7m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

CRN1-2 0,37 2,4 13 14 282 191 473 1SV03 0,37 2,4 14 18 278 209 487

CRN1-3 0,37 2,4 18 19 282 191 473 1SV05 0,37 2,4 22 29 318 209 527

CRN1-4 0,37 2,4 20 25 300 191 491 1SV05 0,37 2,4 22 29 318 209 527

CRN1-5 0,37 2,4 25 31 318 191 509 1SV06 0,37 2,4 26 35 338 209 547

CRN1-6 0,37 2,4 30 38 336 191 527 1SV07 0,37 2,4 30 40 358 209 567

CRN1-7 0,37 2,4 33 42 354 191 545 1SV08 0,55 2,4 37 40 378 231 609

CRN1-8 0,55 2,4 40 50 372 191 563 1SV09 0,55 2,4 42,5 54 398 231 629

CRN1-9 0,55 2,4 43 55 390 191 581 1SV09 0,55 2,4 42,5 54 398 231 629

CRN1-10 0,55 2,4 48 60 408 191 599 1SV11 0,55 2,4 51 65 438 231 669

CRN1-11 0,55 2,4 51 68 426 191 617 1SV11 0,55 2,4 51 65 438 231 669

CRN1-12 0,75 2,4 58 73 450 231 681 1SV12 0,75 2,4 60 74 468 263 731

CRN1-13 0,75 2,4 62 80 468 231 699 1SV13 0,75 2,4 65 79 488 263 751

CRN1-15 0,75 2,4 70 92 504 231 735 1SV15 0,75 2,4 73 91 528 263 791

CRN1-17 1,1 2,4 82 104 540 231 771 1SV17 1,1 2,4 82,5 105 568 263 831

CRN1-19 1,1 2,4 91 118 576 231 807 1SV19 1,1 2,4 88 117 608 263 871

CRN1-21 1,1 2,4 100 128 612 231 843 1SV22 1,1 2,4 110 134 668 263 931

CRN1-23 1,1 2,4 109 140 648 231 879 1SV22 1,1 2,4 110 134 668 263 931

CRN1-25 1,5 2,4 123 155 700 281 981 1SV25 1,5 2,4 125 152 738 298 1036

CRN1-27 1,5 2,4 132 168 736 281 1017 1SV27 1,5 2,4 135 164 778 298 1076

CRN1-30 1,5 2,4 148 185 790 281 1071 1SV30 1,5 2,4 148 181 838 298 1136

CRN1-33 2,2 2,4 166 205 844 321 1165 1SV34 2,2 2,4 172 210 918 298 1216

CRN1-36 2,2 2,4 180 223 898 321 1219 1SV37 2,2 2,4 189 225 978 298 1276

Note:

The new e-SVs have:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3) Equal Nominal Power

Equal Q max

L1+L2 is almost equal

e-SV - Training 20-21/07/2010 55

How To Replace Grundfos CR With e-SV

CRN3 Vs 3SV 50Hz

Grundfos Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

CR Model Power [m 3/h] 3,1m 3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 3m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

CRN3-2 0,37 4,5 8 13 282 191 473 3SV02 0,37 4,4 12 17,5 278 209 487

CRN3-3 0,37 4,5 12 20 282 191 473 3SV02 0,37 4,4 12 17,5 278 209 487

CRN3-4 0,37 4,5 16 28 300 191 491 3SV03 0,37 4,4 17 22 278 209 487

CRN3-5 0,37 4,5 22 32 318 191 509 3SV04 0,37 4,4 21 29 298 209 507

CRN3-6 0,55 4,5 27 40 336 191 527 3SV05 0,55 4,4 30 38 318 231 549

CRN3-7 0,55 4,5 30 47 354 191 545 3SV06 0,55 4,4 35 44 338 231 569

CRN3-8 0,75 4,5 38 52 378 231 609 3SV07 0,75 4,4 42 52 368 263 631

CRN3-9 0,75 4,5 42 60 396 231 627 3SV07 0,75 4,4 42 52 368 263 631

CRN3-10 0,75 4,5 45 65 414 231 645 3SV08 0,75 4,4 48 60 388 263 651

CRN3-11 1,1 4,5 50 72 432 231 663 3SV09 1,1 4,4 55 68 408 263 671

CRN3-12 1,1 4,5 55 80 450 231 681 3SV09 1,1 4,4 55 68 408 263 671

CRN3-13 1,1 4,5 60 86 468 231 699 3SV10 1,1 4,4 60 76 428 263 691

CRN3-15 1,1 4,5 68 98 504 231 735 3SV12 1,1 4,4 71 90 468 263 731

CRN3-17 1,5 4,5 80 112 556 281 837 3SV13 1,5 4,4 79 98 498 298 796

CRN3-19 1,5 4,5 90 125 592 281 873 3SV16 1,5 4,4 96 120 558 298 856

CRN3-21 2,2 4,5 100 140 628 321 949

3SV19 2,2 4,4 117 145 618 298 916

CRN3-23 2,2 4,5 111 153 664 321 985

CRN3-25 2,2 4,5 120 167 700 321 1021 3SV21 2,2 4,4 128 160 658 298 956

CRN3-27 2,2 4,5 129 179 736 321 1057 3SV21 2,2 4,4 128 160 658 298 956

CRN3-29 2,2 4,5 138 192 772 321 1093 3SV23 2,2 4,4 140 175 698 298 996

CRN3-31 3 4,5 150 208 813 335 1148 3SV25 2,2 4,4 150 189 738 298 1036

CRN3-33 3 4,5 160 220 849 335 1184 3SV27 3 4,4 163 205 788 298 1086

CRN3-36 3 4,5 172 240 903 335 1238 3SV29 3 4,4 175 220 828 298 1126

Note:

The new e-SVs have:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3) Equal or Lower Nominal Power

Equal Q max

L1+L2 is almost equal

e-SV - Training 20-21/07/2010 56

How To Replace Grundfos CR With e-SV

CRN5 Vs 5SV 50Hz

Grundfos Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

CR Model Power [m 3/h] 6m 3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 5,7m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

CRN5-2 0,37 9 10 13 282 191 473 5SV02 0,37 8,5 11 15 268 209 477

CRN5-3 0,55 9 14 20 309 191 500 5SV03 0,55 8,5 18 22 293 231 524

CRN5-4 0,55 9 16 28 336 191 527 5SV03 0,55 8,5 18 22 293 231 524

CRN5-5 0,75 9 22 34 369 231 600 5SV04 0,55 8,5 23 30 318 231 549

CRN5-6 1,1 9 27 40 396 231 627 5SV05 0,75 8,5 30 38 353 263 616

CRN5-7 1,1 9 30 48 423 231 654 5SV05 0,75 8,5 30 38 353 263 616

CRN5-8 1,1 9 35 53 450 231 681 5SV06 1,1 8,5 36 45 378 263 641

CRN5-9 1,5 9 42 60 493 281 774 5SV07 1,1 8,5 42 53 403 263 666

CRN5-10 1,5 9 48 68 520 281 801 5SV08 1,1 8,5 47 60 428 263 691

CRN5-11 2,2 9 51 75 547 321 868 5SV09 1,5 8,5 54 68 463 298 761

CRN5-12 2,2 9 60 82 574 321 895 5SV11 1,5 8,5 65 82 513 298 811

CRN5-13 2,2 9 64 88 601 321 922 5SV11 1,5 8,5 65 82 513 298 811

CRN5-14 2,2 9 69 95 628 321 949 5SV12 2,2 8,5 70 90 538 298 836

CRN5-15 2,2 9 72 102 655 321 976 5SV13 2,2 8,5 77 98 563 298 861

CRN5-16 2,2 9 79 108 682 321 1003 5SV14 2,2 8,5 80 106 588 298 886

CRN5-18 3 9 90 122 741 335 1076 5SV16 2,2 8,5 95 120 638 298 936

CRN5-20 3 9 100 138 795 335 1130 5SV18 3 8,5 108 136 698 298 996

CRN5-22 4 9 112 150 849 372 1221 5SV21 3 8,5 123 158 773 298 1071

CRN5-24 4 9 122 164 903 372 1275 5SV21 3 8,5 123 158 773 298 1071

CRN5-26 4 9 130 178 957 372 1329 5SV23 4 8,5 138 175 823 319 1142

CRN5-29 4 9 148 198 1038 372 1410 5SV25 4 8,5 149 190 873 319 1192

CRN5-32 5,5 9 164 220 1148 391 1539 5SV28 4 8,5 162 210 948 319 1267

CRN5-36 5,5 9 185 249 1256 391 1647 5SV33 5,5 8,5 192 250 1093 375 1468

Note:

The new e-SVs have:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3) Lower Nominal Power

Equal Q max

L1+L2 is lower

e-SV - Training 20-21/07/2010 57

How To Replace Grundfos CR With e-SV

10CRN Vs 10SV 50Hz

Grundfos Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

CR Model Power [m 3/h] 10,8m 3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 10,8m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

CRN10-1 0,37 13 8 10 353 191 544 10SV01 0,75 14 10 12 357 263 620

CRN10-2 0,75 13 12 20 357 231 588 10SV02 0,75 14 17 22 357 263 620

CRN10-3 1,1 13 21 30 387 231 618 10SV03 1,1 14 27 37 389 263 652

CRN10-4 1,5 13 30 40 433 281 714 10SV04 1,5 14 36 48 431 298 729

CRN10-5 2,2 13 38 51 463 321 784 10SV04 1,5 14 36 48 431 298 729

CRN10-6 2,2 13 45 61 493 321 814 10SV05 2,2 14 46 60 463 298 761

CRN10-7 3 13 52 72 528 335 863 10SV06 2,2 14 55 72 495 298 793

CRN10-8 3 13 60 82 558 335 893 10SV07 3 14 64 83 537 298 835

CRN10-9 3 13 68 92 588 335 923 10SV08 3 14 70 97 298 298 596

CRN10-10 4 13 77 102 618 335 990 10SV09 4 14 84 109 601 319 920

CRN10-12 4 13 90 122 678 372 1050 10SV11 4 14 96 132 665 319 984

CRN10-14 5,5 13 105 143 770 391 1161 10SV13 5,5 14 119 157 796 375 1171

CRN10-16 5,5 13 120 164 830 391 1221 10SV13 5,5 14 119 157 796 375 1171

CRN10-18 7,5 13 140 185 890 391 1281 10SV17 7,5 14 159 205 924 367 1291

CRN10-20 7,5 13 155 205 650 691 1341 10SV18 7,5 14 168 218 956 367 1323

CRN10-22 7,5 13 170 225 1010 391 1401 10SV18 7,5 14 168 218 956 367 1323

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Equal Nominal Power

Higher Q max

L1+L2 is higher

e-SV - Training 20-21/07/2010 58

How To Replace Grundfos CR With e-SV

CRN15 Vs 15SV 50Hz

Grundfos Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

CR Model Power [m 3/h] 18m 3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 17m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

CRN15-1 1,1 23,5 10 15 397 231 628 15SV01 1,1 24 10 14 399 263 662

CRN15-2 2,2 23,5 20 28 413 321 734 15SV02 2,2 24 21 28 298 298 596

CRN15-3 3 23,5 30 42 463 335 798 15SV03 3 24 35 43 467 298 765

CRN15-4 4 23,5 42 58 508 372 880 15SV04 4 24 47 58 515 319 834

CRN15-5 4 23,5 53 70 553 372 925 15SV05 4 24 58 72 563 319 882

CRN15-6 5,5 23,5 65 85 630 391 1021 15SV06 5,5 24 73 90 678 375 1053

CRN15-7 5,5 23,5 75 99 675 391 1066 15SV06 5,5 24 73 90 678 375 1053

CRN15-8 7,5 23,5 84 112 720 391 1111 15SV07 5,5 24 84 103 726 375 1101

CRN15-9 7,5 23,5 97 128 765 391 1156 15SV08 7,5 24 98 120 774 367 1141

CRN15-10 11 23,5 110 141 887 499 1386 15SV09 7,5 24 110 135 822 367 1189

CRN15-12 11 23,5 130 169 977 499 1476 15SV11 11 24 137 165 948 428 1376

CRN15-14 11 23,5 152 198 1067 499 1566 15SV13 11 24 161 195 1140 428 1568

CRN15-17 15 23,5 185 240 1202 478 1680 15SV15 15 24 180 222 1140 494 1634

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Equal or Lower Nominal Power

Equal Q max

L1+L2 is equal or lower

e-SV - Training 20-21/07/2010 59

How To Replace Grundfos CR With e-SV

CRN20 Vs 22SV 50Hz

Grundfos Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Nominal Q max H (BEP @ H max L1 L2 L1+L2

CR Model Power [m 3/h] 18m 3/h) [m] [mm] [mm] [mm] Model Power [m3/h] 20m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

CRN20-1 1,1 29 10 14 397 231 628 22SV-01 1,1 29 11 15 399 263 662

CRN20-2 2,2 29 23 29 413 321 734 22SV-02 2,2 29 23 30 409 298 707

CRN20-3 4 29 35 44 463 372 835 22SV-03 3 29 34 45 467 298 765

CRN20-4 5,5 29 48 59 540 391 931 22SV-04 4 29 47 61 515 319 834

CRN20-5 5,5 29 60 74 585 391 976 22SV-05 5,5 29 59 77 630 375 1005

CRN20-6 7,5 29 73 84 630 391 1021 22SV-06 7,5 29 75 93 678 367 1045

CRN20-7 7,5 29 85 103 675 391 1066 22SV-07 7,5 29 88 109 726 367 1093

CRN20-8 11 29 98 119 797 499 1296 22SV-08 11 29 100 125 804 428 1232

CRN20-10 11 29 121 148 887 499 1386 22SV-10 11 29 125 155 900 428 1328

CRN20-12 15 29 148 178 977 478 1455 22SV-12 15 29 152 186 996 494 1490

CRN20-14 15 29 170 208 1067 478 1545 22SV-14 15 29 178 217 1092 494 1586

CRN20-17 18,5 29 210 252 1202 518 1720 22SV-17 18,5 29 215 263 1236 494 1730

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Equal or Lower Nominal Power

Equal Q max

L1+L2 is almost equal

e-SV - Training 20-21/07/2010 60

How To Replace Grundfos CR With e-SV

125SV Vs CRN120 50Hz

Grundfos Nominal Q max H (BEP @ H max L1 L2 L1+L2 e-SV Model Nominal Q max H (BEP @ H max L1 L2 L1+L2

CR Model Power [m 3/h] 120 m 3/h) [m] [mm] [mm] [mm] Power [m3/h] 125 m 3/h) [m] [mm] [mm] [mm]

[kW] [m] [kW] [m]

CR120-1 11 160 20 30 834 499 1333 125SV01 7,5 160 14 28 693 367 1060

CR120-2-1 18,5 160 35 50 990 518 1508 125SV02 15 160 32 54 878 494 1372

CR120-2 22 160 43 60 990 610 1600 125SV03 22 160 48 80 1028 494 1522

CR120-3 30 160 65 88 1145 646 1791 125SV04 30 160 64 108 1178 657 1835

CR120-4-1 37 160 78 107 1301 703 2004 125SV05 37 160 79 134 1328 657 1985

CR120-5-1 45 160 103 135 1456 709 2165 125SV07 55 160 110 187 1658 825 2483

CR120-6-1 55 160 125 164 1642 747 2389 125SV08/2A 55 160 124 211 1808 825 2633

CR120-7 75 160 155 203 1797 820 2617

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Equal or Lower Nominal Power

Equal Q max

Different L1+L2

e-SV - Training 20-21/07/2010 61

How To Replace WILO MVI With e-SV

Q [m 3/h]

0 1 2 3 4 5 6 7 8 9

5SV33-5.5kW 250

- MVI 4 - 50Hz

- 5SV - 50Hz

MVI4 Vs 5SV 50Hz 3Phase 2 Poles 5SV28-4kW

Operating Characteristic MVI4-19 -4kW

200

MVI4-17 -3.7kW

Equivalent Pumps are not fully

comparable in terms of performance

curves 5SV21-3kW

MVI4-14 -3kW

150

The selection of the new e-SV pump

should be based on the duty point that can

H [m]

not be known upfront 5SV16-2.2kW

MVI4-10 -2.2kW

100

MVI4-8 -1.85kW

5SV11-1.5kW

MVI4-7 -1.5kW

5SV08-1.1kW

MVI4-5 -1.1kW

The following cross reference charts 50

are based on the assumption that the 5SV05-0.75kW

MVI4-3 -0.75kW

duty point is close to the BEP (Best 5SV04-0.55kW

5SV03-0.37kW

Efficiency Point) MVI4-2 -0.55kW

0

0 20 40 60 80 100 120 140 160

Q [l/m in] BEP

e-SV - Training 20-21/07/2010 62

How To Replace WILO MVI With e-SV

MVI1 Vs 1SV 50Hz

Nominal H (BEP e-SV Nominal Q max H (BEP @ H max L1 [mm] L2 [mm] L1+L2

Q max H max L1+L2

MVI 1 Power @2 L1 [mm] L2 [mm] Model Power [m3/h] 1,7m 3/h) [m] [mm]

[m3/h] [m] [mm]

[kW] m 3/h) [m] [kW] [m]

MVI 102 0,37 3 11 18 552 1SV02 0,37 2,4 10 12 278 209 487

MVI 103 0,37 3 18 28 552 1SV04 0,37 2,4 18 24 298 209 507

MVI 104 0,55 3 28 38 552 1SV06 0,37 2,4 26 35 338 209 547

MVI 105 0,55 3 33 49 592 1SV07 0,37 2,4 30 40 358 209 567

MVI 106 0,75 3 43 60 623 1SV09 0,55 2,4 42,5 54 398 231 629

MVI 107 0,75 3 48 70 643 1SV11 0,55 2,4 51 65 438 231 669

MVI 108 0,75 3 56 79 683 1SV12 0,75 2,4 60 74 468 263 731

MVI 109 1,1 3 64 89 683 1SV13 0,75 2,4 65 79 488 263 751

MVI 110 1,1 3 70 97 703 1SV15 0,75 2,4 73 91 528 263 791

MVI 112 1,1 3 85 118 743 1SV17 1,1 2,4 82,5 105 568 263 831

MVI 114 1,5 3 107 140 816 1SV22 1,1 2,4 110 134 668 263 931

MVI 116 1,85 3 112 158 856 1SV22 1,1 2,4 110 134 668 263 931

MVI 118 1,85 3 132 178 896 1SV27 1,5 2,4 135 164 778 298 1076

MVI 121 2,2 3 157 208 956 1SV32 2,2 2,4 162 198 878 298 1176

MVI 123 2,2 3 164 229 1016 1SV32 2,2 2,4 162 198 878 298 1176

MVI 124 3 3 177 240 1055 1SV34 2,2 2,4 172 210 918 298 1216

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3) The new e-SVs have:

Equal or lower nominal Power

Lower Q max

Different L1+L2

e-SV - Training 20-21/07/2010 63

How To Replace WILO MVI With e-SV

MVI2 Vs 3SV 50Hz

H (BEP

Nominal Nominal H (BEP @

Q max @3 H max L1+L2 e-SV Q max H max L1+L2

MVI 2 Power L1 [mm] L2 [mm] Power 3m 3/h) L1 [mm] L2 [mm]

[m3/h] m 3/h) [m] [mm] Model [m3/h] [m] [mm]

[kW] [kW] [m]

[m]

MVI202 0,37 5 18 22 507 3SV03 0,37 4,4 17 22 278 209 487

MVI203 0,37 5 24 33 544 3SV04 0,37 4,4 21 29 298 209 507

MVI204 0,55 5 30 45 599 3SV05 0,55 4,4 30 38 318 231 549

MVI205 0,55 5 39 58 623 3SV07 0,75 4,4 42 52 368 263 631

MVI206 0,75 5 48 70 647 3SV08 0,75 4,4 48 60 388 263 651

MVI207 0,75 5 55 80 681 3SV09 1,1 4,4 55 68 408 263 671

MVI208 0,75 5 65 92 728 3SV10 1,1 4,4 60 76 428 263 691

MVI210 1,1 5 80 115 776 3SV13 1,5 4,4 79 98 498 298 796

MVI212 1,1 5 95 132 824 3SV16 1,5 4,4 96 120 558 298 856

MVI214 1,1 5 118 157 872 3SV19 2,2 4,4 117 145 618 298 916

MVI217 1,5 5 145 193 983 3SV25 2,2 4,4 150 189 738 298 1036

MVI220 1,85 5 165 225 1055 3SV27 3 4,4 163 205 788 298 1086

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Almost Equal Nominal Power

Lower Q max

L1+L2 is almost equal

e-SV - Training 20-21/07/2010 64

How To Replace WILO MVI With e-SV

MVI4 Vs 5SV 50Hz

Nominal H (BEP Nominal H (BEP @

Q max H max L1+L2 e-SV Q max H max L1+L2

MVI 4 Power @ 5,3 L1 [mm] L2 [mm] Power 5,7m 3/h) L1 [mm] L2 [mm]

[m3/h] [m] [mm] Model [m3/h] [m] [mm]

[kW] m 3/h) [m] [kW] [m]

MVI402 0,55 8 15 22 507 5SV02 0,37 8,5 11 15 268 209 477

MVI403 0,75 8 22 35 575 5SV04 0,55 8,5 23 30 318 231 549

MVI404 1,1 8 31 44 599 5SV05 0,75 8,5 30 38 353 263 616

MVI405 1,1 8 38 56 623 5SV06 1,1 8,5 36 45 378 263 641

MVI406 1,5 8 48 68 680 5SV08 1,1 8,5 47 60 428 263 691

MVI407 1,5 8 55 80 704 5SV09 1,5 8,5 54 68 463 298 761

MVI408 1,85 8 62 89 728 5SV11 1,5 8,5 65 82 513 298 811

MVI410 2,2 8 80 112 776 5SV14 2,2 8,5 83 106 588 298 886

MVI412 3 8 100 133 863 5SV16 2,2 8,5 95 120 638 298 936

MVI414 3 8 112 158 911 5SV18 3 8,5 108 136 698 298 996

MVI417 3,7 8 134 190 983 5SV23 4 8,5 138 175 823 319 1142

MVI419 4 8 152 212 1055 5SV25 4 8,5 149 190 873 319 1192

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Lower Nominal Power

Higher Q max

L1+L2 is almost equal

e-SV - Training 20-21/07/2010 65

How To Replace WILO MVI With e-SV

MVI8 Vs 10SV 50Hz

H (BEP

Nominal Nominal H (BEP @

Q max @ H max L1+L2 e-SV Q max H max L1+L2

MVI 8 Power L1 [mm] L2 [mm] Power 10m 3/h) L1 [mm] L2 [mm]

[m3/h] 9,5m 3/h) [m] [mm] Model [m3/h] [m] [mm]

[kW] [kW] [m]

[m]

MVI802 0,75 14 17 22 577 10SV02 0,75 14 17 22 357 263 620

MVI803 1,1 14 23 38 607 10SV03 1,1 14 27 37 389 263 652

MVI804 1,5 14 30 47 670 10SV04 1,5 14 36 48 431 298 729

MVI805 1,85 14 40 60 700 10SV04 1,5 14 36 48 431 298 729

MVI806 2,2 14 48 72 730 10SV05 2,2 14 46 60 463 298 761

MVI807 3 14 64 85 799 10SV07 3 14 64 83 537 298 835

MVI808 3 14 70 88 829 10SV08 3 14 70 97 298 298 596

MVI810 3,7 14 90 121 889 10SV10 4 14 92 120 633 319 952

MVI811 4 14 95 132 949 10SV10 4 14 92 120 633 319 952

MVI812 5,5 14 104 143 979 10SV13 5,5 14 119 157 796 375 1171

MVI814 5,5 14 120 168 1039 10SV13 5,5 14 119 157 796 375 1171

MVI817 7,5 14 155 205 1219 10SV17 7,5 14 159 205 924 367 1291

MVI819 7,5 14 170 228 1279 10SV18 7,5 14 168 218 956 367 1323

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Equal or lower nominal Power

Equal Q max

Different L1+L2

e-SV - Training 20-21/07/2010 66

How To Replace WILO MVI With e-SV

MVI16 Vs 15SV 50Hz

H (BEP

Nominal Nominal H (BEP @

Q max @ H max L1+L2 e-SV Q max H max L1+L2

MVI 16 Power L1 [mm] L2 [mm] Power 16m3/h) L1 [mm] L2 [mm]

[m3/h] 18m3/h) [m] [mm] Model [m3/h] [m] [mm]

[kW] [kW] [m]

[m]

MVI1602-6 1,5 26 13 22 636 15SV01 1,1 24 10 14 399 263 662

MVI1603-6 2,2 26 20 32 712 15SV02 2,2 24 21 28 298 298 596

MVI1604-6 3 26 32 44 751 15SV03 3 24 35 43 467 298 765

MVI1605-6 3,7 26 40 56 827 15SV04 4 24 47 58 515 319 834

MVI1606-6 4 26 46 66 827 15SV04 4 24 47 58 515 319 834

MVI1607-6 5,5 26 57 82 933 15SV05 4 24 58 72 563 319 882

MVI1608-6 5,5 26 64 94 933 15SV06 5,5 24 73 90 678 375 1053

MVI1609-6 7,5 26 76 106 1099 15SV06 5,5 24 73 90 678 375 1053

MVI1610-6 7,5 26 85 119 1099 15SV07 5,5 24 84 103 726 375 1101

MVI1611-6 7,5 26 94 130 1175 15SV08 7,5 24 98 120 774 367 1141

Note:

- L1 is the height of the pump without the motor

- L2 is the height of the Motor (~3)

The new e-SVs have:

Equal or Lower Nominal Power

Lower Q max

L1+L2 is almost equal

e-SV - Training 20-21/07/2010 67

e-SV Vs CR: Efficiency 50Hz

Q [l/min]

0 100 200 300 400

80

e-SV

70

CR

60

h [%]

50

40

30

0 5 10 15 20 25

Q [m3/h]

1 e-SV 22

1s CR 20

e-SV - Training 20-21/07/2010 68

e-SV Vs CR: Efficiency 50Hz

Q [l/min]

0 500 1000 1500 2000 2500 3000

85

e-SV

75

CR

65

h [%]

55

45

35

0 20 40 60 80 100 120 140 160 180

Q [m3/h]

33 e-SV 125

32 CR 150

e-SV - Training 20-21/07/2010 69

e-SV Vs CR: NPSH

50Hz NPSH Curves

Q [m3/h]

0 5 10 15 20 25 30

7

22SV

6

1SV 10SV

5 3SV

22CR

15SV

15CR

NPSH [m]

4 10CR

5CR

3CR

3 1CR

5SV

0

0 100 200 300 400 500

Q [l/min]

e-SV - Training 20-21/07/2010 70

Operating Cost Saving: SV Vs CR

Running cost savings for End-Users using 3SV instead of 3CR

End-User Running Cost Saving per Year 3SV Vs 3CR

300

250

200 Assumptions

Running time: 6h per day

150

*365 days

100 Working point: BEP

Cost of electricity:

[]

50

0.15/kWh

0

3 4 5 6 7 8 9 10 11 12 13 15 17 19 21 23 25 27 29 31 33 36

-50

-100

-150

-200

N of Stages

e-SV - Training 20-21/07/2010 71

Energy Saving & Environmental Friendliness

Primary Energy Saving using 3SV instead of 3CR

Primary Energy Saving per Year

20%

15%

Assumptions

10%

Running time: 6h per day

5% *365 days

Working point: BEP

[kWh]

0% Cost of electricity:

3 4 5 6 7 8 9 10 11 12 13 15 17 19 21 23 25 27 29 31 33 36 0.15/kWh

-5% Primary Energy Ratio: 2.5

-10%

-15%

-20%

N of Stages

e-SV - Training 20-21/07/2010 72

Energy Saving & Environmental Friendliness

Reduction of GHG Emissions using 3SV instead of 3CR

Reduction of GHG Emissions per Year 3SV Vs 3CR

20%

15%

[GHG Emission Saving [%]]

10% Assumptions

Running time: 6h per day

5% *365 Days

Working point: BEP

0%

Cost of electricity:

3 4 5 6 7 8 9 10 11 12 13 15 17 19 21 23 25 27 29 31 33 36

0.15/kWh

-5%

Primary Energy Ratio: 2.5

-10% El-kw-park-EU-28-2010:

367 g/kWh

-15%

-20%

N of Stages

e-SV - Training 20-21/07/2010 73

Packaging

Graphic of the packaging

Version 1 Version 2

e-SV - Training 20-21/07/2010 74

Documentation

Black and White Catalogue

Standard configurations: 2 catalogues (1 50Hz; 1 60Hz)

Special configurations: 2 catalogues (1 50Hz; 1 60Hz)

Languages: English, Italian, German, French, Dutch,

Russian, Greek, Portuguese, Turkish, Polish, + AMARICAS

& APR

New catalogues with all models including SV33-92 will be

ready by the end of December 2010

Current SV catalogues with all models can be used till end

of 2010

e-SV - Training 20-21/07/2010 75

Documentation

Sales Folder with Black and White leaflets

Topics: Reverse Osmosis, Mechanical Seal options, Boiler Feeding, i-Alert, Dry Run Sensor, e-SV Pump

Configurations, NSF-61, Hydrovar, Laser Welding / Passivation / Electropolished

Languages: Italian, German, French, Dutch, Russian, Greek, Portuguese, Swedish, Norwegian, Finnish,

Danish, Turkish, Polish, Arabic, Hungarian, Bulgarian, Romanian, Czech, + AMAERICAS & APR

e-SV - Training 20-21/07/2010 76

Advertising Concept

Simply said: Superior efficiency gives you control over water.

creative

strategy

Humorous & Direct &

colloquial range of ideas obvious

(abstract) (common)

accessible

metaphor

Target: skews male,

tough, strong, solid.

Market: generally

product-oriented ads,

pump pornography

Efficient Animals

e-SV - Training 20-21/07/2010 77

Advertising Campaign

e-SV - Training 20-21/07/2010 78

Advertising Campaign

e-SV - Training 20-21/07/2010 79

Media Plan

Efficient Media plan

Online and print publications targeting

municipal, industrial and consulting

engineers

Online and print publications reaching

HVAC specifying engineers

Online and print publications targeting

end-user, light-industry and vertical markets

Social media (YouTube, Google video,

professional groups online, etc.)

Trade fair publications

e-SV - Training 20-21/07/2010 80

WEB

WEB

Everything in one place

Links click thru to promotional and

technical material, video

Drive traffic to sites via online ad and

social media campaigns

Possible seal replacement contest

2011 (YouTube)

Build out series of testimonials of

happy users

Promote product appearance at trade

events/fairs

e-SV - Training 20-21/07/2010 81

Video And Animation

Commercial video

1 Commercial/promotional video

Short (2 mins) seal replacement teaser

on web

Longer (12 mins) seal replacement training

video via download

Design animation (time TBD)

Seal replacement training video

Links:

http://www.reallyreallybig.com/wpclients/ITT/E-

SVreplaceVidV2Cut1.wmv

http://www.reallyreallybig.com/wpclients/ITT/E-

SVreplaceVidV1Cut1.wmv

e-SV - Training 20-21/07/2010 82

82

E-mail/Online Marketing

e-SV - Training 20-21/07/2010 83

Trade Shows/Fairs

e-SV - Training 20-21/07/2010 84

Promotional Material

Posters

In progress . It will be translated into all EMEA, AMAERICAS and APR languages

Roll up Gadgets

In progress . It will

be translated into all

EMEA, AMAERICAS

and APR languages

e-SV - Training 20-21/07/2010 85

All-Employee Communication

e-SV - Training 20-21/07/2010 86

Thank You

e-SV - Training 20-21/07/2010 87

S-ar putea să vă placă și

- Saldatura di circuiti elettronici: Guida per principianti e +De la EverandSaldatura di circuiti elettronici: Guida per principianti e +Încă nu există evaluări

- Manuar 'TMS25-R1F' Manuale Di Installazione Per VOUK SH2 D-T&G (T40.0124) (v1.0)Document18 paginiManuar 'TMS25-R1F' Manuale Di Installazione Per VOUK SH2 D-T&G (T40.0124) (v1.0)Juan Carlos AlvarezÎncă nu există evaluări

- Catalogo Motor I BrushlessDocument76 paginiCatalogo Motor I BrushlessSimir MoschiniÎncă nu există evaluări

- Varispeed F7 DatasheetDocument18 paginiVarispeed F7 Datasheetmax_ingÎncă nu există evaluări

- Datasheet: GlishDocument1 paginăDatasheet: Glishkevin YachaÎncă nu există evaluări

- RSM 40 - 80Document2 paginiRSM 40 - 80Nelson Sanches TchimbaliÎncă nu există evaluări

- Aa File 43Document4 paginiAa File 43dbratzu00Încă nu există evaluări

- Document 5353445Document4 paginiDocument 5353445Francisco VieiraÎncă nu există evaluări

- Catalogo Valvulas DireccionalesDocument132 paginiCatalogo Valvulas DireccionalesJonathan LuceroÎncă nu există evaluări

- Transtecno - Electric Motors ACDocument23 paginiTranstecno - Electric Motors ACcriuvosÎncă nu există evaluări

- Idrofoglia - E+j - 90@70Document8 paginiIdrofoglia - E+j - 90@70Rym KrÎncă nu există evaluări

- Catalogo A Prova de ExplosaoDocument76 paginiCatalogo A Prova de ExplosaoRodolfoPSÎncă nu există evaluări

- AD AX PVR Mot Catalog 460V Rv0!12!07Document38 paginiAD AX PVR Mot Catalog 460V Rv0!12!07Mohamed AlkharashyÎncă nu există evaluări

- File 1427716181Document1 paginăFile 1427716181ilberna.bernaÎncă nu există evaluări

- N050 - FPFDDocument2 paginiN050 - FPFDBaiuliang BaiuliangÎncă nu există evaluări

- D8 Fce - PDF 20160601095638Document2 paginiD8 Fce - PDF 20160601095638Milovan TasicÎncă nu există evaluări

- MVVblog ESR Meter DatasheetDocument3 paginiMVVblog ESR Meter DatasheetKen FalcoÎncă nu există evaluări

- Foglio Guida Documentazione SchedaDocument6 paginiFoglio Guida Documentazione SchedaLaurentEuniceÎncă nu există evaluări

- LOGAN 14 06 K7J710 Ls G 1311 000Document13 paginiLOGAN 14 06 K7J710 Ls G 1311 000Bratu MariusÎncă nu există evaluări

- 448Document68 pagini448rossely100% (1)

- Magnetic Tester DatasheetDocument2 paginiMagnetic Tester DatasheetPeppeÎncă nu există evaluări

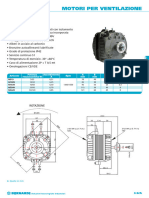

- 03.02 Motori Per Refrigerazione VentilazioneDocument27 pagini03.02 Motori Per Refrigerazione Ventilazionescribd.9gwibÎncă nu există evaluări

- App 1T It R3.0 PDFDocument22 paginiApp 1T It R3.0 PDFlucaÎncă nu există evaluări

- Elenco Inverter - DK5950 - 4Document7 paginiElenco Inverter - DK5950 - 4JEKKI0570Încă nu există evaluări

- Serie H1CDocument28 paginiSerie H1Cserleb44Încă nu există evaluări

- Catalogo OMVLDocument42 paginiCatalogo OMVLJohn frank De la cruz gonzalesÎncă nu există evaluări

- Flow Air ControlDocument50 paginiFlow Air ControlmujahaddadÎncă nu există evaluări

- 159340-300 - SPTDocument229 pagini159340-300 - SPTGiorgio GiuntaÎncă nu există evaluări

- Catalogo 12 2Document180 paginiCatalogo 12 2Mikel BellosoÎncă nu există evaluări

- Catalogo Tecnico Completo BETADocument545 paginiCatalogo Tecnico Completo BETAsaeba981Încă nu există evaluări

- Vega Door Equipment CatalogueDocument17 paginiVega Door Equipment Cataloguehunt huntÎncă nu există evaluări

- EVFTDocument3 paginiEVFTRaffaele RattiÎncă nu există evaluări

- WPQR GS 155 2302Document15 paginiWPQR GS 155 2302yessicaÎncă nu există evaluări

- Serie 8000 3vie Elettrovalvole 3vie NC Ispezionabili 30mm Fluid Control ElettrovalvoleDocument9 paginiSerie 8000 3vie Elettrovalvole 3vie NC Ispezionabili 30mm Fluid Control ElettrovalvoleeulerlinsÎncă nu există evaluări

- Imspae001ki R24 Elc407078 Spae It enDocument10 paginiImspae001ki R24 Elc407078 Spae It enAlphaÎncă nu există evaluări

- FPFD Flow DividerDocument2 paginiFPFD Flow DividerAlireza KhodabandehÎncă nu există evaluări

- AD Documents CollectionDocument76 paginiAD Documents CollectionMohamed AlkharashyÎncă nu există evaluări

- Lanterne Ventilate LR25 PDFDocument8 paginiLanterne Ventilate LR25 PDFPptinzenjering PptÎncă nu există evaluări

- KN100I0311Document56 paginiKN100I0311parayasa50Încă nu există evaluări

- (Ed01-2019) N325tis1 - N326tis1 - N327tis1 Giunto Di Smontaggio A 3 Flange (Completo)Document2 pagini(Ed01-2019) N325tis1 - N326tis1 - N327tis1 Giunto Di Smontaggio A 3 Flange (Completo)Giancarlo MoiÎncă nu există evaluări

- Catalogo Eje Paralelo RAP Bonfiglioli PDFDocument36 paginiCatalogo Eje Paralelo RAP Bonfiglioli PDFJuan Carlos Robles ResurreccionÎncă nu există evaluări

- MVVblog ESR Meter DatasheetDocument3 paginiMVVblog ESR Meter DatasheetDaniel ZeballosÎncă nu există evaluări

- MVVblog Esr Meter DatasheetDocument3 paginiMVVblog Esr Meter DatasheetDaniel ZeballosÎncă nu există evaluări

- B&C Cat Gearpumps Rev7ieDocument112 paginiB&C Cat Gearpumps Rev7ieMINA MiladÎncă nu există evaluări

- R250G 0829it - 2016-05Document2 paginiR250G 0829it - 2016-05JMigRodÎncă nu există evaluări

- j140 g2r - S General-Purpose Relay Datasheet ItDocument12 paginij140 g2r - S General-Purpose Relay Datasheet Itbeto_juriÎncă nu există evaluări

- 21L2ZV55D ItaDocument2 pagini21L2ZV55D Itaomon5000Încă nu există evaluări

- Completo BOX PDFDocument24 paginiCompleto BOX PDFBlAdE 12Încă nu există evaluări

- Pittarc Scheda Tecnica GMAW G6 Rev1 2019Document1 paginăPittarc Scheda Tecnica GMAW G6 Rev1 2019Mirhad PjanićÎncă nu există evaluări

- Catalogos SabDocument7 paginiCatalogos SabCamilo Sanchez RojasÎncă nu există evaluări

- 158264-300 - NTDocument299 pagini158264-300 - NTGiorgio GiuntaÎncă nu există evaluări

- 120 MO CTDocument8 pagini120 MO CTMATEOÎncă nu există evaluări

- Baldassari Cavi - Armonizzati - NazionaliDocument6 paginiBaldassari Cavi - Armonizzati - NazionaliCosimo Damiano PetrachiÎncă nu există evaluări

- WPQR GS 155 2301Document14 paginiWPQR GS 155 2301yessicaÎncă nu există evaluări

- Encodeur TS441Document2 paginiEncodeur TS441Said AzaouiÎncă nu există evaluări

- Plarad Catalogo TecnicoDocument88 paginiPlarad Catalogo TecniconotengofffÎncă nu există evaluări

- 6999 21a2-PwDocument4 pagini6999 21a2-Pwjf2003Încă nu există evaluări

- 9 Brat Port Lampa Stalp FotovoltaicDocument1 pagină9 Brat Port Lampa Stalp FotovoltaicNicoleta-Alina MagureanuÎncă nu există evaluări

- SCS 598-300 - EsDocument1 paginăSCS 598-300 - Esjesus ramirezÎncă nu există evaluări