Documente Academic

Documente Profesional

Documente Cultură

Us 3616264

Încărcat de

Kroze0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări4 paginidiscrete analyzer

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentdiscrete analyzer

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări4 paginiUs 3616264

Încărcat de

Krozediscrete analyzer

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 4

United States Patent

(72) Inventors

Robert A. Ray;

[21]. Appl. No.

[22] Filed June 30, 1969

[45] Patented Oct. 26,1971

(73] Assignee Beckman Instruments, Inc.

[54] TEMPERATURE-CONTROLLED DISCRETE

SAMPLE ANALYZER

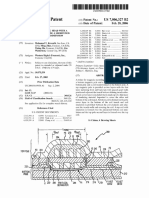

8 Claims, 1 Drawing Fig.

[52] US.Cl. 195/127,

195/103.5, 2/283, 239/3

(si) Incl. 12k 1/10

150] Field of Search 195/127,

1035; 25/283 A; 237/3;236/2-5

(11) 3,616,264

156) References Cited

UNITED STATES PATENTS

3,031,267 4/1962 Martinetal 23/253

3,389(973. 12/1967 Hoffman i9s/i27

Primary Examiner—AWvin E. Tanenholtz

‘Atiorneys—Paul R, Harder and Robert J. Steinmeyer

ABSTRACT: There is disclosed an apparatus for controlling

the temperature of discrete sample containers in analytical in-

strumentation, A conveyor containing discrete samples to be

analyzed is located in a subcompartment within a larger enclo-

sure. A fan is mounted in a first opening in the subcompart

ment to move air from the large enclosure into the subcom-

partment. A second opening in which a thermal energy

{ransfer element is mounted allows the passage of the air over

the thermal energy transfer element back into the larger en-

closure. A temperature sensor contacts a sample container

boeing measured to provide a control signal which is applied to

‘proportionally controlled power supply connected to the

thermal energy tansfer element.

3,616,264

PATENTEDOcT 26 1971

INVENTORS

ROBERT A. RAY

Oe GLa ERG

% wath VATTORNEY

ESC.

3,616,

1

‘TEMPERATURE-CONTROLLED DISCRETE SAMPLE,

ANALYZER

‘The present invention relates to apparatus for maintaining a

sample container ata predetermined temperature in a discrete

sample analyzer and more particularly to apparatus for con-

trolling the temperature of a sample container in a measure-

ment position within a measurement compartment of a

uorescent energy analyzer. Fluorometric analysis requires a

highly sensitive laboratory instrument to make rapid

fluorescent analyses of discrete samples. A number of 10

Muorescence measurements are required to be made at a con-

stant, controlled temperature. Constant temperature isa par-

ticular requirement in studies involving enzyme reactions

where reaction rates area function of temperature. Inthe en

zyme-catalyzed reactions a fluorescing substance is either

formed or consumed in the eazyme reaction. Therefore, the

amount of fuorescence a sample produces upon exposure toa

radiating source, is a measure of the degree of reaction that

has taken place up to the time of the measurement. The

desired quantity or parameter to be determined is the rate of 20

the reaction. Therefore, itis desired to measure the rate of

change of fluorescence as a direct indication of the reaction

tate. Since the rate of enzyme-catalyzed reactions is empera-

ture semsitive, it is necessary to control the temperature ofthe

sample container to maintain a constant temperature over the

period used to determine the reaction rat.

Generally, all fluorescent materials ae affected by tempera-

ture fluctuations. In most materials the fluorescence is inver-

sely proportional to temperature. Therefore, an increase in

temperature results in a decrease in fluorescence intensity

To provide temperature control for high precision measure-

‘ments, most fluorometers are equipped with a temperature

controlled sample compartment. Since the illuminating lamp

source generates a considerably amount of heat, it has been

the practice in some fluorometric analyzers to’ control the

temperature of the sample compartment by controlling the

emoval from the compartment of the heat generated by the

lamp. In such analyzers the sample compartment is equipped

with ¢ water circulation system enclosed in a jacket surround-

ing the measurement compartment. By attaching tubing to an

inlet and an outiet fitting, satisfactory cooling can be achieved

with the flowing of tap water. In order to obtain the highest

precision desired, the cooling system is recommended in all

analysis procedures.

‘The temperature control in other analyzers is obtained by

controlling the temperature of the water which flows through

the jacket surrounding the sample compartment. This tem-

perature control method has been found to be very cumber-

Some because of the need of water carrying hoses and an ex-

‘ermal temperature controlling device forthe water, as well 8,

the need for excessive periodic maintenance and inspection of

the water fittings and jacket for the purposes of detecting

leaks. In addition, even with the water jacket temperature

control, very poor temperature control of the sample com:

partment is obtained. Therefore, the methods which have

been used to control the temperature of a sample compart-

ment in fluorometric analyzers have not proved entirely

satisfactory.

Itis the object of the present invention to provide apparatus

for accurately controlling the temperature of a discrete sam-

ple ina discrete sample analyzer.

‘A further object is to provide temperature control ofa sam-

ple in a discrete sample analyzer by controlling the temper

ture of the fluid medium surrounding and moving by the sam-

ple containers.

A still further object of this invention is to control the tem-

perature of the discrete sample container by sensing the tem-

perature of the container directly.

Sill another objective ofthe present invention is o control

the temperature of discrete sample containers in a sample

conveyor by apparatus which precisely and accurately deter.

tines the temperature of the fuid medium surrounding and

owing by the sample containers, such temperature being

controlled by a temperature sensor contacting a discrete sam-

ple container in the measurement position,

1s

25

30

35

40

45

50

35

60

6s

0

15

264

2

A lil further object is to provide a method of mixing and

blending the fluid medium which has been subjected to the

transfer of thermal energy prior to pasting the Muid into the

sample compartment and over and around the diserete sample

container thereby avoiding unwanted temperature gradients

Other features and objects ofthe present invention will be

better understood from a consideration of the following

detailed description when read in conjunction with the at-

tached drawing which illustrates the temperature control ap-

paratus constructed in accordance with the teachings of the

present invention as part of a discrete sample fluorometric

analyzer.

Referring now to the drawing, a measurement compartment

‘5 is mounted within the enclosure 7, the enclosure 7 contain.

ing all the components of a fluorometer. An opening 9 in the

‘measurement compartment § has a fluid or air mover of fan

1 mounted therein and driven by any suitable means, such as

‘a motor, not shown. Another opening 13 in the measurement

‘compartment § has a thermal energy transfer element 15 posi

tioned therein. The thermal energy transfer element 1S is con-

nected to a source of power 17 which in turn i connected to a

controlling temperature sensor 19. Temperature sensor 19

contacts sample container 21 shown in position 1 of the sam:

ple conveyor or sample tray 23. Sample tray 23 is mechani-

cally linked to a sample position control knob 27. Also con-

tained in measurement compartment § isa source and detec

tor apparatus 25 containing a fluorescent energy source lamp

29, a phosphor sleeve 31, filter elements 33, a reference sol

tion of reference bar 3S, lenses 37, filter 39, and a photomul

tiplier detector 41. The input of signal-procesting electronics

43 is connected to detector 41. Connected to the output of

electronics 43 are display meter 48 and strip chart recorder

47.

‘The operation of the temperature control apparatus illus-

trated in the drawing is described in detail as follows, The

‘measurement compartment $ is constructed to have walls and

‘covers to confine and direct air or uid moving therein. The

air is moved by a fan 11 mounted in opening 9. The ait is

moved from the opening 9 through an opening 13 and past the

thermal energy transfer element 15 mounted therein, The flow

Of air is indicated by the arrows in the drawing. As the air is

‘moved into opening 9 and out of opening 13 in measurement

‘compartment 8, the air passes over the thermal energy

transfer clement 15 thereby being changed in temperature.

Although thermal energy transfer element 15 is illustrated in

‘one exemplary embodiment in the drawing as a heater ele-

‘ment, it could be a cooling clement or a combination of a

cooling and heating element such as provided by a heat pump

or thermoelectric device well known in the at of temperature

control. By providing heating and cooling capability, a wide

range of ambient temperatures can be accommodated. The air

passing out of opening 13 and over thermal energy transfer

element 15 flows out into the confines of the enclosue 7. En-

closure 7 has walls and covers to substantially confine and

deflect the moving air contained therein, Therefore the ait

flowing out of opening 13 and over thermal energy transfer

clement 15 is substantially confined within enclosure 7 as in-

dicated by the arrows. Enclosure 7 may have openings therein

by which air from outside the enclosure may enter or leave.

However, the openings are such that they do not disturb the

substantial airflow within the enclosure 7 thereby allowing the

air motion as indicated. As a result, the heated air flowing

from heater 15 is substantially mixed with the air in enclosure

77 s0 as to become more uniform in temperature before reen:

tering compartment S. This feature of the invention eliminates

fement of mixing baffles to obtain uniform tempera.

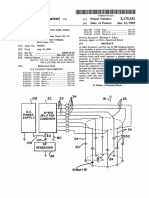

‘The thermal energy transfer element 15 is controlled by the

source of power 17 containing a power supply and electronics

to control power delivered from the power supply to the ther-

‘mal energy transfer element. Temperature sentor 19 provides

‘the conteol signal for the source of power 17. In operation

temperature sensor 19 physically contacts a sample container

21 in a conveyor measurement position 1, thereby measuring,

3,616,264

3

the temperature of the sample container and producing a

signal related thereto to control the power delivered to the

thermal energy transfer element 15. As a result of the air

pasting over thermal energy transfer element 15 through the

‘mixing confines of enclosure 7 and into opening 9 as driven by

fan 11, the air flows in and around the sample containers held

by sample tray 23. As the air passes over sample container 21,

the sample container is changed in temperature until the

signal generated by temperature sensor 19 indicates the sam-

ple container has reached the correct temperature for mea-

surement. By such operation the temperature of sample con-

tainer can be controlled to a few hundredths of a degree cen-

tigrade,

‘Once the sample container 21 has reached equilibrium tem=

perature, indicated by the temperature sensor 19, the

fluorometer is ready to perform a fluorescence measurement

‘of the sample, An enzyme catalyst is added to the contents of

the sample container 21 in the measurement position 1 and

the rate ofthe reaction resulting therefrom is measured by the

fluorescence from the sample container generated in response

to a source of illuminating energy provided by lamp 29. Lamp

29 alternately produces radiation to sample container 21 and

toa reference bar or solution 36, alternately causing the sam-

ple in the sample container and the reference to fluoresce

producing Muorescent energy collected by lenses 37 and

directed into photomultiplier 41 where an electrical signal is

produced in response thereto. Various wavelengths of illu-

‘mination may be produced by selecting various combinations

fof a phosphor sleeve 31 and filters 33. In addition various

fluorescent energy wavelengths may be selected by filter 39,

Since the reference and sample fluorescent energies are al-

ternately directed into photomultiplier detector 41, a signal is

produced by detector 41 having a magnitude proportional to

the ratio of the reference and sample fluorescent radiations.

Such an instrument is called a ratio fluorometer. The electri

cea signal from photomultiplier 41 is amplified and further

processed to produce a direct current signal of magnitude

directly proportional tothe alternating signal produced by the

alternate direction of reference and sample Muorescent radia.

tion into detector 41. Since the rate of reaction is the desired

parameter, the electronics 43 contains a means of differentia-

tion such that the signal displayed by the meter 48 and the

strip chart recorder 47 directly display the rate of reaction

taking place within the sample container 21

Because of the temperature control provided, the tempera-

ture of the sample container and the sample contained the

are maintained constant at a predetermined point to provide

fluorometric reaction rate measurement of such precision and

accuracy heretofore unrealized.

‘Although thermal energy transfer element 15 can be a heat

pump or a thermoelectric device which can either heat or

Cool, it may be desirable to have element 15 as a heating ele-

ment or a cooling element, but not both, and to have a

separate heating or cooling element (not illustrated) mounted

adjacent to a wall of enclosure 7. This relationship may pro-

vide further simplification in control, for example, by provid-

ing a heating element as clement 15 and a separate uncon-

‘rolled cooling clement mounted in enclosure 7. The uncon-

trolled cooling clement enables the temperature control point

‘of the sample container to be lowered below ambient tem-

perature to provide a measurement capability of reactions oc-

‘curring at temperatures below ambient. The arrangement of

tlements can be reversed, having element 18 as a tempera-

ture-controlled cooling element and the element in enclosure

7 as an uncontrolled heating clement. Further, the element in

enclosure 7 can be temperature controlled either separately or

jointly with element 15, thereby providing a greater range and

‘accuracy of temperature control of the sample container.

20

25

30

35

40

45

50

55

60

65

0

8

4

To advance the conveyor tray 23 for the next sample mea-

surement, knob 27 is operated to cause the tray to move into

the dashed line position. The knob is then turned to rotate the

tray to place another sample container inthe sample measure-

‘ment position. The tray is then placed back into the operatin

position by knob 27 thereby causing the new sample containe?

to be contacted by temperature sensor 19.

It now should be apparent that the present invention pro:

vides a temperature control apparatus for controlling the tem-

perature of a discrete sample in a discrete sample analyzer.

Although a particular configuration and arrangement has

‘been discusted in connection with the specific embodiment of

the temperature control apparatus constructed in accordance

with the teachings of the present invention, other arrange:

‘ments and configurations may be utilized. Furthermore, it will

bbe understood that although an exemplary embodiment of the

present invention has been disclosed and discussed, other ap

plications and mechanical arrangements are possible and that

the embodiment disclosed may be subjected to various

changes, modifications and substitutions without necessarily

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- United States Patent (19) : Kaye Oct. 15, 1996Document44 paginiUnited States Patent (19) : Kaye Oct. 15, 1996KrozeÎncă nu există evaluări

- Us 6250486Document14 paginiUs 6250486KrozeÎncă nu există evaluări

- Us8608097 PDFDocument10 paginiUs8608097 PDFKrozeÎncă nu există evaluări

- Aug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitDocument6 paginiAug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitKrozeÎncă nu există evaluări

- Us 3376803Document26 paginiUs 3376803KrozeÎncă nu există evaluări

- United States Patent: (21) Appl. N0.: 13/226,109 (Continued)Document17 paginiUnited States Patent: (21) Appl. N0.: 13/226,109 (Continued)KrozeÎncă nu există evaluări

- Dec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964Document4 paginiDec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964KrozeÎncă nu există evaluări

- United States Patent (19) : (45) Date of Patent: Oct. 12, 1999Document17 paginiUnited States Patent (19) : (45) Date of Patent: Oct. 12, 1999KrozeÎncă nu există evaluări

- Us 4774914Document25 paginiUs 4774914KrozeÎncă nu există evaluări

- Us 3195038Document10 paginiUs 3195038KrozeÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000Document18 paginiUnited States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000KrozeÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000Document18 paginiUnited States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000KrozeÎncă nu există evaluări

- Us 6633161Document21 paginiUs 6633161KrozeÎncă nu există evaluări

- Us 7006327Document11 paginiUs 7006327KrozeÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000Document18 paginiUnited States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000KrozeÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 5,179,332Document14 paginiUnited States Patent (19) (11) Patent Number: 5,179,332KrozeÎncă nu există evaluări

- Us 5818319Document30 paginiUs 5818319KrozeÎncă nu există evaluări

- United States Patent (19) : Nºzizi EDocument11 paginiUnited States Patent (19) : Nºzizi EKrozeÎncă nu există evaluări

- United States Patent (19) : Sinclair Et AlDocument21 paginiUnited States Patent (19) : Sinclair Et AlKrozeÎncă nu există evaluări

- United States PatentDocument25 paginiUnited States PatentKrozeÎncă nu există evaluări

- United States Patent (19) : Nºzizi EDocument11 paginiUnited States Patent (19) : Nºzizi EKrozeÎncă nu există evaluări

- United States PatentDocument14 paginiUnited States PatentKrozeÎncă nu există evaluări

- Us 6577888Document12 paginiUs 6577888KrozeÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 5,207,074Document18 paginiUnited States Patent (19) (11) Patent Number: 5,207,074KrozeÎncă nu există evaluări

- United States Patent (19) : 16 VoltageDocument12 paginiUnited States Patent (19) : 16 VoltageKrozeÎncă nu există evaluări

- United States PatentDocument15 paginiUnited States PatentKrozeÎncă nu există evaluări

- Us 5379832Document16 paginiUs 5379832KrozeÎncă nu există evaluări

- United States PatentDocument15 paginiUnited States PatentKrozeÎncă nu există evaluări

- Us 4866424Document14 paginiUs 4866424KrozeÎncă nu există evaluări