Documente Academic

Documente Profesional

Documente Cultură

Poster Safety

Încărcat de

Jose Ricardo DuranDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Poster Safety

Încărcat de

Jose Ricardo DuranDrepturi de autor:

Formate disponibile

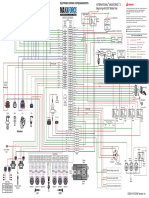

Safety@Festo

Evaluation and assessment of safety measures

in accordance with EN ISO 13849-1/IEC 61508/IEC 61511/IEC 62061

Risk assessment 10 safety functions

Trigger

Input Logic Output Drive

event

Risk analysis Risk evaluation Risk reduction What triggers the Device that Device that Device that controls www.festo.com

safety measure? recognises the safely processes the dangerous

Design measures Pressurising Maintaining Reducing Exhausting Tamper-proof, prevention of

trigger situation the signal movement

pressure pressure and force unexpected starting-up

For example: Light curtain Hard-wiring Pneumatic

Technical measures Approaching a Safety door Safety relay Elektrical

hazardous area Pressure mat Safety PLC Hydraulic

Opening a safety Emergency Stop Pneumatic Energy

Two-hand Reducing Free of forces Reversing Stopping, holding and door Failure control system

User information control speed a movement blocking a movement Laser scanner

Camera

6 steps for evaluating whether safety measures are sufficient

EN ISO 13849-1 Applicable to safety-related parts of control systems and for all types of machines, IEC 61508 Functional safety of electrical/electronic/programmable electronic safety-related systems

regardless of the technology and power used electric, pneumatic, hydraulic, mechanic.

IEC 61511 Functional safety safety instrumented systems for the process industry sector.

IEC 62061 Safety of machinery functional safety of safety-related electrical, electronic and programmable

electronic control systems.

1 Risk assessment Determining the required Performance Level (PLr) Determining the required Safety Integrity Level (SILr)

W1 W2 W3 S Consequence

Low risk S1 Minor injuries to a person

Evaluation of the application

S1 S2 Severe injury to multiple persons

S Severity of injury

P1 up to death of a person

F1

a S1 Slight (normally reversible injury) P1

SIL1 S3 Multiple deaths

P2 S2 Serious (normally irreversible injury, or death) F1

S1 P2 S4 Catastrophic effects with many deaths

P1 b S2 SIL1 SIL1

F Frequency and/or exposure to hazard F Frequency

F2 P1

P2

F1 Seldom to less often and/or exposed time is short F2 SIL2 SIL1 SIL1 F1 Seldom to reasonably frequent

F2 Frequent to continuous and/or exposed P2 F2 Frequent to continuous

c SIL3 SIL2 SIL1

P1 time is long

F1 F1 P Possibility of avoidance

P2 S3 SIL3 SIL3 SIL2

P Possibility of avoiding the hazard P1 Possible under certain conditions

S2 F2

d P1 Possible under specific conditions SIL4 SIL3 SIL3 P2 Scarcely possible

P1

F2 P2 Scarcely possible S4

P2 SIL4 SIL4 SIL3 W Probability of occurrence

e W1 Relatively high

ae Performance Level (PLr)

SIL (Safety Integrity Level) W2 Low

Four discrete steps (SIL1 to SIL4). The higher the SIL of a safety-related W3 Very low

High risk Source: DIN EN ISO 13849-1 Appendix 1.2.3

system, the lower the probability of the system not being able to execute

the necessary safety functions.

2 Designated architectures Specifications of categories HFT Defining the Hardware Failure Tolerance

Category B/Category 1 Category 3

Monitoring HFT 0 HFT 1 HFT 2

Evaluation of safety measures

Input

Input Output

Input Logic Output Input Logic Output

Output

signal

signal signal

signal

Test signal

Monitoring

Input

Input Logic Output Output

signal

Category 2 signal

Test signal Monitoring

Example: 1oo2 Example: 1oo3

Input Output Category 4

Input Logic Output

signal signal Input Monitoring

Input Logic Output

Trigger signal Monitoring signal Output

signal

1oo1 (One out of One) 1oo2 (One out of Two) 1oo3 (One out of Three)

Test signal

Second shut-down Output Monitoring

Test Input A single failure can lead to a At least 2 failures must occur simultaneously At least 3 failures must occur simultaneously

of test

unit criterion or display Input Logic Output loss of safety to cause a loss of safety to cause a loss of safety

unit signal Output

signal HFT (Hardware Failure Tolerance)

Ability of a required function to still perform in case of failures and deviations

3 CCF Common Cause Failure/DC Determining Diagnostics Coverage SFF Defining the Safe Failure Fraction

DD + S High Demand Mode Low Demand Mode

SFF = ________

D + S

Measures against CCF Points Start Component DC SFF 1 FME(D)A

FME(D)A FME(D)A

FME(D)A

for S = 0 > SFF = DC

Separation/Segregation 15 System structure: What failures could occur? for D = 0 > SFF = 1 Type of failure

Ausfallart Detected

Erkannt Undetected

Unerkannt Type of failure

Ausfallart Detected

Erkannt Undetected

Unerkannt

(Detected dangerous failures)

Diversity 20 Category, MTTFd, DC, CCF

Are the failures dangerous? DC1 = ___________________________ safe safe safe safe safe safe

(Total dangerous failures) detected undetected detected undetected

Design/application 20 Checking the achieved PL Can the dangerous failures be detected? S SD SU S SD SU

Assessment/analysis 5

dangerous dangerous dangerous dangerous dangerous dangerous

n

Competence/training 5 Points 65 detected undetected detected undetected

D DD DU D DD DU

Environmental 35 y DC1 DC2 DCn

______ + ______ + ... + ______

MTTF d1 MTTF d2 MTTF

______________________________ dn

End Entire system DC

avg = 1 1 1

______ + ______ + ... + ______ SD + SU + DD SD + SU + DD

DD DD

MTTFd1 MTTFd2 MTTFdn SFF = ___________________ DC = ______ SFF = ___________________ DC = ______

Total D Total D

(failure rates) FME(D)A (Failure Modes, Effects and SFF (Safe Failure Fraction)

S: Failure rate for safe failures SU: Failure rate for safe, undetected failures Diagnostics Analysis) Proportion of all safe and detected

D: Failure rate for dangerous failures DD: Failure rate for dangerous, detected failures Methods of analysis for quantitative failures based on the total amount

SD: Failure rate for safe, detected failures DU: Failure rate for dangerous, undetected failures determination of types of failure and failure rates of failures

4 MTTFd Definition of the Mean Time To Failure PFH/PFD Determination of the probability of failure

High Demand Mode Low Demand Mode

MTBF = MTTF + MTTR

Input Input signal Logic Control signal Output Control signal Drive Formula for determining Input Input signal Logic Control signal Output Control signal Drive Input Input signal Logic Control signal Output Control signal Drive

B10d for MTTF ,, MTTR

MTTF _______ the MTTFd value for

d = > MTBF = MTTF

Characteristic service life values B10d B10d 0,1 . nop a mechanical element in a Characteristic service life values B10d B10d Characteristic service life values B10d B10d

of the individual components channel of the individual components of the individual components

(from the data sheets) Application data (from the data sheets) Application data (from the data sheets) Application data

dop . hop . 3600 s/h Mean number of annual

MTTFd MTTFd MTTFd MTTFd nop = _________________ actuations nop for the MTBF MTBF MTTFd MTTFd MTBF MTBF MTTFd MTTFd

tcycle mechanical element

Calculation of total MTTFd 1

2 1 PFH = ______ Good engineering practice Good engineering practice

1 N ____

1 MTTF = _ MTTF MTTF ________________ for two different channels MTTFd

______ = d 3 dC1 + dC2 1 1 1 N ____

1 Test attempt 1 Test attempt

______ + ______ PFH = ______ =

MTTFd MTTFd,i PFD = _ DU . Tp DU = D . (1-DC)

i=1 MTTFdC1 MTTFdC2 MTTFd MTTFd,i Operating experience 2 Operating experience

i=1

MTTFd (Mean Time to Failure) Evaluation MTTFd

PFH (Probability of failure per hour) PFD (Probability of Failure on Demand)

Mean time until a dangerous failure Low 3 years MTTFd . 10 years Probability of failure of a safety function Probability that a safety function will not be

MTTR (Mean Time to Restoration) Medium 10 years MTTFd . 30 years under continuous use executed on demand at a low requirement rate

Mean repair time High 30 years MTTFd . 100 years MTBF (Mean Time between Failure) Tp (Proof test interval)

Source: DIN EN ISO 13849-1, Chapter 4.5.2 Mean time between two successive failures Regularly complete examination of the function

5 Entire system Target: PL PLr Target: SIL SILr

Example layout of safety-related parts of a control system Typical distribution of the PFH Typical distribution of the PFD

between the sub-systems of a safety function in single safety loops between the sub-systems of a safety function in single safety loops

Input Logic Output Drive Sensor 35% Logic 15% Actuator 50% Sensor 35% Logic 15% Actuator 50%

Component 1 Component 2 Lowest PL Number of lowest PL Entire system

PLlow Nlow PL

B10d B10d B10d PFH SD PFH SD PFH SD PFD SD PFD SD PFD SD

,3 not allowed

a

MTTFd MTTFd 3 a SFF SU SFF SU SFF SU SFF SU SFF SU SFF SU

,2 a

MTTFd MTTFd per channel b

2 b HFT DD HFT DD HFT DD HFT DD HFT DD HFT DD

Cat Cat ,3 b

c

3 c MTBF DU MTBF DU MTBF DU MTBF DU MTBF DU MTBF DU

DC DC ,3 c

d

3 d SILrequired (SILr) SILrequired (SILr)

CCF CCF

,3 d

e

PL PL PL 3 e PFHtotal PFDtotal

Defined by manufacturer To be determined by the system operator Defined by manufacturer To be determined by the system operator Defined by manufacturer To be determined by the system operator

6 Evaluation Target: PL PLr Target: SIL SILr

Definition of MTTFd = Mean Time To Failure (dangerous) Device type A Device type B

SIL-Level Safe Failure Fraction (SFF)

Max. acceptable failure

High Demand Mode .60% 60...90% 90...99% ,99% .60% 60...90% 90...99% ,99% Low Demand Mode

of the safety system

One risk of failure

a 105 PFH . 104 every 10,000 hours

Definition of PL = Performance Level

One risk of failure 102 PFD . 101 Once every 10 years

b 3 . 106 PFH . 105 every 1,250 days

1 HFT 0 HFT 1 HFT 0

One risk of failure

c 106 PFH . 3 . 106 every 115.74 years

One risk of failure Once every 100 years

d 2 107 PFH . 106 HFT 1 HFT 0 HFT 2 HFT 1 HFT 0 103 PFD . 102

every 115.74 years

One risk of failure

e 3 108 PFH . 107 every 1,157.41 years HFT 2 HFT 1 HFT 0 HFT 0 HFT 2 HFT 1 HFT 0 104 PFD . 103 Once every 1,000 years

One risk of failure HFT 1 HFT 1 HFT 1

4 109 PFH . 108 HFT 2 HFT 2 105 PFD . 104 Once every 10,000 years

every 11,574.1 yeras HFT 2 HFT 2 HFT 2

[per hour]

DC . 60% DC . 60% 60% DC 90% DC 60% DC 90% DC 99% DC

. 90% . 99% . 90% . 99%

Device type A

none none

Evaluation MTTFd low medium low medium high Device for which the failure behaviour of all components and the

failure characteristics are sufficiently determined

Low 3 years MTTFd . 10 years

Kat B Kat 1 Kat 2 Kat 3 Kat 4

PL PLr SIL SILr

Medium 10 years MTTFd . 30 Jahre

54707 en 2010/05

Device type B

High 30 years MTTFd . 100 Jahre

CCF not relevant CCF 65 %

Device for which the failure behaviour of at least one component

and the behaviour in case of a failure are not sufficiently determined.

S-ar putea să vă placă și

- Riskassessmenttechnique 170923010930Document33 paginiRiskassessmenttechnique 170923010930jupmulÎncă nu există evaluări

- Form Risk AssessementDocument16 paginiForm Risk AssessementbaluchakpÎncă nu există evaluări

- 06 - Employee Participation WebDocument7 pagini06 - Employee Participation WebBasil M. IkhleifÎncă nu există evaluări

- HSE-Better Alarm Handling PDFDocument4 paginiHSE-Better Alarm Handling PDFAlessio DeOsimoÎncă nu există evaluări

- Process Safety Management: A Legal and Technical Overview: Session No. 526Document15 paginiProcess Safety Management: A Legal and Technical Overview: Session No. 526Waqas Ahmad KhanÎncă nu există evaluări

- Applying Process Hazard Analysis To Laboratory HVAC Design: Ashrae JournalDocument4 paginiApplying Process Hazard Analysis To Laboratory HVAC Design: Ashrae JournalhvananthÎncă nu există evaluări

- Process Safety - Barrier Management: Nageswara Rao HSSE Manager Shell Technology Center BangaloreDocument16 paginiProcess Safety - Barrier Management: Nageswara Rao HSSE Manager Shell Technology Center BangaloreÖzlem ÖzkiliçÎncă nu există evaluări

- Campbell Institute An Implementation Guide To Leading IndicatorsDocument24 paginiCampbell Institute An Implementation Guide To Leading IndicatorsjrcoachÎncă nu există evaluări

- Why We Need Effective Alarm Management White PaperDocument8 paginiWhy We Need Effective Alarm Management White PaperMaria Regina ReyesÎncă nu există evaluări

- ILO - Ambient Factors in The Workplace - 2001Document80 paginiILO - Ambient Factors in The Workplace - 2001nicholisÎncă nu există evaluări

- Integrated Management System Awareness: Switch Off Mobile PhonesDocument39 paginiIntegrated Management System Awareness: Switch Off Mobile PhonesajoshpkÎncă nu există evaluări

- Applying Process Hazard Analysis To Laboratory HVAC Design: Ashrae JournalDocument4 paginiApplying Process Hazard Analysis To Laboratory HVAC Design: Ashrae JournalSyed ShoebÎncă nu există evaluări

- HAZIDDocument2 paginiHAZIDAnonymous zwSP5gvÎncă nu există evaluări

- Sil Quick Guide 1528 PDFDocument4 paginiSil Quick Guide 1528 PDFahmed messallamÎncă nu există evaluări

- Certificado Pilz e TurvDocument12 paginiCertificado Pilz e TurvSantiago.Încă nu există evaluări

- A Short Course On Process Hazard Analysis (PHA) : For Chemical EngineersDocument11 paginiA Short Course On Process Hazard Analysis (PHA) : For Chemical EngineersJose AlvarezÎncă nu există evaluări

- Behavioural Based SafetyDocument1 paginăBehavioural Based SafetyHarthwell CapistranoÎncă nu există evaluări

- How To Achieve Zero AccidentDocument108 paginiHow To Achieve Zero AccidentAjit BhosaleÎncă nu există evaluări

- Safety Integrity Level Selection: Systematic Methods Including Layer of Protection AnalysisDocument2 paginiSafety Integrity Level Selection: Systematic Methods Including Layer of Protection AnalysiswalidÎncă nu există evaluări

- A I P C E Co Aipceco: Ftab Men Arto Onsulting Ngineers MpanyDocument102 paginiA I P C E Co Aipceco: Ftab Men Arto Onsulting Ngineers MpanySajidÎncă nu există evaluări

- Wolf Safety Lamp Company - Atex Explained Leaflet - SL008 Issue 5Document1 paginăWolf Safety Lamp Company - Atex Explained Leaflet - SL008 Issue 5omidÎncă nu există evaluări

- Risk Prevention and MitigationDocument3 paginiRisk Prevention and Mitigationultrasonic81Încă nu există evaluări

- Brochure: Control Hazard and Operability Study (CHAZOP) : Excellence in Dependable AutomationDocument2 paginiBrochure: Control Hazard and Operability Study (CHAZOP) : Excellence in Dependable AutomationDiegoÎncă nu există evaluări

- Concepto ALARP PDFDocument22 paginiConcepto ALARP PDFLuis Olle ArrolaÎncă nu există evaluări

- Incidentinvestigation RecommendationDocument24 paginiIncidentinvestigation RecommendationEmmanuel AnsahÎncă nu există evaluări

- CERT+Basic Unit+6+Participant+Manual EnglishDocument29 paginiCERT+Basic Unit+6+Participant+Manual EnglishBrandon OlsenÎncă nu există evaluări

- Jepg ... SJEC - Jan 2023 Module On PROCESS SAFETYDocument20 paginiJepg ... SJEC - Jan 2023 Module On PROCESS SAFETYL JayanthiÎncă nu există evaluări

- Contemp. Prog. Safety SysDocument43 paginiContemp. Prog. Safety SysCristina Bianca LeãoÎncă nu există evaluări

- Safe Upper and Lower Limits - Understanding & DocumentingDocument26 paginiSafe Upper and Lower Limits - Understanding & DocumentingAshish JainÎncă nu există evaluări

- BOWtie HSE UKDocument92 paginiBOWtie HSE UKRmz ExeÎncă nu există evaluări

- Csms Phe Onwj Forms 2011Document87 paginiCsms Phe Onwj Forms 2011NAZAR ALIÎncă nu există evaluări

- Layer of Protection Analysis: SciencedirectDocument11 paginiLayer of Protection Analysis: SciencedirectDigitalMastersTXÎncă nu există evaluări

- Process Safety Notes 1Document18 paginiProcess Safety Notes 1Zia AhmadÎncă nu există evaluări

- Dekra Leading Indicator For SIFDocument15 paginiDekra Leading Indicator For SIFsdurga1100% (2)

- 07process Safety Performance Indicators Health and Safety ExecutiveDocument23 pagini07process Safety Performance Indicators Health and Safety ExecutiveSergio A. Rdz. F.Încă nu există evaluări

- Puwer 1998Document9 paginiPuwer 1998Jogi Oscar SinagaÎncă nu există evaluări

- A Method For Identifying Human Factors Concerns During The HAZOP Process - Dennis AttwoodDocument5 paginiA Method For Identifying Human Factors Concerns During The HAZOP Process - Dennis AttwoodAlvaro Andres Blanco GomezÎncă nu există evaluări

- Epsc PSFDocument23 paginiEpsc PSFKNS GroupÎncă nu există evaluări

- American National Standard Criteria For Accepted Practices in Safety, Health, and Environmental TrainingDocument32 paginiAmerican National Standard Criteria For Accepted Practices in Safety, Health, and Environmental TrainingOSHTECH LATAMÎncă nu există evaluări

- Lista de Normas Api - RefinaciónDocument14 paginiLista de Normas Api - RefinaciónfaustomgÎncă nu există evaluări

- Safety Engineer Safety Engineering Is An Engineering Discipline Which Assures That Engineered SystemsDocument5 paginiSafety Engineer Safety Engineering Is An Engineering Discipline Which Assures That Engineered SystemsJohn Nate RiveraÎncă nu există evaluări

- General Environmental Management Systems Awareness TrainingDocument44 paginiGeneral Environmental Management Systems Awareness TrainingRamaKantDixitÎncă nu există evaluări

- Safety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Document12 paginiSafety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Priyo DjatmikoÎncă nu există evaluări

- Sis PDFDocument2 paginiSis PDFsteam100deg1658Încă nu există evaluări

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 paginiHSE-RA-029 Straight and Cut Operation - Rev 0عمروÎncă nu există evaluări

- Test 4Document9 paginiTest 4Ahmed HamadÎncă nu există evaluări

- 10 Industrial Accidents Where Poor Shift Handover Was A Contributory FactorDocument2 pagini10 Industrial Accidents Where Poor Shift Handover Was A Contributory FactorsgraureÎncă nu există evaluări

- Risk AssesmentDocument5 paginiRisk AssesmenthipnofenixÎncă nu există evaluări

- Six Steps To Effectively Update and Revalidate PHAsDocument8 paginiSix Steps To Effectively Update and Revalidate PHAspolaris44Încă nu există evaluări

- AI-PS Element Guide No 9Document8 paginiAI-PS Element Guide No 9rahul kavirajÎncă nu există evaluări

- Common CauseDocument4 paginiCommon CauseJorge DuranÎncă nu există evaluări

- Conceptos Basicos ISA MexDocument3 paginiConceptos Basicos ISA MexRaul GonzalezÎncă nu există evaluări

- Emirates ERM Abu Dhabi Process Safety Management Training MethodologyDocument5 paginiEmirates ERM Abu Dhabi Process Safety Management Training MethodologyShailendraÎncă nu există evaluări

- Wcms 164653Document154 paginiWcms 164653Joshua TroglioÎncă nu există evaluări

- Assistant Foreman Major Maintenance Works: OB EscriptionDocument3 paginiAssistant Foreman Major Maintenance Works: OB EscriptionyagolainÎncă nu există evaluări

- HIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018Document5 paginiHIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018ghieee100% (1)

- ABSOLUTE ID-U1025 デジマチックインジケータ Digimatic Meßuhr Indicador Digimatic Digimatic Meetklok Comparateur DigimaticDocument2 paginiABSOLUTE ID-U1025 デジマチックインジケータ Digimatic Meßuhr Indicador Digimatic Digimatic Meetklok Comparateur DigimaticFreddy YánezÎncă nu există evaluări

- Batteries: Color Code For Schematic LinesDocument2 paginiBatteries: Color Code For Schematic LinesIsaac NewtonÎncă nu există evaluări

- Digimatic Bügelmessschraube Micrómetro Digimatic de Exteriores "Digimatic" Buitenschroefmaat Micromètre D'extérieur "DIGIMATIC"Document2 paginiDigimatic Bügelmessschraube Micrómetro Digimatic de Exteriores "Digimatic" Buitenschroefmaat Micromètre D'extérieur "DIGIMATIC"Frogx GoÎncă nu există evaluări

- Pre SureDocument1 paginăPre SureJose Ricardo DuranÎncă nu există evaluări

- U.M.R.P.S.F.X.CH.: Lopez Rueda Javier DavidDocument1 paginăU.M.R.P.S.F.X.CH.: Lopez Rueda Javier DavidJose Ricardo DuranÎncă nu există evaluări

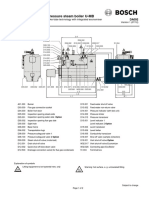

- UNIVERSAL High-Pressure Steam Boiler ZFR: in Three-Pass Double-Flue Flame-Tube Smoke Tube TechnologyDocument2 paginiUNIVERSAL High-Pressure Steam Boiler ZFR: in Three-Pass Double-Flue Flame-Tube Smoke Tube TechnologyJose Ricardo DuranÎncă nu există evaluări

- UNIVERSAL High-Pressure Steam Boiler U-MB: Main DimensionsDocument2 paginiUNIVERSAL High-Pressure Steam Boiler U-MB: Main DimensionsJose Ricardo DuranÎncă nu există evaluări

- UNIVERSAL High-Pressure Steam Boiler ZFRDocument2 paginiUNIVERSAL High-Pressure Steam Boiler ZFRJose Ricardo DuranÎncă nu există evaluări

- UNIVERSAL Steam Boiler UL-S: Main DimensionsDocument3 paginiUNIVERSAL Steam Boiler UL-S: Main DimensionsJose Ricardo Duran0% (1)

- THDP-3 Worm Gear Manual Interchangeable Single Punch Tablet PressDocument8 paginiTHDP-3 Worm Gear Manual Interchangeable Single Punch Tablet Pressdibimrane13Încă nu există evaluări

- Stearic Acid MSDSDocument6 paginiStearic Acid MSDSJay LakhaniÎncă nu există evaluări

- Cutting Aws C5.3 2000 R2011Document33 paginiCutting Aws C5.3 2000 R2011Serkan AkşanlıÎncă nu există evaluări

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 paginiStorage Tank Design Calculation - Api 650: Close Floating RoofhgagÎncă nu există evaluări

- 12V140 Seris Engine Shop ManualDocument471 pagini12V140 Seris Engine Shop ManualRaed Mahyoub100% (4)

- PDF - Gate Valve OS and YDocument10 paginiPDF - Gate Valve OS and YLENINROMEROH4168Încă nu există evaluări

- Q3 - Summative Test2 - Statprob 2022 2023Document2 paginiQ3 - Summative Test2 - Statprob 2022 2023Christian Lloyd ReandinoÎncă nu există evaluări

- Vishay Load Cell Calibration System - ENDocument3 paginiVishay Load Cell Calibration System - ENSarhan NazarovÎncă nu există evaluări

- Intro To Geometric Design and Vertical AlignmentDocument25 paginiIntro To Geometric Design and Vertical AlignmentAhsan ArfanÎncă nu există evaluări

- Labnet MultiGene Manual PDFDocument42 paginiLabnet MultiGene Manual PDFcuma mencobaÎncă nu există evaluări

- KaranDocument4 paginiKarancristioronaldo90Încă nu există evaluări

- Configuration Diagrams: Group 80ADocument24 paginiConfiguration Diagrams: Group 80ASaHdo AbdelHamid100% (1)

- Absolute Containers Brochure 2019 2 27 PDFDocument19 paginiAbsolute Containers Brochure 2019 2 27 PDFEduardo SolanoÎncă nu există evaluări

- G120D Getting Started 0418 en-USDocument94 paginiG120D Getting Started 0418 en-USHamadi Ben SassiÎncă nu există evaluări

- Mahmoud Darwish TMADocument15 paginiMahmoud Darwish TMABassant Ayman Ahmed Abdil Alim100% (1)

- MPDFDocument10 paginiMPDFshanmuganathan716Încă nu există evaluări

- Command Center Processing and Display System ReplacementDocument2 paginiCommand Center Processing and Display System ReplacementImranÎncă nu există evaluări

- Layers of The EarthDocument26 paginiLayers of The EarthLoo DrBrad100% (1)

- ECON 304 Course ContentDocument2 paginiECON 304 Course ContentAanand JhaÎncă nu există evaluări

- 688 (I) Hunter-Killer - User ManualDocument115 pagini688 (I) Hunter-Killer - User ManualAndrea Rossi Patria100% (2)

- Galaxy A8 User ManualDocument193 paginiGalaxy A8 User ManualHüseyin ACARÎncă nu există evaluări

- Student Material CN Version - 2017.11.10Document25 paginiStudent Material CN Version - 2017.11.10Jagaddeesha BRÎncă nu există evaluări

- Loading and Hauling Dump Truck: DumperDocument2 paginiLoading and Hauling Dump Truck: DumperRJÎncă nu există evaluări

- 0192-En 13948-2008Document9 pagini0192-En 13948-2008Borga ErdoganÎncă nu există evaluări

- Getting Started in Steady StateDocument24 paginiGetting Started in Steady StateamitÎncă nu există evaluări

- Comsigua HBIDocument0 paginiComsigua HBIproxywarÎncă nu există evaluări

- Lock Maiolo Savonarola MachiavelliDocument22 paginiLock Maiolo Savonarola MachiavelliHeliogabolusÎncă nu există evaluări

- Floor DiaphragmDocument24 paginiFloor DiaphragmChristian LeobreraÎncă nu există evaluări

- Lab Science of Materis ReportDocument22 paginiLab Science of Materis ReportKarl ToddÎncă nu există evaluări

- Module-2: SolidificationDocument16 paginiModule-2: SolidificationSachin AgnihotriÎncă nu există evaluări