Documente Academic

Documente Profesional

Documente Cultură

2002.1.thermoacoustics For Liquefaction of Natural Gas PDF

Încărcat de

Mayur PKTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2002.1.thermoacoustics For Liquefaction of Natural Gas PDF

Încărcat de

Mayur PKDrepturi de autor:

Formate disponibile

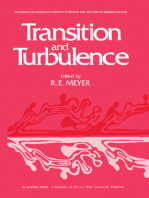

R LNG TECHNOLOGY

Thermoacoustics for By Greg Swift

Los Alamos National Laboratory

and John Wollan

Liquefaction of Natural Gas Praxair

A prototype device for liquefying natural gas using thermoacoustics is capable of producing

500 gallons per day of LNG, consuming 35 percent of the incoming gas in the process.

Larger capacities operating at higher efficiencies are on the drawing board.

ne ordinarily thinks of a sound In this article, we introduce the the half-wave resonance present in the

O wave as consisting only of

coupled pressure and position

oscillations. In fact, temperature

basic principles of thermoacoustics

and describe progress toward their

use for liquefaction of natural gas.

apparatus illustrated by the schematic

in (c), where the engine is at the top

and the refrigerator is at the bottom.

oscillations accompany the pressure Thermoacoustic natural-gas liquefiers Heat exchangers (HX) and a regenerator

oscillations and when there are spatial are surprisingly simple: They use no in the engine convert some of the heat

gradients in the temperature exotic materials, require no close power (QH) from burning natural gas at

oscillations, oscillating heat flow tolerances, and are little more than a hot temperature (TH) into acoustic

occurs. The combination of these welded pipe and heat exchangers power (W), rejecting waste heat power

oscillations produces a rich variety of filled with pressurized helium. This (Q0) to a water stream at ambient

thermoacoustic effects. In everyday simplicity, along with the reliability temperature (T0). Acoustic power is

life, the thermal effects of sound are too and low maintenance inherent in consumed by the refrigerator, which

small to be easily noticed; for example, thermoacoustic technology, suggests uses it to pump heat (QC) from a

the amplitude of the temperature that thermoacoustic liquefiers could liquefying natural-gas load and rejects

oscillation in conversational levels of enable economic recovery of marginal waste heat (Q0 + Q0) to the ambient

sound is only about 0.0001C. gas resources such as associated water stream. Each of the heat

However, in an extremely intense sound gas from offshore oil wells, gas exchangers may be of finned-tube or

wave in a pressurized gas, these accumulations at remote locations, and shell-and-tube construction, as open to

thermoacoustic effects can be even the recovery of landfill gas and helium flow as possible. Each

harnessed to create powerful heat marginal coal seam gas accumulations. regenerator usually consists of a pile of

engines and refrigerators. Whereas In addition, the technology could stainless-steel screens, supporting the

typical engines and refrigerators rely on find an application in areas where smooth temperature profile between the

crankshaft-coupled pistons or rotating smaller-scale gas liquefaction is two adjacent heat exchangers.

turbines, thermoacoustic engines and needed: liquefaction at seasonal Thermodynamically, acoustic power

refrigerators have no moving parts (or at peak shaving facilities and at fleet- is just as valuable as other forms of

most only flexing parts without the need vehicle fueling stations. work such as electric power or

for sliding seals). This simplicity, rotating-shaft power. The first law of

coupled with reliability and relatively Thermoacoustic Basics thermodynamics determines that

low cost, has highlighted the potential Many varieties of heat-driven W+Q0 = QH in the engine. The second

of thermoacoustic devices for practical thermoacoustic refrigeration systems law shows that the engine efficiency

use. As a result, thermoacoustics is exist, but in this article we consider W/QH is bounded by the Carnot

maturing quickly from a topic of basic only a toroidal thermoacoustic-Stirling efficiency, 1 T0/TH. The most efficient

scientific research through the stages of hybrid engine driving a thermoacoustic thermoacoustic engine to date has

applied research and on to important orifice pulse tube refrigerator (Figure achieved 40 percent of the Carnot

practical applications. 1). Parts (a) and (b) of Figure 1 show efficiency, while the most powerful has

Fall 2002 GasTIPS 21

produced 17 kW of acoustic . . . . . . .. . . .\ . .

.. .. . .. . . . . .

~~

., . . . . . . . . . II

power. Similarly, in the

. ,

I

refrigerator, the first law of (a) Position

thermodynamics determines 1

that W + Qc = Qo'+ Q / ;

the second law shows that

the efficiency Q&W,' known regenerator

as the coefficient of

performance, is bounded

by the Carnot expression

'-'

TJ(T, - Tc). The most / Resonator ,-i

moving down, thermaUy

A expandim

efficient thermoacoustic

orifice pulse tube refrigerator

to date has achieved 25

percent of this Carnot bound.

One of the most important

large dimensions in a I

thermoacoustic device is the

length of its resonator, which

(together with the helium

sound speed) determines the

operating frequency, just as

the length of an organ pipe

determines its pitch. This

length typically ranges from

I: . .

l

.. ..... ... . . . . .. .. .... .. .. .

...

. . .

.......

10 cm for the simplest ............ .. .. ... . . . . . . . .

....

experimental systems to 10 . . . . . . . . . . . .

m for today's most efficient

and mature systems. The Figure 1: Schematic of a Heat-driven Thermoacoustic Refrigeration System

resonator shown in Figure 1

uses a half-wavelength standing wave, How the Engine M r k s thermoacoustic engines and

shown schematically in parts (a) and (b) To understand the conversion of heat to refrigerators, the amplitude of the

(but without details of the wave within acoustic power by this simple engine, pressure oscillation is 10 percent of the

the engine and refrigerator). This wave consider the magnified view of part of mean pressure, and the amplitude of

appears spontaneously whenever the the regenerator shown in Figure 1, motion is a similar percentage of the

temperature in the engine's hot heat part (d), which shows a typical parcel length of the regenerator. Thermal

exchanger is high enough, and the of helium at four instants of time as contact between the oscillating helium

amplitude of the wave increases as it oscillates in position, pressure, and the solid wall of the pore, plus the

the heat supplied to the hot heat temperature, and density, exchanging externally imposed temperature

exchanger increases. In parts (a) and heat with the nearby solid in the gradient, add a new feature to what

(b), the pressure and position waves regenerator. The tiny pore of the would otherwise be a simple acoustic

are shown at two times: the red curves regenerator is shown as a smooth-walled oscillation - oscillatory heat transfer

show these variables when the helium channel for simplicity. between the helium and the solid.

is at the uppermost extreme of its The wave carries the helium up and While the heliuq is moving downwards,

position in the resonator, with density down along the pore, compressing and it encounters evdr warmer portions of

and pressure highest at the top of the expanding it, with time phasing such the regenerator, so it absorbs heat and

resonator and lowest at the bottom, that it is most pressurized while it is expands; while the helium is moving

while the blue curves show them 180" moving down and most depressurized upwards, it rejects heat and contracts.

later in the cycle. while it is moving up. In typical Figure 1,part (e), a pressure-volume

22 GasTlPS Fall 2002

( pV ) diagram for the parcel of helium density, cp is its isobaric specific heat low pressure time of the acoustic wave,

illustrated in part (d), shows that the per unit mass, and f is the frequency of and the thermal contraction, attending

helium does net work ( p dV) on its the acoustic oscillation; K is roughly its upward motion, occurs during the

surroundings because expansion takes the distance heat can diffuse through high pressure time. The resulting

during the high-pressure time of the the helium during a time 1/f. In acoustic power absorbed by the helium

cycle and the contraction during the todays thermoacoustic systems, K is is supplied by the thermoacoustic

low-pressure time. This process typically a fraction of a millimeter. engine, transmitted to the refrigerator

depends on the correct time phasing (Pores too tight impose too much through the wave in the resonator.

between motion and pressure, which is viscous drag on the helium.)

maintained by inertial and compressive Development History

effects in the ductwork near the How the Refrigerator Works Heat driven acoustic oscillators have

regenerator. The net work that the The basic principle of operation of the been known for over a century the

helium does on its surroundings is thermoacoustic orifice pulse tube earliest and simplest was discovered

produced at the resonance frequency. refrigerator is very similar to that of the accidentally by European glassblowers.

Thus, the parcel of helium shown in (d), thermoacoustic engine. A magnified But an accurate theory applicable to

and all others like it within the view of part of the refrigerators thermoacoustic phenomena was not

regenerator, deliver acoustic power to regenerator in Figure 1, part (f), developed until the 1970s, through the

the wave, while the wave sets the illustrates one typical parcel of helium efforts of Nicholas Rott and coworkers

frequency of the power production. as it oscillates in position, pressure, at ETH-Zurich. Rotts theory is based

Each parcel of helium also deposits temperature, and density, exchanging on a low-amplitude linearization of the

a little heat (not shown in Figure 1) at heat (dq) with the nearby solid in the Navier-Stokes, continuity, and energy

one location in the regenerator while regenerator, moving that heat up the equations, with sinusoidal oscillations

the pressure is rising and the parcel is temperature gradient. As the helium of all variables.

relatively stationary near the upper oscillates along the refrigerators In the early 1980s, the thermal-

extent of its motion. It absorbs that heat regenerator, it experiences changes in physics team at Los Alamos, supported

near the lower extreme of its motion, at pressure. At the lower extreme of its by BES in DOEs Office of Science,

a warmer location in the regenerator, motion, the typical parcel of helium was frustrated by the large number

when the pressure is falling. With rejects heat (dq) to the regenerator, of precision moving parts required

respect to heat, all parcels act like because the pressure rises while the for their experiments on the

members of a bucket brigade, with the helium is relatively stationary at that thermodynamic behavior of near-critical

overall effect being absorption of heat at location. Similarly, at the upper extreme liquids in heat engines. While looking

the hot heat exchanger and rejection of of its motion, it absorbs heat (dq) from for simpler engine designs, they read

heat at the ambient heat exchanger. the regenerator, because the pressure the publications of Peter Ceperley at

rises while it is relatively stationary George Mason University, who had

Pore Size there. Thus, the parcel of helium moves realized that the timing between

The pore size in the regenerator a little heat along the regenerator, up pressure changes and motion in

determines the nature of the thermal the temperature gradient, during each Stirling engines is the same as in a

contact between the regenerator solid cycle of the acoustic wave. All the other traveling sound wave (Ceperley, 1979).

heat capacity and the moving helium. parcels in the regenerator behave Inspired by his insight, the Los Alamos

Good thermal contact is needed to similarly, so that the overall effect, researchers began considering

accomplish the cycle shown in again like in a bucket brigade, is the acoustic technology to eliminate

Figure 1, because the temperature of net transport of heat from the cold moving parts. Eventually, they brought

the helium should match the local solid heat exchanger to the ambient together a thermodynamic point of view,

temperature while the helium moves. heat exchanger. acoustic techniques, explicit heat

Analysis shows that a spacing between The helium also consumes acoustic exchangers, and Rotts theory,

plates of a fraction of a thermal power from the wave (not shown in producing the first powerful

penetration depthd K = K/fcp is Figure 1), because the thermal thermoacoustic engines and the first

best, where K is the thermal expansion of the helium, attending its thermoacoustic refrigerators.

conductivity of the helium, is its downward motion, occurs during the Fundamental research on

Fall 2002 GasTIPS 23

Figure 2: First Thermoacoustically Driven Pulse

Tube Refrigerator Figure 4: First Acoustic Liquefier

thermoacoustics has grown ever liquefaction of

since, at Los Alamos and throughout natural gas, using

the world. combustion of gas

In the late 1980s, a partnership as the heat source.

between the Los Alamos team and Ray A typical modern

Radebaugh at the National Bureau of gas liquefaction

Standards (now National Institute of plant costs a

Standards and Technology) in Boulder billion dollars,

combined a thermoacoustic engine with liquefies 104

an orifice pulse tube refrigerator to m3/day, and has

create the first cryogenic refrigerator substantial

with no moving parts (Figure 2). This operating and Figure 3: Illustrations of an Acoustic Liquefier

device was dubbed the Coolahoop maintenance costs. and Offshore Applications

because the bent brass portion of the The need for

half-wavelength acoustic resonator relatively small, reliable, inexpensive this technology in 1994. The following

(extending upward in Figure 2) liquefaction equipment seemed year, DOEs Office of Fossil Energy

resembled a hulahoop (Radebaugh, clear and an acoustic liquefier (through NETL) began supporting Los

et al., 1991). In the photo, the pulse seemed to fit the need perfectly. The Alamos teams partnership with

tube refrigerator is the silver-colored goal of an acoustic liquefier with a Cryenco. Hardware development

U at bottom center, while the two capacity of 10,000 gallons per day (gpd) continued in Denver through many

thermoacoustic engines are under the followed, eventually including transitions, most recently as Praxair

bulky white insulation to the right and economic analysis for arrays of such acquired the project. While working on

left of the refrigerator. liquefiers on floating LNG production/ the Denver development, the Los

Even though this early system had storage vessels and oil/gas separation Alamos researchers have continued

only 5 W of cooling power at 120 vessels (van Wijngaarden, 1999; research on fundamentals, increasing

Kelvin, Radebaugh believed from the Figure 3). engine efficiency and bringing

outset that the best application for this Cryenco, a small manufacturing thermoacoustic improvements to orifice

heat-driven refrigerator would be company in Denver, began working on pulse tube refrigerators.

24 GasTIPS Fall 2002

Prototype Acoustic

Liquefier Hardware

The first natural-gas-fired

thermoacoustic liquefier was completed

in Denver in 1997 (Figure 4). It

achieved a liquefaction capacity of

140 gpd of LNG, producing 2 kW of

refrigeration power at 140C.

The second phase of hardware

development, which began in mid 1999,

has been the development of an

efficient 500 gpd system (Figure 5). The

thermoacoustic portion of the system is

prominently visible in Figure 5, with the

engine on top and refrigerators on the

bottom, linked by a half-wave resonator.

The natural gas burner is at the very

top, under the blue banner. The engine

is in the large bulge below the burner.

The refrigerators are hidden inside the

large, cylindrical vacuum insulation

can near the bottom, but two of their

slender inertances and compliances are

visible above the vacuum can. The

thermoacoustic working helium is at an

average pressure of 450 psi, with

oscillations up to 45 psi in amplitude

at a frequency of 40 Hz.

In this system, three refrigerators are

used, driven in parallel by the Figure 5: Current Protoype 500 GPD Acoustic Liquefier

thermoacoustic wave but connected in

series with respect to the natural-gas 65 percent of a natural-gas stream Next Steps

stream so that the first acts as a natural- while burning 35 percent. The next step in capacity will target

gas precooler, the second removes the In 2001, the 500-gpd system was 10,000 gpd, the largest size that we

rest of the sensible heat and some of operated at 60 percent of its design believe can be factory produced en

the latent heat, and the third removes pressure amplitude, with the engine masse and transported by rail. Initial

the rest of the latent heat. The design producing 12 percent of its design brainstorming is underway and serious

calls for the engine and resonator to power and each of the three engineering design will begin soon.

deliver 30 kW of acoustic power to the refrigerators running separately at 25 This effort will be financed by Praxair

refrigerators, whose combined cooling percent of their design powers. All and by the Advanced Technology

power is 7 kW. The burner delivers heat thermoacoustic phenomena were Program of the National Institute of

to the engine, and is made more working as expected, but a crack in an Standards and Technology.

efficient by a traditional recuperator to inaccessible weld prevented testing at However, the development of an

preheat the incoming fresh air by higher powers. During 2002, this efficient, low-cost acoustic liquefier is

capturing heat from the flue. Waste heat system is being rebuilt, including challenging. Even the 500 gpd system

is removed from the engine and the dramatic improvements to the burner is a scaleup of a factor of 1600 in

refrigerators by circulating water at and burner-engine heat exchanger. cooling power over the first laboratory

ambient temperature. Overall system Financial support for this effort is demonstration, which used simple

efficiency should yield liquefaction of provided by Praxair and NETL. electric heat to power the engine and an

Fall 2002 GasTIPS 25

electric-heat test load on the inertance are also local accentuators For more information contact the

refrigerator, and had such poor of inertial mass, enforcing the correct authors, Greg Sw$, with Los Alamos

efficiency that it would have liquefied amplitude and time phasing of the gas National Laboratory at swi@ft@lanl.gov

only 9 percent of a natural-gas motion in the nearby regenerators. or via telephone at 505-665-0640, or

stream while burning the other 91 Portions labeled compliance John Wollan with Praxair at

percent. Nevertheless, the 10,OOOgpd accentuate compressibility. John-Wollan@raxair.com or by

system is expected to liquefy 80 Another key aspect of the telephone at 303-549-7204A more

percent of its throughput, and we elimination of moving parts from complete, animated version of Figure I

expect that further improvements can Stirling systems is the use of pulse Vor PCs, not Macs) can be obtained by

eventually bring the efficiency close tubes and thermal buffer tubes in place downloading TashOpZp.exefrom

to 90 percent without compromising of cryogenic or red-hot pistons. These httpd/www.lanl.gov/thennoacoustics/mov

the low cost and reliability of the portions of the system maintain ies.html. Further background on the

thermoacoustic approach. thermally stratified adiabatic oscillating fundamentals of thennoacoustics is

flow, thereby transmitting acoustic available at http:,%uww.lanl.gov/

Back to Basics power from the cryogenic temperature thermoacousti& which includes l i d s to

Readers familiar with Stirling engines (in a refrigerator) or the red-hot journal publications and a book.

or refrigerators will recognize that the temperature (in an engine) to ambient InJonnation about the natural-gas

processes in the regenerators and heat without suffering from convective heat liquefir is also available at

exchangers discussed above in the leak. Some current fundamental httpd/iuunu.lanl.gov/mstJ

context of Figure 1are identical to the research in thermoacoustics is engidecon. html.

processes in Stirling devices. Hence, directed toward understanding and

another way to view thermoacoustics is maintaining this thermally stratified

References

as one chapter in the story of the condition in the presence of violent Ceperley, P.H., 1979. Apistonless

elimination of moving parts and sliding Stirling engine- The traveling-

oscillating flow.

seals fiom Stirling devices -a story in wave heat engine,Journal of the

Efficiency and power density are two

which earlier chapters include Beales Acoustical Society of America, Vol.

key figures of merit for any energy-

66, p p . 1508-1513.

invention of the free-piston Stirling conversion technology. The power of

engine and Gifford and Longsworths thermoacoustic devices is roughly Radebaugh, R., McDermott, K.M.,

invention of the basic pulse tube proportional to pav$la(vosJpavg)2, with Swifi, G . W., andMartin, R. A.,

refrigerator (Beale, 1969; Gifford and pavgthe average pressure, A the cross 1991. Developmentof a

Longsworth, 1965). A key aspect in the sectional area of the regenerator, a the thermoacoustically driven orifice

thermoacoustics chapter is the sound speed of the helium, and post the pulse tube refrigerator,Interagency

deliberate use of inertial effects in the amplitude of the oscillating pressure. Meeting on Cryocoolers, Plymouth

oscillating helium. A moving slug of Helium has the highest sound speed of MA, October 24.

helium can behave inertially much like the inert gases, so high-pressure helium Van Wijingaarden, W. C., 1999.

a moving solid piston, bouncing against is used in most thermoacoustic systems, Therrnoacousticrefrigeration - A

the compressibility of nearby helium to including the acoustic liquefier. This stirring concept for offshore associated

act like a spring-mounted mass. From leaves p,Jpmg as the primary variable gas liquefaction,MonetizingStranded

this point of view, the half-wave which might be increased in order to Gas Reserves Conference, Houston,

resonator of Figure 1can be thought of increase power per unit area. December 1999.

as if the mass of the helium in the Unfortunately, increasingposJpavg Beale. W. T., 1969. Free-piston

central third of the resonator bounces generally reduces efficiency, as a StirlinP PnPinPs - wmp mnhl tmtc

resonantly against the compressibilities variety of higher loss processes such as and simulations, S.A.E.paper

of the helium in the upper and lower turbulence grow in importance, and as number 690203.<January.

thirds of the resonator, the resulting the demands on heat exchangers Gifford W. E. and Longsworth, R.

resonance acting like a flywheel to keep increase. As thermoacoustics matures

C., 1965. Pulsetube refrigeration

the thermoacoustic engine working from from scientific inquiry to realistic

progress, I Advances in Cryogenic

one expansion stroke to the next. The engineering, these are among the

narrow portions of the system labeled tradeoffs that must be made. rn

S-ar putea să vă placă și

- Fahey Thermoacoustic OscillationsDocument9 paginiFahey Thermoacoustic OscillationsSabiju BalakrishnanÎncă nu există evaluări

- Construction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemDocument6 paginiConstruction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemijeteeditorÎncă nu există evaluări

- High Energy Heat Shield Aero ThermodynamicsDocument10 paginiHigh Energy Heat Shield Aero ThermodynamicsRaman KrishÎncă nu există evaluări

- Thermo Acoustic RefrigerationDocument23 paginiThermo Acoustic RefrigerationSujitÎncă nu există evaluări

- C 14Document26 paginiC 14pfylÎncă nu există evaluări

- NS EquationDocument15 paginiNS Equationpradeepsmart1988Încă nu există evaluări

- Presentation Re-Entry of Space Vehicle 1606129387 383142Document10 paginiPresentation Re-Entry of Space Vehicle 1606129387 383142Sheik FazalÎncă nu există evaluări

- Computational Study On Role of Pimples in Ballistic Entry of Space VehiclesDocument9 paginiComputational Study On Role of Pimples in Ballistic Entry of Space Vehiclesbalasubramanian.sÎncă nu există evaluări

- A 231552Document30 paginiA 231552Vicente Alvero ZambranoÎncă nu există evaluări

- ThermoacousticDocument11 paginiThermoacousticAn@ndÎncă nu există evaluări

- Aerodynamic Design, Characterization and Flight Performance of RLV-TDDocument16 paginiAerodynamic Design, Characterization and Flight Performance of RLV-TDbalasubramanian.sÎncă nu există evaluări

- Thermoacoustic Refrigeratioa Report On Thermoacoustic Model of A RefrigeratorDocument36 paginiThermoacoustic Refrigeratioa Report On Thermoacoustic Model of A RefrigeratorAkhil Anand0% (1)

- Thermoacoustic Engine and RefrigeratorDocument21 paginiThermoacoustic Engine and RefrigeratorSubhan UllahÎncă nu există evaluări

- Thermo-Acoustic System Modelling and Stability AnalysisDocument49 paginiThermo-Acoustic System Modelling and Stability AnalysisWolfgang Polifke100% (1)

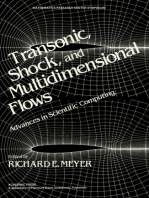

- Transition and Turbulence: Proceedings of a Symposium Conducted by the Mathematics Research Center, the University of Wisconsin–Madison, October 13–15, 1980De la EverandTransition and Turbulence: Proceedings of a Symposium Conducted by the Mathematics Research Center, the University of Wisconsin–Madison, October 13–15, 1980Încă nu există evaluări

- Stirling Engine PDFDocument18 paginiStirling Engine PDFOzaias PraxedesÎncă nu există evaluări

- Book of Heat Transfer ReviewDocument109 paginiBook of Heat Transfer ReviewMd.Faysal Ahamed KhanÎncă nu există evaluări

- TPS and Materials Used in Re-Entry VehiclesDocument13 paginiTPS and Materials Used in Re-Entry VehiclesAbhishek Bera100% (1)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86De la EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Încă nu există evaluări

- Thermoacoustic RefrigerationDocument22 paginiThermoacoustic RefrigerationPawan Kumar Singh0% (2)

- Formsat 5Document6 paginiFormsat 5gramuiitmÎncă nu există evaluări

- Modern Developments in the Mechanics of ContinuaDe la EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziÎncă nu există evaluări

- Lab BasedDocument14 paginiLab BasedMukul Goyal100% (1)

- Lect - I - Cryogenic Fundamentals & Cryocoolers - MDA IDocument90 paginiLect - I - Cryogenic Fundamentals & Cryocoolers - MDA IksvvijÎncă nu există evaluări

- Focusing of Charged ParticlesDe la EverandFocusing of Charged ParticlesAlbert SeptierÎncă nu există evaluări

- Transonic, Shock, and Multidimensional Flows: Advances in Scientific ComputingDe la EverandTransonic, Shock, and Multidimensional Flows: Advances in Scientific ComputingÎncă nu există evaluări

- A New Method of Atmospheric Reentry For Space ShipsDocument7 paginiA New Method of Atmospheric Reentry For Space ShipsN. SWAROOP KUMARÎncă nu există evaluări

- Automatic Purgers in Refrigeration Systems PDFDocument7 paginiAutomatic Purgers in Refrigeration Systems PDFrofasiÎncă nu există evaluări

- Carnot's Theorem (Thermodynamics) - WikipediaDocument4 paginiCarnot's Theorem (Thermodynamics) - WikipediaBhuvanesh BalaÎncă nu există evaluări

- Analysis of Heat Transfer Phenomena From Different Fin Geometries Using CFD Simulation in ANSYS® PDFDocument8 paginiAnalysis of Heat Transfer Phenomena From Different Fin Geometries Using CFD Simulation in ANSYS® PDFAMBUJ GUPTA 17BCM0060Încă nu există evaluări

- Supersonic Wind TunnelDocument15 paginiSupersonic Wind TunnelAseem TanejaÎncă nu există evaluări

- Section On Hypersonic FlowDocument12 paginiSection On Hypersonic FlowP KÎncă nu există evaluări

- A Review of Passive Thermal Management of LED ModuleDocument4 paginiA Review of Passive Thermal Management of LED ModuleJuan DinhÎncă nu există evaluări

- Heat and Fluid Flow in Power System Components: Hmt The Science & Applications of Heat and Mass TransferDe la EverandHeat and Fluid Flow in Power System Components: Hmt The Science & Applications of Heat and Mass TransferA. M. A. RezkÎncă nu există evaluări

- Investigation of Thermo-Acoustic Excess Parameters of Binary Liquid Mixture Using Ultrasonic Non Destructive TechniqueDocument7 paginiInvestigation of Thermo-Acoustic Excess Parameters of Binary Liquid Mixture Using Ultrasonic Non Destructive TechniqueInternational Journal of Latest Research in Engineering and TechnologyÎncă nu există evaluări

- Spacetechnology, Module - 8, Lecture-1: Reentry DynamicsDocument5 paginiSpacetechnology, Module - 8, Lecture-1: Reentry DynamicsSid Siddapa SidhuÎncă nu există evaluări

- Summary of Some Useful Equations: HYPERS301.x Hypersonics From Shock Waves To ScramjetsDocument28 paginiSummary of Some Useful Equations: HYPERS301.x Hypersonics From Shock Waves To ScramjetsShivam AgarwalÎncă nu există evaluări

- High Tc Superconductors: Electronic StructureDe la EverandHigh Tc Superconductors: Electronic StructureA. BianconiÎncă nu există evaluări

- Incineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987De la EverandIncineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987Robert B. DeanÎncă nu există evaluări

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsDe la EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsÎncă nu există evaluări

- Final PPT Major Thermoacoustic RefrigerationDocument14 paginiFinal PPT Major Thermoacoustic RefrigerationSuraj ChaudharyÎncă nu există evaluări

- Notes - Thermal Vs Non-Thermal PlasmaDocument2 paginiNotes - Thermal Vs Non-Thermal Plasmaanmol3Încă nu există evaluări

- Dynamics Re EntryDocument176 paginiDynamics Re EntryaprilswapnilÎncă nu există evaluări

- Reentry Timeline and EventsDocument25 paginiReentry Timeline and Eventsanon_557098088Încă nu există evaluări

- CFD Analysis of Supersonic Combustion Using Diamond-Shaped Strut Injector With K-ω Non-Premixed Combustion ModelDocument11 paginiCFD Analysis of Supersonic Combustion Using Diamond-Shaped Strut Injector With K-ω Non-Premixed Combustion ModelHoàng DavidÎncă nu există evaluări

- Literature ReviewDocument3 paginiLiterature ReviewshrynikjainÎncă nu există evaluări

- Compressible Flow-AerothermodynamicsDocument44 paginiCompressible Flow-AerothermodynamicsGohar KhokharÎncă nu există evaluări

- Plasma Assisted CombustionDocument8 paginiPlasma Assisted CombustionEddie WinklerÎncă nu există evaluări

- Statistical and Low Temperature PhysicsDocument76 paginiStatistical and Low Temperature PhysicsFran JaksicÎncă nu există evaluări

- FIGURE P7.30: (A) Use Dimensional Analysis With The Assumption That The WingbeatDocument6 paginiFIGURE P7.30: (A) Use Dimensional Analysis With The Assumption That The Wingbeatmohamed ahmedÎncă nu există evaluări

- Unit 4Document15 paginiUnit 4SDGFSAGFÎncă nu există evaluări

- Fdocuments - in 1 Introduction To Heat TransferDocument12 paginiFdocuments - in 1 Introduction To Heat TransferShafqat HussainÎncă nu există evaluări

- Build A Pop-Pop Boat PDFDocument7 paginiBuild A Pop-Pop Boat PDFLuis UlakiaÎncă nu există evaluări

- LNG02Document11 paginiLNG02oo_wlÎncă nu există evaluări

- Materials in Aerospace NotesDocument2 paginiMaterials in Aerospace NotesRamadhanìe Dwìe NtanÎncă nu există evaluări

- Vortex TubeDocument15 paginiVortex TubePravinSharmaÎncă nu există evaluări

- MECH448 AerodynamicHeating Sept 2011Document6 paginiMECH448 AerodynamicHeating Sept 2011Sriram Ganesan100% (1)

- 2007.1.experimental Study On The Heat Transfer at The Heat Exchanger of The Thermoacoustic Refrigerating SystemDocument8 pagini2007.1.experimental Study On The Heat Transfer at The Heat Exchanger of The Thermoacoustic Refrigerating SystemMayur PKÎncă nu există evaluări

- Thermoacoustic RefrigerationDocument19 paginiThermoacoustic RefrigerationMayur PKÎncă nu există evaluări

- LOR2Document1 paginăLOR2Mayur PKÎncă nu există evaluări

- 2004.1.thermal-Relaxation Dissipation in Thermoacoustic SystemsDocument13 pagini2004.1.thermal-Relaxation Dissipation in Thermoacoustic SystemsMayur PKÎncă nu există evaluări

- FEA 1 Week 2 AssignmentsDocument1 paginăFEA 1 Week 2 AssignmentsMayur PKÎncă nu există evaluări

- New Doc 2017-02-13Document3 paginiNew Doc 2017-02-13Mayur PKÎncă nu există evaluări

- Syllabus5 6sem and Scheme7 8sem Wef 2016Document65 paginiSyllabus5 6sem and Scheme7 8sem Wef 2016Mayur PKÎncă nu există evaluări

- Literature Review: Flight Performance of The HASI Servo Accelerometer (Date: 11/10)Document4 paginiLiterature Review: Flight Performance of The HASI Servo Accelerometer (Date: 11/10)Mayur PKÎncă nu există evaluări

- BMS College of Engineering, Bangalore-560019: December 2015 Semester End Main ExaminationsDocument2 paginiBMS College of Engineering, Bangalore-560019: December 2015 Semester End Main ExaminationsMayur PKÎncă nu există evaluări

- BMS College of Engineering, Bangalore-560019: December 2014 / January 2015 Semester End Main ExaminationsDocument1 paginăBMS College of Engineering, Bangalore-560019: December 2014 / January 2015 Semester End Main ExaminationsMayur PKÎncă nu există evaluări

- U.S N.Iiiiiiii I: BMS College of Engineering, Bangalore-560019Document2 paginiU.S N.Iiiiiiii I: BMS College of Engineering, Bangalore-560019Mayur PKÎncă nu există evaluări

- BMS College of Engineering, Bangalore-560019Document3 paginiBMS College of Engineering, Bangalore-560019Mayur PKÎncă nu există evaluări

- Water InjectionDocument4 paginiWater InjectionMayur PKÎncă nu există evaluări

- Heat Conduction EquationDocument26 paginiHeat Conduction EquationMayur PK100% (1)

- Review On Recovery and Utilization of Waste Heat in Internal Combustion EngineDocument7 paginiReview On Recovery and Utilization of Waste Heat in Internal Combustion EngineMayur PKÎncă nu există evaluări

- Ice Literature SurveyDocument4 paginiIce Literature SurveyMayur PKÎncă nu există evaluări

- Carbon Monoxide Emission 1Document9 paginiCarbon Monoxide Emission 1Mayur PKÎncă nu există evaluări

- Porous Carriers 2021 BROCHURE 1Document15 paginiPorous Carriers 2021 BROCHURE 1anshul2106Încă nu există evaluări

- 20170710100925-Lubricating Oil Purifier NAKINDocument8 pagini20170710100925-Lubricating Oil Purifier NAKINAntonioAriasÎncă nu există evaluări

- Mina Justa Project: Ausenco Document No. 101946-DS-0081 Marcobre Doc No. JU-001-06-AUS-5500-04-26-0081Document4 paginiMina Justa Project: Ausenco Document No. 101946-DS-0081 Marcobre Doc No. JU-001-06-AUS-5500-04-26-0081jorge floresÎncă nu există evaluări

- Bulk Deformation Processes in MetalworkingDocument39 paginiBulk Deformation Processes in MetalworkingSaAhRaÎncă nu există evaluări

- NumericalsDocument6 paginiNumericalsaditya dhapodkarÎncă nu există evaluări

- Design of Wood Structures Asd LRFD 7th Edition Breyer Solutions ManualDocument38 paginiDesign of Wood Structures Asd LRFD 7th Edition Breyer Solutions Manualsoojeebeautied9gz3h94% (16)

- Heterogeneous Catalysis For Today's Challenges: Synthesis, Characterization and ApplicationsDocument152 paginiHeterogeneous Catalysis For Today's Challenges: Synthesis, Characterization and ApplicationsAbdulhamid AliÎncă nu există evaluări

- Astm C39 C39M-16Document7 paginiAstm C39 C39M-16Yao Leslie Armande MélissaÎncă nu există evaluări

- CHEM 1040 Chapter 1Document2 paginiCHEM 1040 Chapter 1rijzÎncă nu există evaluări

- Seismic Reflection Data: What It Is, How It Can Be Used, & An Application at Elk Hills, CADocument25 paginiSeismic Reflection Data: What It Is, How It Can Be Used, & An Application at Elk Hills, CAvishnurajÎncă nu există evaluări

- Combine Grading and Gap AggregateDocument3 paginiCombine Grading and Gap AggregateKO_ERNIA1Încă nu există evaluări

- The Basics of TorsionDocument4 paginiThe Basics of TorsiondineshbmtÎncă nu există evaluări

- IV B. TECH (Chemical Engineering) I SemesterDocument14 paginiIV B. TECH (Chemical Engineering) I SemesterPiyush AmbulgekarÎncă nu există evaluări

- IbchkineticsDocument16 paginiIbchkineticsapi-293306937Încă nu există evaluări

- Faster Than The Speed of Light Joao Magueijo PDFDocument2 paginiFaster Than The Speed of Light Joao Magueijo PDFJames100% (1)

- (PDF) Concrete Cracks Repair Using Epoxy ResinDocument18 pagini(PDF) Concrete Cracks Repair Using Epoxy ResinAakanksha SaxenaÎncă nu există evaluări

- API 510 Section 8 QuizDocument17 paginiAPI 510 Section 8 Quizamalhaj2013Încă nu există evaluări

- Aluminum Alloys, Theory & Application - 2011Document390 paginiAluminum Alloys, Theory & Application - 2011Ahmadreza AminianÎncă nu există evaluări

- Cooling TowersDocument2 paginiCooling TowersFrancis DacutananÎncă nu există evaluări

- Chap 04-Shear Force and Bending MomentDocument27 paginiChap 04-Shear Force and Bending MomentMuhammad Fahim100% (1)

- General Ser Vice Ball Valves: GB SeriesDocument13 paginiGeneral Ser Vice Ball Valves: GB SeriesRyan DuhonÎncă nu există evaluări

- Science EarthquakeDocument3 paginiScience Earthquakexhem zeusÎncă nu există evaluări

- Operating Instructions: Oily Water Separator SKIT/S-DEBDocument50 paginiOperating Instructions: Oily Water Separator SKIT/S-DEBIzzat Khan Mohd Isnin0% (1)

- Membrane Emulsification - A Literature ReviewDocument11 paginiMembrane Emulsification - A Literature ReviewAsteriaA.SusantoÎncă nu există evaluări

- Theromodynamics 1Document14 paginiTheromodynamics 1UPSC GEOGRAPHYÎncă nu există evaluări

- 10 SteelDocument10 pagini10 SteelSahiÎncă nu există evaluări

- Practical Viva QuestionsDocument1 paginăPractical Viva QuestionsMoni KakatiÎncă nu există evaluări

- PSPM SP025 CH 5Document14 paginiPSPM SP025 CH 5CHEW LI QI MoeÎncă nu există evaluări

- Groundwater Flow and Solute Transport: Solved With Comsol Multiphysics 3.5ADocument9 paginiGroundwater Flow and Solute Transport: Solved With Comsol Multiphysics 3.5AmacryneÎncă nu există evaluări

- Short Curriculum Vitae Dr. Sushanta Kumar Panigrahi Educational ProfileDocument3 paginiShort Curriculum Vitae Dr. Sushanta Kumar Panigrahi Educational ProfileDeepak SharmaÎncă nu există evaluări