Documente Academic

Documente Profesional

Documente Cultură

WPS 2014-002 002 - 1G & 2G S 275 JR

Încărcat de

jeswinDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

WPS 2014-002 002 - 1G & 2G S 275 JR

Încărcat de

jeswinDrepturi de autor:

Formate disponibile

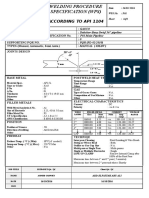

QCF-3.

1 Rev 01

ELCO INTERNATIONAL ENGINEERING Co.LLC

P.O.Box:3353, P C :111, CPO SEEB, , Sultanate of Oman

Ph:+968 97055110, Fax: +968 24503120, E.Mail:ho@omanelco.com

Page No1 of 2

WELDING PROCEDURE SPECIFICATION (AWS D1.1 -2010)

Company : ELCO INTERNATONAL ENGINEERING CO.LLC

WPS : ELCO / WPS / 15-012 / 02 Rev 0 Dated 30-09-2015 PQR : ELCO / PQR / 10 / 051B Rev 0 Dt: 14-01-10

PROCESS : SMAW TYPE(s) : MANUAL CLIENT : PETROLEUM DEVELOPMENT OF OMAN

Contract No : N/A MAIN CONTRACTOR : L & T MFY

PROJECT : RABAB HARWEEL INTEGRATED PROJECT ( RHIP)

JOB : STEEL STRUCTURE WORKS

JOINTS:-

Joint Design : Double V Butt Joint.

Backing : Yes

Backing Material (Type): : Weld Metal / Parent Metal

BASE METALS:-

Specification type and grade : BS EN 10025-2, S275JR

to Specification type and grade : BS EN 10025-2, S275JR

THICKNESS RANGE :-

Base Metal : Groove - 3mm to Unlimited Fillet - All

Pipe Diameter Range : Groove 24 & above Fillet - All

Other : N/A

FILLER METALS:-

Spec. No. : SFA 5.1

AWS No. ( Class) : E 7018

F.No :4

A.No :1

Size of Filler Metals : 2.5 , 3.2 & 4.0mm

Deposited Weld Metal : Unlimited Fillet : All

Electrode Flux (Class) : N/A

Electrode Manufacturer : ADOR / ESAB / Equivalent PDO approved Manufacturer

Other : NA

ELCO L& T MFY PEC

Prepared By Reviewed By Approved By

Sign : Sign : Sign:

Name : S.R.DESHPANDE Name : Name:

Designation: QCM Designation: Designation

Date : 30-Sep-2015 Date : Date:

ELCO / WPS / 15-012 / 02 Rev 0 Dated 30-0-2015

POSITIONS POST WELD HEAT TREATMENT

Positions(s) of Groove : 1G & 2 G Temp Range : N/A

Welding Progression : Horizontal Heating Rate : N/A

Not valid unless stamped: APPROVED FOR FABRICATION

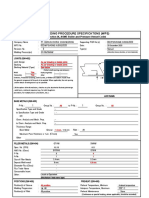

QCF-3.1 Rev 01

ELCO INTERNATIONAL ENGINEERING Co.LLC

P.O.Box:3353, P C :111, CPO SEEB, , Sultanate of Oman

Ph:+968 97055110, Fax: +968 24503120, E.Mail:ho@omanelco.com

Page No2 of 2

WELDING PROCEDURE SPECIFICATION (AWS D1.1 -2010)

ELCO / WPS / 15-012 / 02 Rev 0 Dated 30-0-2015

POSITIONS POST WELD HEAT TREATMENT

Positions(s) of Groove : 1G & 2 G Temp Range : N/A

Positions of Fillet : Horizontal (1F & 2F) Cooling Rate : N/A

Holding Time : N/A

PREHEAT GAS

: t 20mm - 50C Shielding Gas(es) : N/A

20 t 38 - 65C

Preheat Temp. Min 38 t 65 - 110C Percent Composition : N/A

For Joints with different thickness

higher Preheat shall be applied. Flow Rate : N/A

Interpass Temp Min : 50C Max: 115C Gas Backing : N/A

Preheat Method : Propane Gas (Continues or Special Trailing Shielding : None

Heating, where applicable)

ELECTRICAL CHARACTERISTICS

Current AC or DC : DC Electrode Wire Feed Speed Range : N/A

Mode of Metal Transfer for GMAW : N/A

Polarity : SMAW EP

Tungsten Electrode Size and Type : N/A

TECHNIQUE

String or Weave Bead : String for Root & Hot / Weave for Fill & Capping

Orifice or Cup Size : N/A

Initial and Interpass Cleaning Method : Wire brushing ,Grinding & Chipping

Method of Back Gouging : Grinding

Oscillation : N/A

Contact Tube to Work distance : N/A

Multiple or Single Pass ( per side) : Multiple

Multiple or Single Electrodes : Single

Peening : N/A

WELDING DATA

WELD FILLER METAL CURRENT VOLT TRAVEL HEAT

TYPE AMP. SPEED INPUT

LAYER(S) PROCESS CLASS DIA (mm) RANGES

POLARITY RANGES mm/sec KJ/ mm

1st Side

ROOT PASS SMAW E-7018 2.5 mm DC-EP 86 106 22 28 1.51 1.85 1.29 1.57

HOT PASS SMAW E-7018 3.2 mm DC-EP 122 149 23 29 1.93 2.36 1.47 1.80

FILL PASS-1 SMAW E-7018 3.2 mm DC-EP 117 143 23 29 2.12 2.60 1.29 1.59

FILL PASS-2 SMAW E-7018 4.0 mm DC-EP 150 184 23 29 2.25 2.75 1.57 1.91

CAPPING SMAW E-7018 3.2 mm DC-EP 118 - 145 23 - 28 2.39 2.92 1.12 1.36

2nd Side

FILL PASS-1 SMAW E-7018 2.5 mm DC-EP 92 112 21 26 1.72 2.11 1.15 1.41

FILL PASS-2 SMAW E-7018 3.2 / 4.0 mm DC-EP 149 -183 23 29 2.55 3.11 1.36 1.68

CAPPING SMAW E-7018 3.2 mm DC-EP 105 - 129 22 - 28 2.55 3.11 0.93 1.13

ELCO L& T MFY PEC

Prepared By Reviewed By Approved By

Sign : Sign : Sign:

Name : S.R.DESHPANDE Name : Name:

Designation: QCM Designation: Designation

Date : 30-Sep-2015 Date : Date:

Not valid unless stamped: APPROVED FOR FABRICATION

S-ar putea să vă placă și

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 paginiWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniÎncă nu există evaluări

- WPS 304L &316LDocument2 paginiWPS 304L &316LShakeel Memon100% (1)

- GMAW welding parameters for SS400 pipeDocument2 paginiGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- WPS For Smaw06-001 (Pipe 6G CS)Document10 paginiWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- Welding Procedure Specification For 24'' PipeDocument2 paginiWelding Procedure Specification For 24'' Pipeenels77100% (2)

- WPS 6G CS Pipe CorrectDocument4 paginiWPS 6G CS Pipe CorrectAla ReguiiÎncă nu există evaluări

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 paginiPage No: 01: SA 240 GR 304 SA 240 GR 304jobertÎncă nu există evaluări

- Wps Repair WorDocument1 paginăWps Repair WorMajdi JerbiÎncă nu există evaluări

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 paginiWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedÎncă nu există evaluări

- Positive Material Identification (Pmi) ReportDocument2 paginiPositive Material Identification (Pmi) Reportchim_downloadÎncă nu există evaluări

- Val Caraig WPQTDocument1 paginăVal Caraig WPQTMark Jason M. BrualÎncă nu există evaluări

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocument4 paginiWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidÎncă nu există evaluări

- WPS Sitelca S002Document2 paginiWPS Sitelca S002Jose Antonio GomezÎncă nu există evaluări

- WQTDocument1 paginăWQTRamkunwar YadavÎncă nu există evaluări

- ASME IX Sample WPS GTAW SMAWDocument1 paginăASME IX Sample WPS GTAW SMAWDeepak ShrivastavÎncă nu există evaluări

- Joint Detail (Qw-402)Document2 paginiJoint Detail (Qw-402)Nitesh Patel100% (3)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 paginăAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityÎncă nu există evaluări

- Proposed WPSDocument2 paginiProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specification: Page 1 of 1Document2 paginiWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Back Gouging ProcedureDocument8 paginiBack Gouging Proceduremahi1437100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 paginiWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberÎncă nu există evaluări

- Welding Procedure Specification GuideDocument2 paginiWelding Procedure Specification GuidepoulmackÎncă nu există evaluări

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pagini(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaÎncă nu există evaluări

- WPS 316 LDocument4 paginiWPS 316 Llaz_k100% (2)

- Fit Up Report Format-1Document1 paginăFit Up Report Format-1BalkishanDyavanapellyÎncă nu există evaluări

- WPS PQR Smaw + Fcaw D1.1Document8 paginiWPS PQR Smaw + Fcaw D1.1Yhuto W. Putra100% (3)

- WPS MatrixDocument4 paginiWPS MatrixHarshaVeeragandham50% (2)

- Reports - QAQC - R0Document10 paginiReports - QAQC - R0talupurumÎncă nu există evaluări

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 paginiPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- WPS E6013+e7018Document2 paginiWPS E6013+e7018Anvesh Vaddi100% (1)

- Visual Plate Inspection Report SummaryDocument4 paginiVisual Plate Inspection Report SummaryLaith Salman100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 paginăAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipÎncă nu există evaluări

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 paginiWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaÎncă nu există evaluări

- PQR Gmaw3gDocument4 paginiPQR Gmaw3gdevendrasingh2021100% (3)

- WPS PQR A36.20Document5 paginiWPS PQR A36.20gchaves504100% (2)

- WPS For Carbon Steel THK 7.11 GTAWDocument1 paginăWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Welding Procedure Specification (WPS) : According To Api 1104Document1 paginăWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- PT Kuwera Karya Me: PanduDocument2 paginiPT Kuwera Karya Me: PanduGalang Pratama PutraÎncă nu există evaluări

- Wps SawDocument2 paginiWps Sawdevendrasingh2021100% (6)

- P-WPS 135 - MAG (GR 316)Document9 paginiP-WPS 135 - MAG (GR 316)Tarun PatelÎncă nu există evaluări

- Wps - Asme Ix - Gtaw - PipaDocument5 paginiWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 paginiWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajÎncă nu există evaluări

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 paginiAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehÎncă nu există evaluări

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 paginiWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniÎncă nu există evaluări

- Qualified Welder List Valid Until - 03-12-2019Document2 paginiQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Wps For Aluminium WeldingDocument8 paginiWps For Aluminium WeldingPutry NHy Saya0% (1)

- QC WELDING WORKS CHECKLIST Rev.0Document2 paginiQC WELDING WORKS CHECKLIST Rev.0Rajesh Kumar Ravi100% (2)

- WPQR Welding Procedure Qualification RecordsDocument3 paginiWPQR Welding Procedure Qualification Recordsramesh rajaÎncă nu există evaluări

- Welding Procedure Specification Structural-3GDocument3 paginiWelding Procedure Specification Structural-3Gdndudc78% (9)

- FIT UP ReportDocument2 paginiFIT UP Reportsiva8000Încă nu există evaluări

- Wps For Aluminium WeldingDocument8 paginiWps For Aluminium Weldingvishal bailur50% (2)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 paginiWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 paginiPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyÎncă nu există evaluări

- Welding Procedure Specification (WPS)Document2 paginiWelding Procedure Specification (WPS)Ramadhan AdityaÎncă nu există evaluări

- WPS 2014-002 006 - 6G PipeDocument3 paginiWPS 2014-002 006 - 6G PipejeswinÎncă nu există evaluări

- WPS - 600 MW ChampaDocument7 paginiWPS - 600 MW ChampaAmjad PathanÎncă nu există evaluări

- WPS NMB 001Document6 paginiWPS NMB 001mohamed nasserÎncă nu există evaluări

- PQR FC-19-23Document2 paginiPQR FC-19-23cycsi02Încă nu există evaluări

- PQR FC-19-23.1Document2 paginiPQR FC-19-23.1cycsi02Încă nu există evaluări

- Replacement Pipe Welding ProcedureDocument7 paginiReplacement Pipe Welding ProcedureRanjan KumarÎncă nu există evaluări

- Schedule Q (Quality Requirements)Document86 paginiSchedule Q (Quality Requirements)jeswinÎncă nu există evaluări

- Inspection Release for Jacket Leg CoatingDocument2 paginiInspection Release for Jacket Leg CoatingjeswinÎncă nu există evaluări

- MDR FA 200 Welding ProcessDocument2 paginiMDR FA 200 Welding ProcessjeswinÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldDocument2 paginiSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldjeswinÎncă nu există evaluări

- Ethylene GlycolDocument8 paginiEthylene GlycoljeswinÎncă nu există evaluări

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 paginiInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinÎncă nu există evaluări

- Sample DNT Request-2Document1 paginăSample DNT Request-2jeswinÎncă nu există evaluări

- SAEP-385 - Oct 2017 PDFDocument66 paginiSAEP-385 - Oct 2017 PDFAllan Lindo0% (1)

- Sample DNT Request-1Document1 paginăSample DNT Request-1jeswinÎncă nu există evaluări

- Offshore Wind Farm Jacket Inspection ReleaseDocument2 paginiOffshore Wind Farm Jacket Inspection ReleasejeswinÎncă nu există evaluări

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 paginiInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinÎncă nu există evaluări

- ASME B46.1 2009 Standard: Introduction To ASME B46.1-2009 Donald K. Cohen, Ph.D. 3/17/2011Document16 paginiASME B46.1 2009 Standard: Introduction To ASME B46.1-2009 Donald K. Cohen, Ph.D. 3/17/2011Sowmen ChakrobortyÎncă nu există evaluări

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 paginiInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinÎncă nu există evaluări

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 paginiInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinÎncă nu există evaluări

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 paginiInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinÎncă nu există evaluări

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 paginiInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinÎncă nu există evaluări

- Legend: Project Name: LPIC EPC1 SCUDocument1 paginăLegend: Project Name: LPIC EPC1 SCUjeswinÎncă nu există evaluări

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 paginiInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinÎncă nu există evaluări

- Crystal Report Viewer 2Document4 paginiCrystal Report Viewer 2jeswinÎncă nu există evaluări

- Print My Boarding PassDocument1 paginăPrint My Boarding PassjeswinÎncă nu există evaluări

- Specification For PipingDocument34 paginiSpecification For PipingjeswinÎncă nu există evaluări

- TML ProcedureDocument19 paginiTML Procedurejeswin100% (1)

- 2Document1 pagină2jeswinÎncă nu există evaluări

- Hydro test processDocument7 paginiHydro test processjeswinÎncă nu există evaluări

- Radiography CalculationsDocument2 paginiRadiography Calculationsshahgardez100% (2)

- Guidelines For Writing Expediting Report 15.03.01 SOP-01 R01 21-06-2019...Document13 paginiGuidelines For Writing Expediting Report 15.03.01 SOP-01 R01 21-06-2019...jeswin80% (5)

- Perar ProcedureDocument21 paginiPerar ProcedurejeswinÎncă nu există evaluări

- AB-505 Risk Based Inspection Programs For Pressure EquipmentDocument23 paginiAB-505 Risk Based Inspection Programs For Pressure Equipmentjeswin100% (1)

- Aramco Piping LayupDocument2 paginiAramco Piping LayupjeswinÎncă nu există evaluări

- Barch Electric Product CatalogDocument22 paginiBarch Electric Product CatalogjeswinÎncă nu există evaluări

- Manufacturing Process PliersDocument17 paginiManufacturing Process PliersVahap ÖzdemirÎncă nu există evaluări

- SWINBURNE UNIVERSITY CNC LAB REPORT GUIDELINESDocument5 paginiSWINBURNE UNIVERSITY CNC LAB REPORT GUIDELINESChrist LeeÎncă nu există evaluări

- Indexable Drills - Sigma Toolings, Fine Boring Tools, Cutting Tools ManufacturerDocument7 paginiIndexable Drills - Sigma Toolings, Fine Boring Tools, Cutting Tools ManufacturerSigma ToolingsÎncă nu există evaluări

- Fitting Shop Tools Classification and UsesDocument8 paginiFitting Shop Tools Classification and UsesZatchBellÎncă nu există evaluări

- Module 3 - Material Processes - No PretestDocument9 paginiModule 3 - Material Processes - No PretestSofiah Leahneil BergundoÎncă nu există evaluări

- Pre-Heating System Number Designation Engine 611.981/ 983 Engine 612.983Document7 paginiPre-Heating System Number Designation Engine 611.981/ 983 Engine 612.983M̶i̶c̶h̶e̶l̶ MejiaÎncă nu există evaluări

- COFMOW CompendiumDocument22 paginiCOFMOW CompendiumRajiv Mahajan100% (1)

- Unit 2-Chapter 6 - Heat Treatment of MetalsDocument55 paginiUnit 2-Chapter 6 - Heat Treatment of Metalssainath reddy kesam reddyÎncă nu există evaluări

- Hot-rolled carbon steel data sheetDocument7 paginiHot-rolled carbon steel data sheetwulfgang66Încă nu există evaluări

- What Is Exothermic Welding - AIWELD®Document4 paginiWhat Is Exothermic Welding - AIWELD®JayÎncă nu există evaluări

- BHELDocument56 paginiBHELAjay Kumar100% (1)

- CNC Mill Model - GauravDocument4 paginiCNC Mill Model - GauravVivekanand HasaraddiÎncă nu există evaluări

- Welding Procedure Specification - TemplateDocument2 paginiWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (3)

- MCQ WeldingDocument3 paginiMCQ WeldingMostafaRock100% (2)

- Lathe Tool Notation: © Steves-Workshop - Co.ukDocument1 paginăLathe Tool Notation: © Steves-Workshop - Co.ukArtur MeierÎncă nu există evaluări

- Catalogo SunnenDocument199 paginiCatalogo SunnenEduardoCastillo100% (1)

- Aloris p2-3Document2 paginiAloris p2-3Paisaje SilenciosoÎncă nu există evaluări

- EWC CatalogDocument4 paginiEWC Catalogthirumular thiruÎncă nu există evaluări

- Angebot 151313Document7 paginiAngebot 151313luksor lukxorÎncă nu există evaluări

- Bolt Depot CatalogDocument104 paginiBolt Depot Catalogalexmontell100% (2)

- Product Instructions - Barrel Press Kit InstructionsDocument7 paginiProduct Instructions - Barrel Press Kit InstructionsDale WadeÎncă nu există evaluări

- Hilti HIT MMDocument6 paginiHilti HIT MMRobert NedelcuÎncă nu există evaluări

- 360 Flexible Drilling MachineDocument22 pagini360 Flexible Drilling Machinesumit bijwe100% (1)

- Die Casting PDFDocument16 paginiDie Casting PDFGokul PrabuÎncă nu există evaluări

- ProjectDocument34 paginiProjectSTAR PRINTINGÎncă nu există evaluări

- Pengaruh Putaran Spindel, Gerak Makan Dan Kedalaman Potong Terhadap Getaran Spindle Head Hasil Proses DrillingDocument8 paginiPengaruh Putaran Spindel, Gerak Makan Dan Kedalaman Potong Terhadap Getaran Spindle Head Hasil Proses Drillingsri wahyuniÎncă nu există evaluări

- True Mill Training ManualDocument24 paginiTrue Mill Training Manualrick.mccort2766Încă nu există evaluări

- Versa MilDocument45 paginiVersa MilmichaelguzziÎncă nu există evaluări

- Tube Bending - WikipediaDocument6 paginiTube Bending - Wikipediaramthecharm_46098467Încă nu există evaluări

- SchroefDocument14 paginiSchroefCees de JongeÎncă nu există evaluări