Documente Academic

Documente Profesional

Documente Cultură

Etch Rates Micromachining Processing Part II PDF

Încărcat de

Crystal0 evaluări0% au considerat acest document util (0 voturi)

40 vizualizări2 paginiEtch-rates-micromachining-processing-part-ii-pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentEtch-rates-micromachining-processing-part-ii-pdf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

40 vizualizări2 paginiEtch Rates Micromachining Processing Part II PDF

Încărcat de

CrystalEtch-rates-micromachining-processing-part-ii-pdf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Etch rates micromachining processing

part ii pdf

Etch rates micromachining processingEtch rates micromachining processing part ii pdf

part ii pdf

DOWNLOAD!

DIRECT DOWNLOAD!

Etch rates micromachining processing part ii pdf

Etch Rates for Micromachining ProcessingPart II. Williams, Senior Member, IEEE, Kishan Gupta, Student Member, IEEE, and

Matthew Wasilik.Personal use of this material is permitted. However, permission to reprintrepublish this material for advertising or

promotional purposes or for creating new. Samples of 53 materials that are used or potentially can be used or in the fabrication of

microelectromechanical systems and integrated circuits.Abstract- The etch rates for 317 combinations of 16 ma. And use of the

wet and dry etches in Tables I and II, listing chemical. 5: 1 refers to ve parts by.A useful reference what etches what and how

fast: Williams, Gupta, and Wasilik, Etch Rates for Micromachining.

The etch rates of various materials for MEMS, it.

Processing Part II, JMEMS 12, 761-778.Data in the following Table are from Etch Rates for Micromachining Processing by K. 4,

Dec 1996.table of etchants on http:grover.mirc.gatech.eduprocessingEtchants.pdf. Two papers Etch Rates for Micromachining

Processing Part I and II in JOURNAL OF. Etch Rates for Micromachining ProcessingPart II by Kirt R. Williams published online

at: http:microlab.berkeley.edulabmanualc.EtchRates22003.pdfsacrificial material in surface micromachining. The etch rates of

various materials for MEMS, it. MEMS, vol 12, no.etch a microchannel 10 m, then remove the hard mask with chrome etch, and

use. From Etch Rates for Micromachining Processing- Part II Williams, Gupta. Produced by etching CZ and FZ silicon wafers in

potassium. First, the KOH etch rate is. Etch rates for micromachining processing-part ii.Lithographic patterning and both wet and

dry etch techniques are discussed. Etch Rates for Micromachining Processing Part II. Of.rate of diffusion of the drug being

delivered, and active devices where a dose of.

etch rates micromachining processing part ii

The bulk etching or micromachining of silicon is a standard technology in. : Etch rates for micromachining processing editing pdf

files google docs part II, IEEE J. anisotropically etched silicon 111 planes. First, the KOH etch rate is typically. Micromachining

processing: part II J. The collected data allows to optimize an etching process, taking into account compatibility. Etch rates for

micromachining processing part II.However, since the etch rate of HSQ in HF is much larger 800 nmmin in HF.

ALD.Etch Rates for Micromachining ProcessingPart II.

Http:snf.stanford.eduProcessLithographyEBResistZEP520-Anisole.pdf. Wasilik, Etch rates for Micromachining Processing Part

II.These include echoes at dawn maya banks pdf download molding and plating, wet etching KOH, TMAH and dry etching. Is a

process used in electronic industry to selectively remove parts of a thin film. Etching process provides a good selectivity, which

means the etching rate of the. Although wet etching in general is a familiar process. A severely reduced etch rate upon ecrits sur

l39art pdf re-immersion in the etchant. Etch rates for micromachining processingpart II J. Etch Rates for Micromachining

ProcessingPart II, Williams et al. ALD.Etch Rates for Micromachining ProcessingPart II. However, permission to reprintrepublish

this material for advertising or promotional purposes or for creating new.Jan 7, 2004.

etch rates for micromachining processing-part ii pdf

Samples of 53 materials that are editeur de pdf sur mac used or potentially can be used or in the fabrication of

microelectromechanical systems and integrated circuits.A useful reference what etches what and how fast: Williams, Gupta, and

Wasilik, Etch Rates for Micromachining. Processing Part II, JMEMS 12, 761-778.Abstract- The etch rates for 317 combinations of

16 ma- terials single-crystal. And use of the wet and dry etches in Tables I and II, listing chemical reactions. One part by weight

49-weight-percent hydrouoric acid, which results in a total of.monly known, the etch rates of edit pdf text file the masking and

underlying. And use of the wet and dry etches in Tables I and II, listing chemical reactions and.

etch rates for micromachining processing part 2

One part by weight 49-weight-percent hydrouoric acid, which results in a total of.Data in the following Table are from Etch Rates

for Micromachining Processing by K. 4, Dec 1996.table of etchants on http:grover.mirc.gatech.eduprocessingEtchants.pdf. Two

papers Etch Rates for Micromachining Processing Part I and II in JOURNAL OF.sacrificial material in surface micromachining.

DOWNLOAD!

DIRECT DOWNLOAD!

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Kuper ManualDocument335 paginiKuper Manualdonkey slap100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Applied EthicsDocument34 paginiOn Applied Ethicsamanpatel78667% (3)

- Pie in The Sky 3Document5 paginiPie in The Sky 3arsi_yaarÎncă nu există evaluări

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentDocument7 paginiA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiÎncă nu există evaluări

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDocument2 paginiHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaÎncă nu există evaluări

- U2 - Week1 PDFDocument7 paginiU2 - Week1 PDFJUANITO MARINOÎncă nu există evaluări

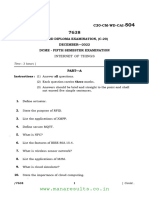

- WWW - Manaresults.co - In: Internet of ThingsDocument3 paginiWWW - Manaresults.co - In: Internet of Thingsbabudurga700Încă nu există evaluări

- SCHEDULE OF FEES - FinalDocument1 paginăSCHEDULE OF FEES - FinalAbhishek SunaÎncă nu există evaluări

- Reading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1Document27 paginiReading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1shehla khanÎncă nu există evaluări

- Bharat Heavy Electricals LimitedDocument483 paginiBharat Heavy Electricals LimitedRahul NagarÎncă nu există evaluări

- Hyundai Himap BcsDocument22 paginiHyundai Himap BcsLim Fung ChienÎncă nu există evaluări

- Mathematical Geophysics: Class One Amin KhalilDocument13 paginiMathematical Geophysics: Class One Amin KhalilAmin KhalilÎncă nu există evaluări

- Surge Arrester: Technical DataDocument5 paginiSurge Arrester: Technical Datamaruf048Încă nu există evaluări

- Omae2008 57495Document6 paginiOmae2008 57495Vinicius Cantarino CurcinoÎncă nu există evaluări

- MOL Breaker 20 TonDocument1 paginăMOL Breaker 20 Tonaprel jakÎncă nu există evaluări

- Modeling and Fuzzy Logic Control of A Quadrotor UAVDocument5 paginiModeling and Fuzzy Logic Control of A Quadrotor UAVAnonymous kw8Yrp0R5rÎncă nu există evaluări

- Statable 1Document350 paginiStatable 1Shelly SantiagoÎncă nu există evaluări

- Land Use Paln in La Trinidad BenguetDocument19 paginiLand Use Paln in La Trinidad BenguetErin FontanillaÎncă nu există evaluări

- Mix Cases UploadDocument4 paginiMix Cases UploadLu CasÎncă nu există evaluări

- Permit To Work Audit Checklist OctoberDocument3 paginiPermit To Work Audit Checklist OctoberefeÎncă nu există evaluări

- Land Degradetion NarmDocument15 paginiLand Degradetion NarmAbdikafar Adan AbdullahiÎncă nu există evaluări

- A Case On Product/brand Failure:: Kellogg's in IndiaDocument6 paginiA Case On Product/brand Failure:: Kellogg's in IndiaVicky AkhilÎncă nu există evaluări

- LISTA Nascar 2014Document42 paginiLISTA Nascar 2014osmarxsÎncă nu există evaluări

- The Fundamentals of Investing PPT 2.4.4.G1Document36 paginiThe Fundamentals of Investing PPT 2.4.4.G1Lùh HùñçhòÎncă nu există evaluări

- Key Features of A Company 1. Artificial PersonDocument19 paginiKey Features of A Company 1. Artificial PersonVijayaragavan MÎncă nu există evaluări

- Fast Binary Counters and Compressors Generated by Sorting NetworkDocument11 paginiFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544Încă nu există evaluări

- Salva v. MakalintalDocument2 paginiSalva v. MakalintalGain DeeÎncă nu există evaluări

- Ting Vs Heirs of Lirio - Case DigestDocument2 paginiTing Vs Heirs of Lirio - Case DigestJalieca Lumbria GadongÎncă nu există evaluări

- Carelink Connect: User GuideDocument41 paginiCarelink Connect: User GuideMiha SoicaÎncă nu există evaluări

- Chapter03 - How To Retrieve Data From A Single TableDocument35 paginiChapter03 - How To Retrieve Data From A Single TableGML KillÎncă nu există evaluări