Documente Academic

Documente Profesional

Documente Cultură

Condenser Simulation

Încărcat de

Amir AbbaszadehDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Condenser Simulation

Încărcat de

Amir AbbaszadehDrepturi de autor:

Formate disponibile

G.

Zhang

Post Doctoral Fellow.

Numerical Simulation of Different

A. C. M. Sousa

Types of Steam Surface

Professor,

Mem. ASME Condensers

A numerical procedure is developed to simulate the fluid flow and heat transfer

J. E. S. Venart processes in the shell-side of steam surface condensers. The governing equations are

Professor. solved in primitive variable form using a semi-implicit consistent control-volume

formulation in which a segregated pressure correction linked algorithm is employed.

Fire Science Center, The procedure is applied to three different types of surface condenser. The numerical

and Department of Mechanical Engineering, predictions are critically assessed by comparison to available experimental data for

University of New Brunswick, condensers, and in general, the solutions are in good agreement with the experimental

Fredericton, New Brunswick, Canada data.

I Introduction

Failure and/or off-design performance of power plant steam CALICO developed at Electricite de France, which uses a two-

surface condenser, as pointed out by Diaz-Tous [6], have re- dimensional, pseudo-transient numerical algorithm. Its pre-

sulted in substantial losses due to plant down-time and/or low dictions may prove useful in optimizing geometric parameters

efficiency. Values of 3.8 and 1.5 to 2 percent are reported for with respect to flow-induced vibration. Al-Sanea et al. [1]

loss of unit availability and performance loss, respectively, of employ a commercial code to solve the partial-differential

installed power in the US utility industry. The costs of these equations governing the two-dimensional flow field and steam

losses during the period 1974-1984 was estimated to be more concentration. The densities for the steam and air, possibly

than US$ 18 billion (1974 US$). These losses indicate that there for computational expediency, were assumed to be constant.

is a clear need of design methods, which can predict the shell- Shida et al. [12] and Takahashi et al. [13] analyze several

side flow distribution and heat transfer. This information is condenser configurations by using the numerical technique first

of critical importance in performing analyses related to flow- reported by Shida et al. [11], In this technique, the mesh is

induced vibration, heat transfer rates and pressure losses, based on a triangular pattern as in the finite element method,

which, eventually, will lead to enhanced unit performance and and the calculations are performed using upwind two-step La-

reliability. For instance, an average 1-in. Hg increase of back grangian and Eulerian time-marching techniques.

pressure costs US$ 1 million and US$ 2 million annually for The procedure developed employs coupled heat transfer and

typical 600 MWe oil-fired and nuclear units, respectively. fluid flow calculation techniques combined with a continuum

To attain the goal of developing new methods, a viable approach, where the steam/air mixture is assumed to be flow-

approach is through advanced numerical models, which are ing through a porous medium. Densities for steam and air vary

based on governing differential equations and appropriate con- according to the local conditions, and in addition the procedure

stitutive relations. In this way the designer can investigate the incorporates a model, which can accommodate multipass con-

effects of different shapes of tube nest, placement of baffles, densers with the assumption that at the end of each pass, the

steam lanes and venting points. outlet cooling water temperature is well mixed and equal to

The open nonproprietary literature dealing with numerical that into the next pass. The present study is a further extension

modeling of condensers is not extensive, and, in many cases, of recent work by Zhang and Sousa [16,17], in which single-

critical details of the models and/or relevant results are omit- phase flow was modeled for a shell-and-tube heat exchanger

ted. In the present work a numerical procedure is proposed, [16], and preliminary computations were carried out for a

which combines some of the features suggested by Davidson condenser with a simple geometric configuration [17].

and Rowe [5], Davidson [4], Caremoli [3], Al-Sanea et al. [1], Three different steam surface condenser configurations as

Shida et al. [11,12], and Takahashi et al. [13]. Davidson and described by Fuji et al. [8], Naviglio et al. [9], and Al-Sanea

Rowe [5] and Davidson [4] outline the basis of the continuum et al. [1] are utilized in the evaluation of the code. The results

modeling approach for the thermal design of condensers, and are compared with available experimental data so to bench-

review some related work. Caremoli [3] describes the program mark the procedure and on a preliminary basis to validate the

program.

Contributed by the Petroleum Division for publication in the JOURNAL OF II Numerical Method

ENERGY RESOURCES TECHNOLOGY. Manuscript received by the Petroleum Di-

vision, July 20, 1990; revised manuscript received April 11, 1991. Two different approaches may be used for condenser mod-

Journal of Energy Resources Technology JUNE 1991, Vol. 113/63

Copyright 1991 by ASME

Downloaded From: http://energyresources.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

eling: nodal equations, which call for the specification of the Mass Conservation Equation

local equations for each tube within the bundle, and continuum

models where the steam is considered to be flowing in a porous -?-((3pu)+j-tfpv)=-(3m . (2)

medium. For power plant condensers, however, the latter ap- ox dy

proach is the only viable one for engineering thermal-hydraulic Momentum Conservation Equations

analyses, since the first method may yield impractically large

computer requirements. Thus, the porous medium concept is 3 , , a , , d ( bu\ d ( ou

used in this study, and an isotropic porosity, 13, employed to

describe the flow volume reduction due to the tube bundle and

baffles, is defined as -(3^-pmu + 0Fu (3)

Volume occupied by the fluid 0 d d

(1) ,o s ,o s (o V\ d

(o dv

Total volume

- 3Puv) + - ( M = - ^ - j +- ^ -

This method has been shown by Rhodes and Carlucci [10] and -!3^-l3mv + f3Fv (4)

Theodossiou et al. [14] to describe adequately the flow in tube dy

banks. Conservation of Air Mass Fraction

The shell-side and water-side flows are treated as steady

state. On the steam side the model considers the fluid to be a

mixture of noncondensable gases (air) and steam, behaving as l ^U) + Ty ^V) = YX ( * fx) + Ty (* fy) (5)

a Newtonian fluid with constant viscosity. The mixture of

steam and noncondensable gases, for simplicity, is assumed to 2.2 Auxiliary Relationships

be a perfect gas, although other equations of state can be

considered, and its density varies locally according to the per- (/) Momentum Source Term. The local hydraulic flow

fect gas state equation. The steam is assumed at its saturation resistances, Fu and F, in the momentum equations caused by

temperature throughout the condenser. This assumption is the tube bundle and/or baffles, are related to the pressure loss

based on the observation reported by Bush et al. [2] that su- coefficients, and , by

perheating has little effect upon heat transfer. Fu = kuuUp (6)

The governing equations are the equations of conservation

Fv=^vUp (7)

of mass, momentum and air mass fraction, and they are solved

by a modified control-volume formulation based on the al- Since there is no general expression for the pressure loss in

gorithm suggested by Van Doormaal and Raithby [15], and to condensing tube banks, as a first approximation, the expres-

be described in Section 2.4. sions proposed by Rhodes and Carlucci [10] for the loss coef-

ficients and are used; namely,

2

2.1 Conservation Equations. The two-dimensional fu\ P(3 1-/

steady-state porous medium volume-averaged conservation iu=2 (8)

P-D,

equations of mass, momentum and air mass fraction, with

flow, heat and mass transfer resistances are written in the P(3 1-/3

Cartesian coordinate system, as follows: f. = 2ft P-Dr 1-A.

(9)

Nomenclature

A = heat transfer area [m ] P - tube pitch [m]

C = gas constant [m2/s2K] Pr = Prandtl no. = cp\x/k

cp = specific heat at constant p = pressure [Pa] local volume porosity

pressure [J/kg K] q = heat flux [W/m 2 ] A = porosity in tube bundle re-

D = diffusivity of air in vapor R = thermal resistance [m 2 K/W] gion

[m2/s] Rem = Reynolds no. for maximum V = dynamic viscosity [kg/m s]

D, = inner diameter of tube [m] He effective dynamic viscosity

=

flow area = pcMD0/psixc

D0 = outer diameter of tube [m] [kg/m s]

Re u = x direction Reynolds no. =

Fr = Froude no. = M2/ps2gD0 puD0/ii Hi = effective dynamic viscosity

, F = flow resistance forces in mo- Re = y direction Reynolds no. = [kg/m s]

mentum equations [N/m 3 ] pvD0/jx P density [kg/m 3 ]

fu, fv = friction factors <t> air mass fraction = pjp

T = temperature [K]

g = gravitational acceleration Up = velocity vector magnitude = > = l s s coefficients [m ']

[m/s2] (w 2 +i; 2 ) 1/2 [m/s]

k = thermal conductivity [W/m u = velocity component in x di- Subscripts

K] rection [m/s]' a air

L = latent heat of condensation V = volume [m3] C condensate

[J/kg] v = velocity component in y di- cs steam-condensate interface

M = mass velocity of steam rection [m/s] s steam

through maximum flow area x = main flow direction coordi- t tube wall

[kg/m 2 s] nate [m] u parameter in x-momentum

M' = steam condensation rate y = cross stream coordinate [m] equation

[kg/s] a = heat transfer coefficient at parameter in j-momentum

m = steam condensation rate per shell-side = q/(T-T,) equation

unit volume [kg/m 3 s] [W/m 2 K] w = cooling water

6 4 / V o l . 113, JUNE 1991 Transactions of the ASME

Downloaded From: http://energyresources.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

The friction factors,/ andfv, and the porosity in the tube

bundle region, ft, are defined as

0.619 Re- ; Re < 8000

fu =

1.156 Re" 0 - 2647 ; 8000 < Re < 2*105

0.619 R e , / 0 " 8 ; Re < 8000

/ =

1.156 Re,r 0 ' 2 6 4 7 ; 8000 < Re < 2*105

*--J@

(ii) Mass Source Term. The mass condensation rate per

unit volume, m, can obtained by a simple energy balance equat-

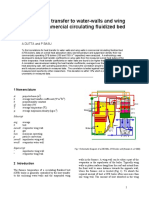

Fig. 1 Grid arrangement

ing the phase change enthalpy with the heat transfer rate

* S -* W

mLV= (10) p = pCT=PaCaT+PsCsT (16)

R

where T is the saturation temperature determined by partial

where the cooling water temperature Tw is obtained from the

steam pressure, and C, Ca and Cs are the gas constants for the

heat balance between the steam and cooling water for each

mixture, air and steam, respectively.

control volume. The overall thermal resistance for each control

volume, R, is calculated from various semi-empirical heat (iv) Effective Viscosity. The concept of an effective vis-

transfer correlations, as described in the forthcoming. cosity is used, which is defined as the sum of the laminar and

For the water-side thermal resistance, the relationship sug- turbulent viscosity, namely,

gested by Dittus and Boelter [7] is employed; namely,

He = H + H, (17)

-^- = 0.023 R e / 8

Pr 04 For all simulations the turbulent viscosity, /*,, mainly to save

computer time in this exploratory stage of the study, is assumed

The wall resistance for each tube is obtained with the as- to be constant. Its value, based on previous work by Zhang

sumption of one-dimensional, steady-state conduction and Sousa [17,18], is kept at a range of 10 to 100 times the

dynamic viscosity, /x.

/},= [AJog(ZVA)]/(2*,) (12)

In this paper, since its purpose is to demonstrate the nu- 2.3 Boundary Conditions. The boundary conditions for

merical calculation method rather than to conduct a detailed the inlet, outlet and solid walls are:

analysis of the process, filmwise condensation is assumed. The

resistance due to condensation is calculated based on the work Inlet: The velocity and air mass fraction are specified at the

of Fujii et al. [8] inlet boundary.

Outlet: The pressure is fixed at the outlet and a mass imbalance

J_ correction scheme is used to update the normal outflow ve-

KX[ 1 +0.276/(x 4 Fr H)}lM Re m 1/2 k/D (13)

R, locity.

Walls: The shell walls of the condenser are assumed to be non-

where

K=0.% for in-line arrangement slip, impervious to flow, and adiabatic.

K= 1.0 for staggered arrangement 2.4 Solution Procedure. The discretization of the differ-

ential equations, equations (2)-(5), is carried out by integrating

X = 0.9 [l + \/(rH)]xn

liner piecewise profiles over the control volumes defined on a

Fr = M2/psg D0; H=cpc(Ts- Tw)/PrcL staggered grid as shown in Fig. 1. In this grid configuration,

the velocity components are stored on the center of the control

Re, = pcM D0/psjic; r= (pciic/ps/j,s)wl volume surfaces, while all other variables, such as pressure,

The fouling resistance (R/) is taken as 3.5*10~5 m 2 K/W as temperature, and air mass fraction are located on the center

suggested by Naviglio et al. [9] and the resistance due to the of the control volume. The control volumes for each velocity

presence of an air film is evaluated via a mass transfer coef- component and for the scalar quantities do not coincide; this

ficient as reported by Caremoli [3] arrangement has the convenient feature of storing the velocity

components at points where they are required for the calcu-

1/3 lation of their convective contribution. Also, the important

(14)

advantage of this type of grid is that the pressure difference

where between two adjacent grid points relates the driving force for

the velocity component located between these grid points.The

= 0.52 and 6 = 0.7 for Re,< 350 resulting discretized equations are solved in primitive variables

a = 0.82 and 6 = 0.6 forRe s >350 using the algorithm proposed by Van Doormaal and Raithby

[15]. Since these equations are coupled together and are highly

The overall resistance to heat transfer for each control vol- nonlinear, an iterative approach is used for their solution. A

ume, R, is the sum of the individual resistances just outlined; cyclic outer iteration is employed comprising the following

thus, R, when related to the outer surface of the tube, can be sequence of operations:

written as

(/') The momentum equations, equations (3) and (4) after

R = Rw-^ + R, + Rc + Rf+Rs (15) discretization, are solved based on a pressure field taken from

the previous iteration.

(Hi) Equation of State. The air and steam mixture is (ii) A Poisson equation for the pressure correction, derived

assumed to behave as an ideal gas; namely, from the continuity equation, equation (2), is solved, and at

Journal of Energy Resources Technology JUNE 1991, Vol. 113/65

Downloaded From: http://energyresources.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Vinyl tube

Steam

outlet - Cooling water

inlet

Cooling water

outlet

Fig. 2 Configuration of condenser no.1(a) in-line arrangement, (b) staggered arrangement

Table 1 Experimental and computational conditions for condenser con- (vi) The overall energy balance for cooling water, steam,

figuration no.1

and condensate is checked.

Arrangement of Tube In-line

2.5 Convergence Criteria. Based on numerical tests, the

Test No. Run No.3 Run No.6

convergence criteria for the overall computational procedure

Test

Conditions

Exp. Cal. Exp. Cal. have been specified as:

Inlet Pressure Pa 5476 b

5424 a 6481 b 6508 a j

a

(/) the Euclidean error norm for the momentum equations

Inlet Temperature C 34.48 34.27 37.55 37.59a|

is less than 10~5;

Inlet Velocity m/s 16.74 16.74 28.21 28.21 J (//) the total continuity error is less than 0.01 percent of the

1 Steam Outlet Pressure Pa 5365 b 5365 b 6345 b 6345 b l mass inflow.

a

Outlet Temperature C 34.11 34.07 37.16 37.123] III Experimental Condenser: Application Example

M'*10+3 kg/s 7.12 6.82 a 14.05 14.09 a l No.

Inlet Temperature C 7.75 7.75 10.72 10.72 I 3.1 Configuration of Condenser No. 1. The experimental

Water Inlet Velocity m/s 0.505 0.505 1.350 1.350 data of fluid flow and heat transfer in the steam surface con-

denser of Fujii et al. [8] is used as one test of the proposed

Outlet Temperature C 14.16 13.86 a 15.44 15.43 a

numerical method. This small steam condenser with a five-

pass layout was designed to study the heat transfer and pressure

8 Arrangement of Tube Staggered B loss in the steam side for the two tube banks of in-line and

staggered arrangements. Figure 2 shows the configurations of

I Test No. Run No.12 Run No.14 I

two tube banks. Each bank was composed of brass tubes of

I Test

Conditions

Exp. Cal. Exp. Cal. 1 14.0 mm o.d., and 10.4 mm i.d., and 100 mm heat transfer

Inlet Pressure Pa 3413 b 3414 a 4739 b 4694 a I length, the tubes were arranged in 15 rows normal to the

a

direction of the steam flow and with 22 mm normal spacing.

Inlet Temperature c 26.22 26.18 31.90 31.69 a

Steam temperature and bulk mean temperature of cooling water

Inlet Velocity m/s 16.85 16.85 27.22 27.22 entering and leaving the tubes were measured by copper-con-

Steam Outlet Pressure Pa 3371 b 3371 b 4560 b 4560b stantan sheath thermocouples of 16 mm diameter. The flow

rate of cooling water through each row was measured by 15

Outlet Temperature C 26.01 25.97 a 31.22 31.18 a

sets of an inverse U-tube water manometers and an orifice,

,

M *10 +:J

kg/s 4.59 4.67 a

10.10 9.18 a and was distributed uniformly within an accuracy of 2 percent.

Inlet Temperature C 7.70 7.70 8.01 8.01 The total condensation rate of the tube bank was evaluated

through the accumulation rate of the condensation in a meas-

Water Inlet Velocity m/s 0.634 0.634 1.186 1.186

uring glass tube attached to a drain separator.

Outlet Temperature C 11.36 10.91 a 11.91 11.52a

3.2 Results and Discussion. The experimental conditions

a - Predicted results; Saturation pressure. of four filmwise condensation test cases (run no.3, run no.6,

run no. 12 and run no. 14 (Fujii et al. [8])), as shown in Table

the end of each outer iteration loop, pressures and velocities 1 were chosen to evaluate the numerical model. In this case,

are corrected. the steam inlet velocity and outlet pressure are given, and the

steam inlet pressures are calculated from the outlet pressure

(Hi) The air mass fraction <j> is obtained from the discretized and pressure drop.

form of its transport equation, equation (5).

(iv) The temperatures of mixture and cooling water, den- (/') Grid-Independence Tests. Calculations were carried

sity, mass source term, and momentum source term are then out in grids of 40x20 in the main and cross-flow directions,

updated. respectively. To test the grid-independence of the solutions,

(v) A new cycle is started unless the prescribed accuracy three different grids, 21 x 10, 40x20 and 59x30, were used.

has been reached. Convergence trends indicated an asymptotic behavior. Com-

66 / V o l . 113, JUNE 1991 Transactions of the ASME

Downloaded From: http://energyresources.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 2 Grid-independence tests for condenser configuration Table 3 Predicted results with different turbulent viscosities

no.l (run no.12) for condenser configuration no.l (run no.12)

Mesh size 20x10 40x20 59x30 /*( 10/i 20/t 100/1

/W(Pa) 3410.8 3414.5 3415.9 Pinia , ( P a ) 3412.8 3414.5 3422.8

M'*10 3 (kg/s) 4.4666 4.4672 4.4675 M'*10 3 (kg/s) 4.4667 4.4672 4.4698

V-* ivJoutlet ( *-v 10.913 10.914 10.914 Ww)out!et ( C ) 10.913 10.914 10.915

CPU time (s) 7.4 19;3 38.4

Table 4 Predicted results with different inlet air mass fraction

for condenser configuration n o . l (run no.12)

4>m\a 0 0.15 0.5 2

(percent) (percent) (percent)

Pinlet 3414.5 3416.6 3416.8 3417.9

M'*10 3 (kg/s) 4.4672 4.4453 4.4085 4.2832

(* iv/outlet ( W 10.914 10.898 10.872 10.783

TUBE ROW NO.

Fig. 3 Steam and outer tube surface temperatures in condenser con-

figuration no.1 (run no.3)

Fig. S Layout of tube bundle In condenser configuration no.2

6

* T

between the heat obtained by cooling water and the heat re-

leased from condensed steam, which was always kept at a value

less then 1 percent.

(Hi) Influence of Turbulent Viscosity. Typical values of

the turbulent viscosity, /*,, are about 20 times the value of the

dynamic viscosity, JX. As shown in Table 3, predictions for

Run No. 12 with three different turbulent viscosities present

TUBE ROW NO. only slight differences when /i, is changed from 10 to 100 times

Fig. 4 Heat flux and shell-side heat transfer coefficient in condenser the value of the dynamic viscosity.

configuration no.1 (run no.3)

(iv) Effectsof Inlet Air Mass Fraction. As is well known,

air in steam condensers will lower the heat transfer rates, which

parison of the different grids was conducted for run no. 12, as will seriously affect the overall thermal performance. This is

depicted in Table 2, and it is found that the grid 40x20 is exemplified in Table 4 for Run No. 12, for which different inlet

sufficiently fine to yield a grid-independent solution. air mass fractions are considered. As indicated, an increase of

2 percent in the inlet air mass fraction yields to a decrease of

(ii) Predicted Results and Comparisons With Experimen- 4.5 percent of the steam condensation rate.

tal Data. The predicted results and their corresponding ex-

perimental conditions are listed in Table 1. The simulation is

in good agreement, with the maximum difference between IV Industrial Surface Condenser: Application Ex-

prediction and experiment being under 9 percent. This accuracy ample No. 2

is within the experimental accuracy, which, according to Fujii 4.1 Configuration of Condenser No. 2. The numerical

et al. [8], was of the order of 10 percent. The predicted results procedure proposed in this work was used to predict the two-

shown in Table 1 are averaged values either at inlet or outlet, dimensional fluid flow and heat transfer in an industrial surface

although the variables change little in the cross direction due condenser reported by Naviglio et al. [9]. The layout of the

to the configuration of this condenser. tube bundle for one-half of the condenser is depicted in Fig.

The variations of steam and outer tube surface temperatures 5. The whole tube bundle is composed of 3968 stainless steel

(T and T,) on the centerline are given in Fig. 3. The steam tubes arranged in a triangular pitch, the characteristic feature

temperature as shown in Fig. 3 is nearly constant across the of this condenser is one single central outlet for the extraction

tube bank, except at the inlet where a small decrease does of noncondensible gases. The calculation domain is limited to

occur. The outer tube surface temperature decreases in the the plane of symmetry passing through the corresponding ex-

tube axial direction since condensation occurs near tubes, The traction outlet. The geometrical and operating parameters are

heat flux (q) on the centerline is almost uniform across the listed in Table 5.

tube bundle. The centerline shell-side heat transfer coefficient,

a, defined as dividing heat flux (q) by temperature difference 4.2 Results and Discussion. The calculations were per-

between steam and outer tube (T Ti), decreases as shown in formed in a nonuniform mesh to accommodate the shape of

Fig. 4. In this experiment, the temperature rise of cooling water tube bundle. It was found that a grid of 30 x 18 in the main

is much smaller than the temperature difference between steam and cross-flow directions, respectively, was sufficient to yield

and cooling water, so, the heat flux {q) varies only slightly grid-independent solutions. The grid used for the simulation

along the tube axis. A futher check upon the accuracy of the is shown in Fig. 6. An average of 95 computational cycles was

calculation was conducted by verifying the energy imbalance found to yield adequate convergence.

Journal of Energy Resources Technology JUNE 1991, Vol. 113/67

Downloaded From: http://energyresources.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 5 Geometrical and operating parameters for condenser Up (m/s)

configuration no.2

Geometrical parameters

Condenser length (m) 7.3

Tube outer diameter (mm) 19.05

Tube inner diameter (mm) 17.65

Tube pitch (mm) 26.0

Operating parameters

Inlet temperature of cooling water (C) 20.0

Inlet velocity of cooling water (m/s) 1.19

Inlet pressure of steam (Pa) 7500 Fig. 9 Velocity distribution for condenser configuration no.2

Inlet velocity of steam (m/s) 45.0

a (KW/m2 K)

Fig. 6 Grid used for the simulation of condenser configuration no.2 Fig. 10 Shell-side heat transfer coefficient distribution in condenser

configuration no.2

and a uniform pressure distribution around the bundle was

assumed. This may lead to large errors, as noted in the pre-

dictions by Al-Sanea et al. [1] and Caremoli [3] for an exper-

imental condenser and a nuclear power plant condenser,

respectively, the velocity vectors around the tube bundle are

nearly "parallel" to the tube bundle except near the rear wall,

where they are directed towards the tube bundle, as shown in

Fig. 7 Velocity vector plot for condenser configuration no.2 Fig. 7. In the work reported here no such restriction was im-

posed and full development of the flow was permitted.

P (KPa)

V Experimental Condenser: Application Example

No. 3

5.1 Configuration of Condenser No. 3. The configura-

tion of condenser no.3 (geometry no.l) from Al-Sanea et al.

[1] is depicted in Fig. 11(a). Also, an alternative configuration

for condenser no.3 (geometry no.2), with a wider steam lane

between the tube bundle and rear wall, is shown in Fig. 11(b).

Fig. 8 Pressure distribution for condenser configuration no.2

It presents an internal vent, and the tube bank is composed

of 400 tubes of triangular arrangement. It is assumed that the

horizontal centerline is a symmetry plane, so, the calculations

The predicted vector velocity field is plotted in Fig. 7. It can are performed only for one-half of the condenser. The geo-

be clearly seen that flow deflection occurs away from the tube metrical and operating parameters are listed in Table 6.

bank. The flow turns towards the tube bundle due to the rear

wall and the suction effect of the tube bundle. The velocity in 5.2 Results and Discussion. Nonuniform grids of 31 X 17

the vicinity of the extraction is low as predicted by Naviglio and 33 x 17 in the main and cross flow directions are used in

et al. [9], and the velocities decrease to very small values in the calculations for geometry nos. 1 and 2, respectively. The

the middle of the tube bundle as the vapor condenses. grids used for the simulations are shown in Fig. 12.

The contour map plots of pressure (p) and velocity (Up) are Figure 13 shows the velocity plots for geometry no.l (Fig.

presented in Figs. 8 and 9. The gradient of pressure is very 13(a)) and geometry no.2 (Fig. 13(b)). As anticipated, the

large in the venting region due the effect of the baffles. The steam velocity is very low near the venting region. Again there

results show that the pressure drop from the inlet of the tube is some deflection of the flow away from tube bank, a feature

bundle to the venting zone is of the order of 500 Pa. The that was also observed in the calculations of Al-Sanea et al.

gradient of velocity is large in the vicinity of the tube bundle, [1]. Figure 14 compares the velocity distributions for geometry

while the velocity is small inside the tube bundle due to the no.l (Fig. 14(a)) and geometry no.2 (Fig. 14(b)). In these two

condensation. The shell-side heat transfer coefficient (a) is flow situations, the inlet mass flow rates are the same, 1.008

shown in Fig. 10, and its values in the vicinity of the tube kg/s, with condensation rates of 1.006 kg/s and 1.004 kg/s,

bundle are very large. Thus, as expected, the heat transfer rate respectively, indicating that 99.8 and 99.6 percent of the steam

near tube bundle is larger then that inside of tube bundle. is condensed in geometry nos. 1 and 2 of condenser no.3,

Choice of the boundary condition at the tube bundle edge respectively. The velocities in the region opposite the inlet and

plays an important role in the modeling of condensers. In the close to the line of symmetry in geometry no.2 are larger than

study of Naviglio et al. [9], the simulation of the flow outside those in geometry no.l. Since the steam lane at the rear wall

the tube bundle and shell of the condenser was not implemented of condenser is wider for geometry no.2 more steam enters

6 8 / V o l . 113, JUNE 1991 Transactions of the ASME

Downloaded From: http://energyresources.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Oj02m

* 0,3m* -a 07n> B ^

Tube bank j

Vent 1

Steam

inlet

(a) Geometry no.1

U (a) Geometry no.1

0.1m

3m+ 0.7m-

(b) Geometry no.2

Fig. 12 Grids used for the simulation of condenser configuration no.3

Steam

inlet

u (b) Geometry no.2

Fig. 11 Configuration of condenser no.3

(a) Geometry no.1

Table 6 Geometrical and operating parameters for condenser

configuration no.3

Geometrical parameters

Condenser length (m) 1.219

Tube outer diameter (mm) 25.4

Tube pitch (mm) 34.9

Operating parameters

Inlet temperature of cooling water (C) 17.8

Inlet velocity of cooling water (m/s) 1.19

(6) Geometry no.2

Inlet pressure of steam (Pa) 27670

Inlet velocity of steam (m/s) 12.05 Fig. 13 Velocity vector plots for condenser configuration no.3

this lane, and turns towards the tube bundle due to combined VI Closing Remarks

effects of the rear wall and the "suction" of the tube bundle.

The lowest velocities on the centerline of condenser occur at The numerical procedure proposed in the present study has

x = 0.8 and x=0.1 m for geometry nos. 1 and 2, respectively. shown its capability of predicting the performance of con-

Figure 15 shows the pressure (p) distribution for geometry densers of different geometries. The predictions have produced

no.1, while Figs. 16 and 17 present the distributions of shell- physically meaningful results, but full benchmarking of the

side heat transfer coefficient (a) and heat flux (<?). The lowest procedure, however, requires further testing against experi-

pressure, heat transfer coefficient and heat flux values occur mental data for condensers with different configurations and

in the venting region. It is noted from the contour maps that operating conditions. This information will guide future de-

both the pressure and heat transfer coefficient distributions velopments of the model, particularly in what concerns the

are similar. In both distributions the gradients of pressure and constitutive relations. This particular aspect is of primary im-

shell-side heat transfer coefficient are larger at the tube bundle portance, since vapor superheating, condensate subcooling,

boundaries. Figure 17 shows that the highest heat flux occurs flooding and condensation conditions will dictate the relations

on the first row of tubes as may be expected since the steam for the heat transfer and pressure loss parameters to be em-

velocity is highest there. The heat flux is largest at the tube ployed.

bundle periphery and falls rapidly to lower values in the venting

region. In Fig. 16, it can be seen that the shell-side heat transfer

coefficient decreases sharply from the tube bundle boundaries Acknowledgment

to the inside of bundle. Financial support for this work was received from the Uni-

Joumal of Energy Resources Technology JUNE 1991, Vol. 113/69

Downloaded From: http://energyresources.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

a (KW/m2 K)

(a) Geometry no.1 Fig. 16 Shell-side heat transfer coefficient distribution for condenser

configuration no.3 (geometry no.1)

q(KW/i

(fj) Geometry no.2

Y(m)

Fig. 14 Velocity distributions for condenser configuration no.3

0.22

X(m)

P (KPa)

Fig. 17 Heat flux distribution for condenser configuration no.3 (ge-

ometry no.1)

7 Dittus, F. W., and Boelter, L. M. K., "Heat Transfer in Automobile

Radiators of the Tubular Type," Engineering, University of California, Berke-

ley, Vol. 2, 1930, pp. 443-461.

8 Fujii, T., Uehara, H., Hirata, K., and Oda, K., "Heat Transfer and Flow

Resistance in Condensation of Low Pressure Steam Flowing Through Tube

Banks," International Journal of Heat and Mass Transfer, Vol. 15, 1972, pp.

247-260.

9 Naviglio, A., Sala, M., Socrate, S., Stefani, A., and Vigevano, L., "Dis-

tribution of Non-Condensable Gases Within the Tube Bundle of Surface Con-

Fig. 15 Pressure distribution for condenser configuration no.3 (ge- densers," TEC 88-Conference, Recent Advances in Heat Exchangers, Grenoble,

ometry no.1) France, December 10-13, 1988.

10 Rhodes, D. B., and Carlucci, L. N., "Predicted and Measured Velocity

Distributions in a Model Heat Exchanger," AECL-8271, Atomic Energy of

versity of New Brunswick, and Natural Sciences and Engi- Canada Limited, Chalk River Nuclear Laboratories, Chalk River, Ontario, Jan.

neering Research Council of Canada (NSERC Grant No. 1984.

A1398), and a joint University Industry NSERC Cooperative 11 Shida, H., Kuragasaki, M., and Adachi, T., "On the Numerical Analysis

Method of Flow and Heat Transfer in Condensers," Proceedings of the 7th

Research grant (NSERC Grant No. CRD-0039112). International Heat Transfer Conference, Munchen, Fed. Rep. of Germany, Vol.

6, 1982, pp. 347-352.

12 Shida, H., Kuragasaki, M., Soda, M., and Urabe, T., "A Computational

References Method for Flow and Heat Transfer Analysis of Condensers," Proceedings of

1 Al-Sanea, S., Rhodes, N., Tatchell, D. G., and Wilkinson, T. S., " A the Second International Symposium on Condensers and Condensation, Heat

Computer Model for Detailed Calculation of the Flow in Power Station Con- Transfer and Flow Service, University of Bath, U.K., March 28-30, 1990, pp.

densers," Condensers: Theory and Practice, Institute of Chemical Engineers 245-255.

Symposium Series, No. 75, Pergamon Press, 1983, pp. 71-88. 13 Takahashi, F., Harada, I., Fujitani, Y., and Koizumi, M., "Computation

2 Bush, A. W., Marshall, G. S., and Wilkinson, T. S., "The Prediction of of Steam Flows in Power Plant Condensers," Proceedings of the Second In-

Steam Condensation Using a Three Component Solution Algorithm," Pro- ternational Symposium on Condensers and Condensation, Heat Transfer and

ceedings of the Second International Symposium on Condensers and Conden- Fluid Flow Service, University of Bath, U.K., March 28-30, 1990, pp. 235-244.

sation, Heat Transfer and Fluid Flow Service, University of Bath, U.K., March 14 Theodosiou, V. M., Sousa, A. C. M., and Carlucci, L. N., "Flow Field

28-30, 1990, pp. 233-234. Predictions in a Model Heat Exchanger," Computational Mechanics, Vol. 3,

3 Caremoli, C , "Numerical Computation of Steam Flows in Power Plant 1988, pp. 419-428.

Condensers," Numerical Methods in Thermal Problems, eds., R. W. Lewis and 15 Van Doormaal, J. P., and Raithby, G. D., "Enhancements of the SIMPLE

K. Morgan, Volume IV, Pineridge Press, Swansea, U.K., 1985, pp. 315-325. Method for Predicting Incompressible Fluid Flow," Numerical Heat Transfer,

4 Davidson, B. J., and Rowe, M., "Simulation of Power Plant Condenser Vol. 7, 1984, pp. 147-163.

Performance by Computational Method: An Overview," Power Condenser 16 Zhang, C , and Sousa, A. C. M., "Numerical Predictions of Steam and

Heat Transfer Technology, eds., P. Marto and R. Nunn, Hemisphere, Wash- Heat Transfer in a Condenser," Numerical Methods in Thermal Problems, eds.,

ington, 1981, pp. 17-49. R. W. Lewis and K. Morgan, Vol. VI, Part 2, Pineridge Press, Swansea, U.K.,

5 Davidson, B. J., "Condensers for Large Turbines," Aerothermodynamics 1989, pp. 1368-1378.

of Low Pressure Steam Turbines and Condensers, eds. M. J. Moore and C. H. 17 Zhang, C , and Sousa, A. C. M., "Comparison of Different Turbulence

Sieverding, Chap. 8, Hemisphere Publishing Corporation, Washington, D.C., Models for Shell-Side Flow in a Model Heat Exchanger," International Journal

1987, pp. 217-251. of Heat and Technology, Vol. 17, No. 1, 1989, pp. 99-110.

6 Diaz-Tous, I. A., "Keynote Address," Symposium on State-of-the-Art 18 Zhang, C., and Sousa, A. C. M., "Numerical Simulation of Turbulent

Condenser Technology, eds., I. A. Diaz-Tous and R. J. Bell, Orlando, Florida, Shear Flow in an Isothermal Heat Exchanger Model," ASME Journal of Fluids

1983, pp. 1:1-1:22. Engineering, Vol. 112, 1990, pp. 48-55.

7 0 / V o l . 113, JUNE 1991 Transactions of the ASME

Downloaded From: http://energyresources.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

S-ar putea să vă placă și

- Chilton CoburnDocument5 paginiChilton Coburnandreluisalberton100% (1)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7De la EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Încă nu există evaluări

- Superheated SteamDocument15 paginiSuperheated SteamluriahÎncă nu există evaluări

- CE Refresher: Steam Tables and Typical Liquid VelocitiesDocument1 paginăCE Refresher: Steam Tables and Typical Liquid Velocitieshugo mendozaÎncă nu există evaluări

- Boiler: Sabari Girish N Sr. Engineer (O)Document37 paginiBoiler: Sabari Girish N Sr. Engineer (O)Deepak SinghÎncă nu există evaluări

- Over Water WingDocument7 paginiOver Water WingtsaipeterÎncă nu există evaluări

- Practical Chemical Thermodynamics for GeoscientistsDe la EverandPractical Chemical Thermodynamics for GeoscientistsÎncă nu există evaluări

- Open Source Chemical Engineering Related SoftwaresDocument9 paginiOpen Source Chemical Engineering Related SoftwaresdhanyaÎncă nu există evaluări

- CH 4 Pressure Drop in Heat ExchangersDocument14 paginiCH 4 Pressure Drop in Heat Exchangersapi-3765936100% (5)

- CrackingDocument33 paginiCrackingEman El DsoukyÎncă nu există evaluări

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDe la EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesÎncă nu există evaluări

- Suc DrumsDocument6 paginiSuc DrumsrkoGear100% (1)

- Vacuum CondenserDocument4 paginiVacuum CondenserCecilia Tan0% (1)

- WPL Lamella Separator Technical DatasheetDocument1 paginăWPL Lamella Separator Technical Datasheettallef001Încă nu există evaluări

- Thermal Performance Assessment of Steam Surface CondenserDocument8 paginiThermal Performance Assessment of Steam Surface CondenserJeeEianYannÎncă nu există evaluări

- 3194 PDF PDFDocument7 pagini3194 PDF PDFdillipsh123Încă nu există evaluări

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4De la EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Evaluare: 5 din 5 stele5/5 (1)

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocument4 paginiAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalÎncă nu există evaluări

- CFD Analysis of Heat Transfer in Helical CoilDocument5 paginiCFD Analysis of Heat Transfer in Helical CoilAnonymous kw8Yrp0R5rÎncă nu există evaluări

- Gas/Liquids Separators - Part 2: Quantifying Separation PerformanceDocument13 paginiGas/Liquids Separators - Part 2: Quantifying Separation PerformanceLizbeth Ramirez AlanyaÎncă nu există evaluări

- 38 1006 Thermal EngineeringDocument84 pagini38 1006 Thermal EngineeringZeljko GagicÎncă nu există evaluări

- 1 s2.0 S0263876299717624 MainDocument7 pagini1 s2.0 S0263876299717624 Mainryan123459Încă nu există evaluări

- Heat Rate of Thermal Power PlantDocument15 paginiHeat Rate of Thermal Power Plantsameer betal100% (1)

- STC (Buffer Tank 25KL) - Calc PDFDocument4 paginiSTC (Buffer Tank 25KL) - Calc PDFAvril Rindra T PÎncă nu există evaluări

- Condenser Sizing Calculation Tool: InputDocument17 paginiCondenser Sizing Calculation Tool: InputAkash GedamÎncă nu există evaluări

- Kettle Reboilers Chemical Engineering Design Ray SinnoyDocument6 paginiKettle Reboilers Chemical Engineering Design Ray SinnoyFederico BogettiÎncă nu există evaluări

- Peng Robinson Virial Equations of State ComparisonDocument7 paginiPeng Robinson Virial Equations of State Comparisondix6ieÎncă nu există evaluări

- Vacuum Systems PDFDocument12 paginiVacuum Systems PDFSnigdha YadavÎncă nu există evaluări

- Nm3 To M3Document4 paginiNm3 To M3Aniket royÎncă nu există evaluări

- Simulation of Distillation For ACETONE-BENZENE-CHLOROFORMDocument8 paginiSimulation of Distillation For ACETONE-BENZENE-CHLOROFORMfjcgÎncă nu există evaluări

- Falling FilmDocument21 paginiFalling FilmGhaya Bani RushaidÎncă nu există evaluări

- Checkl List For Boiler Specification by K.K.parthibanDocument8 paginiCheckl List For Boiler Specification by K.K.parthibanparthi20065768Încă nu există evaluări

- Graham - Lessons From The Field - Ejector SystemDocument5 paginiGraham - Lessons From The Field - Ejector SystemAnonymous DJrec2Încă nu există evaluări

- 3 Element Drum Level ControlDocument3 pagini3 Element Drum Level ControlSriteja JosyulaÎncă nu există evaluări

- Working Principle of Cooling Tower PDFDocument12 paginiWorking Principle of Cooling Tower PDFEmmaÎncă nu există evaluări

- VLE data regression using maximum likelihoodDocument18 paginiVLE data regression using maximum likelihoodamoÎncă nu există evaluări

- Kinetics of Chemisorption of Gases On Solids Chem Rev 1960 PDFDocument46 paginiKinetics of Chemisorption of Gases On Solids Chem Rev 1960 PDFArmando LermaÎncă nu există evaluări

- 04-Flame TemperatureDocument23 pagini04-Flame TemperatureLindi Newman100% (1)

- Grand Composite Curve (GCC) - Heat PumpDocument4 paginiGrand Composite Curve (GCC) - Heat PumpMuhammad IqmalÎncă nu există evaluări

- Performance Evaluation of Air Preheater at off Design ConditionDocument32 paginiPerformance Evaluation of Air Preheater at off Design ConditionSuresh DewanganÎncă nu există evaluări

- eArt-Performance Analysis of Spiral Tube Heat ExchangerDocument4 paginieArt-Performance Analysis of Spiral Tube Heat ExchangerMoly69xÎncă nu există evaluări

- SERIES 22.2: Heavy Duty Gear ReducersDocument2 paginiSERIES 22.2: Heavy Duty Gear ReducersAmir KhanÎncă nu există evaluări

- Chemical Process Design: Computer-Aided Case StudiesDe la EverandChemical Process Design: Computer-Aided Case StudiesÎncă nu există evaluări

- Boiler Drum Level Measurement and ControlDocument13 paginiBoiler Drum Level Measurement and ControlasdmoomÎncă nu există evaluări

- 12 PDO Heat TransferDocument55 pagini12 PDO Heat Transferaxel2100Încă nu există evaluări

- Energy Balance:: Logarithmic Mean Temperature Difference (LTMD)Document3 paginiEnergy Balance:: Logarithmic Mean Temperature Difference (LTMD)Rae Nikka May PabloÎncă nu există evaluări

- 10-Vertical Horizontal CondenserDocument14 pagini10-Vertical Horizontal CondenserPraneet BoggarapuÎncă nu există evaluări

- 13.8kV AUTO BUS TRANSFER SCHEME PANEL +ABTSDocument1 pagină13.8kV AUTO BUS TRANSFER SCHEME PANEL +ABTSAnonymous BZQOJwWIh6Încă nu există evaluări

- Design and Analysis of Fire Tube Boiler With Heat Flow AnalysisDocument3 paginiDesign and Analysis of Fire Tube Boiler With Heat Flow Analysisbez100% (1)

- Design Guidelines For Urea Hydrolysers For Ammonia Demand of The SCR DENOX Project in Coal-Fired Power Plants PDFDocument6 paginiDesign Guidelines For Urea Hydrolysers For Ammonia Demand of The SCR DENOX Project in Coal-Fired Power Plants PDFkangsungjinÎncă nu există evaluări

- Effect of Fin SpacingDocument12 paginiEffect of Fin SpacingAnkit LonareÎncă nu există evaluări

- 1996 - Misplon - Pinhole Grate Conversions ofDocument4 pagini1996 - Misplon - Pinhole Grate Conversions ofmchoi23Încă nu există evaluări

- Heat Exchanger VibrationDocument3 paginiHeat Exchanger VibrationTim KuÎncă nu există evaluări

- Condenser DesignDocument12 paginiCondenser Designbirendrajee100% (1)

- Circulation of BoilerDocument5 paginiCirculation of BoilerMuralikrishna ArigondaÎncă nu există evaluări

- Chemical Reactor Analysis and Applications for the Practicing EngineerDe la EverandChemical Reactor Analysis and Applications for the Practicing EngineerÎncă nu există evaluări

- Vapour–Liquid Equilibrium Data at Normal PressuresDe la EverandVapour–Liquid Equilibrium Data at Normal PressuresEvaluare: 5 din 5 stele5/5 (1)

- Experimental Thermodynamics: Experimental Thermodynamics of Non-Reacting FluidsDe la EverandExperimental Thermodynamics: Experimental Thermodynamics of Non-Reacting FluidsB. Le NeindreÎncă nu există evaluări

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDe la EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationÎncă nu există evaluări

- ST730993-3 2dDocument1 paginăST730993-3 2dAmir AbbaszadehÎncă nu există evaluări

- Mechanisms of Sulfate Removal From Subsurface Calcium Chloride Brines: Heletz-Kokhav Oilfields, IsraelDocument9 paginiMechanisms of Sulfate Removal From Subsurface Calcium Chloride Brines: Heletz-Kokhav Oilfields, IsraelAmir AbbaszadehÎncă nu există evaluări

- Simulation of Forward Feed Multiple Effect Desalination PlantDocument38 paginiSimulation of Forward Feed Multiple Effect Desalination PlantAmir AbbaszadehÎncă nu există evaluări

- ReadmeDocument1 paginăReadmeAmir AbbaszadehÎncă nu există evaluări

- Thermocompressors: Engineered For EfficiencyDocument4 paginiThermocompressors: Engineered For EfficiencyAmir AbbaszadehÎncă nu există evaluări

- Ijsrp p2830 PDFDocument4 paginiIjsrp p2830 PDFprasadgssÎncă nu există evaluări

- Review of Methods for Detecting Air Leaks in Steam Turbine CondensersDocument10 paginiReview of Methods for Detecting Air Leaks in Steam Turbine CondensersAmir AbbaszadehÎncă nu există evaluări

- Executive Summary - FinalDocument22 paginiExecutive Summary - FinalAmir AbbaszadehÎncă nu există evaluări

- Executive Summary - FinalDocument22 paginiExecutive Summary - FinalAmir AbbaszadehÎncă nu există evaluări

- Review of Methods for Detecting Air Leaks in Steam Turbine CondensersDocument10 paginiReview of Methods for Detecting Air Leaks in Steam Turbine CondensersAmir AbbaszadehÎncă nu există evaluări

- Falling-Film Evaporation On Horizontal Tubes-A Critical ReviewDocument19 paginiFalling-Film Evaporation On Horizontal Tubes-A Critical ReviewAmir Abbaszadeh100% (1)

- Review of Methods for Detecting Air Leaks in Steam Turbine CondensersDocument10 paginiReview of Methods for Detecting Air Leaks in Steam Turbine CondensersAmir AbbaszadehÎncă nu există evaluări

- Page 14Document20 paginiPage 14Amir AbbaszadehÎncă nu există evaluări

- PV EliteDocument6 paginiPV ElitevikrantgulhaneÎncă nu există evaluări

- Turbair Blower (Type RC)Document2 paginiTurbair Blower (Type RC)Amir AbbaszadehÎncă nu există evaluări

- Lithium Bromide Absorption Refrigeration SystemDocument15 paginiLithium Bromide Absorption Refrigeration SystemAmir AbbaszadehÎncă nu există evaluări

- Turbair Blower (Type RT)Document2 paginiTurbair Blower (Type RT)Amir AbbaszadehÎncă nu există evaluări

- CTV Svx009a GB - 07012016Document56 paginiCTV Svx009a GB - 07012016Amir AbbaszadehÎncă nu există evaluări

- Rasmussen Eric SPX PDFDocument18 paginiRasmussen Eric SPX PDFAmir AbbaszadehÎncă nu există evaluări

- Rasmussen Eric SPXDocument18 paginiRasmussen Eric SPXAmir AbbaszadehÎncă nu există evaluări

- API Standard 560: Fired Heaters For General Refinery ServiceDocument1 paginăAPI Standard 560: Fired Heaters For General Refinery ServiceJogn SmitÎncă nu există evaluări

- Kong 2017Document15 paginiKong 2017Amir AbbaszadehÎncă nu există evaluări

- Cooling Technology Institute "Why Every Air Cooled System Condensor Needs A Cooling Tower" (2003)Document16 paginiCooling Technology Institute "Why Every Air Cooled System Condensor Needs A Cooling Tower" (2003)Amir AbbaszadehÎncă nu există evaluări

- Numerical Approach to Off-design Performance of Dry Cooling SystemsDocument16 paginiNumerical Approach to Off-design Performance of Dry Cooling SystemsAmir AbbaszadehÎncă nu există evaluări

- Car Bottom Furnace: Standard FeaturesDocument2 paginiCar Bottom Furnace: Standard FeaturesAmir AbbaszadehÎncă nu există evaluări

- Effect of Ambient Design Temperature On Air-Cooled Binary Plant OutputDocument16 paginiEffect of Ambient Design Temperature On Air-Cooled Binary Plant OutputAmir AbbaszadehÎncă nu există evaluări

- Wall Heat Transfer in Gas-Fired Furnaces: Effect of Radiation ModellingDocument12 paginiWall Heat Transfer in Gas-Fired Furnaces: Effect of Radiation ModellingAmir AbbaszadehÎncă nu există evaluări

- Bogie Hearth Furnaces enDocument2 paginiBogie Hearth Furnaces enAmir AbbaszadehÎncă nu există evaluări

- Air Coolers Excerpt From Rules of Thumb For Chemical EngineersDocument3 paginiAir Coolers Excerpt From Rules of Thumb For Chemical Engineershalder_kalyan9216Încă nu există evaluări

- Wiring Diagram V7Document1 paginăWiring Diagram V7NadeeshÎncă nu există evaluări

- Hand Operated Can CrusherDocument60 paginiHand Operated Can CrusherParen Trivedi100% (2)

- EMTOP Tools Guide: Affordable Power Tools & Hand ToolsDocument32 paginiEMTOP Tools Guide: Affordable Power Tools & Hand ToolsDIELECTRIC INSTALACIONES S.A.SÎncă nu există evaluări

- Experiment No. 3 Measurement of Specific Weight and Pressure Intensity of LiquidsDocument4 paginiExperiment No. 3 Measurement of Specific Weight and Pressure Intensity of LiquidsChristine KimÎncă nu există evaluări

- The Next Generation in Air Intake DesignDocument4 paginiThe Next Generation in Air Intake DesignCastro RicardoÎncă nu există evaluări

- AM1101 Structures KSDocument62 paginiAM1101 Structures KSKnowledge MiningÎncă nu există evaluări

- Specification Chart of Pipes - Stainless Steel - Seamless Pipe - Mild Steel - Hollow SteelDocument3 paginiSpecification Chart of Pipes - Stainless Steel - Seamless Pipe - Mild Steel - Hollow SteelSunitha KumariÎncă nu există evaluări

- Unit 4Document36 paginiUnit 4hisuresh196Încă nu există evaluări

- BDA37401-Lab Sheet Engineering Mechanic Laboratory IIDocument70 paginiBDA37401-Lab Sheet Engineering Mechanic Laboratory IIkfodskfoÎncă nu există evaluări

- CMT Capitolul 4 - Transmisii Curele DintateDocument19 paginiCMT Capitolul 4 - Transmisii Curele DintateANAÎncă nu există evaluări

- Autoscan P12 04 16 enDocument12 paginiAutoscan P12 04 16 enCouscoussiere GrandgazÎncă nu există evaluări

- Response of a turbulent boundary layer to a step change in surface roughnessDocument41 paginiResponse of a turbulent boundary layer to a step change in surface roughnessFreddie RomeroÎncă nu există evaluări

- Biffi IS2000Document16 paginiBiffi IS2000Kolbert ArpadÎncă nu există evaluări

- Lab 2 HardnessDocument8 paginiLab 2 HardnessMuhammad Zulhilmi0% (1)

- Ansys Fluent Simulation ReportDocument7 paginiAnsys Fluent Simulation Reportsaitharun reddy.munthaÎncă nu există evaluări

- Tokico P.D. Oil Flowmeter KatalogDocument6 paginiTokico P.D. Oil Flowmeter KatalogPRIMA UTAMA MULYAÎncă nu există evaluări

- Mr-75-163-Tds Critical SparesDocument3 paginiMr-75-163-Tds Critical Sparescmrig74Încă nu există evaluări

- Engineering Plastic Properties and Processing GuidelinesDocument28 paginiEngineering Plastic Properties and Processing GuidelinesSamuel Berger VeltenÎncă nu există evaluări

- Y-Geo New Combined Finite-Discrete Element Numerical Code For Geomechanical ApplicationsDocument14 paginiY-Geo New Combined Finite-Discrete Element Numerical Code For Geomechanical ApplicationsRicardo Huisa BustiosÎncă nu există evaluări

- Aluminium Using AFSDDocument12 paginiAluminium Using AFSDKinesys TechsolutionsÎncă nu există evaluări

- Manual Motor Crrcpro26iDocument8 paginiManual Motor Crrcpro26ieduardo_albornoz_5Încă nu există evaluări

- Check List-For LMI-on Bypassing Protn & Interlocks-OGN/OPS/SYST/005-021Document13 paginiCheck List-For LMI-on Bypassing Protn & Interlocks-OGN/OPS/SYST/005-021rudra singhÎncă nu există evaluări

- CAT 320/323GC Electrical DiagramDocument33 paginiCAT 320/323GC Electrical DiagramSammyÎncă nu există evaluări

- Volvo Ecr50D: Parts CatalogDocument469 paginiVolvo Ecr50D: Parts CataloggiselleÎncă nu există evaluări

- Implementing Turbulence Models Into The Compressible RANS EquationsDocument3 paginiImplementing Turbulence Models Into The Compressible RANS EquationsSiva RajÎncă nu există evaluări

- Flushmate 501B Series Owners Service ManualDocument6 paginiFlushmate 501B Series Owners Service ManualiloÎncă nu există evaluări

- AS 1056.1-1991 Storage Water Heaters - General RequirementsDocument43 paginiAS 1056.1-1991 Storage Water Heaters - General RequirementsChetan ChopraÎncă nu există evaluări

- Module 5.2a: Gas Laws Part 1Document26 paginiModule 5.2a: Gas Laws Part 1Ryan PazonÎncă nu există evaluări

- High-Temperature High-Strength Nickel-Base Alloys: A Practical Guide To The Use of Nickel-Containing Alloys N 393Document86 paginiHigh-Temperature High-Strength Nickel-Base Alloys: A Practical Guide To The Use of Nickel-Containing Alloys N 393DNH RND - VijaykumarÎncă nu există evaluări