Documente Academic

Documente Profesional

Documente Cultură

Technical Procedure For Mattress Installation

Încărcat de

flawlessy2kTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Technical Procedure For Mattress Installation

Încărcat de

flawlessy2kDrepturi de autor:

Formate disponibile

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

SURVEY PROCEDURE

FOR

PIPELINE MATTRESS

INSTALLATION

Author: ABISOYE OLUWO Page 1

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

Table of Contents

1.0 SCOPE ............................................................................................................................................. 3

2.0 TERMS AND DEFINITIONS ...................................................................................................... 3

3.0 REFERENCES ............................................................................................................................... 3

4.0 ROLES AND RESPONSIBILITIES............................................................................................. 4

5.0 ENVIRONMENT, HEALTH AND SAFETY .............................................................................. 4

6.0 MOBILIZATION AND PROJECT RESOURCES ...................................................................... 8

7.0 FIELD OPERATION ................................................................................................................... 12

8.0 EXECUTION PROCEDURES .................................................................................................... 14

9.0. DEMOBILIZATION .................................................................................................................... 15

Author: ABISOYE OLUWO Page 2

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

1.0 SCOPE

This document highlights the Procedures for Surface Positioning and Subsea Monitoring to

support the Pre-installation, Installation and Post-Installation operations of protective mattresses on

Subsea Riser Spools and Pipelines with concrete mattresses onboard a Dive Support Vessel (DSV).

While this document serves to outline the methodologies, there will be certain activities and

vessel movements that will be planned, defined, agreed, and coordinated on site between the

Parties involved and the various Vessel Masters. This will include, but not be limited to, Vessel

standby locations, Vessel mooring line details, mooring connection points, etc.

2.0 TERMS AND DEFINITIONS

Term Definitio

BMS n

Barge Management System

Company TBA

Contractor TBA

CALM Cantenary Anchor Leg Mooring

C-O Calculated Minus Observed

CTD Conductivity-Temperature-Depth

CRP Central Reference Point

DSV Dive Support Vessel

DGPS Differential Global Positioning System

DPR Daily Progress Report

HES Health, Environment & Safety

TRA Task Risk Analysis

KP Kilometer Point

LBL Long Base Line

MRU Motion Reference Unit

PLEM Pipeline End Manifold

RPL Route Position List

TMS Tug Management System

USBL Ultra Short Base Line

WGS World Geodetic System

3.0 REFERENCES

3.1 Companysupplied Drawings and References

These are documents to be supplied by the Company to the Contractor. This includes but is not

limited to the following; Base Map of the Work Location, Contract Document, Drawing Index,

Pipeline Route, Riser Spool Details, Riser Support and Riser Clamp Details, Riser Sections and

Details.

Author: ABISOYE OLUWO Page 3

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

3.2 Contractorsupplied Documentation and Drawings

These are documentations to be supplied by the Contractor to the Company. This include but are not

limited to the following; Project Execution Plan, Project HSE Plan, Emergency Response Plan,

Project Quality Plan, , Survey Dive Support during Mattress Installation, Pre-Installation Survey

Procedure, Fuel Transfer Procedure, Personnel Transfer Procedure, JHA for Jacket Installation,

JHA for Marine Pre-Installation Survey, JHA for Mooring Operations, Overall Field Layout.

4.0 ROLES AND RESPONSIBILITIES

Contractor responsibilities shall include but are not limited to the following:

Submission of methodology and field procedures.

Submission of data processing and interpretation procedures.

Submission of quality control and data management procedures.

Project organization offshore and onshore.

Submission of current equipment certification.

Submission of CVs of prospective field team members for 24hour operation.

Submission of Mobilization/Demobilization Plan.

5.0 ENVIRONMENT, HEALTH AND SAFETY

Contractor shall adhere strictly and comply with Environment, Health and Safety rules, regulations,

procedures and policies such as:

Alcohol and Drug Policy

Transport Policy

Environmental Compliance

Emergency Response

Incident Reporting

PPE Regulations

Medicals and Safety Trainings

Audit and Inspection

Task Risk Assessment and Hazard Identification

Toolbox Meetings, Safety Meetings etc.

5.1 Personnel Protective Equipment

At the most basic level, offshore staff shall take sensible responsibility for their personal health and

safety, and that of their co-workers. When venturing out on deck appropriate safety gear shall be

worn at all times, this will include, but not limited to:

Full sleeve coveralls

Safety helmet

Safety boots

Safety glasses

Ear defenders

Gloves.

When working near the side of the DSV/vessel or on the back deck, a life jacket or work-vest will be

worn. The Party Chief has responsibility for all health and safety matters relating to survey safety at

Author: ABISOYE OLUWO Page 4

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

all times on this project, although ALL personnel have a duty to perform tasks in a safe and

appropriate manner. Appropriate PPE shall be worn by personnel at ALL times when on deck

involved in survey operations. This will include, but not be limited to, coveralls, safety helmet,

safety boots, and gloves if handling wire or equipment. A Life Jacket shall be worn when engaged in

work at or near the side of the DSV/vessel.

The HSE Officer shall ensure that personnel onboard the survey vessel comply with all safety

regulations at all times. He shall also have responsibility for maintaining all safety records and also

for reporting all safety observations and violations to the Party Chief and also to the client

representative.

A documented safety meeting involving the Party Chief, client representative(s) and Captain and

ALL available crew members will be held during mobilization and survey location. Toolbox Talks

shall also be held as applicable prior to deployment / recovery of equipment or before any non-

routine task. The purpose of the Toolbox talk will be to discuss the objectives, plan the operation

and allocate personnel and resources.

5.2 HSE notice boards

Crew HSE notice board will be located in a strategic place on the vessel to cascade other

informations such as:

Company HSE policies

HSE Memos

Crew HSE Objectives

Minutes of HSE meetings

Monthly HSE Reports

Best Practice notifications

Safety alerts

Action items status sheet

5.3 Safety Operations

Upon arrival onboard the vessel, all personnel shall undergo an induction briefing that will address

the primary safety issues surrounding the vessel and the general offshore operations.

An induction shall be conducted by the HSE officer and other visual aids shall be utilized.

Personnel shall be made aware of the following issues:

Life boat drills and fire drill procedures

Escape routes

Protective clothing requirements

Risk assessment procedure

All operations shall be carried out in a safe and responsible manner. Safety policies and safe

practices shall be considered at all times. Personnel shall actively participate in schemes designed to

enhance their health and safety onboard the vessel.

Author: ABISOYE OLUWO Page 5

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

5.4 Personnel Transfer

All personnel shall board the DSV/vessel at client requested location and personnel transfer

anticipated offshore shall be done via a COMPANY approved means of personnel transfer.

5.5 Emergency Response Plan (ERP)

The crew maintains ERP plans for responding to potential emergencies as specified in GOSL Site

Specific Emergency Response Plans (ERP). The ERP details the following:

Specific emergency procedures

Crew organizational structure during an emergency

Crew responsibilities during an emergency

Crew authority during an emergency.

5.6 Medical / Emergency Response Plan

The Medical/Emergency Response Plan is illustrated as below;

Author: ABISOYE OLUWO Page 6

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

Accident or Emergency

First Aid at scene of Accident

Survey Party Chief

Client Contractor's Office HSE Manager

Informs Medical and Logistics Report to Operations Manager Liaise with Client for Transport

with accident report and Medical aid onshore

Arrangement for Transport Files and Records the accident

report

Arrangement to provide Liaise with Hospital for

immediate medical aid medical report of victim upon

his admission

Notifies party Chief to prepare

victim for Medivac

Victim evacuated from offshore

field

Victim transported to Hospital

via Ambulance

HSC Manager collects medical

report from Hospital for Victim

HSC Manager Close out the

accident report after

investigation

5.7 Communication

Communication is a vital operational requirement and will be treated as such. Therefore,

communication will be established between Project Crew and Client as well as GOSL base office via

the following means:

Global satellite for mobile communication (GSM) where there is network service or email where

internet facility is available.

Author: ABISOYE OLUWO Page 7

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

VHF-FM Receivers can also be used to pass the message to other facilities onwards to base office if no

means of communications are available. At any point in time, whichever service is quickly accessible

will be used.

6.0 MOBILIZATION AND PROJECT RESOURCES

6.1 Mobilization

Prior to starting the installation of the equipment on board the DSV, it shall be confirmed that all

equipment has arrived using the equipment checklist. This includes all the necessary tools, tested

equipment, safety gear and clothing, consumables, handbooks, equipment and software manuals,

software (with full complement of backups) and documents issued during the briefing. During the

unpacking of the equipment they shall be checked for any loss, omission or damage. In the event of

omission, loss or damage, the Party Chief shall report the deficiency to the Project Manager and

arrange repair or replacement at the earliest opportunity.

Company is requested to ensure that all permits and permissions to conduct survey operations in the

fields and along the proposed routes are obtained.

The mobilization consists of the following activities as a minimum:

a.) Select the best locations for navigation and antennae.

b.) Installation of all survey equipment at the destined location.

c.) Function test of each individual system and / or peripheral (including all the spare systems).

d.) Individual interfacing checks to each sensor and subsequently a check of all systems as one

entity simulating the operational situation as near as possible

e.) The offline and backup systems/software shall be tested with reference to accessibility as a

minimum.

f.) Carry out gyro calibration and GPS verification.

g.) Measure and document vessel offsets and check these by scaling them off a large scale vessel

plan.

h.) Secure all equipment and store spares and consumables on a dry and easy accessible location.

All checks and calibrations accomplished during the mobilization shall be documented to ensure that

all equipment is tested prior to departure.

During mobilization all calibrations and verifications shall be in accordance with section 7.1 and must

be conducted prior to the commencement of any work.

At completion of the mobilization activities, the survey personnel shall make themselves familiar

with the vessel's safety procedures, equipment and escape routes. Personnel shall at all times adhere

to the vessel's safety regulations and join safety meetings and drills as instructed.

Contractor shall mobilize all positioning systems on the DSV as specified after all necessary audits.

Author: ABISOYE OLUWO Page 8

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

6.2 Personnel

The following survey crew is proposed for the project:

1 x Party Chief

2 x Online Surveyors

2 x Survey Engineers

6.3 Survey Equipment

The following survey equipment / software (or similar) shall be present onboard a dedicated DSV:

2 x Primary Positioning: DGPS (C-NAV) with accuracy 1m

Software: EIVA NaviPac

1 x Motion Sensor: TSS Motion Reference Unit

1 x Total station Leica TS-09

1 x Monitoring Sonar Sector scan

2 x Gyro-compass: SG Brown with an accuracy of 0.1

1 x USBL Applied Acoustics 900 series

Mobilization activities shall be deemed complete with the survey personnel making themselves

familiar with the DSVs safety procedures, equipment and escape routes. Personnel shall at all times

adhere to the DSV's safety regulations and join safety meetings and drills as instructed.

6.4 Geodetic References and Datums

The Geodetic, Projection and Transformation parameters to be utilized for the survey positioning and

subsea monitoring throughout the duration of the mattress installation shall be supplied by the

Company.

6.5 Geodetic Computation Check

On completion of mobilization, a geodetic computation check shall be conducted using the online

navigation software to transform a coordinate from WGS 84 datum to the reference local datum

specified by the Company.

A datum transformation result for the geodetic computation shall be shown on a table as illustrated

below;

Datum Transformation Example

Geographical Coordinates Grid Coordinates

Spheroid / Datum

Latitude Longitude Easting Northing

Source:

Table 1: Datum Transformation Example

Author: ABISOYE OLUWO Page 9

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

6.6 Survey Units

The survey units of measure to be used during the project are represented in the table below.

Project Survey Units

Type Unit

Local Time (GMT + 01:00 hours).

Time

GPS data will be logged in GMT + 00:00 hours.

Linear units International Meters (m).

Velocity Meters per second (m/s).

Angular units Degrees, Minutes, Seconds ( ).

Table 2: Project Survey Units

6.7 Project Deliverable Checklist

The list of deliverables is to be transferred from the DSV to the Project Manager throughout the

duration of the project and at the time of demobilization is shown below.

Deliverable Check List

Item Formats / Media Required Completed

Project Setup

Personnel responsibilities and WEP

Hard copy

awareness

Vessel offset and layout diagram AutoCAD & PDF

Geodesy computation check PDF

Calibrations & QC

DGPS verification MS-Excel & PDF

Gyro calibration MS-Excel & PDF

Transit check MS-Excel & PDF

Reports

Survey report MS-Word (one (1)

Field Reports (installation reports) MS- Excel/Word & PDF

Daily reports (ODR) Signed hard copies/MS-Excel/PDF

Author: ABISOYE OLUWO Page 10

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

Deliverable Check List

Item Formats / Media Required Completed

Project Data

Offshore Pack DVD

Field file and all hard copies n/a

Table 3: Project Deliverable Check List

6.8 Offsets

The Central Reference Point (CRP), from which all offsets are to be measured, shall be the center stern

of the DSV, the DSV center of gravity or any other point on the DSV that is considered suitable for

purpose.All offsets will be measured using land survey techniques and verified with tape measure

during mobilization. Offsets from survey datum point to all survey sensors will be measured and

input into the system and the logged position based on the offset verified.

All measurements will be reduced, logged and entered into the navigation system and verified by the

Survey Party Chief.

Author: ABISOYE OLUWO Page 11

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

7.0 FIELD OPERATION

Prior to mobilization, a complete calibration of the systems outlined below shall be carried out.

Mobilization shall not be deemed to be complete until calibration is completed and accepted by

Company.

The Survey Crew shall be responsible for the accurate positioning of the DSV at the proposed

installation location, USBL fixes and position for spool deployment would be monitored real time as

required. They shall also assist the DSV personnel by supplying information as required.

The Survey crew shall ensure that an updated field map of the area (as per client specification) is

loaded on the navigation screen of the DSV and also real time monitoring of the DSV position at all

times.

Monitors shall be installed on the DSV bridge, dive shark, offshore project engineers office, Control

tower, Company office showing range location, updated field layout, surrounding features such as

existing pipelines, cables, platforms etc. and any other information requested by the DSV personnel.

The USBL shall be well configured and interfaced with the Navigation display unit which shall be

easily viewed by all the required parties on board and the data stream shall be well captured and

logged.

The Sector Scan Sonar shall be well configured viewed real time by all the required parties on board

and the data stream shall be well captured and logged.

Confirmation that on-line computer and peripheral systems are operational and that all data are

being interfaced, decoded, processed, presented and logged. This will be achieved by logging

positioning data on the system and processing it to confirm its validity.

7.1 Equipment Calibrations and Verifications

The calibrations and verifications presented below shall be completed for Companys acceptance

prior to the commencement of any survey work and / or departing the port of mobilization. All

calibrations and testing will be recorded and form part of the survey report.

If any of the verifications/calibrations are unable to be concluded during mobilization or prior to the

DSV sailing, the Client and Project Manager must be informed.

7.1.1 Gyro Calibration

The gyro calibration shall be carried out alongside the quay. The DSV axis shall be defined by

accurate offset measurements, the misalignment between the gyro axis and the DSV axis shall be

determined using either GPS baseline method or the Solar Observation method on-board the DSV at

the quay.

The GPS baseline method requires establishing a baseline by simultaneously logging the position two

points along the DSV axis and logging the gyro heading for at least thirty minutes. The bearing of the

line established by the average logged points from the two DGPS units shall be compared with that

obtained from the gyro to compute the misalignment.

Author: ABISOYE OLUWO Page 12

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

The Solar observation method involves computing the bearing of the baseline from east (sunrise) and

west (sunset) observations to the sun while simultaneously logging the gyro heading. The

misalignment obtained from the gyro calibration shall be entered in the Navigation computer as a

correction.

7.1.2 DGPS Verification

Where applicable, the total station shall be utilized for position verification on the GPS units while

the vessel/DSV is alongside at the port before the vessel moves to the field. The total station shall be

utilized to transfer control from any quayside benchmark/control point provided by (Company) to

the DGPS points on board the vessel. The Company provided benchmarks may also be directly

occupied provided there is enough space and power supply to the DGPS units. Data shall be logged

over a period of one hour with at least 100 observations. In case there are no quayside benchmarks,

total station EDM or tape measure (where feasible) using land survey techniques shall be utilized for

distance verification of a baseline established by the DGPS units. The results should compare

favorably.

7.2 Positioning

The DSV will be positioned as per Company specifications. If required, DSV Master shall adjust the

position plan in consultation with Company representative onboard if within acceptable tolerance.

7.3. Data Acquisition

All equipment shall be operated in accordance with the relevant procedures and work practices such

that optimum results are obtained given the local circumstances are favorable. From the start of the

mobilization until completion of the demobilization, an accurate Daily Operations Report shall be

kept by the online personnel describing all activities providing details as necessary. Entries shall be

neat, clear and concise and be recorded with local time of occurrence.

The position of the DSV shall be monitored at all times. Equipment settings, offsets, laybacks in use

and relevant changes thereto shall be accurately registered in the Daily Operations Report.

7.3.1. C NAV DGPS System

The C-Nav system is an innovative global, real-time, decimeter accurate GPS system commonly

referred to as a GcGPS system (Globally Corrected GPS). C-Nav corrections are not based on

traditional pseudo range DGPS. C-Nav GcGPS operates in real time, providing seamless global

coverage and decimeter capable position in the offshore world, between the latitudes of 75 degree

North and South. The system provides corrected positions to an accuracy of +/- 1m without the need

for a shore-based transmitted system.

7.3.2. Heading Data

The heading sensor shall be capable of observing data with an accuracy of +/-0.10. During installation

the heading sensor would be checked for gross errors and any alignment errors (the difference

between the heading of the sensor and the heading of the DSV). These would have been compensated

for during the calibration. Heading data would be logged during survey activities.

Author: ABISOYE OLUWO Page 13

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

8.0 EXECUTION PROCEDURES

All equipment shall be operated in accordance with the relevant procedures and work practices such

that optimum results are obtained given the local circumstances. From the start of the mobilization

until completion of the demobilization, an accurate Daily Operations Report shall be kept by the on

line personnel describing all activities providing details as necessary. Entries shall be neat, clear and

concise and be recorded with local time of occurrence.

The position of the DSV shall be monitored at all times. Equipment settings, offsets and relevant

changes shall be accurately registered in the Daily Operations Report. When applicable, the USBL

positioning system shall be operated to assist the divers with their operations and spool piece

deployment.

The Party Chief shall further inform the Project Manager on the progress of the operations by means

of a Daily Operations Report. This is a written report transmitted to the office by means of telex or

fax. Subjects reported on, shall as a minimum consist of:

A Daily Progress Report (DPR) which shall be submitted each day from the DSV to the Client in the

agreed format and will contain as a minimum the following:

Date, DSV name, Project, DPR sequential number

DSV position at 00:00hrs

Summary of events during the last 24 hours

Any problem experienced

Equipment, personnel status and changes

Operational, standby and lost time per day and cumulative

Schedule for the next 24 hrs

Weather conditions and weather outlook for the next 24 hours

Safety related matters, incidents, drills and meetings

Company comments

Spare equipment and contingency systems shall be checked at least once a week and be stored or

installed such that it can be made operational with minimum loss of time in case of emergency

requirement.

On completion of the work, calibration checks shall be performed as specified by the project

procedures.

Author: ABISOYE OLUWO Page 14

SURVEY PROCEDURE FOR PIPELINE MATTRESS INSTALLATION APRIL, 2014

9.0. DEMOBILIZATION

Demobilization activities shall not be started until receiving written demobilization permission from

the Client and GOSL project manager. All equipment shall be packed such that it will safely resist

damage during transport. Original equipment boxes shall be used whenever possible. All boxes shall

be clearly labeled with contents, box identification and destination as necessary.

Inoperable or broken equipment shall be clearly marked as such, providing as much detail as

possible on the reported faults.

Superfluous consumables shall be packed separately and marked as such.

Documentation, records and data shall be packed separately from the equipment, clearly being

marked as such, detailing the contents of each box. Original data shall be isolated from copies and, if

possible, shipped individually.

9.1 Project Debrief

As a measure of Contractor's continual improvement, a detailed post demobilization debriefing will

be conducted where the following points will be addressed:

Survey results

Team structure.

Survey procedures.

Offshore suite, software and equipment.

Reporting.

Administration and contractual/commercial.

Vessel/Rig/DSV.

HSE.

Operations.

On completion of survey operations the project directories will be cleaned of any temporary files.

The project folder/files must be completed and up to date at the time of demobilization prior to final

backup and returning to the office.

The project debriefing form is to be completed prior to the demobilization and handed/transmitted to

the Project Manager at the first available opportunity.

Author: ABISOYE OLUWO Page 15

S-ar putea să vă placă și

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDe la EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsÎncă nu există evaluări

- Subsea Rigid Pipelines – Methods of InstallationDe la EverandSubsea Rigid Pipelines – Methods of InstallationEvaluare: 5 din 5 stele5/5 (1)

- Spool Deployment and Laying ProcedureDocument86 paginiSpool Deployment and Laying ProcedurePhani Kumar G SÎncă nu există evaluări

- 23 Mooring Analysis During ShorepullDocument53 pagini23 Mooring Analysis During ShorepullNoverdo Saputra100% (1)

- IMCA D060 Publication 254 Guidelines For Lifting OperationsDocument70 paginiIMCA D060 Publication 254 Guidelines For Lifting OperationsAnonymous VqTus7QAwÎncă nu există evaluări

- ADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Document15 paginiADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Mohamed MostafaÎncă nu există evaluări

- Spool Lift and Loadout ProcedureDocument75 paginiSpool Lift and Loadout ProcedurePhani Kumar G SÎncă nu există evaluări

- Installation of Anchors For Mooring System of Floating Wind TurbinesDocument134 paginiInstallation of Anchors For Mooring System of Floating Wind Turbines정재영100% (1)

- Orcaflex Training ScopeDocument3 paginiOrcaflex Training ScopeGodwinÎncă nu există evaluări

- TowingSailaway Transportation and Installation PlanDocument27 paginiTowingSailaway Transportation and Installation PlaneÎncă nu există evaluări

- Microsoft Word - PRELIMINARY MOORING ANALISYS DSV TS504Document48 paginiMicrosoft Word - PRELIMINARY MOORING ANALISYS DSV TS504halimÎncă nu există evaluări

- EGP3-01.22 Transportation of Cargo by Barge or ShipDocument32 paginiEGP3-01.22 Transportation of Cargo by Barge or ShipMathias OnosemuodeÎncă nu există evaluări

- FLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedDocument92 paginiFLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedWilliam O OkolotuÎncă nu există evaluări

- Lazy AssignmentDocument5 paginiLazy Assignmentthefoot39Încă nu există evaluări

- Pipe Lay Barge - SolitaireDocument50 paginiPipe Lay Barge - Solitairejfisher2534Încă nu există evaluări

- Use Underwater Dry WeldingDocument19 paginiUse Underwater Dry Weldingvendry mofuÎncă nu există evaluări

- Flexible Jumper Design PremiseDocument12 paginiFlexible Jumper Design PremiseAgus BudionoÎncă nu există evaluări

- Offshore Installations Marine Operations and Marine AnalysisDocument64 paginiOffshore Installations Marine Operations and Marine Analysisravi_4908Încă nu există evaluări

- Quayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)Document35 paginiQuayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)cliff1234Încă nu există evaluări

- Re-Evaluation of DNV Simplified Formulae For Crane Tip MotionsDocument10 paginiRe-Evaluation of DNV Simplified Formulae For Crane Tip Motionsguxiaom100% (1)

- OMAE2012-83522: Pipeline Stabilisation Using Pre-Trenching and Sand BackfillDocument8 paginiOMAE2012-83522: Pipeline Stabilisation Using Pre-Trenching and Sand BackfillLucas FladinirÎncă nu există evaluări

- 14 - NRG - Pipe Installation - Davit LiftDocument16 pagini14 - NRG - Pipe Installation - Davit LiftBalanÎncă nu există evaluări

- Jacket Installation FlowchartDocument1 paginăJacket Installation FlowchartNath YauÎncă nu există evaluări

- B23-14 - TERMPOL Surveys and Studies - Section 3.14 - Single Point Mooring Provisions and Procedures A1Z6J8Document17 paginiB23-14 - TERMPOL Surveys and Studies - Section 3.14 - Single Point Mooring Provisions and Procedures A1Z6J8HASHMI MAHMOODÎncă nu există evaluări

- JR2010010 Marine Warranty Surveyors CoP PDFDocument14 paginiJR2010010 Marine Warranty Surveyors CoP PDFhiyeonÎncă nu există evaluări

- Jr2016 012 Rig Move Cop SowDocument22 paginiJr2016 012 Rig Move Cop SowImran Siddiqui100% (1)

- Company Profile: IHC Engineering Business LTDDocument35 paginiCompany Profile: IHC Engineering Business LTDSatyavan L RoundhalÎncă nu există evaluări

- Cable On Bottom Stability CommentsDocument12 paginiCable On Bottom Stability CommentsSourabhÎncă nu există evaluări

- Underwater Submarine Pipe LineDocument30 paginiUnderwater Submarine Pipe LinevillanuevamarkdÎncă nu există evaluări

- NH/LAM/303/001/09: Flowline Partial Replacements On Call Off BasisDocument7 paginiNH/LAM/303/001/09: Flowline Partial Replacements On Call Off BasisbenonÎncă nu există evaluări

- Pre Trenching ProsedurDocument19 paginiPre Trenching Prosedurmaniacs14Încă nu există evaluări

- Offshore Structures Slides IIDocument23 paginiOffshore Structures Slides II66apenlullenÎncă nu există evaluări

- 0029 - ND Rev - 0 22-Jun-13 Guidelines For Submarine Pipeline InstallationDocument54 pagini0029 - ND Rev - 0 22-Jun-13 Guidelines For Submarine Pipeline InstallationGiray Çıvak100% (1)

- Hand-Out Rigging Design For Offshore Heavy Lifting LeefmansDocument24 paginiHand-Out Rigging Design For Offshore Heavy Lifting LeefmansAcid Hadi100% (1)

- OrcaFlex Demonstration IIT MadrasDocument11 paginiOrcaFlex Demonstration IIT MadrasvigambetkarÎncă nu există evaluări

- Spool and Riser Flooding & HydrotestDocument30 paginiSpool and Riser Flooding & HydrotestPhani Kumar G SÎncă nu există evaluări

- Splash Zone Lifting Analysis of Subsea StructuresDocument11 paginiSplash Zone Lifting Analysis of Subsea StructuresAnonymous PibYPghÎncă nu există evaluări

- Offshore Pipe Line and RisersDocument27 paginiOffshore Pipe Line and Riserssaeed ghafooriÎncă nu există evaluări

- Buoyed Up: Proven in The Past, Prepared For The FutureDocument10 paginiBuoyed Up: Proven in The Past, Prepared For The FutureantidemosÎncă nu există evaluări

- Minisat 120-00 - 1407410602Document25 paginiMinisat 120-00 - 1407410602RicardoÎncă nu există evaluări

- Offshore Load Out Day 3Document109 paginiOffshore Load Out Day 3bubbly_blu2Încă nu există evaluări

- Jacket Response AnalysisDocument8 paginiJacket Response Analysisrobert.johns1028Încă nu există evaluări

- Simple Stability MosesDocument11 paginiSimple Stability Mosesikhwanul_muslimÎncă nu există evaluări

- OrcaFlex For PipelayDocument4 paginiOrcaFlex For PipelaySandeep RangapureÎncă nu există evaluări

- 12002-AMC-TIN-PRO-0028 - Rev 0 Concrete Mattress Installation and Relocation Procedure - IssuedDocument58 pagini12002-AMC-TIN-PRO-0028 - Rev 0 Concrete Mattress Installation and Relocation Procedure - IssuedWilliam O Okolotu100% (3)

- Tandem Loading Guidelines v1 21Document129 paginiTandem Loading Guidelines v1 21Cindy100% (1)

- Method Statement - Crane Barge Tie-InsDocument6 paginiMethod Statement - Crane Barge Tie-InsAdaghara100% (1)

- FLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedDocument94 paginiFLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedWilliam O Okolotu100% (1)

- Catenary Cation of Cables PDFDocument153 paginiCatenary Cation of Cables PDFPrashanth Talkad Rajagopal100% (1)

- Seafastening Manual For The Carriage of Anode Cages On Seagoing Vessels Rev. 3Document17 paginiSeafastening Manual For The Carriage of Anode Cages On Seagoing Vessels Rev. 3JackÎncă nu există evaluări

- Guidances For Single Point MooringDocument53 paginiGuidances For Single Point Mooringgenesis L. OrtizÎncă nu există evaluări

- MOSES Advanced TrainingDocument4 paginiMOSES Advanced TrainingYudha MeremÎncă nu există evaluări

- WAfrica Metocean Data Rev20Document55 paginiWAfrica Metocean Data Rev20Ένκινουαν Κόγκ Αδάμου100% (2)

- BPCL Kochi SPM Pig Study 01Document9 paginiBPCL Kochi SPM Pig Study 01Arun Kumar PancharajÎncă nu există evaluări

- Lifting Analysis Preview)Document4 paginiLifting Analysis Preview)Faisal AjaÎncă nu există evaluări

- Moses Mooring Analysis - Introduction - 230903 - 101634Document42 paginiMoses Mooring Analysis - Introduction - 230903 - 101634Hermawan Saini100% (1)

- Dynamic positioning The Ultimate Step-By-Step GuideDe la EverandDynamic positioning The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Mechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestDe la EverandMechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestÎncă nu există evaluări

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDe la EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityÎncă nu există evaluări

- Technical Procedure For Jacket Installation PDFDocument19 paginiTechnical Procedure For Jacket Installation PDFflawlessy2k100% (3)

- IMCA-Download-15065 (Observation Record)Document1 paginăIMCA-Download-15065 (Observation Record)flawlessy2kÎncă nu există evaluări

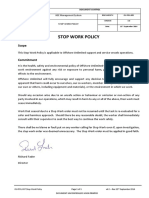

- Stop Work PolicyDocument1 paginăStop Work Policyflawlessy2kÎncă nu există evaluări

- QAQCDocument15 paginiQAQCflawlessy2k100% (1)

- Technical Procedure For Jacket Installation PDFDocument19 paginiTechnical Procedure For Jacket Installation PDFflawlessy2k100% (3)

- Geodetic Offshore Services LTD: S H & E ManualDocument55 paginiGeodetic Offshore Services LTD: S H & E Manualflawlessy2kÎncă nu există evaluări

- Iso 9001Document4 paginiIso 9001flawlessy2kÎncă nu există evaluări

- QMS ProposalDocument22 paginiQMS Proposalflawlessy2kÎncă nu există evaluări

- 12 - Helmsmans DisplayyyDocument96 pagini12 - Helmsmans Displayyyflawlessy2kÎncă nu există evaluări

- EIVA ManualDocument74 paginiEIVA Manualflawlessy2kÎncă nu există evaluări

- Change Management Plan, V2.0Document6 paginiChange Management Plan, V2.0flawlessy2kÎncă nu există evaluări

- Paramount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceDocument1 paginăParamount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceSwapnil TiwariÎncă nu există evaluări

- Schneider Contactors DatasheetDocument130 paginiSchneider Contactors DatasheetVishal JainÎncă nu există evaluări

- MCQs - Chapters 31 - 32Document9 paginiMCQs - Chapters 31 - 32Lâm Tú HânÎncă nu există evaluări

- Topic Group Present (Week 8) Chapter 1:sociology and Learning ManagementDocument2 paginiTopic Group Present (Week 8) Chapter 1:sociology and Learning ManagementLEE LEE LAUÎncă nu există evaluări

- De DusterDocument6 paginiDe DusterArstÎncă nu există evaluări

- LDSD GodseDocument24 paginiLDSD GodseKiranmai SrinivasuluÎncă nu există evaluări

- Mule 4 Error Handling DemystifiedDocument8 paginiMule 4 Error Handling DemystifiedNicolas boulangerÎncă nu există evaluări

- Minuets of The Second SCTVE MeetingDocument11 paginiMinuets of The Second SCTVE MeetingLokuliyanaNÎncă nu există evaluări

- Cad Data Exchange StandardsDocument16 paginiCad Data Exchange StandardskannanvikneshÎncă nu există evaluări

- Nestlé CASEDocument3 paginiNestlé CASEAli Iqbal CheemaÎncă nu există evaluări

- Introduction To M365 PresentationDocument50 paginiIntroduction To M365 Presentationlasidoh0% (1)

- Formal Letter LPDocument2 paginiFormal Letter LPLow Eng Han100% (1)

- Manual: Functional SafetyDocument24 paginiManual: Functional SafetymhaioocÎncă nu există evaluări

- MECANISMOS de Metais de TransicaoDocument36 paginiMECANISMOS de Metais de TransicaoJoão BarbosaÎncă nu există evaluări

- Blake 2013Document337 paginiBlake 2013Tushar AmetaÎncă nu există evaluări

- Resume NetezaDocument5 paginiResume Netezahi4149Încă nu există evaluări

- The International Poker RulesDocument2 paginiThe International Poker RulesOutontheBubbleÎncă nu există evaluări

- Linear Dynamic Analysis of Free-Piston Stirling Engines OnDocument21 paginiLinear Dynamic Analysis of Free-Piston Stirling Engines OnCh Sameer AhmedÎncă nu există evaluări

- Homework 1Document8 paginiHomework 1Yooncheul JeungÎncă nu există evaluări

- Jayesh PresentationDocument22 paginiJayesh PresentationanakinpowersÎncă nu există evaluări

- 2013 Cases Penned by Justice BernabeDocument11 pagini2013 Cases Penned by Justice BernabeJoan PabloÎncă nu există evaluări

- Hetal Patel: Team Leader - SalesDocument2 paginiHetal Patel: Team Leader - SalesPrashant kumarÎncă nu există evaluări

- Pest of Field Crops and Management PracticalDocument44 paginiPest of Field Crops and Management PracticalNirmala RameshÎncă nu există evaluări

- The Minimum Means of Reprisal - China's S - Jeffrey G. LewisDocument283 paginiThe Minimum Means of Reprisal - China's S - Jeffrey G. LewisrondfauxÎncă nu există evaluări

- 1"a Study On Employee Retention in Amara Raja Power Systems LTDDocument81 pagini1"a Study On Employee Retention in Amara Raja Power Systems LTDJerome Samuel100% (1)

- Principles of Business Grade 10 June 2021 Time: 1 1/2 Hrs. Paper 2 Answer ONLY 1 Question in Section I. Section IDocument3 paginiPrinciples of Business Grade 10 June 2021 Time: 1 1/2 Hrs. Paper 2 Answer ONLY 1 Question in Section I. Section Iapi-556426590Încă nu există evaluări

- Ginger Final Report FIGTF 02Document80 paginiGinger Final Report FIGTF 02Nihmathullah Kalanther Lebbe100% (2)

- Terminal Blocks: Assembled Terminal Block and SeriesDocument2 paginiTerminal Blocks: Assembled Terminal Block and SeriesQuan Nguyen TheÎncă nu există evaluări

- WinCC Control CenterDocument300 paginiWinCC Control Centerwww.otomasyonegitimi.comÎncă nu există evaluări

- Fmicb 10 02876Document11 paginiFmicb 10 02876Angeles SuarezÎncă nu există evaluări