Documente Academic

Documente Profesional

Documente Cultură

Acid - Gangue Reactions PDF

Încărcat de

JereeHansGonzalezAchumascaloTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Acid - Gangue Reactions PDF

Încărcat de

JereeHansGonzalezAchumascaloDrepturi de autor:

Formate disponibile

A STUDY OF ACID-GANGUE REACTIONS IN HEAP-LEACH

OPERATIONS

Ali Seyedbagheri, Petrus Van Staden & Chris Mclaren

Mintek Company, Randburg, South Africa

ABSTRACT

During exploration projects, it is important to be able to predict, as early as possible, the

behaviour of an ore with respect to metal extraction. In the case of heap leach projects, where

gangue is the major constituent of the feed material being treated, the anticipated gangue-acid

consumption (affecting operating cost) and the associated alteration and precipitation

reactions (affecting heap permeability) are equally important. A survey of the literature on the

mineralogy of porphyry-copper resources indicates that silicates with a high extent of

polymerisation of the silica tetrahedral structure have a relatively low tendency to react with

acid. Hence, most of these silicates tend to undergo merely alteration reactions in contact with

acid (as opposed to breaking down to their elements), and precipitate alteration products in the

process. Plagioclase feldspars tend to dissolve under acidic conditions in a heap and create

gelatinising silicate minerals as alteration products which can blind the ore particles and lead

to a heap with poor permeability. Biotite and chlorite are examples of slow acid consumers and

their dissolution is proportional to the acid strength. Quartz, alkali feldspars, and

phyllosilicates are slightly reactive gangue minerals and dissolve in acid very slowly. An

outline is provided of how information regarding the chemistry of silicate-gangue minerals can

be incorporated into a model to serve as a tool for the early prediction of larger scale heap

leach performance from laboratory scale investigations on small samples.

INTRODUCTION

Ores considered for heap leaching are sometimes evaluated without adequate attention to the

gangue mineralogy, despite the fact that ore and gangue mineralogy is probably the single most

important parameter affecting operational costs and recoveries and can change significantly from

one area of the resource to another. Apparently minor changes in gangue mineralogy can have a

significant impact on the requirements for curing and agglomeration, and on the acid consumption,

metal extraction, and PLS solution chemistry observed during leaching [1]. Adams [2] has

considered several examples of the impact of mineralogical composition on process performance,

and argues for the necessity of having an automated mineralogical analysis to serve as a useful

predictor of expected plant performance. Baum suggests that any results of chemical acid

consumption must be supported by mineralogical acid consumption data [1]. In order to maximise

HYDROCOPPER 2009, Antofagasta, Chile 68

the efficiency of metal recovery while minimising the consumption of acid by gangue, a wide range

of mineralogical aspects needs to be considered [3].

Certain gangue minerals, like calcite (CaCO3), are very reactive to acid and will in time dissolve

completely in contact with even very dilute sulfuric acid. Ores that contain a significant proportion

of such minerals will be clearly unsuitable for acidic heap leaching and as such represents a trivial

case for gangue chemistry studies.

However, large groups of the silicate gangue minerals found in igneous rock react incompletely

with sulfuric acid and with several of them the extent of acid-gangue reaction is a function of the

acid strength in the leach liquor. The moderate reactivity to acid of these gangue minerals limits

their acid consumption sufficiently, such that acid heap leaching of the ore can be economically

viable with relatively low valuable metal grade. It leaves a margin of control over the acid

consumption, and permits an economic optimum to be sought between acid cost and leach kinetics,

by varying the acid curing parameters and the acidity of the irrigation liquor.

This further implies that from an understanding of the reactions between particularly the silicate

gangue minerals and sulfuric acid, it is possible to make predictions about the likely acid

consumption of the ore under various conditions of irrigation acid strength, and from that can

follow predictions about the precipitates that are likely to form inside the heap, as well as the (both

valuable and nuisance) soluble species that are likely to report to the pregnant leach liquor feeding

the downstream recovery steps. Such predictions can already start to be made during the earliest

phase of a project, when only a limited amount of drill core sample may be available, based on a

knowledge of the gangue mineralogy, coupled to geochemical database information and modelling

software. Deriving this type of information should not be based only on very crude scale-up factors

from small-scale tests, and should not be delayed until large ore samples are made available for

column leach tests.

Silicate Gangue Minerals

Silicate gangue minerals comprise more than 95 percent of most porphyry copper ores, with a few

important examples being listed in Table 1. Consequently, it can be expected that the behaviour of

these minerals in sulfuric acid solutions would exert an important influence on the performance of

copper and other heap leaching process [4]. They form a group of inorganic compounds of great

chemical, as well as structural, complexity. They are essentially divided into primary and secondary

silicate minerals depending on whether they are the original minerals (e.g. quartz, feldspar, mica,

amphibole, and pyroxene) or are formed by the dissolution, alteration and byproduct precipitation

of primary silicates. The secondary silicates in turn are divided into two groups including clay

minerals (e.g. illite, vermiculite, montmorillonite and kaolinite) and residual oxides and hydroxides.

Of the nine common cations in silicate rocks, only four (Si4+, Ti4+, Al3+, and Fe3+) form stable

oxides or hydroxides or both [5].

HYDROCOPPER 2009, Antofagasta, Chile 69

Table 1: Important silicate minerals present in porphyry copper deposits [4]

Mineral Ideal chemical formula Silicate type

Quartz SiO2 tecto

orthoclase

KAlSi3O8 tecto

(K-feldspar)

NaAlSi3O8 (albite) - CaAl2Si2O8

Plagioclase tecto

(anorthite)

Biotite K(Mg,Fe)3[(Al,Fe)Si3O10)](F,OH)2 phyllo

Chlorite (Mg,Fe)5Al(Si3Al)O10(OH)8 phyllo

muscovite/sericite KAl2(Si3AlO10)(F,OH)2 phyllo

Montmorillonite (Na,Ca)0..3 (Al,Mg)2Si4O10(OH)3.nH2O phyllo

Vermiculite (Mg,Fe,Al)3[(Al,Si)4O10](OH)2.4H2O phyllo

Kaolinite Al4Si4O10(OH)8 phyllo

Hornblende

(Ca,Na)2-3(Mg,Fe,Al)5Si6(Al,Si)2O22(OH)2 Ino (double chain)

(amphibole)

Actinolite Ca(Mg,Fe)3(SiO3)4 Ino (double chain)

Factors Determining Silicate Minerals Reactivity In Acidic Media

Silicate Structure

One common component of all silicates is the tetrahedral SiO4-4 structural sub-unit. The manner in

which these units associate provides a basis for classification of the silicates into six distinct groups.

They range from meso-(or ortho)-silicates in which the silica tetrahedra are independently joined by

some metal cations, thereby rendering the mineral very susceptible to acid attack, to the

tectosilicates, in which all oxygen atoms are shared between silicon atoms making the mineral

resistant to acid leaching. The other intermediary groups show a proportional reactivity depending

on the proportion of oxygen atoms shared by silica tetrahedra. Hence, from knowledge about the

silicate group that a specific mineral belongs to, an indication can be obtained of the reactivity of

the mineral and its potential to react with acid. This rough classification is illustrated in Figure 1

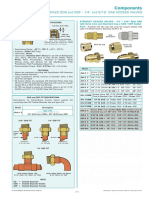

which illustrates Bowens reaction series of the order in which minerals crystallise from a magma.

Olivine

Hypersthene basalt, diabase Ca plagioclase

Increasing

Augite Ca-Na plagioclase

Si or other

Hornblende Na-Ca plagioclase cations with

increasing high energy

rate of Biotite mica potassic alteration Na plagioclase oxygen bonds

breakdown K Feldspar

quartz sericite alteration

in acid solutions

Muscovite

Sericite

Quartz

Figure 1: Common rock-forming (gangue) minerals arranged by crystallisation

order and dissolution kinetics in acid sulfate leach solutions [4]

HYDROCOPPER 2009, Antofagasta, Chile 70

Metal Cation-Oxygen Bond

The metal cation-oxygen bonds in silicates are generally weaker than the silicon-oxygen bonds, and

are thus more susceptible to acid attack. Within a given silicate structural group, the reactivity is

determined to a large extent by the strength of the metal-oxygen bond and therefore by the nature of

metal cation [6]. Table 2 lists the strengths of some typical metal-oxygen bonds in oxygen

containing glasses and crystals, as estimated by Huggins and Sun [7].

Table 2: Metal-oxygen bond energy for some metal cations [7]

Ion Metal-oxygen bond energy Ion Metal-oxygen bond energy

(KJ mol-1) (KJ mol-1)

4+ 2+

Si 13012-13146 Mg 3816

4+ 2+

Ti 12058 Mn 3745

Zr4+ 11033 Cu2+ 3598

2+

Ca 3510

Al3+ 7201-7858 Pb2+ 3469

3+ 2+

Cr 7092 Sr 3347

3+ 2+

Y 6552 Ba 3213

Be2+ 4774

2+

Zn 3937 Li+ 1469

2+

Ni 3887 Na+ 1347

2+ +

Fe 3845 K 1251

The bond energies in Table 2 suggest that the resistance to acid attack of a silicate mineral will

increase with an increasing proportion of silicon and other high bond-energy metals. A practical

example illustrating this principle can be found in the comparison between biotite and muscovite

(Table 1), both being phyllosilicates of very similar composition except that muscovite has Al in

the structure instead of the Fe and Mg of biotite. Snall [Snall et al. 2000], in his silicate reactivity

studies, showed that biotite dissolved completely in acid, while muscovite dissolution was only

5.6 to 8.7 percent. As a result, it is found in heap leach operations that muscovite remains almost

unreacted in contact with acid, whereas biotite is an acid consumer and its extent of dissolution is

proportional to the strength of the acid that it is in contact with. The magnesium contained in

biotite tends to hydrolyse quite readily, while the ferrous iron oxidizes, resulting in biotite

alteration products.

Gelatinising silicates provide a good example of the influence of silicate structure and metal

oxygen bond factors on the chemical behaviour of minerals. Silicate mineral groups that gelatinise

under acid attack are:

Silicate minerals of small molecular weights, like nesosilicates (e.g. olivine (Mg,Fe)SiO4),

sorocilicates (e.g. kermanite Ca2MgSi2O7), and silicates containing ring structures of three

silicon atoms (e.g. catapleiite Na2ZrSi3O92H2O )

Chain-silicates like ussingite (Na2AlSi3O5(OH) )

HYDROCOPPER 2009, Antofagasta, Chile 71

Phyllosilicates containing appreciable ferric iron in the sheets (nontronite

Na0.3Fe+32(Si,Al)4O10(OH)2n(H2O))

Tectosilicates containing aluminium in their structure in the ratio of at least two aluminium

atoms to three silicon atoms like nepheline {(K,Na)AlSiO4}, anorthite (CaAl2Si2O8) and natrolite

(Na2Al2Si3O10 2H2O).

A complete list of gelatinising minerals is given by Terry and Murata [Terry part II, 1983, Murata

1943]. Gel formation in a heap can obviously interfere with the permeability of the ore, whereas

elevated levels of silica in the pregnant leach solution can interfere with the operation of the solvent

extraction and electrolysis stages. It is therefore important to be able to predict when significant

dissolution of silica is likely to occur so that precautions can be taken to reduce the likelihood of

silica dissolution and gelatinisation. Measures that can be taken in this regard include moderation of

the acid regime used for curing and leaching, and intermittent irrigation to promote cyclic

precipitation in the heap of the potential gel-forming species before polymerisation with the

concomitant water encapsulation occurs.

Acid Anion and Mineral Interaction

Complexing of the metal ion with an anion derived from an inorganic acid can enhance the

dissolution rate of metal silicates. For example, the observed order of reactivity of acids toward the

silicate mineral chrysocolla ((Cu,Al)2H2Si2O5nH2O) is as follows:

H2SO4>HCl>HNO3>HClO4

With sulfuric acid being found to yield a faster rate of dissolution of chrysocolla than the other

acids, which can be explained by the relative strength of the metal cation-acid anion complexes [6].

Factors such as crystallinity, the presence of inclusions and dissolved impurities, grain size and

dislocations are also known to influence the rates of chemical reactions of all minerals. According

to Grim, for example [11], fine-grained chlorite can be decomposed in warm HCl, whereas well

crystallised chlorite can remain unattacked by 10 M HCl for over 72 hours. Therefore, in the

mineralogical report of an ore, the crystallinity should also be described.

Modelling of Acid-Siliicate Reactions in Heap Leaching

Stages In Silicate Mineral Dissolution/Alteration Reactions

The reactions between acid and silicate minerals can be regarded as an accelerated weathering

process, which proceeds along a similar sequence of stages as is found during natural weathering, as

illustrated in Table 3. Firstly, the primary minerals dissolve (either partially or completely) and

secondary minerals can result as remaining undissolved residues or re-precipitated

oxides/hydroxides. Leaching of elements such as calcium, magnesium, sodium, potassium, and

soluble silica supports further transformation processes. Successive secondary minerals can form

and be leached again, following a sequence of gradual loss of silica during each leaching step and

finally leaving secondary products that contain no silica, i.e., the hydrous oxides, while the leached

silica re-precipitates as secondary quartz. These minerals tend to persist as the final products of long

and intense silicate mineral leaching [5, 12].

As a result, the rigorous modelling of the performance of a heap leach operation requires a

complete set of all the reactions, and their equilibrium constants, in which the silicate minerals

HYDROCOPPER 2009, Antofagasta, Chile 72

present in the ore under study, can participate, from their original form up to its complete

decomposition.

Table 3: Stages in dissolution/alteration and precipitation of silicate minerals [4]

Silicate Structure

Group of Primary Primary Mineral Secondary Minerals

Mineral

Ti Anatise

Discrete Olivine

Fe Geotite

Tetrahedra Augite, Amorphous

1 Hematite

Single Chains Hypersthene Hydrous Oxides

Double Chains Al Gibbsite

Hornblende

Si Boehmite

Amorphous Volcanic Glass Fe

2 linked (basic) Amorphous

Al Gibbsite

Tetrahedra Zeolites Hydrous Oxides

Si Allophane

H, Ca

Trioctahedral Illite Ca

3- Layer K

K H - SiO2

Structures with Biotite Kaolin

3 Clay Vermiculite Ca Montmorillonite

Hexagonal Muscovite

K H H, Ca + SiO2

Linkages

Dioctahedral Illite K

Amorphous Volcanic Glass Amorphous Al Gibbsite

4 linked (acid) Hydrous Oxides Si

Tetrahedra Feldspars

Linked Silicic Acid Chalcedonite Silicic Acid

5 Quartz

Tetrahedra

Secondary Quartz

Current Modelling Tools for Acid-Gangue Reactions During Heap Leaching

The reaction stoichiometry and equilibrium data referred to above can be used in a geochemical

model to perform the simultaneous equilibrium calculations for the time and special elements into

which a heap leach operation can be discretisised for its numerical simulation.

Numerical models have been used for assessing the potential for the transport of soluble

species in mine waste dumps, which can obviously also be applied to heap leaching. Various

studies have also been undertaken on the modelling of mass and energy transport specifically in

ore heaps [13, 14, 15, 16].

The existing numerical flow and reactive transport models can be divided into three broad

categories: (a) water flow models, (b) geochemical models, and (c) models that integrate flow and

geochemistry.

Water flow models can be further divided into:

those that assume unsaturated water flow, saturated water flow, and surface water flow and

those that integrate flow between two or more of these domains.

Static geochemical models are typically equilibrium-based and include acid-base, oxidation-

reduction, aqueous complexation, precipitation-dissolution, ion exchange, adsorption-desorption,

and gas transfer reactions. However the prediction of contaminant or solution species transport as it

HYDROCOPPER 2009, Antofagasta, Chile 73

occurs in heap leaching requires integration of flow and geochemical processes. This integration

can range from a simple mixing cell approach to fully coupled multicomponent reactive transport

formulations with the possible inclusion of equations to account for slow reaction kinetics [17], that

is reactions that do not proceed to equilibrium.

A number of computer models are available for integrating water flow, oxygen transport, and a

broad range of geochemical reactions to predict the movement of contaminants in the subsurface

[18, 19, 20, 21]. These models have been applied to a number of mine sites representing a range of

climatic settings. For example, reactive solute transport models have been applied to assess solute

release from coal mines and to evaluate closure scenarios. In general, the quality of the predictions

is related to the quality and amount of data used for the calculations and the complexity of

processes included. Examples of existing models mentioned in the literature are listed below, some

of which are in the public domain, and some are proprietary codes, while others were developed for

research applications only.

Model Categories

Saturated Water Flow through Porous Media (not suitable for fractured media): e.g. MODFLOW

Unsaturated Water Flow through Porous Media

e.g. SEEPW, HYDRAS, HYDRAS2D

Saturated Water Flow through Fractured Media:

e.g. FRAC3DVS, FRACTRAN, NETFLO, SWIFT-98, TRAFRAP-WT

Unsaturated Water Flow through Fractured Media:

e.g. FRAC3DVS

Surface Water Flow:

e.g. HEC-RAS

Geochemical Equilibrium Models:

e.g. MINTEQA2, PHREEQC, GEOCHEMISTS WORKBENCH, MODPHRQ

Reactive transport models (Integrated flow and Geochemical models):

e.g. PHREEQC, MINTRAN, FLOTRANS, HYDROGEOCHEM, UNSATCHEM,

Reactive Solute Transport Models Incorporating Sulfide Oxidation Reactions:

MINTOX, MIN3P, MULTIFLOW, POLYMIN

Sulfide Oxidation Models:

e.g. PYROX, SULFIDOX

For early-stage investigations, it is probable that insufficient input information will be available to

warrant the use of a sophisticated proprietary model, but already valuable insights can be gained

from simply a mineralogical study of the gangue and holistic stoichiometric calculations over the

life time of a heap. Sophistication can be added to these calculations by discretisising the process

spatially and in time, with the outputs from earlier elements providing the inputs for later elements.

For the simultaneous solution of the stoichiometry while satisfying all equilibrium constants,

acquiring one of the existing models (many of which include extensive databases) would in most

cases be warranted, as opposed to attempting to develop the required software and developing the

entire database in-house.

The shortfalls of even the best and latest solution chemistry theory and models are commonly

known. But despite that, the undertaking of at least some level of theoretical calculation of the

HYDROCOPPER 2009, Antofagasta, Chile 74

gangue stoichiometry to be expected from an ore over the life time of a heap, based on its

mineralogical information, is a level of interpretation that is worth undertaking at the earliest stage

of a project, but which currently does not seem to be common practice.

SUMMARY AND CONCLUSIONS

Obtaining ore samples from a prospective ore body by diamond core drilling is an expensive

undertaking, and it is important that as much as possible information is derived from those samples,

and that such information be interpreted to the maximum extent possible. Only in that way can

investors be provided with the best information for further investment decisions.

Acid consumption is likely to be one of the major, if not the dominating, operating cost element

during the life of a heap leach project. The blinding of a heap of ore by precipitates can terminate its

useful life, and the presence of elevated levels of nuisance elements in the liquor feed to the

downstream metals recovery plant can present significant operational problems. All these factors

are related to the gangue mineralogy and chemistry of the ore.

Even during the earliest stages of a project, when only a limited amount of sample may be

available, some estimates regarding acid consumption, re-precipitation in the heap and pregnant liquor

composition can already be made from the mineralogical characterisation of the gangue minerals.

In this paper, examples are provided of how the reactivity of various gangue minerals are

related to their general classification, chemical composition, and structure. This information can be

coupled to mathematical models and databases of various possible levels of sophistication to

simulate a commercial heap leach operation, to provide a level of interpretation that currently does

not seem to be common practice, and which is often delayed until only much later in the project

when tall column leach or pilot plant experiments are undertaken.

REFERENCES

Baum, W. (1999). The use of a mineralogical data base for production forecasting and

troubleshooting in copper leach operations. Proceedings of Copper 99 Cobre 99

International Conference, Volume IV, Hydrometallurgy of copper, p.p. 393-407. [1]

Adams, M. D. (2007). Towards a virtual metallurgical plant 2: Application of mineralogical data.

Minerals Engineering, 20, p.p. 472-479. [2]

Jansen, M. & Taylor, A. (2003). Overview of Gangue Mineralogy Issues in Oxide Copper Heap

Leaching. ALTA 2003 copper - 8: technical proceedings - Global technical interchange,

Rendevous Observation City Hotel Perth, Western Australia. Alta Metallurgical Services. [3]

Dreier, J. (1998). Geochemical aspects of copper heap leaching. The short course: copper heap

leach in conjunction with the 1998 SME annual meeting and exhibit, Orlando, Florida. [4]

Loughana, F. C. (1969). (ed.) Chemical weathering of the silicate minerals. American Elsevier

Publishing company, Inc. [5]

Terry, B. (1983). The acid decomposition of silicate minerals, Part I. Reactivities and modes of

dissolution of silicates. Hydrometallurgy, 10, p.p. 135-150. [6]

HYDROCOPPER 2009, Antofagasta, Chile 75

Huggins, M. L. & Sun, K. H. (1946). Energy additivity in oxygen containing crystals and glasses.

J. Phys. Chem., 50, p.p. 319-328. [7]

Snall, S. & Liljefors, T. (2000). Leachability of major elements from minerals in strong acids.

Journal of Geochemical Exploration, pp. 71, 1-12. [8]

Terry, B. (1983). The acid decomposition of silicate minerals. Part I I. Hydrometallurgical

applications, Hydrometallurgy, 10, pp. 151-171. [9]

Murata, K. J. (1943). Internal structure of silicate minerals that gelatinise with acid. The

American Mineralogist, 28, pp. 545-562. [10]

Grim, R. E. (1968). Clay mineralogy. 2nd edition, McGraw- Hill, New York. [11]

White, R. E. (1987). Introduction to the Principles and Practice of Soil Science. Blackwell

Scientific Publ. Inc. [12]

Jansen, M. & Taylor, A. (2002). A new approach to heap leaching modeling and scale-up. ALTA

2002, copper, Perth. [13]

Decker, D. L. & Tyler, S. W. (1999). Hydrodynamics and Solute Transport in Heap Leach

Mining. in Kosich D. and Miller G (eds.), Closure, Remediation & Management of Precious

Metals Heap Leach Facilities, pp. 113, Univ. of Nevada, Reno. [14]

Crawford, J. & Stepanyants, Y. A. (2005). Influence of bottom boundary condition on heat

distribution within oxidising heaps. ANZIAM J, 46 (E), pp. C1104-C1125. [15]

Ritchie, A. I. M. (1977). Heap leaching, a gas diffusion rate-limited model. Australian Atomic

Energy Commission, AAEC/E429. [16]

Research Council, Washington, D. C. (2006). Managing Coal Combustion Residues in Mines. [17]

National HydroGeoLogic, Inc. (1999). Herndon, Virginia and Allison Geoscience Consultants,

Inc. Flowery Branch, Georgia, MINTEQA2/PRODEFA2, A Geochemical Assessment Model

for Environmental Systems: User Manual Supplement for Version 4.0. Report for U.S.

Environmental Protection Agency. [18]

Molson, J. W., Fala, O., Aubertin M. & Bussie`re, B. (2005). Numerical simulations of pyrite

oxidation and acid mine drainage in unsaturated waste rock piles. Journal of Contaminant

Hydrology, Vol. 78, No.4, p.p. 343-371. [19]

RockWare, an earth science software. (2008). http://www.rockware.com [20]

Eary, E. & Williamson, M. A. (2006). Simulation of the neutralising capacity of silicate rocks in

acid mine drainage environments. In: Barnhisel R.I., (ed.), 7th International Conference on

Acid Rock Drainage (ICARD), Published by the American Society of Mining and

Reclamation (ASMR). [21]

HYDROCOPPER 2009, Antofagasta, Chile 76

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Experiment 4Document12 paginiExperiment 4Doğukan Aybars ÖztürkÎncă nu există evaluări

- Thermal Insulation Products - Jacketing & CladdingDocument15 paginiThermal Insulation Products - Jacketing & CladdingSreekumar K SÎncă nu există evaluări

- LC3: A breakthrough technology to reduce CO2 emissions from cementitious materialsDocument62 paginiLC3: A breakthrough technology to reduce CO2 emissions from cementitious materialsSubhan MuhammadÎncă nu există evaluări

- Anaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)Document7 paginiAnaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)syafiqzainordinÎncă nu există evaluări

- Welding DefectsDocument4 paginiWelding DefectsSD Recruiters100% (1)

- Extended AbstractDocument10 paginiExtended AbstractSarang GohÎncă nu există evaluări

- Industrial Project Report (WPS)Document79 paginiIndustrial Project Report (WPS)Khairil Anwar MuhajirÎncă nu există evaluări

- Making The Keats Angle Plate From CastingsDocument15 paginiMaking The Keats Angle Plate From CastingsJohn SmithÎncă nu există evaluări

- Why Is Stainless Steel Corrosion ResistantDocument4 paginiWhy Is Stainless Steel Corrosion ResistantMELVIN MAGBANUAÎncă nu există evaluări

- Objectives: - Describe - Identify - Describe - CalculateDocument29 paginiObjectives: - Describe - Identify - Describe - CalculateJanaÎncă nu există evaluări

- Evolution of Dye TechnologyDocument28 paginiEvolution of Dye TechnologyNaeem MalikÎncă nu există evaluări

- Review Amine Based Capture Review - IChemE - PartA - Full - Paper - V9 - 28may2010Document23 paginiReview Amine Based Capture Review - IChemE - PartA - Full - Paper - V9 - 28may2010Ghochapon MongkhonsiriÎncă nu există evaluări

- Oreas 402Document2 paginiOreas 402flysch_ukÎncă nu există evaluări

- Mil-DTL-27500: Please Note The Following ExampleDocument4 paginiMil-DTL-27500: Please Note The Following ExampleTeboho RamakatsaÎncă nu există evaluări

- Distillation Column ReportDocument81 paginiDistillation Column ReportJaspreet Singh67% (9)

- Acyclic Hydrocarbons Naming RulesDocument14 paginiAcyclic Hydrocarbons Naming Rulesvishal_kalraÎncă nu există evaluări

- Coating of SuperalloysDocument4 paginiCoating of SuperalloysFaraj MohamedÎncă nu există evaluări

- OPRD - Optimization of Manufacturing Route To PF-610355Document11 paginiOPRD - Optimization of Manufacturing Route To PF-610355rrgodboleÎncă nu există evaluări

- Biochemical Processes: Activity 3Document2 paginiBiochemical Processes: Activity 3Althea ValenzuelaÎncă nu există evaluări

- Nitrogen CycleDocument9 paginiNitrogen CyclePriyanshu KumarÎncă nu există evaluări

- Synthesis of Styrene-Acrylic Copolymers and Their Use inDocument93 paginiSynthesis of Styrene-Acrylic Copolymers and Their Use inMohamed HalemÎncă nu există evaluări

- Activity 4 - Flame Test For Metal - CRUZ ARJAYDocument5 paginiActivity 4 - Flame Test For Metal - CRUZ ARJAYArjay Francisco CruzÎncă nu există evaluări

- Enzymes and Their ClassificationDocument30 paginiEnzymes and Their ClassificationSadia DinÎncă nu există evaluări

- On Gating SystemDocument19 paginiOn Gating SystemMurali Krishnan SelvarajaÎncă nu există evaluări

- Impact of Non-Uniform Fouling On Operating Temperatures in Heat Exchanger NetworksDocument7 paginiImpact of Non-Uniform Fouling On Operating Temperatures in Heat Exchanger NetworksZul FakriÎncă nu există evaluări

- The Cuprex Metal Extraction Process: Recovering Copper From Sulfide OresDocument6 paginiThe Cuprex Metal Extraction Process: Recovering Copper From Sulfide OresAwaken69Încă nu există evaluări

- SOLDER or BRAZE ODS & ODFDocument4 paginiSOLDER or BRAZE ODS & ODFP.SELVAKUMARÎncă nu există evaluări

- Marshall's Reagent: Origins, Modifications, and New ApplicationsDocument2 paginiMarshall's Reagent: Origins, Modifications, and New Applicationso_l_0Încă nu există evaluări

- Nominal Size 20mm (/ In) : Flange TablesDocument1 paginăNominal Size 20mm (/ In) : Flange TablesReşat DEMİRÎncă nu există evaluări

- Offset InksDocument7 paginiOffset InksRizwan KhanÎncă nu există evaluări