Documente Academic

Documente Profesional

Documente Cultură

22.1 Itp Rot 001 PDF

Încărcat de

Adades Safede EfdDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

22.1 Itp Rot 001 PDF

Încărcat de

Adades Safede EfdDrepturi de autor:

Formate disponibile

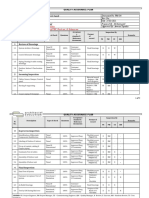

Inspection And Test Plan

for

Centrifugal Pump

HPCL, Vishakhaptnam TOYO ENGINEERING INDIA LTD.

ISSUED : 10/10/2008 JOB NO. : 6261

DOC.NO. HGU PROJECT Page 1 of 3

CLIENT : HPCL, VISHAKHAPATNAM

TEIL JOB NO. : 6261 APPLICABLE CODE : As per PR, PS

ITEM NO. /

PO. NO. :

COMMODITY : CETRIFUGAL PUMP

INSPECTION BY

S. NO. DESCRIPTION OF ACTIVITY EPCC / PMC / RECORD

TPIA

VENDOR OWNER

01 Detailed Inspection & Test Plan after issue of P A A* X

PO/PR/PS including for all auxiliaries of the Pump

skid like Pump driver, Lube oil console, API Plan,

Instrumentation, Piping etc.

02 Inspection & Test Procedures like NDT, Hydro test, P A R** X

Performance test, Mechanical run test, Painting etc.

03 Pre inspection meeting, after issue of PO/PR/PS, P H X

agenda to be prepared by VENDOR

04 Summary of all supplementary requirements as P A X

specified in the PO/PR/PS

05 Sub order verification for Bought out items like P R X

Drivers, API Plan, LO Console, Piping etc.

06 Inspection of Bought out items at Sub vendors W H X

works for Drivers, API Plan, LO Console, Piping

etc.

07 Welding Procedure Specification & Procedure P A X

Qualification Records Pressure retaining

components of the Pump, API plan, Piping etc.

08 Material Test Certificate in accordance with A A X

EN10204 3.1 / ISO10474 3.1B & meeting the

requirements of Material specification,

PR/PS/Design code

Pump components as Casing, Stuffing box, Bearing

housing, Impellers, Shaft, Shaft sleeve, Wear rings,

any other pressure retaining part / part exposed to

process fluid. Also, oil pumps , oil filters , oil

coolers, oil tank,

09 Material Compliance Certificate for Gaskets, A A X

Fasteners, Gland Packing, Valves, Piping items, etc.

10 Mechanical Seal (Testing & certificates / reports as A A X

per API 682 including Hydro test, Air test, Material

certification)

11 Coupling (Dynamic balancing report, Compliance A A X

certificate of Manufacturer)

12 Manufacturers Test Certificate / Calibration A A X

certificate for Instruments

13 NDT Examination as per PR/PS/Design code

a. Pump components as Casing, Stuffing box, P A X

Impellers, Shaft, Wear rings etc.

b. API Plan P A X

c. Auxiliary piping, Plan piping P A X

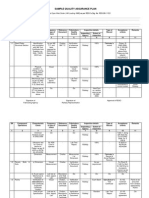

S. NO. DESCRIPTION OF ACTIVITY INSPECTION BY RECORD

Inspection And Test Plan

for

Centrifugal Pump

HPCL, Vishakhaptnam TOYO ENGINEERING INDIA LTD.

ISSUED : 10/10/2008 JOB NO. : 6261

DOC.NO. HGU PROJECT Page 1 of 3

EPCC / PMC /

TPIA

VENDOR OWNER

14 Hydrostatic Pressure Test

a. All Pressure Casing components P H X

b. Auxiliary piping P H X

c. Plan Piping P H X

d. Cooling jacket of bearing, Stuffing box P H X

e Pressure vessels. P H X

f Heat Exchangers P H X

g Filters P H X

h Other applicable items P H X

15 Dynamic balancing (including for Spares)

a. Individual Impellers P H X

b. Rotor assembly (as per PR/PS/Design code) P H X

16 Mechanical & Electrical run out of Shaft P R X

17 Lube Oil Console at sub vendor place

a. Pressure test W H X

b. Cleanliness check W H X

c. Mechanical running for 4 hours & Operation check W H X

d. Review of Material test certificates A A X

e. Review of Manufacturers Test certificates & A A X

Reports for Motor, Pump, Instruments etc.

f Contract Drivers, & Instruments W A X

g Check changeover valves W A X

h Check Auto- Start, Running and stop of stand-by W A X

pumps

i Check controls and all instrument functions W A X

18 API Plan Vessels, Coolers etc.

a. WPS / PQR A A X

b. NDT as per PR/PS/Design code A A X

c. Pressure test W H X

d. Visual & Dimensional check W H X

e. Review of Material test certificates A A X

19 Assembled Pump :

a. Performance Test as per PR/PS/Design code (with P H H** X

Mech run test) including Spare Rotar.

b. NPSH Test as per PR/PS/Design code P H H** X

c. Vibration measurement as per PR/PS/Design code P H X

d. Sound level measurement P H X

e. Mechanical running for 4 hours minimum (after P H H** X

stabilizing of Bearing temperature), with Bearing

housing resonance test

f. Bearing temperature rise as per PR/PS/Design code : P H X

Bearing and lube oil.

g. Strip test (Visual check & Wear ring clearance P H X

check)

20 Complete unit Test / String Test (can be done with P H H** X

Performance / Mech Run test). Note-9

With all Job accessories : Motor / HPRT, coupling,

seal, LO Console, Instruments, vibration/temp.

probes , if required as per PR/PS/Design code

Inspection And Test Plan

for

Centrifugal Pump

HPCL, Vishakhaptnam TOYO ENGINEERING INDIA LTD.

ISSUED : 10/10/2008 JOB NO. : 6261

DOC.NO. HGU PROJECT Page 1 of 3

21 Surface preparation & painting P A X

22 Final inspection of Complete Unit

a. Visual check for completeness & appearance P H

b. Dimensional check P H X

c. DFT check of final painting P H X

23 Review of final documents, minimum as marked in P H H** X

the column for RECORDS

24 Final stamping & issue of Inspection release H H X

certificate.

LEGEND 1) VENDOR, 2) TPAI THIRD PARTY INSPECTION AGENCY APPOINTED BY VENDOR ( LLOYDS, DNV & BVIS )

3) PMC - TOYO ENGINEERING INDIA LIMITED, 4) OWNER HPCL, VAISAKH 5) H HOLD (OFFER FOR WITNESS

& OBTAIN CLEARANCE), 6) W - WITNESS, 7) RN - RANDOM WITNESS, 8) A REVIEW & APPROVE,

9) R REVIEW ONLY, 10) P PERFORM, 11) X REQUIREMENT OF RECORD.

NOTE 1) THIS IS ONLY A INDICATIVE ITP AND VENDOR SHALL PREPARE A DETAILED ITP IN LINE WITH ABOVE AND

SPECIFIC TECHNICAL REQUIREMENTS OF APPLICABLE PR/PS/DESIGN CODE.

2) VENDOR SHALL ENSURE THAT ALL TEST AND MEASURING INSTRUMENTS ARE DULY CALIBRATED AND

CALIBRATION SHALL BE VALID AT THE TIME OF INSPECTION. CALIBRATION PROCEDURE & RECORDS SHALL BE

REVIEWED BY TPIA

3) SUB VENDOR FOR BOUGHT OUT ITEMS SHALL BE FROM PMC / OWNER APPROVED VENDOR LIST.

4) * INDICATES FOR CATEGORY A, B ONLY & ** FOR CATEGORY A ONLY

5) PMI TEST SHALL BE PERFOMED ON ALL AS/SS PRESSURE RETAINING PUMP COMPONETS, AUXILIARY PIPING,

API PLAN ETC. AT THE TIME OF PRESSURE TESTING. PMI TEST SHALL BE WITNESS BY TPIA

6) FOUNDATION TEMPLATE, GAGE PLATE FOR BASE RING & FOUNDATION BOLTS SHALL BE SUBJECT TO A FINAL

INSPECTION BY TPIA INCLUDING VISUAL, DIMENSIONAL CHECK AND REVIEW OF TEST CERTIFICATES.

7) PUMP DRIVERS SHALL BE INSPECTED AT MANUFACTURERS SHOP AS PER RELEVENT INSPECTION & TEST PLAN

8) NO SHIPMENT OF GOODS MAY BE EFFECTED UNLESS AN INSPECTION RELEASE CERTIFICATE HAS BEEN

SUBMITTED TO SELLER.

9) PERFORMANCE TEST FOR SPARE ROTOR TO BE DONE SEPARATELY

S-ar putea să vă placă și

- Inspection of Test Plan: Rotating EquipmentDocument7 paginiInspection of Test Plan: Rotating Equipmentzvlcar nainÎncă nu există evaluări

- Itp For Installation of Pressurization UnitDocument1 paginăItp For Installation of Pressurization UnitvictorÎncă nu există evaluări

- 035-Itp For Pumps PDFDocument30 pagini035-Itp For Pumps PDFKöksal Patan100% (3)

- Method Statement For Coal Feeder ErectionDocument20 paginiMethod Statement For Coal Feeder ErectiontreyÎncă nu există evaluări

- 02 MechanicalDocument44 pagini02 Mechanicalmusaismail8863Încă nu există evaluări

- R057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor PackageDocument10 paginiR057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor Packagedharwin100% (1)

- Installation of Over Head CraneDocument4 paginiInstallation of Over Head Cranemansih457100% (1)

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 paginiQuality Plan and Checklist (HVAC) - Sandvik G BlockParasÎncă nu există evaluări

- Inspection Test Plan Fuel Gas Conditioning SkidDocument19 paginiInspection Test Plan Fuel Gas Conditioning SkidDin AizuÎncă nu există evaluări

- Pump Centrifugal Pre Commissioning ITPDocument10 paginiPump Centrifugal Pre Commissioning ITPMohamad IbrahimÎncă nu există evaluări

- FQP 16.11.18 Vol-I - BoilerDocument90 paginiFQP 16.11.18 Vol-I - Boilerashis chatterjeeÎncă nu există evaluări

- 002-Method of Statement of Row PreparationDocument11 pagini002-Method of Statement of Row Preparationahmed08839494Încă nu există evaluări

- SOW Fabrikasi C-335-01 - 19.116.1Document1 paginăSOW Fabrikasi C-335-01 - 19.116.1AlfanÎncă nu există evaluări

- IRN For QC 64210-1 Ansao Venturi Pin (1-800)Document1 paginăIRN For QC 64210-1 Ansao Venturi Pin (1-800)Senthil KumarÎncă nu există evaluări

- Check List - Puff Test of FM 200 PipingDocument1 paginăCheck List - Puff Test of FM 200 PipingAneesh ConstantineÎncă nu există evaluări

- Expansion Joint Inspection and Test Plan Task Vendor TPI Inspection ClientDocument2 paginiExpansion Joint Inspection and Test Plan Task Vendor TPI Inspection ClientMussab Salih100% (1)

- (API 610-10th) Centrifugal Pump - SI UnitsDocument2 pagini(API 610-10th) Centrifugal Pump - SI UnitsParaschiv AlexandruÎncă nu există evaluări

- PP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0Document14 paginiPP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0ibrahimÎncă nu există evaluări

- MD1-0-T-030-05-00069 - ITP For Rotating Equipment InstallationDocument9 paginiMD1-0-T-030-05-00069 - ITP For Rotating Equipment InstallationTran Khuynh100% (1)

- Commissioning Procedures For ConveyorsDocument2 paginiCommissioning Procedures For ConveyorsNur KhamidÎncă nu există evaluări

- Steam BoilerDocument3 paginiSteam BoilerMohammad AzlanÎncă nu există evaluări

- KP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksDocument7 paginiKP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksUtku Can KılıçÎncă nu există evaluări

- WWW .Abs Fir E.it: Vertical Foam Bladder TankDocument4 paginiWWW .Abs Fir E.it: Vertical Foam Bladder TankJorge InostrozaÎncă nu există evaluări

- Form Comisionig&Performance Conveyor TestDocument2 paginiForm Comisionig&Performance Conveyor Testariyanagung29Încă nu există evaluări

- Inspection and Test PlanDocument58 paginiInspection and Test PlanTouil Houssem100% (1)

- Lifting & Installation Pipes Plan - Romp 05Document6 paginiLifting & Installation Pipes Plan - Romp 05syed khaja misbhuddinÎncă nu există evaluări

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Document9 paginiMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil OzanÎncă nu există evaluări

- Storage Tank Shell Banding Quality Control and Inspection Report FormDocument1 paginăStorage Tank Shell Banding Quality Control and Inspection Report FormAlif Rahmat FebriantoÎncă nu există evaluări

- 6 MM TCDocument1 pagină6 MM TCpranesh kadamÎncă nu există evaluări

- Hoist Monorail Pre Commissioning ITPDocument7 paginiHoist Monorail Pre Commissioning ITPmetroroadÎncă nu există evaluări

- 80MT Weigh Bridge SpecificationDocument4 pagini80MT Weigh Bridge SpecificationDhamodaran PandiyanÎncă nu există evaluări

- MD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationDocument30 paginiMD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationTran KhuynhÎncă nu există evaluări

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 paginiSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriÎncă nu există evaluări

- CR QapDocument2 paginiCR QapSimbu ArasanÎncă nu există evaluări

- MD1-0-T-030-05-00072 - ITP For AG Piping of Alloy SteelDocument8 paginiMD1-0-T-030-05-00072 - ITP For AG Piping of Alloy SteelTran KhuynhÎncă nu există evaluări

- ITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CDocument2 paginiITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CAmel Rayhan Aira100% (5)

- Itp Transfer Tower - Xls (Bvi Comment)Document52 paginiItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoÎncă nu există evaluări

- Inspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistDocument2 paginiInspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistAdades Safede EfdÎncă nu există evaluări

- ERECTION & INSTALLATION PROCEDURE ClarifierDocument23 paginiERECTION & INSTALLATION PROCEDURE ClarifierMohammad IqbalÎncă nu există evaluări

- 3p081-Itp ADocument17 pagini3p081-Itp AMariah PearsonÎncă nu există evaluări

- Technical SpecificationsDocument19 paginiTechnical SpecificationsMalik RiazÎncă nu există evaluări

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 paginiProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123Încă nu există evaluări

- Itp and Test Plan Rubber Fender Rev. 0Document5 paginiItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- List of Itp新 for HrsgDocument16 paginiList of Itp新 for HrsgzhangÎncă nu există evaluări

- 1-Check List CF PumpDocument2 pagini1-Check List CF PumpStarla HillÎncă nu există evaluări

- QC Dossier 1Document1 paginăQC Dossier 1VishnuGKÎncă nu există evaluări

- Hydro Test FormatDocument2 paginiHydro Test FormatMuralitclÎncă nu există evaluări

- Sakuti Method - Statement - For - HRSG - Works CrsherDocument32 paginiSakuti Method - Statement - For - HRSG - Works CrsherMIL RABÎncă nu există evaluări

- Itp Installation of FcuDocument4 paginiItp Installation of FcuAkmaldeen AhamedÎncă nu există evaluări

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 paginiSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinÎncă nu există evaluări

- Checklist For Fabrication & Erection of Structural Steel WorkDocument1 paginăChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuÎncă nu există evaluări

- Itp - 002 - Duct Installation - IfrDocument3 paginiItp - 002 - Duct Installation - IfrMari BelajarÎncă nu există evaluări

- SBG1-00-0K-1-CLD-0008-A ITP For Thermal Control Actuator Installation PDFDocument6 paginiSBG1-00-0K-1-CLD-0008-A ITP For Thermal Control Actuator Installation PDFsalamlinÎncă nu există evaluări

- Lifting - SAMPLE-Method of StatmentDocument1 paginăLifting - SAMPLE-Method of Statmentsudeesh kumarÎncă nu există evaluări

- Method Statement-HDPE-MWSPDocument16 paginiMethod Statement-HDPE-MWSPKumar AbhishekÎncă nu există evaluări

- CC ITP Sample PDFDocument4 paginiCC ITP Sample PDFMRezaÎncă nu există evaluări

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Document2 paginiSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Suraj ShettyÎncă nu există evaluări

- Inspection and Test Plan Itp No.: Itp/Sta/007Document3 paginiInspection and Test Plan Itp No.: Itp/Sta/007sumit kumarÎncă nu există evaluări

- Itp For ValvesDocument2 paginiItp For ValvesSuraj ShettyÎncă nu există evaluări

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocument2 paginiSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- Automatic Back-Flushing Filter Autofilt Rf10Document8 paginiAutomatic Back-Flushing Filter Autofilt Rf10Adades Safede EfdÎncă nu există evaluări

- Syscontrol Ahu 10hp SDocument12 paginiSyscontrol Ahu 10hp SAdades Safede EfdÎncă nu există evaluări

- Storage Tank Erection Procedure PDFDocument6 paginiStorage Tank Erection Procedure PDFEko Kurniawan89% (19)

- ITP For Centrifugal Pump4Document1 paginăITP For Centrifugal Pump4Adades Safede EfdÎncă nu există evaluări

- Inspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistDocument2 paginiInspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistAdades Safede EfdÎncă nu există evaluări

- Sysvrf 500 Air Evo HP RDocument3 paginiSysvrf 500 Air Evo HP RAdades Safede EfdÎncă nu există evaluări

- Sysvrf 252 Air Evo HP RDocument4 paginiSysvrf 252 Air Evo HP RAdades Safede EfdÎncă nu există evaluări

- Inspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistDocument2 paginiInspection and Test Plans (ITP) - MUM-05 Pump Installation ChecklistAdades Safede EfdÎncă nu există evaluări

- Marley Cooling TowerDocument16 paginiMarley Cooling TowerAdades Safede EfdÎncă nu există evaluări

- Sample QAP of Steel Bridge GirderDocument5 paginiSample QAP of Steel Bridge Girderuday64668Încă nu există evaluări

- Ice Class TankerDocument231 paginiIce Class Tankerapi-27176519100% (1)

- Base Part Numbers and Weights: Butterfly ValvesDocument2 paginiBase Part Numbers and Weights: Butterfly ValvesAdades Safede EfdÎncă nu există evaluări

- VAV DamperDocument7 paginiVAV DamperAdades Safede EfdÎncă nu există evaluări

- VAV DamperDocument7 paginiVAV DamperAdades Safede EfdÎncă nu există evaluări

- Mobile Buildings CatalogueDocument18 paginiMobile Buildings CatalogueAdades Safede EfdÎncă nu există evaluări

- Trencor Electric (25k)Document72 paginiTrencor Electric (25k)Adades Safede EfdÎncă nu există evaluări

- KilmakDocument2 paginiKilmakAdades Safede EfdÎncă nu există evaluări

- Ship Production PDFDocument33 paginiShip Production PDFAdades Safede EfdÎncă nu există evaluări

- GBS BrochureDocument12 paginiGBS BrochureAdades Safede EfdÎncă nu există evaluări

- Psu 50012-IvDocument1 paginăPsu 50012-IvAdades Safede EfdÎncă nu există evaluări

- The Virtual Shipyard: A Simulation Model of The Shipbuilding ProcessDocument12 paginiThe Virtual Shipyard: A Simulation Model of The Shipbuilding ProcessAdades Safede EfdÎncă nu există evaluări

- Pavc Series Variable Volume Piston Pump: Service Parts GuideDocument10 paginiPavc Series Variable Volume Piston Pump: Service Parts GuideRafael RodriguezÎncă nu există evaluări

- Dp&T-Sup Centrifugal Pumps Specification: 0 Original IssueDocument19 paginiDp&T-Sup Centrifugal Pumps Specification: 0 Original IssueAllyson LisboaÎncă nu există evaluări

- What Is Chlorinated Polyvinyl Chloride (CPVC) - CorzanDocument8 paginiWhat Is Chlorinated Polyvinyl Chloride (CPVC) - CorzanmrpalmistÎncă nu există evaluări

- Motion in One Dimension MCQs Sheet 2Document7 paginiMotion in One Dimension MCQs Sheet 2eka123100% (1)

- Specification Sheet 400Document3 paginiSpecification Sheet 400moh_ichwanuddinÎncă nu există evaluări

- Nzcs tr32Document145 paginiNzcs tr32Jianhua WuÎncă nu există evaluări

- Betopom Arastirma 2Document31 paginiBetopom Arastirma 2KvncGmz DzrÎncă nu există evaluări

- A-A B (5: 1) B: InventorwizardDocument1 paginăA-A B (5: 1) B: InventorwizardAjiSenoÎncă nu există evaluări

- Science 10 Las 4-1Document5 paginiScience 10 Las 4-1Michael TuyayÎncă nu există evaluări

- Incompressible Flow Solution Using SIMPLE AlgorithmDocument26 paginiIncompressible Flow Solution Using SIMPLE AlgorithmxavierÎncă nu există evaluări

- CV Piping EngineerDocument3 paginiCV Piping EngineerHamza BounezraÎncă nu există evaluări

- Vag - ComDocument26 paginiVag - ComwujkoÎncă nu există evaluări

- Robotic Configurations 10.08 PDFDocument15 paginiRobotic Configurations 10.08 PDFVenkateshAthava50% (2)

- E1002-11 Standard Practice For Leaks Using UltrasonicDocument4 paginiE1002-11 Standard Practice For Leaks Using UltrasonicudomÎncă nu există evaluări

- Briggs Small Engine Single - Cylinder - OHV - Repair PDFDocument179 paginiBriggs Small Engine Single - Cylinder - OHV - Repair PDFmartdot7349086% (7)

- GED Lecture (Energy)Document26 paginiGED Lecture (Energy)dogezukaÎncă nu există evaluări

- FEEG2003 Exam Paper 2020-21-PrintDocument12 paginiFEEG2003 Exam Paper 2020-21-Print3220355Încă nu există evaluări

- Inverse Kinematic Analysis and Simulation of The SCARA Robot Based On Recurrent Neural NetworksDocument4 paginiInverse Kinematic Analysis and Simulation of The SCARA Robot Based On Recurrent Neural NetworksHung Nguyen-CongÎncă nu există evaluări

- Turret LatheDocument82 paginiTurret LatheReyven ReconÎncă nu există evaluări

- CASE IH Farmall 115U EP Tractor Service Repair ManualDocument30 paginiCASE IH Farmall 115U EP Tractor Service Repair Manualejky93201573Încă nu există evaluări

- Demag Drives PDFDocument24 paginiDemag Drives PDFRafael Linarez100% (1)

- Sample Mechanical Basis of Design For UW - Chiller SystemsDocument4 paginiSample Mechanical Basis of Design For UW - Chiller SystemsdaveleyconsÎncă nu există evaluări

- NASA SP36 ExtractoDocument82 paginiNASA SP36 ExtractoDiego Guerrero VelozÎncă nu există evaluări

- Sph4u Kinematics Exam ReviewDocument2 paginiSph4u Kinematics Exam ReviewevanjohnstonespamÎncă nu există evaluări

- Review Problems From Diff BooksDocument9 paginiReview Problems From Diff BooksHannah AzucenaÎncă nu există evaluări

- PROSIS Part Information: 8/3/2011 1054905 20060 EC700B LC Volvo 10001-214/100 Valve MechanismDocument3 paginiPROSIS Part Information: 8/3/2011 1054905 20060 EC700B LC Volvo 10001-214/100 Valve MechanismPower MobileÎncă nu există evaluări

- IRC-58 2015 Excel SheetDocument3 paginiIRC-58 2015 Excel SheetBilal Ahmed Barbhuiya72% (18)

- Pso Blaze 4TDocument1 paginăPso Blaze 4TicrcgisÎncă nu există evaluări

- ETABS. - Fuerzas Internas en Vigas y ColumnasDocument1 paginăETABS. - Fuerzas Internas en Vigas y ColumnasFelipe GrandónÎncă nu există evaluări

- Subject Name:Electrical Machines-IDocument3 paginiSubject Name:Electrical Machines-IAkhil VemulaÎncă nu există evaluări