Documente Academic

Documente Profesional

Documente Cultură

Rocker Housing Installations

Încărcat de

Oumarba KamandaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Rocker Housing Installations

Încărcat de

Oumarba KamandaDrepturi de autor:

Formate disponibile

Lubricating Oil Pan - Installation Engine Assembly (00-02)

Page 0-98 N14

Lubricating Oil Pan - Installation

Install the oil pan gasket and the oil pan on the cylinder

block. Use your fingers to install and tighten one of the

7/16-inch oil pan mounting capscrews on each side of the

oil pan, halfway between the front and the rear of the oil

pan. Use your fingers to install and tighten all the mount-

ing capscrews.

Tighten the four 5/16-inch capscrews in the rear of the oil

pan in the sequence shown.

Torque Value: 27 Nm [20 ft-lb]

Tighten the thirty-two (32) 7/16-inch capscrews in the

sequence shown.

Torque Value: 68 Nm [50 ft-lb]

Fuel Crossovers - Installation

Use new o-rings, and install the two fuel crossover con-

nections and the two cover plates. Tighten the capscrews.

Torque Value: 4.0 Nm [35 in-lb]

Rocker Lever Housing - Installation

Install two o-rings (1) on each of the two water tubes (2).

Install one o-ring (1) on each of the two water plugs (3).

Apply a non-petroleum based lubricant such as soap or

vegetable oil to the o-rings on the tubes and the plugs and

to the bores in the rocker housing.

Engine Assembly (00-02) Rocker Lever Housing - Installation

N14 Page 0-99

Install the water tubes (A) in the front of the No. 2 and No.

3 rocker lever housings. Install the plugs (B) in the front

of the No. 1 rocker lever housing and in the rear of the No.

3 rocker lever housing.

Install new rocker lever housing gaskets on the cylinder

heads.

Install the rocker lever housings.

Tighten the rocker lever housing capscrews in the se-

quence shown (1 through 6).

Torque Value: 115 Nm [85 ft-lb]

Tighten the rocker lever housing capscrews in the se-

quence shown (7 and 8).

Torque Value: 47 Nm [35 ft-lb]

Injectors - Installation Engine Assembly (00-02)

Page 0-100 N14

Use service tool, Part No. 3823819, to slide the two water

tubes into the adjacent water manifold.

Install the two water tube retainer clamps.

Install and tighten the retainer clamp capscrews.

Torque Value: 45 Nm [33 ft-lb]

Injectors - Installation

CELECT Engines

NOTE: When installing injectors for reuse, new o-rings must

be installed on the injector.

NOTE: The CELECT injectors require three different in-

jector o-rings. The o-rings are color coded as follows:

Top o-ring - Black

Center o-ring - Brown

Bottom o-ring - Black with a white identification dot.

Lubricate the o-rings with lubricating oil just before

installation.

Caution: Do not strike the top stop spring cage when

installing CELECT injectors.

Using the CELECT injector puller/installer, Part No.

3823579, install the injector into the cylinder head injec-

tor bore with the injector solenoid valve facing the intake

side of the engine.

After partial installation of the injector, take precautions

to center the solenoid valve between the valve springs.

Avoid contact with the spring coils. If the injector is con-

tacting a valve spring, use a screwdriver to position the

injector again.

Warning: Do not strike or pry on the solenoid. Other-

wise, injector damage will occur.

Continue driving the injector into the bore using the puller/

installer, Part No. 3283579.

S-ar putea să vă placă și

- 202 10rev PDFDocument8 pagini202 10rev PDFJOHN WrightÎncă nu există evaluări

- BS 2303 - The Pressure Limiter Valve Has A Break BS 0163 - Short or Interrupted CAN WiringDocument1 paginăBS 2303 - The Pressure Limiter Valve Has A Break BS 0163 - Short or Interrupted CAN WiringOumarba KamandaÎncă nu există evaluări

- PB9147 Eje Motriz RT40 PDFDocument65 paginiPB9147 Eje Motriz RT40 PDFJohn Adonis Yataco AlmeydaÎncă nu există evaluări

- CFPB Students Sample-LetterDocument3 paginiCFPB Students Sample-LetterMihaela StavilaÎncă nu există evaluări

- PoladDocument1 paginăPoladOumarba KamandaÎncă nu există evaluări

- Volvo VNL Electrical PDFDocument100 paginiVolvo VNL Electrical PDFAnonymous XyQTC21f100% (3)

- What To Do If There Is A Problem With Your Meter?: Utility ProviderDocument3 paginiWhat To Do If There Is A Problem With Your Meter?: Utility ProviderOumarba KamandaÎncă nu există evaluări

- Macoto PDFDocument1 paginăMacoto PDFOumarba KamandaÎncă nu există evaluări

- Effects of Climate Change and Their Indelible Impact On Social Work Profession in ZimbabweDocument6 paginiEffects of Climate Change and Their Indelible Impact On Social Work Profession in ZimbabweOumarba KamandaÎncă nu există evaluări

- Cimc Vehicles Co.,Ltd: Cimc Fuel Tanker TrailerDocument3 paginiCimc Vehicles Co.,Ltd: Cimc Fuel Tanker TrailerOumarba KamandaÎncă nu există evaluări

- Food Security PDFDocument1 paginăFood Security PDFOumarba KamandaÎncă nu există evaluări

- Stamp Duties Act 2309updatedDocument15 paginiStamp Duties Act 2309updatedOumarba KamandaÎncă nu există evaluări

- 2018 World Cup WallchartDocument1 pagină2018 World Cup WallchartskylerboodieÎncă nu există evaluări

- Guide to Common Vehicle Message Identifiers (MIDs), Parameters (PIDs), and Failure Modes (FMIsDocument26 paginiGuide to Common Vehicle Message Identifiers (MIDs), Parameters (PIDs), and Failure Modes (FMIsOumarba Kamanda100% (7)

- Volvo Fmi, Sid PidDocument19 paginiVolvo Fmi, Sid PidOumarba Kamanda100% (2)

- CartrackDocument1 paginăCartrackOumarba KamandaÎncă nu există evaluări

- TodaytvseriesDocument1 paginăTodaytvseriesOumarba KamandaÎncă nu există evaluări

- Car TrackDocument1 paginăCar TrackOumarba KamandaÎncă nu există evaluări

- Zimbulk De-Fleet Auction 20th - 24th August 2018Document5 paginiZimbulk De-Fleet Auction 20th - 24th August 2018Oumarba KamandaÎncă nu există evaluări

- Axle Load Brochure 2016 UpdatedDocument2 paginiAxle Load Brochure 2016 UpdatedOumarba KamandaÎncă nu există evaluări

- Audi Air Filter - 2017 - 7 - 2 - 10 - 49 - 57Document1 paginăAudi Air Filter - 2017 - 7 - 2 - 10 - 49 - 57Oumarba KamandaÎncă nu există evaluări

- Julian 2010Document2 paginiJulian 2010bradmallikaÎncă nu există evaluări

- MAN TG A FFR Code ListDocument14 paginiMAN TG A FFR Code ListOumarba Kamanda100% (2)

- Designations 111Document5 paginiDesignations 111Oumarba KamandaÎncă nu există evaluări

- Caltex Lubricants Product Guide 2016 PDFDocument193 paginiCaltex Lubricants Product Guide 2016 PDFRafael Zurita0% (1)

- Intarder Operating ManualDocument12 paginiIntarder Operating ManualOumarba KamandaÎncă nu există evaluări

- ZF Astronic Error LevelsDocument1 paginăZF Astronic Error LevelsOumarba KamandaÎncă nu există evaluări

- Api Guide 2013Document4 paginiApi Guide 2013Ts-Radzif OmarÎncă nu există evaluări

- 04 AC200-1 Drive GearboxDocument28 pagini04 AC200-1 Drive GearboxAdal VeraÎncă nu există evaluări

- DGDOBDIILogDocument1 paginăDGDOBDIILogOumarba KamandaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- SAP MM - Defining Organizational Structure: Client (T880)Document3 paginiSAP MM - Defining Organizational Structure: Client (T880)RamaKrishna ErrojuÎncă nu există evaluări

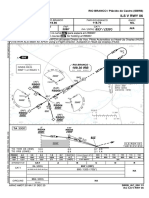

- SBRB Ils-V-Rwy-06 Iac 20201231Document1 paginăSBRB Ils-V-Rwy-06 Iac 20201231Matheus GuerraÎncă nu există evaluări

- Game Developers Survey 2021: PlayStation 5 Leads Interest While Remote Work ContinuesDocument29 paginiGame Developers Survey 2021: PlayStation 5 Leads Interest While Remote Work ContinuesspotÎncă nu există evaluări

- Secure Data in Cloud Using Offensive Decoy TechnologyDocument4 paginiSecure Data in Cloud Using Offensive Decoy Technologysonaiya software solutions100% (1)

- LG 21FG5AG TV (Manual de Servicio)Document23 paginiLG 21FG5AG TV (Manual de Servicio)WilfredoRodriguezÎncă nu există evaluări

- Caterpillar EMCP 4.1 Spec SheetDocument2 paginiCaterpillar EMCP 4.1 Spec Sheetnhocti007Încă nu există evaluări

- Wordfast Training PDFDocument12 paginiWordfast Training PDFs_scriÎncă nu există evaluări

- ISM Toyota With Work FlowDocument9 paginiISM Toyota With Work FlowAvnit kumarÎncă nu există evaluări

- Issues in E-Commerce: Competition, Loyalty, ReturnsDocument24 paginiIssues in E-Commerce: Competition, Loyalty, Returnsgerry dacerÎncă nu există evaluări

- File Backup Using PCINDocument3 paginiFile Backup Using PCINnestor gonzalez de leonÎncă nu există evaluări

- SolarPro 7.2Document80 paginiSolarPro 7.2Antonio GomesÎncă nu există evaluări

- Security Controls To Reduce Risks and Cyber InsuranceDocument13 paginiSecurity Controls To Reduce Risks and Cyber InsuranceMarcio CassianoÎncă nu există evaluări

- The Systems Development Life Cycle (SDLC)Document49 paginiThe Systems Development Life Cycle (SDLC)Sanam ChouhanÎncă nu există evaluări

- What Is APQPDocument2 paginiWhat Is APQPshanramaÎncă nu există evaluări

- Philippine Currency Security FeaturesDocument16 paginiPhilippine Currency Security FeaturesMid AcidÎncă nu există evaluări

- SSJ100 Product BrochureDocument17 paginiSSJ100 Product BrochureChandru SÎncă nu există evaluări

- DHLDocument55 paginiDHLwillacÎncă nu există evaluări

- Munotes inDocument59 paginiMunotes inshivam mishraÎncă nu există evaluări

- Fieldgate Data Access SoftwareDocument44 paginiFieldgate Data Access SoftwareDavid PiresÎncă nu există evaluări

- Generative AI-v4Document17 paginiGenerative AI-v4James Siva Kumar100% (1)

- Trunk Posbox ManualDocument19 paginiTrunk Posbox ManualJuzanda HasnomoÎncă nu există evaluări

- Pneumatic Tire Roller HP 240 Specs & FeaturesDocument2 paginiPneumatic Tire Roller HP 240 Specs & FeaturesHamdi JemmaliÎncă nu există evaluări

- Character Sets, Encodings, and UnicodeDocument26 paginiCharacter Sets, Encodings, and UnicodeSergioPascoalÎncă nu există evaluări

- L-3 Ocean Systems Helras Ds-100Document2 paginiL-3 Ocean Systems Helras Ds-100Shiva SinghÎncă nu există evaluări

- TL86 Devices SupportedDocument10 paginiTL86 Devices SupportedmarcosÎncă nu există evaluări

- Best Practices For Browser Settings and Performance On Fusion ApplicationsDocument3 paginiBest Practices For Browser Settings and Performance On Fusion ApplicationsVaraReddyÎncă nu există evaluări

- SW V&V TECHNIQUESDocument18 paginiSW V&V TECHNIQUESZaryaab AhmedÎncă nu există evaluări

- Manual Jfet and MosfetDocument8 paginiManual Jfet and MosfetSubhadip MaityÎncă nu există evaluări

- Lab 3Document10 paginiLab 3YasirÎncă nu există evaluări

- " Trade: " Electrician ": Draft Syllabus FORDocument6 pagini" Trade: " Electrician ": Draft Syllabus FORprasadum2321Încă nu există evaluări