Documente Academic

Documente Profesional

Documente Cultură

Drain Design Calculation

Încărcat de

aselabambarandageDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Drain Design Calculation

Încărcat de

aselabambarandageDrepturi de autor:

Formate disponibile

Reference Calculation Output

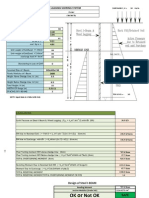

Design of Standard DitchType 1 ( 0.3m H 0.6m)

Design of Walls

Dimensions

Height of wall,Hw = 600 mm

Thickness of wall, Tw = 125 mm

Design Moments & Shear Forces

Maximum ULS Bending Moment, BMuls = 3.27 kNm

Maximum SLS Dead Load Bending Moment , BMsls_d = 0.64 kN

Maximum SLS Live Load Bending Moment , BMsls_l = 1.34 kNm

BS 5400-4 Maximum ULS Shear Force, SFuls = 6.39 kNm

1990 Concrete Characteristic strength fcu = 25 N/mm2

Table 5,6 Reinforcement Characteristic strength fy = 460 N/mm2

BS 5400-4 There is no axial load on walls, therefore it is treated as cantilever slab &

1990 designed accordance with Clause 5.4

Cl 5.6.1 Consider 1000mm length section, b = 1000 mm

Assume, Cover = 45 mm

Bar dia meter = 10 mm

Effective Depth, d = 125 -10 /2 - 45

= 75 mm

Reinforcement Design for Ditch wall

BS 5400-4

= 2

1990 0.15x 25 x 1000 x 75

Equ. 2 = 21.09 kNm > 3.270

Hence section is Singly Reinforcement

Mu ,Maximum flexural capacity of a singly reinforced section

BS 5400-4

1990

Equ. 1

Equ.5 z, Lever arm

5.057

= 0.5 1 + 1

2

6

z = 0.5x 75 1+ 1 -5.057 x 3.270 x10^

25 x 1000 x 75 2

z = 72.7 mm

0.95d = 0.95 x 75

= 71.3 < 72.7

Therefore z = 71.3 mm

DESIGN OFFICE Designed

Checked

Job Code Page

13.....

Reference Calculation Output

Required reinforcement area = 0.87

= 3.270 x 10^6

0.87 x 460 x 71.3

2

= 115 mm

BS 5400-4 Minimum reinforcement required = 0.15% bd

1990 = 0.15% x 1000 x 75

2

Cl 5.8.4.1 = 113 mm

BS 5400-4 Hence , = 115 mm

2

2

1990 Provide T 10 @ 150 , , = 524 mm T 10 @

Cl 5.8.9 To prevent shinkage & temperature cracking 150mm spacing is provided 150 mm

BS 5400-4 Secondary Reinforcement

1990 Minimum secondary reinforcement requirement,

Cl 5.8.4.2 = 0.12% bd

= 0.12% x 1000 x 75

2

BS 5400-4 = 90 mm

2

1990 Provide T 10 @ 150 , , = 524 mm T 10 @

Cl 5.8.9 To prevent shinkage & temperature cracking 150mm spacing is provided 150 mm

BS 5400-4 Check for Shear

1990 Maximum Shear Force = 6.390 kN

Cl 5.4.4 Maximum Shear Stress = F/A Max shear

= 6.390 x 10^3 stress

1000 x 75 = 0.085

2 2

= 0.085 N/mm < 4.75 N/mm N/mm2

< 0.75

2

Hence OK 18.75 N/mm

BS 5400-4 Depth factor, s = = (500/d)^(1/4)

1990 = 500 ^(1/4)

Table 9 75

= 1.61

0.27 100 1/3 1/3

=

BS 5400-4 Ultimate shear stress in concrete

1/3 1/3

1990 = 0.27 100 x 524 25

Table 8 1.25 1000 x 75.0

2

= 0.560 N/mm Alow shear

stress

Allowable Shear Stress = x s = 0.902

= 0.560 x 1.61 N/mm2

2

= 0.902 > 0.085 N/mm

Hence OK

DESIGN OFFICE Designed

Checked

Job Code Page

14.....

Reference Calculation Output

BS 5400-4 Creack Width Calculation

1990

Cl 5.8.8.2 Design Crack width

Equation 24

Where,

a cr = Dis tan ce from the crack to the nearest bar

= Calculated strain at level where cracking is being considered

C nom= required nominal cover

h = Overall depth of the section

= Depth of the concrete in compression

BS 5400-4

1990

Equation 25

Where,

Mq = 1.340 kNm

Mg = 0.640 kNm

Cover for the reinforcemen = 45 mm

Bar Spacing = 150 mm

Bar diameter = 10 mm

2 2 1/2

a cr = 150 + 45 + 10/2 - 10 /2

2

= 85.1 mm

= 200 / ( 26 /2 )

= 15.38

DESIGN OFFICE Designed

Checked

Job Code Page

15.....

Reference Calculation Output

2 + 2

=

x =- 15.38 x 524 +

0.5

15.38 x 524 2 + 2x 1000x 15.38 x 524 x 75

15.38 x 524

1000 15.38 x 524

x = 27.63 mm 15.38 x 524

z = d-x/3

= 75 - 27.63 /3

= 65.79 mm

Srevice Moment = Mq + Mg

= 1.340 + 0.640

= 1.980 kNm

Servivce Stress, =

Service

= 1.980 x 10^6 stress,

65.79 x 524 = 57.48

2 2

= 57.48 N/mm N/mm

Steel Stain = 57.48

200 x 103

= 0.00028739

( 125 - 27.63 ) x 57.48

( 1000 - 27.63 ) 200 x 103

= 2.8779E-05

= 2.8779E-05 -

3.8 x 1000 x 125 x( 125 - 27.63 ) x

0.000287388 x 524 x( 125 - 28 )

1- 1.340 x 103

3

0.640 x 10

BS 5400-4

1990 = 2.8779E-05 - -0.0034526

Equation 25 = 0.0035 >

= 2.8779E-05

DESIGN OFFICE Designed

Checked

Job Code Page

16.....

Reference Calculation Output

BS 5400-4 Design Crack width

1990 =

Cl 5.8.8.2

Table 1

= 3x 85.1 x 2.87791E-05

1 +2( 85.1 - 45 )/( 125 - 27.63 )

= 0.004 mm > 0.25 mm

Hence, Crack width is OK

BS 5400-4 Stress Limitations

1990 For concrete

Cl 4.1.2 Compress stress ditribution due to Bending for the SLS

= Mser /Z

Section Modulus of section, Z = 1/6 x bd2

2

= 1/6 x 1000 x 75

3

= 937,500.00 mm

Service Stress of concrete = Mser /Z

6

= 1.980 x 10

937,500.00

2

= 2.11 N/mm

BS 5400-4 Service Stress limit of concrete = 0.50

1990 = 0.50 x 25

2 2

Table 2 = 12.50 N/mm > 2.11 N/mm

Hence OK

BS 5400-4 Compress stress ditribution due to axial load for the SLS

1990 Axial Load on member = 0 kN

Table 2 Therefore uniform compressive distribution, 0 < 0.38

Hence OK

For Reinforcements

Tensile stress ditribution for the SLS

2

Sevice tensile stress of concrete = 57.48 N/mm

BS 5400-4 Service Stress limit of reinforcment = 0.75

1990 = 0.75 x 460

2 2

Table 2 = 345 N/mm > 57.48 N/mm

Hence OK

DESIGN OFFICE Designed

Checked

Job Code Page

17.....

Reference Calculation Output

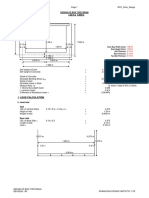

Design of Base

Dimensions

Width of Base, BB = 600 mm

Thickness of Base, TB = 125 mm

Design Moments & Shear Forces

Maximum Sagging ULS Bending Moment, BMuls = 3.29 kNm

Maximum Hogging ULS Bending Moment, BMuls = 1.23 kNm

Maximum SLS Dead Load Bending Moment , BMsls_d = 0.67 kN

Maximum SLS Live Load Bending Moment , BMsls_l = 1.33 kNm

Maximum ULS Shear Force, SFuls = 8.91 kNm

2

Maximum Bearin Pressure at SLS = 9.98 kN/m

BS 5400-4 Concrete Characteristic strength fcu = 25 N/mm2

1990 Reinforcement Characteristic strength fy = 460 N/mm2

Table 5,6

For Hogging Moment

Consider 1000mm length section, b = 1000 mm

Assume, Cover = 45 mm

Bar dia meter = 10 mm

Effective Depth, d = 125 -10 /2 - 45

= 75 mm

2

Section Modulus of section, Z = 1/6 x bd

2

= 1/6 x 1000 x 75

3

= 937,500.00 mm

Flexural Tensile Stress = M/z

6

BS 5400-4 = 1.23 x10 / 937,500.00

1990 = 1.312 N/mm2

Table32 Permissible Flexural Tensile Stress = 3.6 > 1.31 Hence OK

Hence flexural tensile stress is within the permissible limit

For Sagging Moment

Reinforcement Design for Ditch wall

BS 5400-4

= 2

1990 0.15x 25 x 1000 x 75

Equ. 2 = 21.09 kNm > 3.29

Hence section is Singly Reinforcement

Mu ,Maximum flexural capacity of a singly reinforced section

BS 5400-4

1990

Equ. 1

Equ.5 z, Lever arm

5.057

= 0.5 1 + 1

2

DESIGN OFFICE Designed

Checked

Job Code Page

18.....

Reference Calculation Output

6

z = 0.5x 75 1+ 1 -5.057 x 3.290 x10^

25 x 1000 x 75 2

z = 72.7 mm

0.95d = 0.95 x 75

= 71.3 < 72.7

Therefore z = 71.3 mm

Required reinforcement area = 0.87

= 3.290 x 10^6

0.87 x 460 x 71.3

2

= 115 mm

BS 5400-4 Minimum reinforcement required = 0.15% bd

1990 = 0.15% x 1000 x 75

2

Cl 5.8.4.1 = 113 mm

BS 5400-4 Hence , = 115 mm2

150 , , =

2

1990 Provide T 10 @ 524 mm T 10 @

Cl 5.8.9 To prevent shinkage & temperature cracking 150mm spacing is provided 150 mm

BS 5400-4 Secondary Reinforcement

1990 Minimum secondary reinforcement requirement,

Cl 5.8.4.2 = 0.12% bd

= 0.12% x 1000 x 75

2

BS 5400-4 = 90 mm

150 , , =

2

1990 Provide T 10 @ 524 mm T 10 @

Cl 5.8.9 To prevent shinkage & temperature cracking 150mm spacing is provided 150 mm

BS 5400-4 Check for Shear

1990 Maximum Shear Force = 8.910 kN

Cl 5.4.4 Maximum Shear Stress = F/A Max shear

= 8.910 x 10^3 stress

1000 x 75 = 0.119

2 2

= 0.119 N/mm < 4.75 N/mm N/mm2

< 0.75

2

Hence OK 18.75 N/mm

BS 5400-4 Depth factor, s = = (500/d)^(1/4)

1990 = 500 ^(1/4)

Table 9 75

= 1.61

0.27 100 1/3 1/3

=

BS 5400-4 Ultimate shear stress in concrete

1/3 1/3

1990 = 0.27 100 x 524 25

Table 8 1.25 1000 x 75.0

2

= 0.560 N/mm

DESIGN OFFICE Designed

Checked

Job Code Page

19.....

Reference Calculation Output

Allowable Shear Stress = x s Alow shear

= 0.560 x 1.61 stress

2

= 0.902 > 0.119 N/mm = 0.902

Hence OK N/mm2

BS 5400-4 Creack Width Calculation

1990

Cl 5.8.8.2 Design Crack width

Equation 24

Where,

a cr = Dis tan ce from the crack to the nearest bar

= Calculated strain at level where cracking is being considered

C nom= required nominal cover

h = Overall depth of the section

= Depth of the concrete in compression

BS 5400-4

1990

Equation 25

Where,

Mq = 1.330 kNm

Mg = 0.670 kNm

Cover for the reinforcemen = 45 mm

Bar Spacing = 150 mm

Bar diameter = 10 mm

2 2 1/2

a cr = 150 + 45 + 10/2 - 10 /2

2

= 85.1 mm

DESIGN OFFICE Designed

Checked

Job Code Page

20.....

Reference Calculation Output

= 200 / ( 26 /2 )

= 15.38

2 + 2

=

x =- 15.38 x 524 +

15.38 x 524 2 + 2x 1000x 15.38 x 524 x 75 0.5

15.38 x 5241000 15.38 x 524

x = mm x 524

27.63 15.38 15.38 x 524

z = d-x/3

= 75 - 27.63 /3

= 65.79 mm

Srevice Moment = Mq + Mg

= 1.330 + 0.670

= 2.000 kNm

Servivce Stress, =

Service

= 2.000 x 10^6 stress,

65.79 x 524 = 58.06

2

= 58.06 N/mm N/mm2

Steel Stain = 58.06

200 x 103

= 0.00029029

( 125 - 27.63 ) x 58.06

3

( 1000 - 27.63 ) 200 x 10

= 2.907E-05

= 2.907E-05 -

3.8 x 1000 x 125 x( 125 - 27.63 ) x

0.000290291 x 524 x( 125 - 28 )

1- 1.330 x 103

0.670 x 103

DESIGN OFFICE Designed

Checked

Job Code Page

21.....

Reference Calculation Output

BS 5400-4

1990 = 2.907E-05 - -0.0030784

Equation 25 = 0.0031 >

= 2.907E-05

BS 5400-4 Design Crack width

1990 =

Cl 5.8.8.2

Table 1

= 3x 85.1 x 2.90698E-05

1 +2( 85.1 - 45 )/( 125 - 27.63 )

= 0.004 mm > 0.25 mm

Hence, Crack width is OK

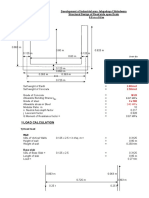

Bearing Pressure

2

Bearing Pressure under the base = 10.0 kN/m

2

Asummed bearin pressure = 100 kN/m > 10.0 kN/m2

Hence, Bearing pressure is OK

BS 5400-4 Stress Limitations

1990 For concrete

Cl 4.1.2 Compress stress ditribution due to Bending for the SLS

= Mser /Z

Section Modulus of section, Z = 1/6 x bd2

2

= 1/6 x 1000 x 75

3

= 937,500.00 mm

Service Stress of concrete = Mser /Z

6

= 2.000 x 10

937,500.00

2

= 2.13 N/mm

BS 5400-4 Service Stress limit of concrete = 0.50

1990 = 0.50 x 25

2 2

Table 2 = 12.50 N/mm > 2.13 N/mm

Hence OK

BS 5400-4 Compress stress ditribution due to axial load for the SLS

1990 Axial Load on member = 0 kN

Table 2 Therefore uniform compressive distribution, 0 < 0.38

Hence OK

For Reinforcements

Tensile stress ditribution for the SLS

2

Sevice tensile stress of concrete = 58.06 N/mm

BS 5400-4 Service Stress limit of reinforcment = 0.75

1990 = 0.75 x 460

2 2

Table 2 = 345 N/mm > 58.06 N/mm

Hence OK

DESIGN OFFICE Designed

Checked

Job Code Page

50

75 22.....

S-ar putea să vă placă și

- Calculation Report For Box Culvert RebarDocument3 paginiCalculation Report For Box Culvert Rebarariefrizki100% (1)

- 5.1 Design of Sanitary Wastewater Manholes - 1456Document4 pagini5.1 Design of Sanitary Wastewater Manholes - 1456sitehab100% (2)

- Water Retaining Structures To Bs 8007 and Bs 8110: Calculations OutputDocument93 paginiWater Retaining Structures To Bs 8007 and Bs 8110: Calculations Outputazwan100% (2)

- Drain DesignDocument106 paginiDrain DesignBilal Ahmed Barbhuiya100% (2)

- Design of SumpDocument7 paginiDesign of SumpRASSAL KARIMÎncă nu există evaluări

- Water Tank Load CalculationDocument2 paginiWater Tank Load CalculationPre Sheet100% (2)

- Cable Trench Desiign Report 26.04.2020 PDFDocument50 paginiCable Trench Desiign Report 26.04.2020 PDFkkgcÎncă nu există evaluări

- Reverse L Shaped Cantilever RETAINING WALLDocument6 paginiReverse L Shaped Cantilever RETAINING WALLHusen Ghori100% (2)

- L Shaped Retaining Wall With Out Toe SlabDocument7 paginiL Shaped Retaining Wall With Out Toe Slabmohammed sami100% (1)

- Footing Design According To BS8110 CodeDocument4 paginiFooting Design According To BS8110 CodePre SheetÎncă nu există evaluări

- Examples Design Reinforced Concrete Buildings Bs8110 PDFDocument2 paginiExamples Design Reinforced Concrete Buildings Bs8110 PDFDanielle59% (17)

- Footing Design According To BS8110 CodeDocument4 paginiFooting Design According To BS8110 CodeMohit VatsÎncă nu există evaluări

- Basement Wall Design PDFDocument7 paginiBasement Wall Design PDFBilly Joe Breakfast100% (1)

- Circular Water TankDocument7 paginiCircular Water Tanksimon maaaklaÎncă nu există evaluări

- Retaining WallDocument11 paginiRetaining Wallardi rahadianÎncă nu există evaluări

- Design of Underground Water TankDocument6 paginiDesign of Underground Water TankAlfred PatrickÎncă nu există evaluări

- Design of Reinforced Concrete ManholeDocument2 paginiDesign of Reinforced Concrete Manholenephembani100% (2)

- Design of Sanitary Wastewater ManholesDocument4 paginiDesign of Sanitary Wastewater ManholessajeeralaÎncă nu există evaluări

- Top Circular Slab DesignDocument3 paginiTop Circular Slab Designanshutomar791580% (5)

- 1lateral Earth PressureDocument21 pagini1lateral Earth PressureHanafiahHamzahÎncă nu există evaluări

- Retaining Wall DesignDocument5 paginiRetaining Wall DesignGsUpretiÎncă nu există evaluări

- Ribbed Slab 1Document20 paginiRibbed Slab 1ephrem100% (2)

- Soil Nailing BOQDocument3 paginiSoil Nailing BOQKrushna Rama0% (1)

- Shoring SystemDocument3 paginiShoring SystemJason RoyÎncă nu există evaluări

- Cantilever Retaining Wall ExampleDocument8 paginiCantilever Retaining Wall ExampleRahul Sinha100% (1)

- Calculation For SurchargeDocument1 paginăCalculation For Surchargemayankjain333Încă nu există evaluări

- Analysis and Design of Pump HouseDocument9 paginiAnalysis and Design of Pump HouseKandousi YassineÎncă nu există evaluări

- Basement Wall CalculationDocument3 paginiBasement Wall CalculationSaurav Silwal100% (1)

- Final Design of DrainDocument17 paginiFinal Design of Drainayan khan0% (1)

- Cantilever Retaining Wall Design (3m)Document6 paginiCantilever Retaining Wall Design (3m)Dhukwan CivilÎncă nu există evaluări

- Cantilever Retaining Wall Example - PDF EurocodeDocument14 paginiCantilever Retaining Wall Example - PDF Eurocodepatrick chegeÎncă nu există evaluări

- Pad Footing BS8110Document1 paginăPad Footing BS8110Mer Din75% (4)

- Retaining Wall Design To ProkonDocument6 paginiRetaining Wall Design To ProkonIMJ JÎncă nu există evaluări

- Bridge Dead Load Calculation in Excel SheetDocument1 paginăBridge Dead Load Calculation in Excel SheetMagdy Bakry100% (1)

- 3.2-Bearing Capacity of SoilsDocument23 pagini3.2-Bearing Capacity of SoilsSamson Yonas100% (1)

- Underground Circular Tank R2 Sump WellDocument14 paginiUnderground Circular Tank R2 Sump Wellsurendra_panga100% (1)

- RCC Drain DesignDocument11 paginiRCC Drain DesignShashank Yadav100% (3)

- Geotechnical Soil Investigation Report o PDFDocument6 paginiGeotechnical Soil Investigation Report o PDFPutra RyanÎncă nu există evaluări

- Random Rubble MasonryDocument3 paginiRandom Rubble MasonryMalith De Silva100% (2)

- Excel Template For Strap Footing Using ES en CodeDocument9 paginiExcel Template For Strap Footing Using ES en CodeJim JamÎncă nu există evaluări

- Boq Retaining Wall 19052017Document17 paginiBoq Retaining Wall 19052017Andrie PrabowoÎncă nu există evaluări

- Abusag Bridge Project: Structural Calculation For The Proposed Sheet PileDocument20 paginiAbusag Bridge Project: Structural Calculation For The Proposed Sheet PileRolly Marc G. SoteloÎncă nu există evaluări

- Eurocode Side BarsDocument6 paginiEurocode Side BarsraymondÎncă nu există evaluări

- Lift Wall DesignDocument4 paginiLift Wall DesignBajracharya A-sub25% (4)

- Design of Rectangular Water TankDocument169 paginiDesign of Rectangular Water TankNikhil100% (2)

- Box Culvert Design CalculationDocument15 paginiBox Culvert Design CalculationYoshua Yang62% (21)

- CSE 313 Lecture 4 - ExamplesDocument22 paginiCSE 313 Lecture 4 - ExamplesKelvho Gitonga75% (4)

- Truss DesignDocument10 paginiTruss DesignAboalmaail AlaminÎncă nu există evaluări

- Circular OH Water TankDocument24 paginiCircular OH Water TankV.m. RajanÎncă nu există evaluări

- Counterfort Retaining WallDocument25 paginiCounterfort Retaining WallAmit Patel100% (1)

- British Standard Bs 8110Document10 paginiBritish Standard Bs 8110م.عمرو عبداللهÎncă nu există evaluări

- Slab DesignDocument87 paginiSlab Designshamen amarasekaraÎncă nu există evaluări

- Unit 5 Plate Girder&GantryGirder NotesDocument18 paginiUnit 5 Plate Girder&GantryGirder NotesGautham SgÎncă nu există evaluări

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2800: Design Calculation For Pilecap 4Rc250Document2 paginiT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2800: Design Calculation For Pilecap 4Rc250Tj TanÎncă nu există evaluări

- Ribbed Slabs: Design ConsiderationsDocument6 paginiRibbed Slabs: Design ConsiderationsAwadÎncă nu există evaluări

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 1500: Design Calculation For Pilecap 2Rc250Document2 paginiT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 1500: Design Calculation For Pilecap 2Rc250Tj TanÎncă nu există evaluări

- Base Plate +and Foundation Bolt Design +connection Design 30-08-2021Document9 paginiBase Plate +and Foundation Bolt Design +connection Design 30-08-2021Deepanshu GargÎncă nu există evaluări

- Base Plate INDIA CODEDocument4 paginiBase Plate INDIA CODEbama sankari100% (1)

- From Staadpro Output: Eff EffDocument3 paginiFrom Staadpro Output: Eff EffASHISAÎncă nu există evaluări

- Design of Corbel: (Check)Document14 paginiDesign of Corbel: (Check)Ashish GÎncă nu există evaluări

- Design of Toe Wall PDFDocument15 paginiDesign of Toe Wall PDFaselabambarandageÎncă nu există evaluări

- SLS 452 Specification For Concrete Non Pressure Pipes PDFDocument36 paginiSLS 452 Specification For Concrete Non Pressure Pipes PDFkanishka75% (4)

- Design of Toe Wall PDFDocument15 paginiDesign of Toe Wall PDFaselabambarandageÎncă nu există evaluări

- Anchor Bolt Calculation For Sign PostDocument5 paginiAnchor Bolt Calculation For Sign PostaselabambarandageÎncă nu există evaluări

- Dowel Calculation For Ramp DDocument2 paginiDowel Calculation For Ramp DaselabambarandageÎncă nu există evaluări

- Damma Chakka Suthraya1Document5 paginiDamma Chakka Suthraya1aselabambarandageÎncă nu există evaluări

- Expansion Joint Design Ramp DDocument7 paginiExpansion Joint Design Ramp DaselabambarandageÎncă nu există evaluări

- Good PaperDocument89 paginiGood PapermÎncă nu există evaluări

- ReWaRD 2.5 Reference ManualDocument110 paginiReWaRD 2.5 Reference ManualaselabambarandageÎncă nu există evaluări

- Design of Cantileaver Toe Wall (H 3.0m)Document13 paginiDesign of Cantileaver Toe Wall (H 3.0m)aselabambarandageÎncă nu există evaluări

- Good PaperDocument89 paginiGood PapermÎncă nu există evaluări

- Bearing Pad Dsign BS 5400Document5 paginiBearing Pad Dsign BS 5400aselabambarandageÎncă nu există evaluări

- CH 27 - CulvertsDocument38 paginiCH 27 - CulvertsAsankaRathnayakaÎncă nu există evaluări

- Good PaperDocument89 paginiGood PapermÎncă nu există evaluări

- Design Water TankDocument20 paginiDesign Water Tankaselabambarandage95% (21)

- Hydraulic Design On SlopesDocument16 paginiHydraulic Design On SlopesEm MarÎncă nu există evaluări

- Design Report 10.6x7 Skew Under Pass 8+815 (01.07.2017)Document2 paginiDesign Report 10.6x7 Skew Under Pass 8+815 (01.07.2017)aselabambarandageÎncă nu există evaluări

- Lateral Earth Pressure Coefficients Kerisel and Absi 1970 PDFDocument3 paginiLateral Earth Pressure Coefficients Kerisel and Absi 1970 PDFjaidy28Încă nu există evaluări

- Field FormulasDocument39 paginiField FormulasRoma EstradaÎncă nu există evaluări

- Graded Examples in Reinforced Concrete Design DiasDocument118 paginiGraded Examples in Reinforced Concrete Design DiasAmgad Talal92% (13)

- Crack Width Calculation - Iit MadrasDocument7 paginiCrack Width Calculation - Iit MadrasJeet DesaiÎncă nu există evaluări

- Total Stress and Effective StressDocument11 paginiTotal Stress and Effective StressDr-Moamen Abd El RaoufÎncă nu există evaluări

- GEOTECNICAL Depth Set 2 SampleDocument7 paginiGEOTECNICAL Depth Set 2 SamplePreetikumari LakraÎncă nu există evaluări

- Comparison of The Linear and Nonlinear Dynamic Rroperties of Gravels, Sands, Silts and Clays (Stokoe Et Al., 2004)Document4 paginiComparison of The Linear and Nonlinear Dynamic Rroperties of Gravels, Sands, Silts and Clays (Stokoe Et Al., 2004)Paul Febre MuyonÎncă nu există evaluări

- Kishida Et Al. (2009a)Document10 paginiKishida Et Al. (2009a)giuseppe.colamarinoÎncă nu există evaluări

- 07a40102 Strength of Materials-IIDocument8 pagini07a40102 Strength of Materials-IISRINIVASA RAO GANTA0% (1)

- Anatomia D Eela ManoDocument61 paginiAnatomia D Eela ManoJason A. Hernández LópezÎncă nu există evaluări

- Footing DetailDocument1 paginăFooting DetailRatnesh PatelÎncă nu există evaluări

- AISC 13.0 Properties Viewer1Document140 paginiAISC 13.0 Properties Viewer1Frank HuancoyoÎncă nu există evaluări

- Strength Of Materials Review: α with the longitudinalDocument5 paginiStrength Of Materials Review: α with the longitudinalGee - FÎncă nu există evaluări

- Pernos Hansville PDFDocument8 paginiPernos Hansville PDFÁlvaro SerranoÎncă nu există evaluări

- Thermal Stresses (Statically Indeterminate Bodies)Document38 paginiThermal Stresses (Statically Indeterminate Bodies)Al Dominic GatlabayanÎncă nu există evaluări

- Behaviour of FRP Reinforced Concrete Beam-Column Joints Under Cyclic Loading PDFDocument8 paginiBehaviour of FRP Reinforced Concrete Beam-Column Joints Under Cyclic Loading PDFAhmed NafieÎncă nu există evaluări

- Ductile Detailing Useful ReferencesDocument6 paginiDuctile Detailing Useful ReferencesMandar NadgaundiÎncă nu există evaluări

- Pressuremeter Testing An IntroductionDocument17 paginiPressuremeter Testing An IntroductionVeenoyÎncă nu există evaluări

- 35 KL DesignDocument10 pagini35 KL DesigneduardoambientalÎncă nu există evaluări

- 1.5 Practice Questions & Answers - 1 PDFDocument5 pagini1.5 Practice Questions & Answers - 1 PDFMega GamesÎncă nu există evaluări

- Enio DenekoDocument10 paginiEnio DenekoEcaterina DraghiciÎncă nu există evaluări

- Hge - Geotech 3Document19 paginiHge - Geotech 3Pat SisonÎncă nu există evaluări

- Gier, Estiven M. Ultimate Strength Stage (Write-Ups)Document3 paginiGier, Estiven M. Ultimate Strength Stage (Write-Ups)Estiven Gier100% (1)

- Irregular Shape BuildingDocument38 paginiIrregular Shape Buildingbabu1434Încă nu există evaluări

- Exercise 05: Structural Analysis of TrussDocument7 paginiExercise 05: Structural Analysis of TrussSohamÎncă nu există evaluări

- Application of Hyperstatic Reaction Method For Designing of Tunnel Permanent Lining, Part I: 2D Numerical ModellingDocument11 paginiApplication of Hyperstatic Reaction Method For Designing of Tunnel Permanent Lining, Part I: 2D Numerical ModellingIngrid Irreño PalomoÎncă nu există evaluări

- SteelwiseDocument3 paginiSteelwiseAnonymous 7MdZQn1Încă nu există evaluări

- PIANC Seismic StructuresDocument471 paginiPIANC Seismic StructuresVicky Loreto100% (2)

- Slides of SFRCDocument5 paginiSlides of SFRCjhony06Încă nu există evaluări

- Annales de Chimie: Science Des Materiaux: Received: 13 January 2019 Accepted: 2 April 2019Document4 paginiAnnales de Chimie: Science Des Materiaux: Received: 13 January 2019 Accepted: 2 April 2019purnashisÎncă nu există evaluări

- Address: Southern Pan Ofllaidong Industjy ParkDocument1 paginăAddress: Southern Pan Ofllaidong Industjy ParkRiaan PretoriusÎncă nu există evaluări

- Answer Key Structural Quiz 4Document5 paginiAnswer Key Structural Quiz 4Anonymous L4VPBZÎncă nu există evaluări

- (ABU) Reinforced Concrete I - L-3 Plastic Design PDFDocument83 pagini(ABU) Reinforced Concrete I - L-3 Plastic Design PDFEmre ÖzkatÎncă nu există evaluări