Documente Academic

Documente Profesional

Documente Cultură

Survey On Intermodal Transfer Technologies - Za Infrastructure Transport Equipment and Trtansfer Means PDF

Încărcat de

Miloš MilenkovićTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Survey On Intermodal Transfer Technologies - Za Infrastructure Transport Equipment and Trtansfer Means PDF

Încărcat de

Miloš MilenkovićDrepturi de autor:

Formate disponibile

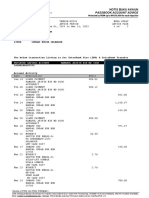

DELIVERABLE D1

State of the Art of conventional and innovative techniques

in intermodal transport

Annex 1: Survey on intermodal transfer technologies

Public

CONTRACT N: 2000-AM.10005

ACRONYM : ITIP

Innovative Technologies for

Inter-modal Transfer Points

TITLE : Innovative Technologies for Intermodal transfer Points

MAIN AUTHOR: Edoardo Peterlini (Euretitalia s.r.l.)

PROJECT CO-ORDINATOR: PTV Planung Transport Verkehr AG (DE)

PROJECT PARTNERS : EURA A/S (DK)

Euretitalia s.r.l. (IT)

Heusch/Boesefeldt GmbH (DE)

NTUA (GR)

Technicatome SA (FR)

VTT (FI)

PROJECT START DATE : April 2000 DURATION : 48 months

DATE OF ISSUE OF THIS REPORT : June 2001

Project funded by the European

Community under the Competitive

and Sustainable Growth Programme

(1998-2002)

Innovative Technologies for

Inter-modal Transfer Points

TECHNICAL AND ORGANISATIONAL DESCRIPTION OF ELEMENTS

LIST OF CONTENTS

For the technical and organisational description of possible new and improbable existing

systems an inquiry form and additional items or parameters have been used. The following

elements have been described in the framework of this study:

1 TRANSHIPMENT EQUIPMENT AS ELEMENT OF THE MEANS OF

TRANSPORT ITSELF 6

1.1 ACTS ABROLL CONTAINER TRANSPORT SYSTEM 7

1.1.1 The ACTS technique 7

1.1.2 Description of the System 7

1.1.3 Transport Cycle 8

1.1.4 Diffusion of the System 11

1.1.5 General Evaluation 11

1.1.6 Compatibility 12

1.1.7 Conclusion 13

1.2 Bimodal Techniques 14

1.2.1 Introduction 14

1.2.2 System 14

1.2.3 The Loading Unit 16

1.2.4 Present situation in Europe 16

1.2.5 General Evaluation of the Bimodal System 17

1.2.6 Conclusion 18

1.3 Mercedes Benz (MB-) Kombi Lifter 19

1.4 Semi-trailer equipped with side loader 21

1.5 ULS 23

1.6 SeIf - Unloading Ship(s) 26

1.6.1 Ships with Revolving (or Swinging) Cranes 26

1.6.2 Ship Equipped with Gantry Cranes 26

1.6.3 The LASH Carrier 27

1.6.4 The SEABEE Ship 27

1.6.5 Ship with Cargo Section Located above pier 28

2 TRANSHIPMENT DEVICES 29

2.1 Fast Transfer TECHNICATOME COMMUTOR Handling Device 29

2.2 Krupp Fast Handling Device 30

ITIP D1, Annex 1 Survey on intermodal transfer technologies 2

Innovative Technologies for

Inter-modal Transfer Points

3 TRANSHIPMENT AND INTERNAL TRANSPORT DEVICES 32

3.1 Terminal Truck with Lifting Device for Swap Bodies 32

3.2 SeIf loading AGV Robot 32

4 INTERNAL TRANSPORT EQUIPMENT 33

4.1 Shuttle Wagon (Navette) 34

4.2 Multi Trailer System (MTS) 34

4.3 Skid/Pallet (Longitudinal Conveyor) 35

4.4 Moving Train 35

4.5 Skid/PalIet (Cross Conveyor) 35

4.6 Conveyor Concepts 36

4.6.1 Equipment to equipment conveyor 36

4.6.2 Internal transport conveyor 38

4.6.3 Overhead conveyor 38

4.7 Bi-directional Rail mounted Shuttle B+ 38

4.8 Train Movement and Positioning Devices 38

4.8.1 Semiautomatic fixed installations 39

4.8.2 Automatic fixed installations 40

4.8.3 Traction Robots and Locomotives with Remote Control 40

4.8.4 COMMUTOR Train Transfer and Positioning Devices 41

4.8.5 Conclusions 41

5 STACKING DEVICES 43

5.1 Portal Crane for Stacking 43

5.2 One-Arm Crane (Stack Lifter) 43

5.3 High-Rack Handling Device for Shelf-Store 44

5.3.1 Shelf Store Hall 44

5.3.2 Hall for Cross Transport Device (Skid / Pallet System) 45

5.3.3 High Rack Handling Device with Transversal Bridge 46

5.4 Mechanical Storage 46

6 TECHNICAL AND ORGANISATIONAL CONCEPTS 47

6.1 Technicatome COMMUTOR Concept 47

6.1.1 Introduction 47

6.1.2 Conceptual basis 48

6.1.3 Different applications of the COMMUTOR Concept 50

ITIP D1, Annex 1 Survey on intermodal transfer technologies 3

Innovative Technologies for

Inter-modal Transfer Points

6.2 KRUPP Fast Handling System 51

6.2.1 Identification System 51

6.2.2 Transhipment Area 51

6.2.3 Movement of the train through the plant 52

6.2.4 Conveying and Storage Technology 52

6.2.5 System Control 52

6.2.6 Civil Engineering 52

6.2.7 Production Forms 53

6.3 Automated Guided Vehicle System and Automated Stacking Crane 54

6.3.1 Introduction 54

6.3.2 MSS Concept 54

6.3.3 Navigation 55

6.3.4 Intelligence: System Concept 56

6.3.5 Vehicle Concept 56

6.3.6 Safety Provisions 57

6.3.7 Reliability 58

6.3.8 Maintainability 58

6.3.9 Future 58

6.4 CARGO 2000 CONCEPT 59

6.5 NOELL FAST TRANSHIPMENT SYSTEM 63

7 TERMINAL AND TERMINAL NODE CONCEPTS IN EUROPE 64

7.1 RAIL TERMINAL CONCEPTS 64

7.1.1 Noell Megahub 64

7.1.2 Commutor 64

7.1.3 Krupp Fast Handling System 65

7.1.4 Transmann Handling Machine 65

7.1.5 Noell Fast Transhipment Terminal (SUT) 65

7.1.6 CCT Plus 66

7.1.7 RoadRailer 66

7.1.8 Compact Terminal Tuchschmid 66

7.1.9 Gateway Terminal HUPAC 67

7.1.10 Lttkombi Terminal 67

7.1.11 Train Coupling Sharing/Cargo Sprinter 67

7.1.12 North East Terminal Paris 68

7.1.13 Irun and Portbou Terminal 68

7.1.14 Rail Terminal Maasviakte 68

7.2 BARGE TERMINAL CONCEPTS 69

7.2.1 Barge Express (BEX) 69

7.2.2 Rollerbarge 69

7.2.3 Self unloading Vessels 70

7.3 RO-RO TERMINAL CONCEPTS 71

7.3.1 FlexiWaggon 71

7.3.2 G 2000 Ro-Ro 71

7.3.3 Shwople Train 71

7.3.4 Shwople Barge 71

ITIP D1, Annex 1 Survey on intermodal transfer technologies 4

Innovative Technologies for

Inter-modal Transfer Points

7.4 SEA TERMINAL CONCEPTS 72

7.4.1 Container Pallet Transfer (CPT) System 72

7.4.2 Thamesport 72

7.4.3 Coaster Express (CoEx) 73

7.4.4 Train Loader 73

7.4.5 River-Sea Push Barge System 74

7.4.6 Combined Traffic Carrier Ship/Barge (CTCB) 74

7.5 NODE TRANSPORT SYSTEMS 75

7.5.1 Combi-Road 75

7.5.2 Selbsttgis Signalgefhrtes Triebfahrzeug 75

7.5.3 Internal Transport Node Maasvlakte (MTS/AGV) 76

7.6 INNOVATIVE TRANSSHIPMENT UNITS 77

7.6.1 Cassettes 77

7.7 INNOVATIVE BUNDLING NETWORK CONCEPTS 78

7.7.1 RAIL CONCEPTS 78

7.7.2 DEDICATED ROAD CONCEPTS 82

7.7.3 RO-RO CONCEPTS 82

7.7.4 BARGE CONCEPTS 83

7.7.5 NODE CONCEPTS 85

7.8 CLASSIFICATION OF INTERMODAL TRANSPORT TERMINAL IN EUROPE 86

7.8.1 RAIL ROAD TERMINALS 86

7.8.2 BARGE ROAD TERMINALS 86

7.8.3 BARGE RAIL ROAD TERMINALS 86

7.8.4 MARITIME FULL CONTAINER TERMINALS WITH ROAD AND RAIL CONNECTIONS 86

7.8.5 MARITIME FULL CONTAINERS TERMINALS WITH ROAD RAIL BARGE

CONNECTIONS 86

7.8.6 RAIL ROAD BIMODAL TERMINALS 86

7.8.7 RAIL RAIL TRANSFER TERMINALS 86

ITIP D1, Annex 1 Survey on intermodal transfer technologies 5

Innovative Technologies for

Inter-modal Transfer Points

1 Transhipment Equipment as Element of the Means of Transport itself

In this functional category in which the external means of transport are fitted with transhipment

equipment we have found the following elements:

1. ACTS

2. Bimodal Technique

3. MB Kombi Lifter

4. Semi-Trailer with Side Loader

5. U.L.S.

6. Self-Unloading Ship(s)

which are described in detail hereafter.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 6

Innovative Technologies for

Inter-modal Transfer Points

1.1 ACTS ABROLL CONTAINER TRANSPORT SYSTEM

The following explanations summarise the ACTS transportation system for rail road transport,

and similar systems like Germanys RSS or MSTS. ACTS stands for Abroll Container

Transportsystem, RSS for Roland Umschlag Schiene Strasse.

1.1.1 The ACTS technique

The technique ACTS was developed by Multilift BV, Dronten, The Netherlands.

It consists basically of lorries equipped with special hydraulic jib and skip containers; to extend

utilisation of the system to the rail transport, special swivel frames are mounted on flat

wagons; these swivel frames permit, in connection with the lorry, to transfer skip containers to

and from rail.

1.1.2 Description of the System

The system requires no special equipment of the terminals: it is only necessary to have

access to the wagons by road; the roads shall be of adequate dimensions; they must permit

free access of heavy lorries to all the wagons involved in the loading operations; in fact the

lorries require adequate spaces in order to position themselves at an angle of 450 degress

required for the transhipment of the loading unit.

The system consists of three basic elements:

the ACTS loading unit,

the chain lift equipment mounted on truck chassis,

the turntables mounted on a wagon.

1.1.2.1 Loading Units

The loading units are composed of two basic elements: a sub-frame and a container fixed on

the sub-frame. The sub-frame is a standard element composed of two main girders and three

transversal elements; this structure supports rollers and locking axles for a chain lift system in

order to permit loading operations by lorry, stability rollers and blockage devices.

The sub-frame structure is provided for the coupling with the lorrys or the turntables structure

to obtain sure and safe fixation of loading units and to resist any damages occurring during

the road / rail transport or the shunting operation.

On the sub-frame a loading unit is fixed; there are various types of containers special units

for bulk freight, for palletised freight, flat containers and others.

The dimesnions of a standard bulk freight container are - 5950 mm length, 2500 mm width

and 2500 mm height with a tare weight of about 2600 kg. The total gross weight amounts to

about 20000 kg

ITIP D1, Annex 1 Survey on intermodal transfer technologies 7

Innovative Technologies for

Inter-modal Transfer Points

1.1.2.2 Lorries

Lorries are fitted with a special hydraulic jib (in accordance with AFNOR or DIN standards),

with a counter frame for guiding and fixing the loading units and for the application of

stabilisers. Total weight is about 29.000 kg.

Normally lorries are used; the utilisation of a trailer is possible but operations are very

complicated: the trailer also needs loading/unloading equipment. In some cases trailers are in

use that only transport one unit: in that case the lorry transfers its own loading unit and then,

empty, unloads the unit-unit (actual consignment) from the trailer; from here onwards tran-

shipment is the same as usual.

It is important to note that in cases where there is a lorry plus a trailer the total weight on the

road is higher than 50 tons which is not allowed by the European Highway Code and the

legislation in most European countries.

1.1.2.3 Wagons

Wagons are generally bogie flat wagons equipped with three turntables (in some particular

cases two); each turntable can accept a loading unit of 5.950 mm length (in some particular

cases 7.300 mm long) weighing up to 20.000 kg.

The standard flat wagons have a tare weight of about 26-28 tons, and the wagons designed

for this special purpose have a tare weight of about 24-25 tons; the high tare of vehicles is due

to the equipment mounted on the wagons: the total weight of three turntables is about 6.000

kg.

Older wagons have a total max. weight on rail of 80 tons, modern wagons one of 90 tons.

Therefore three ACTS units of a total weight from 18 to 22 each can be transported.

1.1.3 Transport Cycle

The container transportation road-rail-road is functioning as follows (see figure below).

ITIP D1, Annex 1 Survey on intermodal transfer technologies 8

Innovative Technologies for

Inter-modal Transfer Points

ITIP D1, Annex 1 Survey on intermodal transfer technologies 9

Innovative Technologies for

Inter-modal Transfer Points

ITIP D1, Annex 1 Survey on intermodal transfer technologies 10

Innovative Technologies for

Inter-modal Transfer Points

The container is loaded by the sender. For each material the right type container is available.

After having loaded the container (with the chain lift - system) the truck brings it to the nearest

station, where a wagon with turntables is ready to receive it after swinging-out the turntable by

450 degrees. The driver drives his truck backwards to the turntable. The reflectors mounted

on both sides of the turntable serve as orientation points for the driver.

With the help of a chain system mounted on the lorry the container is now pushed onto the

wagon. The special construction of the turntable, in combination with the push possibility of

the chain lift system makes a constant movement of the loading unit from the truck to the

wagon possible. For this movement, which lasts less than two minutes, the driver does not

have to leave his cabin.

After moving the loading unit from the truck to the wagon the turntable will be turned back.

Dependent on the weight, the turntable will be turned back by hand or with a cable linked to

the truck.

Now the turntable is locked and the wagon is ready for transportation.

The cycle at the station of arrival is basically the same, just the other way round.

It has to be noted that there are stability problems during transhipment and the driver does

also have to pay attention to the different heights of truck and wagon due to possible different

levels because of springs and earth base.

1.1.4 Diffusion of the System

Switzerland is the main user, today 60/80 bogies wagons carrying 3 loading units each are in

service. They are generally used for the following services:

transport of waste;

transport of vegetables;

transport of loam;

general purpose.

In the Netherlands only a small number of bogies wagons carrying 3 loading units each is in

use. The only use known in Netherlands is transport of waste to the incinerator.

In other European countries there are similar systems and in some cases these road systems

have been adapted for railroad exchange.

1.1.5 General Evaluation

The existing transport cases are all regional services with low level of traffic.

The main advantages are:

no special equipment is needed in rail stations for the transhipment of loading

units;

loading units are suitable for rail or road transportation;

ITIP D1, Annex 1 Survey on intermodal transfer technologies 11

Innovative Technologies for

Inter-modal Transfer Points

short transhipment time for a single box in a small yard;

simple to control as operated by one man only;

efficient transfer technology.

The main disadvantages are:

equipment of all lorries;

relative high tare of equipment of wagons;

high total weight of the lorry with the ACTS loading unit;

high cost of loading unit and equipment;

high demand of space for transhipment operations.

The balance of advantages/disadvantages seems corresponding to the effective diffusion of

those systems.

The efficiency of the system is relatively good: the load/tare ratios are comparable to the ratios

of containers, the special equipment mounted on vehicles give high tares of rail and road

vehicles. The system can efficiently operate with a small number of elements: a very limited

number of lorries and wagons can operate 50-100 loading units.

The system is very flexible and it is not depending on fixed equipment at the rail - road

transhipment point.

The costs of loading units, however, are higher than standard loading units, the costs of the

equipment of lorries and wagons are also high.

1.1.6 Compatibility

ACTS boxes can be vertically transhipped from the wagon, but can not be vertically moved on

lorries. Therefore it seems to be complicated to adapt them in the terminals equipped with

vertical transhipment devices.

ACTS wagon can drive in normal trains (coupling type and strength) but there are some

conditions to be respected: improvements on strength and fixing devices of turntables and

boxes are being developed.

Concerning the compatibility of ACTS loading units to conventional Combined Transport (CT)

equipment three options have been identified:

Fig. : Adaptation of ACTS loading units to conventional CT equipment

ITIP D1, Annex 1 Survey on intermodal transfer technologies 12

Innovative Technologies for

Inter-modal Transfer Points

The costs of different adaptations cannot be evaluated in the framework of this study.

1.1.7 Conclusion

The ACTS system is a modern road system, based on lorries with hydraulic jib and skip

containers; the system can operate also in connection with rail and can then be a solution for

road - rail transport.

For the transhipment road rail the system needs no fixed equipment in the terminals. It does

need good road access to the wagons (pavement) and space, however.

The system characteristics and its own cost structure seems to locate the optimal utilisation of

ACTS at a low level of traffic, for regional flows of special or industrial goods and also waste

transport to the treatment plants.

Cost assumptions are only qualitative because the system today operates only with very small

quantities of load-units and therefore no practical evaluation of the B-point in the graph below

is possible.

Fig. : Qualitative cost comparison of ACTS and Vertical Transhipment Systems

The graph shows schematic relations between the total cost of systems and traffic volume

(number of loading units). The ACTS system can start with small investment for small traffic

flows; a growing volume is directly related to the increase of investment in loading units,

wagons and lorries. For vertical transhipment of loading units the investment in fixed

equipment e.g. cranes has to be done before starting the operation. But then it does not have

to be adapted to the growing volume for some time. Only when the maximum capacity of the

equipment is exceeded an additional investment is necessary.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 13

Innovative Technologies for

Inter-modal Transfer Points

1.2 Bimodal Techniques

This section summarises studies undertaken on the bimodal system in Europe.

1.2.1 Introduction

The bimodal system was born about thirty years ago in USA and there are a number of trailers

which have been experienced with. Originally only one trailer axle was mounted on the trailer

(because the max. weight in the USA is higher than in Europe).

Later the increasing dimensions and weights made the use of railway bogies necessary;

bogies today are detachable from trailers.

Since the system has been introduced in Europe many bimodal solutions based on trailers

and detachable railway bogies have been developed and today there is a large number of

prototypes.

1.2.2 System

The basis of the system is a special road trailer: to circulate on railways the trailer is

transformed into a railway vehicle.

To transform the trailer it is necessary to mount it on special bogies and to couple all railways

devices (as, for example, brake pipes).

Each trailer is supported at the ends by the bogies and each trailer is then connected to the

following one. There are different types of couplings.

To couple this special vehicle to locomotives or to standard railway vehicles it is necessary to

have special bogies on both ends carrying coupling gears and buffers or the same

intermediate bogie with a special adapter with buffers. The operation of re-railing a bimodal

loading unit is shown in the following figure.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 14

Innovative Technologies for

Inter-modal Transfer Points

Fig. : Operation Scheme Bimodal System

ITIP D1, Annex 1 Survey on intermodal transfer technologies 15

Innovative Technologies for

Inter-modal Transfer Points

1.2.3 The Loading Unit

The basic loading unit for the European bimodal system is a trailer as permitted by European

road laws. Maximal characteristics of a trailer are:

length 12,5 13,65 m

wide 2,5 m (2,6 only refrigerated)

height on road 4m

max. total weight on road 37 t

There is a wide range of trailer configurations but the most utilised trailer is the three axles box

type.

1.2.4 Present situation in Europe

In Europe many different systems were developed which are summarised in the following

table:

Technique by country

bimodal FERROSUD Italy

road railer ARBEL ROAD RAIL France

semirail REMAFER France

rail trailer S.&.M. France

road railer ROADRAIL EUROPE Germany

kombitrailer TALBOT Germany

ACKERMANN-FRUEHAUF

TRAILERZUG

Coda- E STORK Alpha Engineering Netherlands,

NS Netherlands Spoorwegen Denmark

Wagon Union Sweden

Transtrailer TAFESA Spain

There is also a road railer in Great Britain.

Systems are all different and it is in general not possible to couple trailers of different types.

The UIC working group tested all systems to have a common basis of evaluation (only

technical evaluation) and there already is a standardisation document (UIC leaflets).

Amerger from kombi trailer and semi rail originated and became the new kombi rail. The first

prototype was agreed by the UIC.

This kombi rail permits larger compatibility. In effect bimodal technical characteristics do not

allow the use of different types of trailers on single trains: for example the coupling system can

be direct (trailer to trailer) or indirect (made by support traverses); the trailer is mounted on the

bogie with many different solutions also for safety devices. Despite the great number of

solutions and prototypes, only a German company BTZ (Bayerische Trailerzug) and FS Italy

have ordered about 200 trailers (150 roadrailers by BTZ and 20 bimodal Ferrosud FS).

ITIP D1, Annex 1 Survey on intermodal transfer technologies 16

Innovative Technologies for

Inter-modal Transfer Points

It seems that a first regular service will be Munich - Verona and a future regular service from

Holland to the Milan area is also envisaged.

In Europe today no regular service exists and only prototypes are circulating to make tests.

1.2.5 General Evaluation of the Bimodal System

Today only in America there is some experience with regular service. The US Triple Crown

Company (owned by important railway companies such as Santa Fe and Southern Pacific)

owns practically all the bimodal trailers existing; the total amount of bimodal trailers in the

USA is about 3000 (wagons owned by the railway company are about one million).

All these evaluations are theoretic because there are no comparable experiences for the use

on European railways; the American exploiting system is quite different, so are the rail and

road laws; also the American railway system is far from European characteristics (distances,

train frequencies, weights allowed, train characteristics and railways rules).

These differences do not allow to use the USA exploitation experiences for precise evalua-

tions on European routes.

The bimodal system's main advantages are:

No fixed terminal installations necessary, the system needs only a special road tractor (for

terminal operations).

Good tare/load ratio of 28-30 t of load and 15-16 t of tare (trailer and bogie), total weight on

rail 42 to 43 t.

Moderate reduction of transport equipment costs.

Possibility to transport a high number of trailers on a single train (30 - 40 trailers per train).

Possibility to reach customers with no direct railway access (pre- and post-haulage by

road).

It is impossible to open trailer doors while the trailers are mounted on the bogies.

Main disadvantages are:

The system needs complete trains or sections of trains of bimodal type.

The bimodal trailer has a stronger chassis as usual and therefore the payload of the

trailer is reduced (by about 2 to in relation to standard road trailers).

Operators at terminals are obliged to assemble a wagon from a number of elements

(bogies, trailers and connections) and then to form a long train; these operations take time

and a number of tests are mandatory (braking and coupling tests before train departure).

It has to be kept in mind that equipment property and exploitation involve procedures that

differ from the traditional and are therefore in conflict with road or rail rules.

Any defect on one trailer involves a full stop of the train.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 17

Innovative Technologies for

Inter-modal Transfer Points

1.2.6 Conclusion

Taking into account the technical and operational parameters one can draw the following

conclusions:

The bimodal system allows to operate on small terminals with very economic equipment.

The tare/pay-load ratio is reasonably good, but on the road it is lower in comparison with

standard lorries.

Due to rather good tare load/train length relation bimodal systems may have advantages

on links with restricted trail length.

Due to the characteristics of bimodal vehicles (bimodal vehicles need reduced train

longitudinal forces and special interface bogies to be coupled with locomotives or wagons;

marshalling is not allowed) specific rules for trains operations are required.

In each terminal the number and type of bogies must correspond to the number of trailers

and to the number of trains.

Therefore to avoid transport of bogies between different terminals, a balance of traffic

flows and good management of the system is necessary.

Bimodal is not a fast handling technology in the narrower sense. Bimodal systems are

normally stand alone projects on fixed relations and they are not element of the logistical

chains of containers and swap bodies.

Terminal equipment of Combined Transport (CT) terminals is not needed due to the fact

that bimodal semi-trailers are transhipped only horizontally.

Vertical transhipment of bimodal units is not possible because they are not equipped with

the appropriate devices (corner fittings, grapple pockets).

The bimodal system today is moderately successful in the USA; there are yet some

difficulties in Europe.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 18

Innovative Technologies for

Inter-modal Transfer Points

1.3 Mercedes Benz (MB-) Kombi Lifter

The Mercedes-Benz Kombi-Lifter (MB Kombi Lifter) is described mainly by the following items:

The MB Kombi-Lifter is a rail-wagon with installed equipment for transhipment of swap-bodies.

The swap-bodies are positioned over the rail-track directly by the truck. Afterwards the train

with the MB Kombi-Lifter-wagons drives under the boxes, positions and lifts them up

sequentially (hydraulicly or by air pressure). When the swap-bodies are locked by the MB

Kombi-Lifter, their legs have to be lifted manually (to be automated in future).

Standard swap-bodies according to CEN 284 (types: 7,1 5m; 7,45m; 7,82m) as they are used

anywhere for road transport can be used without any modifications. The accurate positioning

of the swap bodies - which is one of the crucial points over the track is still in development

status. One main advantage may be that the transfer function between road and rail will be

decentralised so that many extensively used terminals can be supported in taking tran-

shipment away from there. On the other hand the operation of trains between these smaller

loading stations has to be organised in an economic way. The following time standards have

been provided by the developer:

Time to arrange an outgoing train of 20 swap-bodies (incoming of the first truck until outgoing

of train): 1:06 h

Latest delivery of the last two swap-bodies by truck: 15 minutes prior to train departure.

Time to dismantle an incoming train of 20 swap-bodies (incoming of the train until outgoing of

the last truck): 70 minutes

The first two swap-bodies are leaving the terminal: 10 minutes after train arrival.

A standard train of combined transport has the length of 700 m, consists of about 40 railcars

and has a carriage capacity of 64 loading units.

The figure below demonstrates the positioning and loading process of with the MB Kombi

Lifter:

ITIP D1, Annex 1 Survey on intermodal transfer technologies 19

Innovative Technologies for

Inter-modal Transfer Points

Positioning and Loading Process with the MB Kombi Lifter System

ITIP D1, Annex 1 Survey on intermodal transfer technologies 20

Innovative Technologies for

Inter-modal Transfer Points

1.4 Semi-trailer equipped with side loader

Side loader, Seitenlader or Kranmobile of this category are semi-trailers equipped with special

crane devices to handle the loading units. The following description is based on the type KM

32 - 298 of the manufacturer Klaus as a reference equipment.

An additional manufacturer of comparable technology is e.g. HAMMAR MASKIN AB, Sweden

(see Cargo Systems 3/93).

The equipment is capable of lifting, transferring, stacking and transporting all containers from

20 - 40. The high mobility is combined with the double sided operation and a lifting capacity

of maximum 32 tons.

A rack cannot be served, because of the geometrical movement possibilities of the handling

device (see Fig. 5.2.1.4/1).

The complete unit consists of a tractor and a three axle, compulsory steered semi-trailer fitted

with front and rear hydraulic Kranmobil aggregates. The aggregates are hydraulically adjust-

able to accept all containers in the 20 - 40 range. The standard version with an adjustable

spreader allows for all ISO, DIN, Sealand and inland containers of the Deutsche Bundesbahn

(DB) to be used.

The containers can be picked up from both sides and set down either onto a chassis or onto

the ground. Furthermore, the containers can be lifted from a rail wagon and transferred onto

the chassis, from the left to the right and vice versa, as well as stacked two high on the right

side. Also, containers stacked in rows with a minimum of 3 space between them can be lifted

out and loaded for transportation.

The containers are lifted by using a spreader incorporating a hydraulic twist lock turning

system with a visible marker. In place of the spreader, the well tested rope slings can be used

with connections for the lower corner castings. By using the clamp-attachment (grappled

arms) with the standard spreader also swap bodies can be lifted and transferred.

In terminal areas between 70-90 containers a day can be handled, the number of deliveries

depends to a large extent on the distance to be travelled. The Klaus Kranmobil KM 32 - 298

has been in service with the Deutsche Bundesbahn (DB), freight and shipping lines as well as

transport and industrial organisations for many years as an indisputable link in the combined

road-rail transport of containers.

Other applications with less carriage capacity or a fixed spreader are possible. The operation

as such is shown in the pictures below:

The main advantages of the side loader are:

it replaces stationary equipment or small sized terminals,

it is a mobile, quick and inexpensive handling system being one-man-operated,

it offers double sided on/off loading from railway wagons or storage points to its own

chassis or other road vehicles,

it can safely pick containers out of rows if these are at least 3 apart and the containers are

stacked two high,

it offers simple but safe operations by means of a portable, remote control panel,

it requires no specially prepared surface area to work on,

ITIP D1, Annex 1 Survey on intermodal transfer technologies 21

Innovative Technologies for

Inter-modal Transfer Points

it requires no specially developed tractor unit.

Side loader (type Klaus Kranmobil)

Transport vehicles equipped with a transhipment technology like the Kranmobil' seem to show

good performance on small yards with a restricted catchment area for pre- and post haulage

and with clients asking for additional handling (transhipment) by the shipper because they lack

their own equipment. For terminals of European scale, which are part of the international

network with medium and large volumes they are useful as additional devices only. A number

of them serving a train at the same time will interfere with each other and conflicts are

unavoidable in the loading lanes.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 22

Innovative Technologies for

Inter-modal Transfer Points

1.5 ULS

In the early 1980s the German Minister of Research and Technology launched several studies

to develop an alternative system for (combined) goods traffic.

Aim was to ensure that the Deutsche Bundesbahn (DB) could handle the forecasted

increasing amount of goods, especially in Combined Transport.

One main element of these studies was the ULS, which stands for 'Umschlagfahrzeug Lassig /

Schwanhausser. Lassig and Schwanhausser are the names of the inventors of the concept,

Umschlagfahrzeug means transhipment vehicle.

The basic idea is to transfer boxes in a railway station in a way similar to passengers.

The following requirements were requested:

autonomous driving on track,

integration into and of existing DB-systems,

transhipment of ISO-Containers and DB-Inland-Containers in the sizes 20, 30 and 40 as

well as swap bodies,

transhipment of boxes

from Container-Flat-Wagon to Container-Flat-Wagon,

from Container-Flat-Wagon to ramp and vice versa,

from Container-Flat-Wagon to trucks and vice versa,

transhipment under the catenary,

service of siding tracks,

adherence to gauges according to EBO II (DB regulations for building and operations of rail

infrastructure),

carry the ULS as a goods-traffic-wagon in the normal train with disconnected gear,

ability to pull two charged Container-Flat-Wagons.

The transhipment vehicle which was developed in this framework consists of a vehicle under

frame with a driver-cabin on either side and a cranepart in-between.

The cranepart consists of two middle frames, able to be hoisted and lowered, four swing-out

jibs with one screw jack each, a spreader-bridge and the spreader which is hanging on ropes

under the bridge.

After the positioning of the transhipment vehicle at the side of a loaded Container-Flat-Wagon

or truck, the jibs will be swung out and lowered to support. Now the spreader-bridge is able to

move on the track next to the the container to be transhipped. Than the spreader is lowered

and coupled. The container is hoisted and moved via the bridge. By swinging out the jibs to

the other side of the transhipment vehicle the container can be deposited on a second flat

wagon, truck or on the ramp. The principle is shown in the picture below.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 23

Innovative Technologies for

Inter-modal Transfer Points

Operation of ULS

The positioning is accurate for automatic transfer

The ULS prototype has been tested in DB operations and re-developed several times

Improvement possibilities concern the spreader, the screw jacks and the coupling and

information system.

ULS I, e.g., consists of a two-fold spreader, whereas ULS IV has a single spreader frame with

integrated grappled arms.

The screw jacks were developed to tranship swap bodies of up to 2.76 m height. The height of

the pavement above rail surface is up to 300 mm and the surface for the screw jacks is up to

250 mm under the actual rail track surface.

A low cost revision would consist of only two axle bogies instead of the expansive three axle

bogies but is not able to drive in normal trains. The hoisting frame could be simplified as well.

The positioning system works either manually or automatically. In the manned operation

scheme the driver is positioning the ULS and the container towards the pins (spigots) with the

aid of four video cameras. The automatic operation needs a fixed tag on both sides of the

Container-Flat-Wagon in the centre between the pins (spigots). On the transhipment vehicle a

laser detector is installed. Below one meter the accuracy is +/- 1 cm.

Four different vehicles have been built and have been in service for the DB, some are still in

use for the Austria Federal Railways (BB). The price for one unit has been about 1.5 Mio DM

(07 Mio ECU) in the early 1980s.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 24

Innovative Technologies for

Inter-modal Transfer Points

After the testing phase the DB stopped operating with the ULS.

As main reasons the following were given:

long cycle times due to the complexity of the mechanical and positioning system (new

positioning including operating the swing-out jibs and screw jacks),

investment expenses due to the mixed requirement of using the carriage as a goods-

traffic-wagon in normal trains and its mandatory ability to pull two wagons,

strategic decision not to serve intermediate stops at low equipped terminals and siding

tracks.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 25

Innovative Technologies for

Inter-modal Transfer Points

1.6 SeIf - Unloading Ship(s)

Some container vessel operators use ships which are equipped with on-ship transhipment

devices or which are capable to unload/reload themselves without using fixed terminal

installations. The following types are detailed below:

1. ships with revolving (or swinging) cranes,

2. ships equipped with gantry cranes,

3. the LASH Carrier,

4. the SEABEE Ship,

5. ships with the cargo section located above pier.

1.6.1 Ships with Revolving (or Swinging) Cranes

The revolving crane is flexible and of low cost. Two cranes can be combined to handle heavy

loads. Containers are either lifted with the use of four chains which are locked in the upper

corner fittings or by another technique that makes use of a special frame. A hook is propelled

via a rope. The main disadvantage of this equipment in the container handling is therefore its

low productivity due to the pendulum swing.

The swinging crane reduces the swing disadvantage: it uses a heavy lift gear with a boom that

swings between king pots. Multipurpose container ships are sometimes equipped with

different deck cranes, inland vessels are often equipped with one crane on a telescopic post.

In conclusion swinging cranes are a low cost, multi-purpose handling equipment but have low

productivity in container handling for overseas shipping. However, their advantages for the

coastal shipping and the inland waterways must be considered.

1.6.2 Ship Equipped with Gantry Cranes

From the operational point of view the gantry crane is the most advantageous on-ship

container handling equipment. It can work almost up to its full capacity for a long time without

significant pendulum problems.

Apart from the price, the major disadvantage of the gantry crane is an immense top-side

weight. The weight of the crane, plus any additional ballast required must be subtracted from

the deadweight capacity. Installation is possible on overseas container ships and inland

vessels.

Conclusion: As maritime container terminals increase in number and throughput, ship-borne

gantry cranes are more and more replaced by shore cranes. The cost of a ship-borne gantry

is half of that of a shore crane but the utilisation of the equipment is low. Concerning Inland

Water Transport studies show that the concept of barges equipped with gantries is not cost

effective, since additional riverside infrastructure is needed, whose utilisation again is low.

Also, due to the height of the equipment, problems are caused in case of low bridges above

the waterway.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 26

Innovative Technologies for

Inter-modal Transfer Points

1.6.3 The LASH Carrier

The general design of the LASH (Lighter Aboard Ships) vessel is very similar to that of a

conventional carrier. Transverse bulkheads divide the vessel into holds which are fitted to

stow tiers or barges. Barges are also stacked two high on the hatch cover of each hold.

Larger LASH vessels have seven holds containing 16 stacks of barges and can stow a total of

up to 90 barges, 1/3 of them being on the top of the hatch covers.

The main handling equipment of the LASH vessel is a portal crane that runs along the deck,

picks up barges and stacks them in the ship holds or conversely moves them from the holds

into the water. The lifting strength is about 500 tons and the cycle time for one barge is about

20 minutes.

In some circumstances the LASH vessel may also carry containers instead of barges.

A disadvantage of the LASH concept is that the lighters can be handled only if the sea is calm

and thus the ship has to be unloaded in a protected area.

A number of LASH ships are now in operation.

Conclusion: The LASH carrier is a barge carrier with self unloading capabilities and a very

significant handling productivity in tons/hr.

1.6.4 The SEABEE Ship

SEABEE is another type of barge carrier that employs a completely different hustling system.

An enormous lift platform (about 32m x 23m) capable of lifting 2700 tons is located at the

stern. The elevator can lower down into the water and allows two lighter / barges to flow over

it. With this two lighters/barges, each having a maximum dead-weight of about 1070 tons, can

be raised out of the water to the level of a cargo deck. Rail-mounted trolleys are then pushed

under the lighters and carry them along the length of the ship to their stowage position.

The SEABEE concept has some variations (USSR, USA, Bacat I, Bacat IL) that concern

mainly the barge weight and the handling equipment for transporting and storing the barges

inside the ship. The first two Soviet barge carriers of the Seabee type entered service in

1979.

The productivity of the SEABEE concept (in tons/hr) can be seen in the following table in

comparison with the productivity of other handling systems.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 27

Innovative Technologies for

Inter-modal Transfer Points

Table: Comparison of SEABEE concept with other handling systems

Ship type Average hourly cargo handling rate for ship in tons/hr

General cargo ships 70 - 80

Container ship 3 00-600

Roll-on / roll-off ship 200 - 400

LASH carrier 1.200- 1.500

SEABEE ship 2.500 - 3.000

Source: Ships and Shipping of tomorrow, R. Schonkecht, J. Lusch, M. Schelzel, H. Obenaus,

McGregor, 1983.

Conclusion: The SEABEE carrier is a barge carrier with self unloading capabilities and a very

significant handling productivity in tons/hr.

1.6.5 Ship with Cargo Section Located above pier

These are multi-hull ships which are equipped with a cargo section that can be positioned on

a finger pier.

Another technical solution of the same idea is named Sealift concept. The ship can ballast

down below a dedicated container flat supported between two finger piers. Containers are

pre-loaded onto large flats, similar to the hatch covers of a container ship. The specific design

envisages a 384 TEU vessel able to carry four flat of 96 TEU each.

The concept behind the latter system is to enable small export terminals, which may not be

able to justify ship-to-quay handling equipment, to handle containers on a regulars basis.

The disadvantages of the latter system are:

Additional civil engineering investment for the quay installation.

At least one lift truck or reach stacker is necessary to store containers on flats.

It would not be possible to handle this type of vessels in tidal conditions, except at very

specific times, a fact which would severely disrupt a timetable.

Lashing of all containers is needed since all are on deck.

Conclusion: The above concept is in its initial phase of design. Although (after the solution of

its inherent problems) it could offer some advantages mainly for the coastal and / or inland

waterway

ITIP D1, Annex 1 Survey on intermodal transfer technologies 28

Innovative Technologies for

Inter-modal Transfer Points

2 TRANSHIPMENT DEVICES

In this functional category we have found the following systems:

1. Fast Transfer TECHNICATOME COMMUTOR Handling Device

2. KRUPP Fast Handling Device

The Fast Transfer TECHNICATOME COMMUTOR Handling Device and the KRUPP Fast

Handling Device are described in detail hereafter.

2.1 Fast Transfer TECHNICATOME COMMUTOR Handling Device

These COMMUTOR fast transfer handling devices are essentially composed of the

transhipment equipment which has been designed and developed as an entity of the loading

units (container and swap body), the rolling stock (wagon or truck) and the spreader.

This COMMUTOR transhipment equipment is equipped with a typical spreader allowing

automatic handing. The spreader uses the bottom lift technique in order to be able to handle

different types of loading units on its own.

It can be:

static, with a fixed length, able to handle all the loading units present on a wagon during

only one move,

or mobile, with adjustable length.

The transhipment equipment is:

a uni-directional bridge crane, perpendicular to the rail track moving within one span cor-

responding to a wagon which has been accurately positioned in this span,

a bi-directional rolling gantry crane, moving in two directions, perpendicular and parallel to

the rail track.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 29

Innovative Technologies for

Inter-modal Transfer Points

2.2 Krupp Fast Handling Device

The automatic unloading and reloading of flat-wagons in the planned transhipment plant - and

in general between two service places - is carried out by Fast Handling Devices. The opera-

ting range of the system spans one loading track, one empty track and one service position

e.g. for transhipment to a cross conveyor or skid / pallet-system.

The rail of the crane bridge is elevated on one side in order to show the cross conveyor

operation.

The Fast Handling Devices can be moved over the whole length of the transhipment area in

order to achieve redundancy. The Fast Handling Devices are designed to be adapted

individually to varying configurations of transhipment plants. By extending the bridge also

storage lanes can be served. An application for roadside operation is foreseen.

The loading units are picked up by a spreader. The spreader is equipped with telescopic

pivots for different container length as well as gripping pliers / grappler arms for swap bodies

and semi-trailers.

All typical container lengths (20, 24, 30, 40 and 49), swap bodies (between 6.25m and

13.6m) and semi-trailers up to 13.6 m can be transhipped automatically.

The loading units can have a maximum weight of 42 t.

After pick up of the loading units by the Fast Handling Devices the bodies are transhipped to

the feeder position for the internal transport.

The cycle time of one transhipment, i.e. from picking the loading unit, via transport to the

feeder position up to the back move to the picking position for the next loading unit amount

between 35 seconds for containers and 72 seconds for semi-trailers.

As described before the Fast Handling Devices are designed for fully automatic operation. For

emergency service a manual control is foreseen.

In the transhipment area there is no catenary installed. The train enters drawbn by its own

engine up to an exchange point. Afterwards the train is moved by a switching engine or by a

special train - push / pull -device through the transhipment area.

The whole Fast Handling System is carried out by the following components:

crane way,

crane bridge,

trolley with lifting gear,

telescopic spreader,

absolute distance measuring system,

sensors and data transmission unit.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 30

Innovative Technologies for

Inter-modal Transfer Points

ITIP D1, Annex 1 Survey on intermodal transfer technologies 31

Innovative Technologies for

Inter-modal Transfer Points

3 Transhipment and Internal Transport Devices

Another functional category are transhipment and internal transport devices. This means that

the vehicles are equipped to serve both functions. The following systems can be listed and are

partly described hereafter:

1. Terminal Truck (Swap Body)

2. Self Loading AGV Robot

3.1 Terminal Truck with Lifting Device for Swap Bodies

This kind of equipment is a special vehicle with a hydraulic lifting equipment, able to tranship

and transport mainly swap bodies in the lengths from 7.150 mm up to 8.130 mm (according to

DIN EN 284). It is also possible to transport containers and move trailers and semi-trailers

with one-man-operation.

One manufacturers example is the INNOVA Wechselbrcken-Hubwagen (lifting vehicle for

swap bodies). All safety measures and regulations according to state of the art have been

taken into account in the design procedure in order to ensure a continuous and riskless

operation. The engine has been developed as a Mittelflur-Powerpack (situated beneath the

platform between the axis), with a 10w noise and allowing easy maintenance.

Some vehicles are in operation, today.

3.2 SeIf loading AGV Robot

The self Loading AGV robot is:

an AGV

a robot

As an AGV, Automatic Guided Vehicle, it is an autonomous transporter of boxes able to

transfer boxes from one location to another, with free movement in all directions. It is an

automotive and autonomous vehicle, self-propelled without any wire or physical link, either for

energy or for navigation. It can navigate by reference to passive beacons set in the ground.

The move of the AGV can be longitudinal with normal run by symmetrical rotation of the

wheels or transversal by rotation of the wheels on a 90 angle. The vehicle can therefore draw

in below a storage table with accuracy.

This AGV robot is self loading and is able to handle boxes by itself: it can pick up a box dis-

posed on a storage table or set a box down on a storage table, by means of an auxiliary

vertical move of the platform of the vehicle. Of course, this AGV can also be loaded or

unloaded by means of a crane or any other vertical transhipment device.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 32

Innovative Technologies for

Inter-modal Transfer Points

4 INTERNAL TRANSPORT EQUIPMENT

In this functional category we list the following systems, which are described in detail here-

after:

1. Shuttle Wagon (Navette)

2. Multi Trailer System (MIS)

3. Skid/Pallet (Longitudinal Conveyor)

4. Moving Train

5. Skid/Pallet (Cross Conveyor)

6. Other Conveyor Concepts

7. Bi-directional Rail mounted Shuttle B+

8. Train Transfer and Positioning Devices

ITIP D1, Annex 1 Survey on intermodal transfer technologies 33

Innovative Technologies for

Inter-modal Transfer Points

4.1 Shuttle Wagon (Navette)

The shuttle wagons are automatic and autonomous wagons, designed for the COMMUTOR

concept to ensure with accuracy the longitudinal transfer of boxes along a rail track.

For the COMMUTOR high flow application - as each overhead crane moves the boxes within

its span shuttle wagons are used when span changing is needed: they move the boxes from

one span to another.

The shuttle wagon is self propelled, electrically fed by a cable trolley situated on the rail side

and able to position itself with accuracy within a span.

Obviously, these shuttle wagons can be used for any other application, e.g. for the automatic

transportation of boxes within a terminal or between terminals.

4.2 Multi Trailer System (MTS)

The multi trailer system (MTS) has been designed and developed by ECT, especially for the

Delta Terminal, where it is now successfully employed in the main transportation system.

The system basically consists of a heavy duty tractor coupled to a train of five trailers

(wagons).

The tractor is a customized 415 horsepower FTF design, capable of towing up to 400 tons.

The FTF is equipped with an automatic coupler, operated from the drivers cabin, for coupling

and uncoupling complete trains.

Each trailer is fitted with two steerable four wheeled axes connected by means of a computer

designed steering mechanism that results in the trailers exact tracking of the trucks path.

Each trailer may carry one 40 or 45 container or two 20 containers with a total weight of up

to 50 tons. The trailers are designed to be used in conjunction with chassis loaders on the

crane. The MTS is in fact a buffer in itself, capable of accepting the fluctuations in crane cycle-

time without delay to the crane.

This results in better crane production with fewer drivers necessary for transport per crane

than a yard tractor/chassis operation. At the Delta Terminal, an average performance of 40

containers per crane operating hour are achieved using two tractors per crane.

In the buffers, located in the stack, the MTS-trains are towed in by the tractor and uncoupled

when lined up. The driver then picks another train from the buffer and proceeds to the crane in

much the same way as is done in the tractor/chassis operation.

The total savings in the transportation system costs of the MTS, compared to the conventional

yard tractor/chassis system, is about 20% in ECTs situation. Although requiring more capita!

cost, the system results in substantial savings in labour, maintenance, energy, tires, less

damage, safer handling and higher crane productivity.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 34

Innovative Technologies for

Inter-modal Transfer Points

4.3 Skid/Pallet (Longitudinal Conveyor)

Skid or Pallet Systems can be utilized for longitudinal movement of loading units or transport

crosswise (perpendicular) to the rail track or other tracks in a terminal as well as in the

application of crosswise transport of units in a Fast Handling System linking rail and road.

Other applications are possible.

The skid systems consist of passive frames to carry the loading units and guide ways which

compose also the actuation system. The pallets are self propelled, but need guide ways and

power and data lines.

4.4 Moving Train

The moving train supports the Krupp Fast Handling System and has therefore been described

above.

The main advantage is, that no further equipment for longitudinal movement of loading units is

necessary and all loading unit are passing the transhipment plant automatically being moved

on rail cars. Therefore the transhipment area can be very compact.

4.5 Skid/PalIet (Cross Conveyor)

A skid and pallet system can be used for the transport of loading units between fixed points or

feeder-points. It allows quick transfer with high performance under automatic control. The

following description refers to the cross conveying system used in a Fast Handling System

linking rail and road, but other applications are possible as well.

The pallet system takes over the loading units from the handling system on the rail track side

and moves them into the store or directly to the feeder position which is in the railroad terminal

and directly to the truck loading lane.

The cross conveyor consists of single, electro-mechanically accelerated palettes controlled by

the central processing unit. They are operating on rails which are situated in the cross lane.

In a further level beneath, a second rail-system allows the retrieval of empty pallets. At the

respective end of the conveyor there is a crossbar lifting table to connect both transport

systems and to allow a circuit movement of pallets. In the middle of the lane a third crossbar

lifting table is possible. The truck and train loading is disconnected and two circuits are

running in an opposite direction. An appropriate control and security system is integrated. By

means of this configuration of cross conveyors one can react flexibly and individually to the

course of events of the transhipment process.

The cross conveyor serves the following functions:

transport into the storage area,

transport to the feeder position for direct transhipment to the truck lane,

buffer for the fast unloading of trains as well as

ITIP D1, Annex 1 Survey on intermodal transfer technologies 35

Innovative Technologies for

Inter-modal Transfer Points

pre-sorting when reloading of the train.

The pallets are designed to carry all common types of loading units including semi-trailers

One pallet consists of the following components:

framework with

drives, working separately and independently,

trestles which can be slewed by Electro cylinders for the saddle plates of semi-trailers,

sensors, central processing unit, energy and data transmission system, absolute

distance measurement system,

emergency service unit.

One cycle contents the following activities:

transport of a loaded pallet,

lowering of the cross bar lifting table,

moving of new pallets in the table,

lifting of the table,

set down of loading unit.

A more simple application are transfer tables which consist of only one level and one pallet

which moves between two feeder places to exchange loading units between fixed installation

which can not communicate directly or which have to operate independent from each other.

4.6 Conveyor Concepts

The basic designs of conveyor concept were included:

1. The equipment to equipment conveyor

2. The internal transport conveyor

3. The overhead conveyor

In the framework of this study, it has been decided to focus on one system only, the

equipment to equipment conveyor. The reason for this selection was that it is a design

already

The Equipment to Equipment Conveyor has been implemented and tested by some manufac-

turers, while the rest are still in preliminary stage of design or in prototype forms. Nevertheless

all three are described hereafter:

4.6.1 Equipment to equipment conveyor

This transhipment device must be considered as an additional equipment in the transhipment

activity, that can interchange containers between harbour crane (or self-unloading ship) and

the internal transport.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 36

Innovative Technologies for

Inter-modal Transfer Points

The basic concept of this container Equipment to Equipment Conveyor is to match the pro-

ductivity of two pieces of equipment and to provide buffers where possible to even out

temporary differences in cycle times.

Matson Terminals Inc. has developed a conveyor of this type to support the sea side

operations of a container terminal. This conveyor was installed in the companys container

terminal in Los Angeles. The equipment is rubber tiered and follows the shore side crane

automatically.

The main feature of this container conveyor is to bridge the gap between the yard crane and

the vessel crane, allowing direct transfer of containers between the two equipments without

chassis or straddle carriers. Provision was made to use the container conveyor between two

yard cranes. This permits fast re-handing of containers from one area to another without

intermediate handling by other manned equipment.

Advantages:

Eliminates traffic interferences in the yard and under the crane

Reduces hoist travel

Improves crane productivity without major redesign in the crane structure

The rubber tyre conveyor can be assigned to different ship-cranes (one at a time)

Disadvantages:

It is an additional equipment and that means additional! purchase and maintenance costs.

It was designed for a special purpose (ship to quay transfer) but is not very efficient in

other terminal activities in comparison with a straddle carrier. Note that a straddle carrier

can be used -not so efficiently though- to do the conveyors job in the quay.

The primary container handler will be the yard crane. It will be matched to a vessel crane for

vessel loading and discharging and, when not working vessels, to a defined area for serving

community truckers. The transtainer is used to service trucks during the times when the yard

crane is working the vessel or during peak periods when additional capacity is needed. It will

operate under the yard crane so that containers handled will be accessible to both.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 37

Innovative Technologies for

Inter-modal Transfer Points

4.6.2 Internal transport conveyor

The internal transport conveyor is build to shift containers horizontally between the shore side

crane and a stacking crane (e.g. Container system Meeusen Consultants BV, Netherlands).

This internal transport system seems to be similar to the Longitudinal Skid Pallet system and

therefore can be omitted.

4.6.3 Overhead conveyor

The specific design has been developed by Translift GmbH and IFK Karlsruhe but similar con-

veyors have been developed by other designers too.

It consists of an elevated crane way which is capable to carry a number of vehicles / trolleys.

The crane way is designed for straight line and bows. It is also possible to include switches.

The vehicle is composed of a trolley with lifting gear and a telescopic spreader. A distance

measuring system, sensors and a data transmission unit also have to be installed.

It could be possible to consider the type of conveyor as additional internal transport means

even though this kind of designs has not been widely implemented up to now.

Another type of overhead conveyor combines with internal transport conveyors and

transhipment devices to perform all the transport and handling activities on ship side. The

crane way is build to outreach the quay wall to span the ship, which has to be moved in order

to reach all bays for container.

4.7 Bi-directional Rail mounted Shuttle B+

The bi-directional shuttle B+ is an automatic device designed for COMMUTOR.

The purpose is to provide a dynamic storage (or mechanical storage) of boxes. The device

ensures:

Gripping of boxes situated on storage tables from underneath. The gripping and the setting

down is performed by a vertical move of the main platform of the shuttle.

Fast moves of boxes on two perpendicular axes by moves of the main platform of the

shuttle on a network of orthogonal rail tracks.

4.8 Train Movement and Positioning Devices

Train Movement and Positioning Devices assist the train operation in the terminals. The

different concepts available on the market in the moment are:

1. semiautomatic fixed installation:

systems of chains and hooks move wagons or group of wagons

ITIP D1, Annex 1 Survey on intermodal transfer technologies 38

Innovative Technologies for

Inter-modal Transfer Points

2. automatic fixed installations:

special chariots in the space between rails move groups of wagons or in some cases com-

plete trains

3. remote control locomotives move trains or train sections

4. COMMUTOR train transfer and positioning devices

Main advantages of these systems are:

reduction of investment costs, through simplification of installations (mobile loading

machinery, etc. are rendered unnecessary),

reduction of operating costs, since there is no equipment for skilled labour assigned to

handling operations only,

reduction of maintenance costs, through the use of rugged and sturdy equipment This

equipment is in use over 3000 installations all over the world, in mines, petrochemicals,

metal refineries, steelworks, agricultural co-operatives, cement works, container-

terminals, railway companies.

The main producers of this specific equipment are De Dietrich (France) and Windhoff

(Germany). Remote controlled locomotives are produced by many important companies

specialized in shunting locomotives.

4.8.1 Semiautomatic fixed installations

Chains and hooks move wagons or group of wagons

These systems are used in small installations and can be useful only in case of low quantity of

wagons of groups of wagons. The cost of the equipment is very low. We list some kinds of this

equipment:

SEMI-AUTOMATIC / SIDE CHAIN

Manual fixing of a chain to a hook on the side of the wagon, the chain being pulled by a rope

alongside the track.

SEMI-AUTOMATIC / SIDE CARRIAGE

An electrical motor drive by means of gears a system of ropes; the ropes drives a carriage

which runs on a section member or rail alongside the track. A rigid bar or sling is manually

fixed from this carriage to a hook on the side of the wagon.

(SEMI) AUTOMATIC / BALLAST VEHICLE

An electrical motor drive by means of gears a system of ropes; the ropes drive a two-axle bal-

last vehicle on the main track, which is attached manually or automatically to the main cou-

pling of the wagon.

A not common application is made for the barges. The system is especially designed for the

handling of barges and other vessels alongside quays. The rope drives two carriages along a

ITIP D1, Annex 1 Survey on intermodal transfer technologies 39

Innovative Technologies for

Inter-modal Transfer Points

section member or rail along the quay, and the hawsers are mutually fixed to the carriages.

4.8.2 Automatic fixed installations

Special chariots in the space between rails move a group of wagons or in some case

complete trains.

The equipment is used in large terminals and shunting yards. The investment and mainte-

nance costs are not very important. The equipment is based on chariots driven by a system of

ropes; the ropes drive a carriage which runs on an auxiliary track inside the main track.

Wagon axles are engaged by trolleys on the carriage activated by remote control.

Electric motors and gears control the movements of the ropes.

Major installations have a lot of equipment of this kind and these are then connected to obtain:

sequences of movements

parallel movements

combinations of movements.

Description of the system (e.g. WINDHOFF system)

The ends of the haulage cable are fixed to a low level carriage, which runs inside the main

track on an auxiliary track, or even in some cases on the rail feet. The carriage is fitted with

retractable arms and rollers, of which the transverse motions of extension and retraction can

be carried out at a predetermined point or by remote control at any location. The rollers

engage the wheels of a wagon axle, so that the haulage force can be applied in either

direction.

All hooking, unhooking and control operations are carried out by remote control, without the

need for personnel along the track at any stage of the marshalling operation.

This arrangement is suitable for repetitive operations, (wagons or complete rakes of 1500 tons

and over), enables precise positioning, passage over a weight-bridge, feeding a rocker, etc.,

and is adaptable to most track gauges in use. It can obviously be included as part of a

complete automation system.

There also is an automatic pusher (pushing only ), which consists of a unidirectional pushing

device acting on the axles of the cars, without the use of hooks.

4.8.3 Traction Robots and Locomotives with Remote Control

Increasingly locos without driver on board are employed; the locos are remote controlled by

an operator on fixed installations.

The weight of the loco can be:

from 15 20 t (for group of wagons)

to 60 90 t (for- heavy trains)

Speed can be very low 2-6 km/h in order to present vehicles to a fixed installation for

loading/unloading and 10+15 km/h for transferring trains in shunting yards.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 40

Innovative Technologies for

Inter-modal Transfer Points

Different protocols of radio control are in use today and the robot can be equipped with auto-

matic couplings. The cost of these robots is important and comparable with shunting loco-

motives. The main advantage is the possibility of safe-operating without locomotive driver.

4.8.4 COMMUTOR Train Transfer and Positioning Devices

In the TECHNICATOME COMMUTOR process, the whole train must be moved and centered

by means of positioning devices, so that each wagon is positioned in the middle of its span

and right beneath its crane, before automatic handling can begin. One positioning device

every 5 wagons is needed to have the whole train positioned.

Several types and technological solutions have been developed:

hydraulic (jack or motor)

chain or cable drive, with hydraulic winch.

The device commonly used pulls or pushes on a part of the wagon. The positioning system

must comply with the following main requirements:

Automatic operation for the positioning of the whole train, as soon as the train is

initially stopped in a correct range by the locomotive driver.

Security : any risk of interference with the elements of the bogie must be eliminated,

specially when the operation starts after the train stop.

Strength : the device develops a strength in relation with wagon rolling, slope, starting

and acceleration, deceleration and braking, elongation or compression of the wagon

couplings, induced efforts by spreader during automatic handling. That gives an effort

of more than 100 kN per device.

Speed : the devices have a sufficient speed to allow a total positioning time under 3

minutes for the train.

For a train of 750 m length, different kinds of positioning devices can be disposed along the

rail track in order to optimise the investment and operation:

long stroke positioning device at the head of the train

short stroke positioning devices for the other elements between head and rear of the train.

4.8.5 Conclusions

In the modern shunting yards robots on rail and fixed installations can be integrated in order to

transfer and position wagons. The above mentioned systems permit the automation of the

operations on rails and so it is possible to co-ordinate the transhipment system as well as to

integrate these systems in the general organization of automated terminals.

Today only very few container terminals have automation of the movements on rails because

the automation of the terminals is not high (movements on road are not automated, tranship-

ment operations are controlled directly by operators).

ITIP D1, Annex 1 Survey on intermodal transfer technologies 41

Innovative Technologies for

Inter-modal Transfer Points

In the near future the automatic transhipment will also make the automation of the movements

on road and on rail obligatory. The automatic means of storage will demand the automation of

the movements.

ITIP D1, Annex 1 Survey on intermodal transfer technologies 42

Innovative Technologies for

Inter-modal Transfer Points

5 STACKING DEVICES

In this functional category we have found the following systems:

1. Portal Crane for Stacking

2. One-Arm Cane (Stack Lifter)

3. High-Rack Handling Device

4. Mechanical Storage

which are described in detail hereafter

5.1 Portal Crane for Stacking

The portal crane for stacking operations is very similar to the one designed for transshipment.

In fact, in most cases the transshipment crane fulfils storage functions.

The semi-gantry crane consists of the following components:

Crane way

Semi Gantry

Trolley with turntable and hoisting machinery

Anti Sway Device,

Telescopic Spreader

Control

5.2 One-Arm Crane (Stack Lifter)

The O & K Stack Lifter is similar to a deck crane of container vessels.

The stack lifter is able to serve all areas in the terminal such as quayside, train and road

separately so while working they are not interfering with one another.

The system's advantages compared with a standard transtainer (container-gantry crane) are

the following:

underground foundation points with minimum loss of stacking space,

energy supply by permanently laid cables with slip ring assembly,

data transmission by slip ring assembly undisturbed by environment,

short travel distances due to compact yard,

practical arrangement of the number of stacks,

high definition angle measuring devices in enclosed spaces,

positioning independent of weather,

integration in the whole terminal control and monitoring system,

automatic positioning system with permanently programmed spots in the stacking area.

(Block, Bay, Row and Tier with two digital each. Loading positions are programmed by

approaching them once by hand then the stack lifter approaches the target position

ITIP D1, Annex 1 Survey on intermodal transfer technologies 43

Innovative Technologies for

Inter-modal Transfer Points

automatically including lifting and powering the container. Shortly before the spreader

or the container touches down, speed is slowed down automatically in order to avoid

setting the load down too abruptly),

low noise level due to closed machine spaces,

maintenance of small surface, independent of ice and snow, machinery in heated

rooms...

The stack lifter consists of a foundation column, a basic jib, a top jib and a top turntable. The

overall outreach between centre column and hoisting axle is 44.5 m, but other outreaches are

possible. The operators cabin is situated beneath the hoisting gear under the top turntable.

Each stack lifter serves 1255 TEU stacking spaces over the entire range of 5 container-tiers.

On average 36 duty cycles per hour are reached.

5.3 High-Rack Handling Device for Shelf-Store

For the short- and middle term storage of containers, swap-bodies and semi-trailers within the

Fast Handing Terminal a shelf store has been conceived as one possible element of the

KRUPP Fast Handling System.

In order to meat the varying capacity-requirements the shelf store is of modular design and

can be configured according to the demands.

The whole shelf store is composed of an end modul on the left and right side of 16 m length

each and several middle modules. These middle modules are carried out with lengths of 16 m

and 32 m alternatively.

The shelf modules usually have 3 up to 6 floors and 8 up to 16 columns. Due to this modular